Sowing machine capable of realizing intelligent precision dibbling

A seeder, precision technology, applied in the field of seeders, can solve the problems of inaccurate seeding, time-consuming and laborious, low work efficiency, etc., and achieve the effect of high seeding accuracy and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

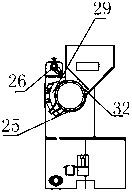

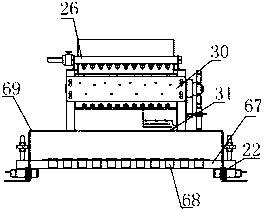

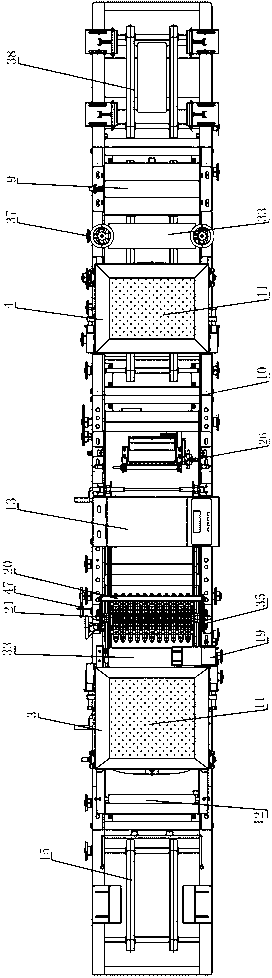

[0035] like figure 1 , figure 2 , image 3 , which is a schematic structural view of the planter of the present invention, including a main controller 13, a frame 1, a motor 5, a transmission assembly 8 arranged on the frame, a substrate assembly 3, a planting assembly 6, a soil covering assembly 4, a synchronous Unit, cracking assembly 9, a scraper 2 for scraping off excess matrix on the seedling raising tray 45;

[0036] The motor 5 drives the transmission assembly 8 to rotate; the transmission assembly includes a V-shaped belt and a variable speed sprocket arranged below the guard plate assembly,

[0037] The transmission assembly 8 can drive the seedling tray 45 to pass through below the matrix assembly 3, the planting assembly 6 and the soil covering assembly 4 in sequence;

[0038] Packing substrate assembly 3 comprises the packing substrate bucket 55 that is fixed on the frame, is used for carrying the carrying unit of substrate, synchronous unit, packing foundation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com