Internal heating oxidation method for preparing silicon material on isolator

A silicon-on-insulator, internal heat technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low thermal oxidation efficiency, long annealing time, unsuitable for industrial production, etc., to improve quality and accelerate nucleation. and growth, the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The specific implementation of the internal thermal oxidation method for preparing a silicon-on-insulator material provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

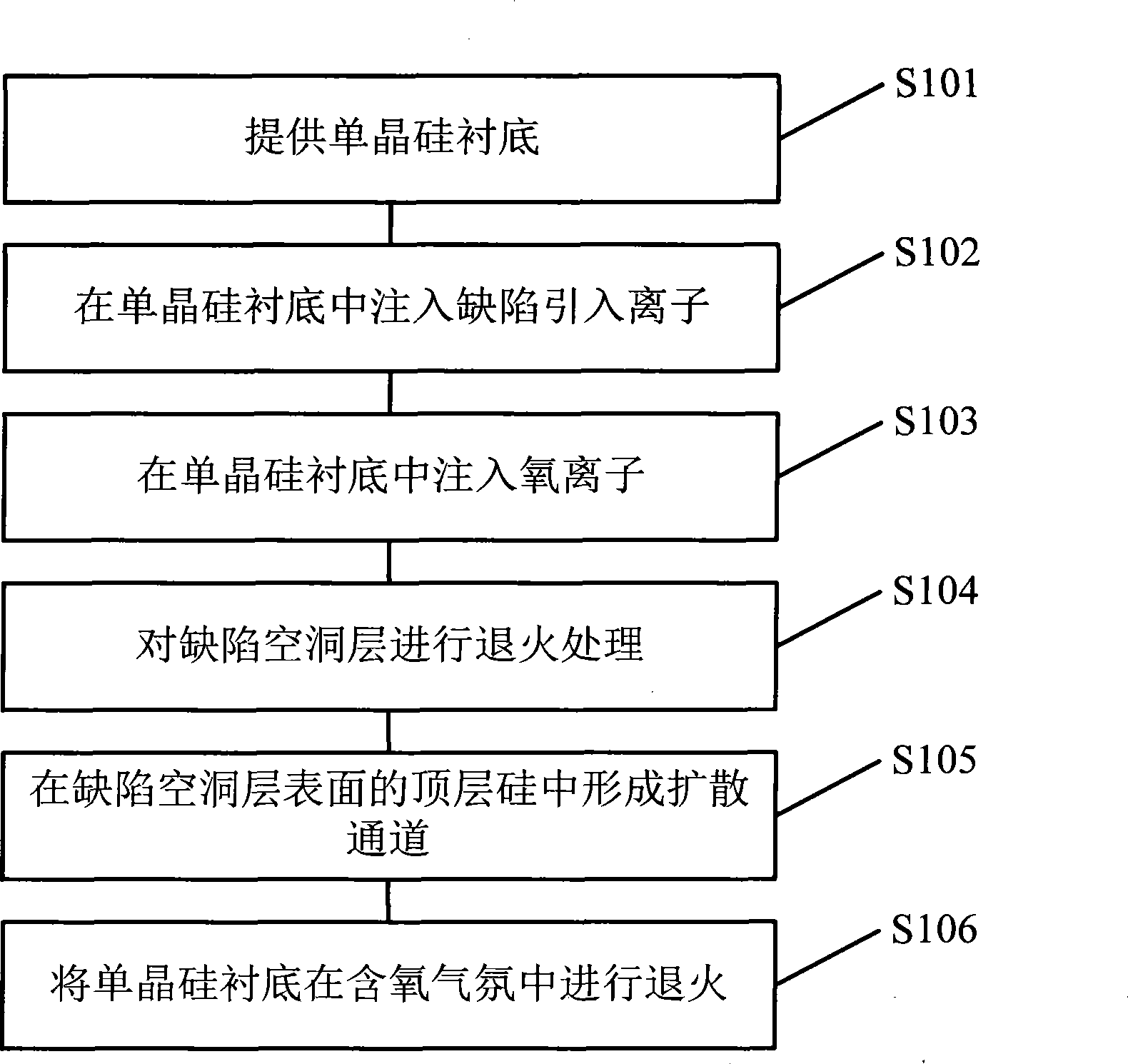

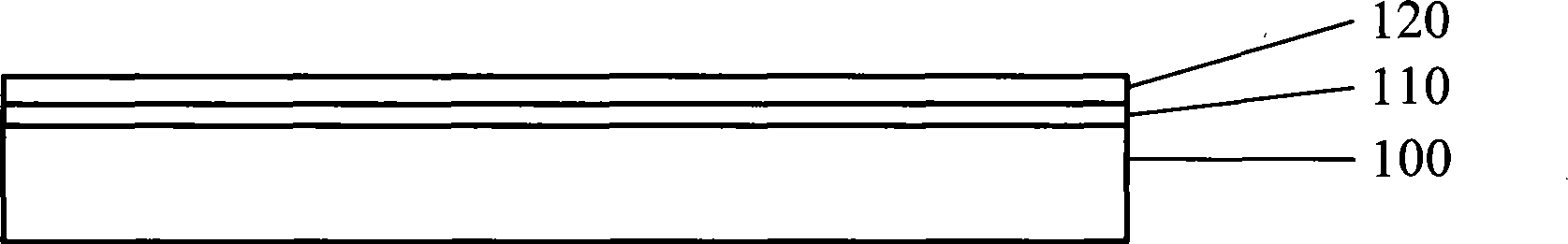

[0023] attached figure 1 Shown is the flow chart of the implementation steps of this specific embodiment, including the following steps: step S101, providing a single crystal silicon substrate; step S102, implanting defect-introducing ions into the single crystal silicon substrate, so that the single crystal silicon substrate Forming a defect hole layer and a top layer of silicon on the surface of the defect hole layer; step S103, implanting oxygen ions into the single crystal silicon substrate; step S104, performing annealing treatment on the defect hole layer; step S105, forming the top layer on the surface of the defect hole layer Diffusion channels are formed in the silicon; step S106 , annealing the single crystal silicon substrate in an...

Embodiment 1

[0057] 1. Provide a single crystal silicon substrate.

[0058] 2. At room temperature, helium ions were implanted into the single crystal silicon substrate with a dose of 4×10 16 cm -2 , the energy is 45keV, and a defect cavity layer is formed, and the depth of the defect cavity layer is at 0.35 μm. attached Figure 7 Shown is a transmission electron micrograph of the defect-cavity layer.

[0059] 3. Anneal at 1000°C for 1 hour.

[0060] 4. Through SiO2 2 Template shadowing and Ga + Diffusion grooves with a width of 2 μm and a depth of 0.5 μm were etched on the silicon layer above the defect hole layer by ion etching, and the distance between the grooves was 5 μm. attached Figure 8 Shown is a scanning electron micrograph of the surface topography of the top silicon layer after etching.

[0061] 5. In the pure oxygen annealing atmosphere, keep the temperature at 1200°C for 20 minutes, then raise the temperature to 1340°C in the annealing atmosphere with a gas concentra...

Embodiment 2

[0064] 1. Provide a single crystal silicon substrate.

[0065] 2. At room temperature, implant hydrogen ions into the single crystal silicon substrate with a dose of 2×10 16 cm -2 , the energy is 40keV, forming a defect hole layer.

[0066] 3. Implant the silicon wafer with the defect hole layer at room temperature with a dose of 1×10 15 cm -2 , the energy is 150keV, at this time an amorphous silicon layer is formed on the upper interface of the void layer, and the maximum concentration of oxygen distribution is located in the void layer.

[0067] 4. In an annealing atmosphere with a gas concentration ratio of oxygen and argon of 100:2 and a temperature of 1340°C, keep the temperature for 5 hours.

[0068] 5.10% HF solution corrodes the surface SiO 2 layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com