Palygorskite load nickel base biomass tar oil recapitalization hydrogen manufacturing catalyzer and preparation method thereof

A palygorskite and catalyst technology, which is applied in the field of nickel-based biomass tar steam reforming hydrogen production catalyst and its preparation field, can solve the problems of easy carbon deposition, high cost, low low temperature activity, etc., and achieves low price and water-gas reaction. Increase and promote the effect of tar cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

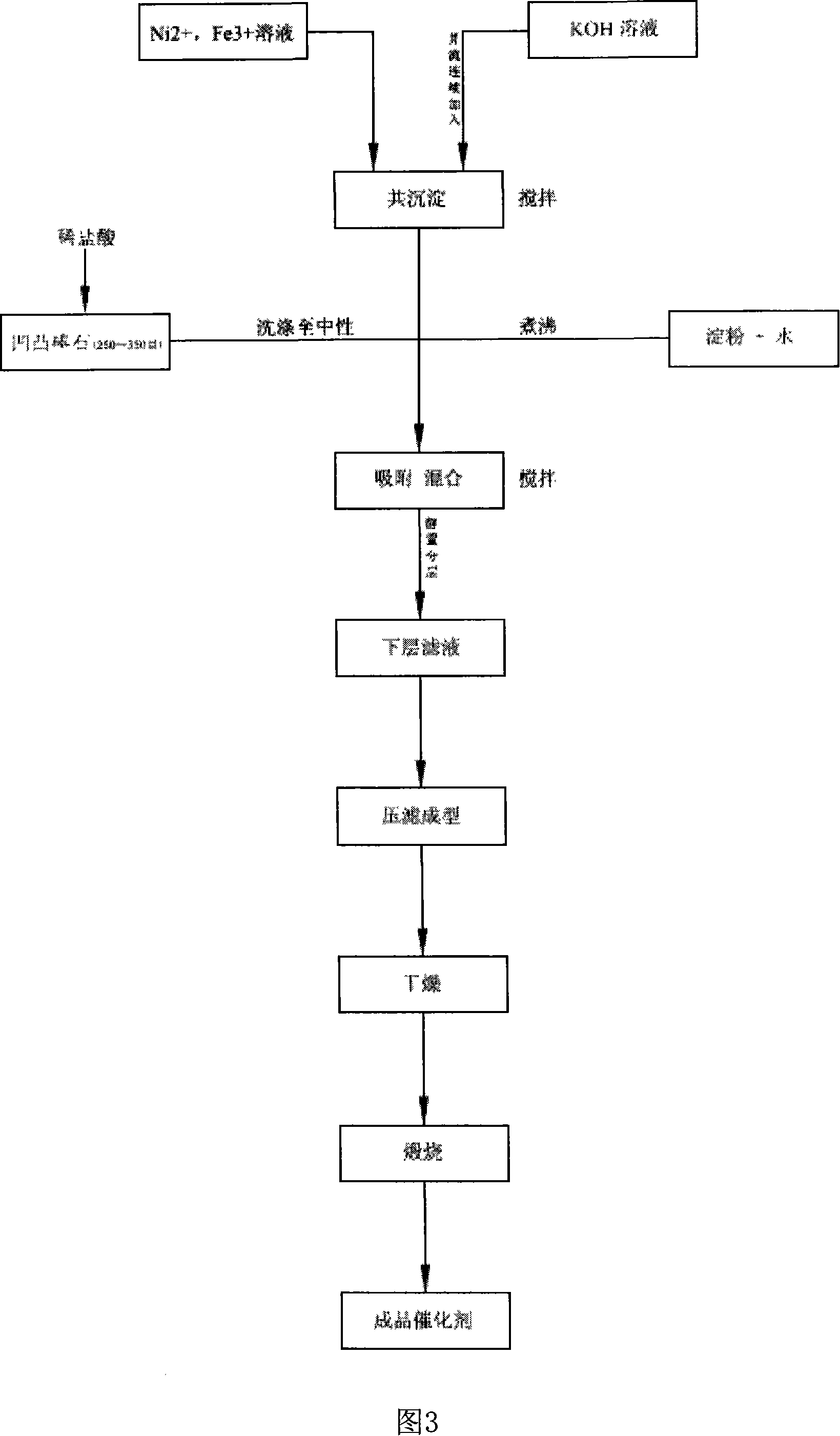

Method used

Image

Examples

example 1

[0020] Laboratory prepares 15 grams of catalyst (35wt%, NiO) formula:

[0021] Raw material type

example 2

[0023] Partially shaped catalyst (12wt%, NiO) recipe:

[0024] Raw material type

nickel nitrate

weight / gram)

125

48.68

70.26

52.86

5

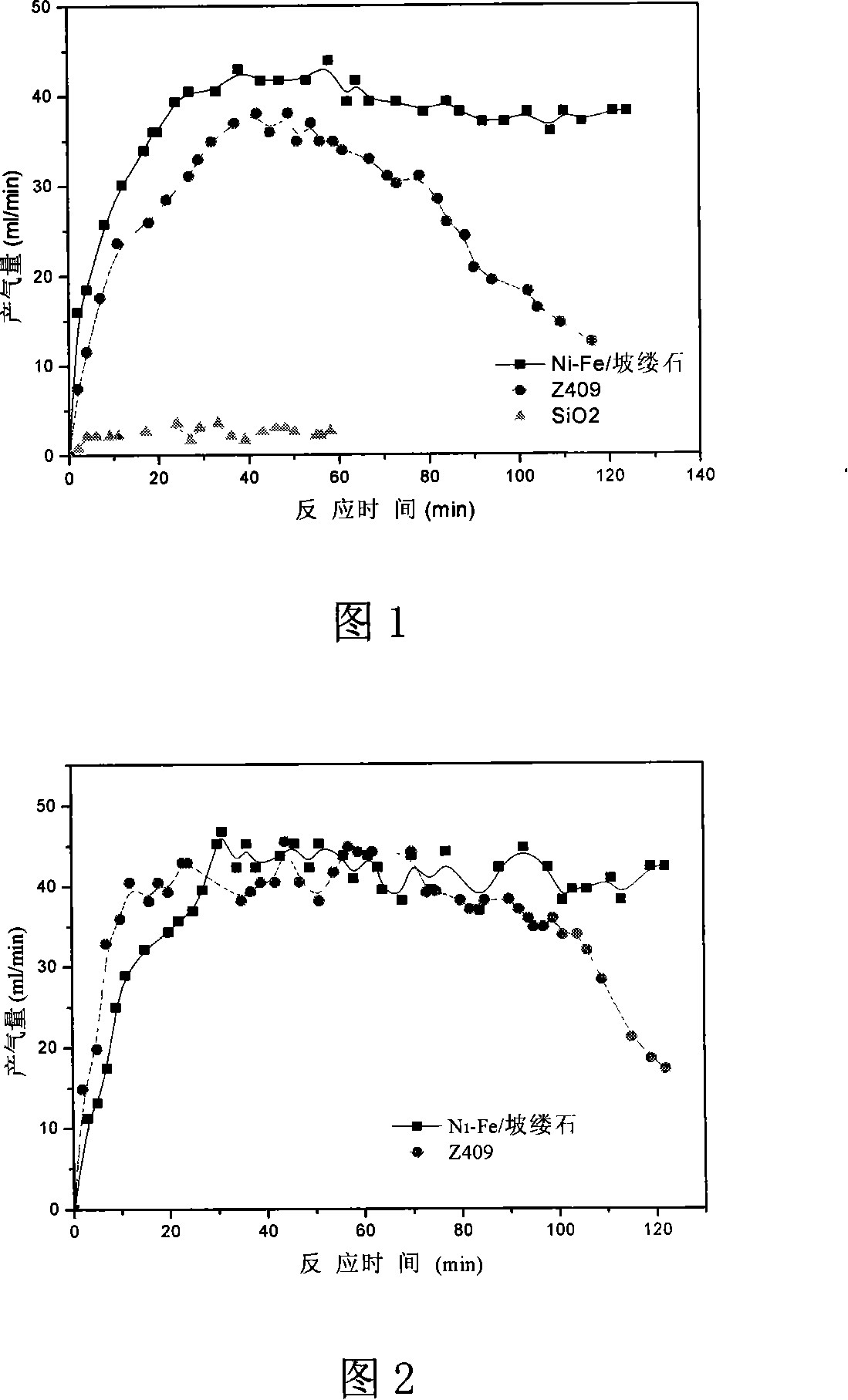

[0025] The steam reforming of tar by pyrolysis of fixed bed apricot kernel was used as the catalyst activity evaluation experiment, and compared with the commercial light oil steam reforming hydrogen production catalyst Z409. The comparison results show that the self-made Ni-Fe / palygorskite catalyst has significantly better catalytic effect than the commercial Z409 catalyst at 500 °C, and the self-made catalyst has significantly better anti-coking deactivation ability than the Z409 catalyst at 600 °C, although the initial activity is the same.

[0026] Evaluation conditions and results:

[0027] Tar intake: 1.1ml / h; N 2 : 44ml / min; catalyst: 2.0g; water-carbon ratio (molar ratio): 4.3.

[0028] Table 1: Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com