Biochar-based nanometer zero-valent iron material and preparation method thereof

A nano-zero valent iron and biochar technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve problems such as energy consumption, environmental pollution, poor material performance, etc. The effect of causing environmental pollution and enhancing the removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

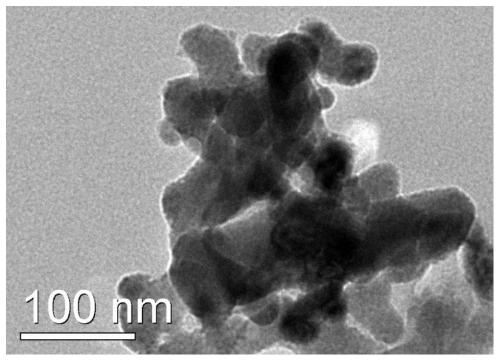

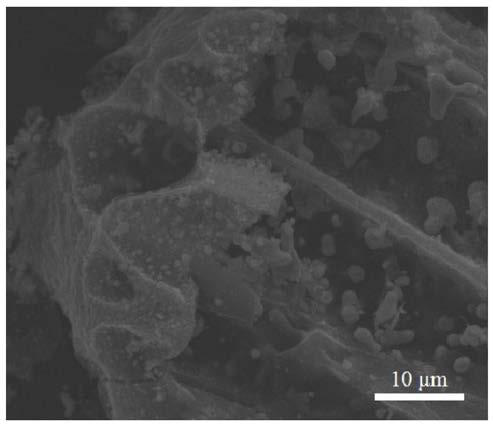

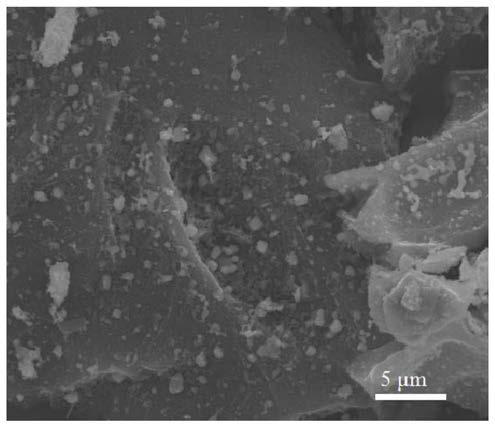

[0028] The invention provides a preparation method of biochar-based nanometer zero-valent iron material, which comprises the following steps:

[0029] S1) dissolving the iron salt in water, and adding nitric acid to adjust the pH to less than 4.0;

[0030] S2) Add the ground and sieved biochar into the iron salt solution, and magnetically stir to obtain the composite material; the mass ratio of biochar to iron salt is 1:(2~3);

[0031] S3) drying the composite material, the dried composite material is subjected to a carbon thermal reduction reaction under the protection of nitrogen, and the biochar-based nanometer zero-valent iron material is obtained after cooling; the condition of the carbon thermal reduction reaction is 8-12 ° C. min -1 Heating at a rate of 600-800°C and keeping it for 1-2 hours.

[0032] Preferably, the iron salt is ferric nitrate or ferrous sulfate, and the concentration of the nitric acid is 2mol / L;

[0033] Preferably, in step S2, the biochar is prep...

Embodiment 1

[0038] The present embodiment provides a preparation method of biochar-based nanometer zero-valent iron material, which comprises the following steps:

[0039] S1) dissolving ferric nitrate in water, and adding 2mol / L nitric acid to adjust the pH to less than 4.0;

[0040] S2) Add the ground and sieved biochar into the iron salt solution, and stir magnetically for 9 hours to obtain the composite material; the biochar is prepared by pyrolyzing poplar leaves, rice husks, straw, corncobs or fruit husks at 300°C, The mass ratio of biochar to iron salt is 1:2;

[0041] S3) Dry the composite material. The drying method of the composite material is to dry at 105°C for 48 hours; put the dried composite material into a quartz boat (10cm×3cm), and place it in a tube furnace for charcoal thermal reduction under the protection of nitrogen. After cooling, the biochar-based nano-zero-valent iron material can be obtained; the condition of charcoal thermal reduction reaction is 10℃·min -1 T...

Embodiment 2

[0043] The present embodiment provides a preparation method of biochar-based nano zero-valent iron material, which comprises the following steps:

[0044] S1) dissolving ferric nitrate in water, and adding 2mol / L nitric acid to adjust the pH to less than 4.0;

[0045] S2) Add the ground and sieved biochar into the iron salt solution, and stir magnetically for 9.5 hours to obtain the composite material; the biochar is prepared by pyrolyzing poplar leaves, rice husks, straw, corncobs or fruit shells at 600 °C , the mass ratio of biochar to iron salt is 1:2.5;

[0046] S3) Dry the composite material. The drying method of the composite material is to dry at 105°C for 48 hours; put the dried composite material into a quartz boat (10cm×3cm), and place it in a tube furnace for charcoal thermal reduction under the protection of nitrogen. After cooling, the biochar-based nano-zero-valent iron material can be obtained; the condition of charcoal thermal reduction reaction is 8°C·min -1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com