Method for efficiently preparing two-dimensional black phosphorus crystal by taking SnP3 as catalyst

A catalyst and black phosphorus technology, applied in the field of two-dimensional materials, can solve the problems of stability of tin-phosphorus compounds, poor controllability of the synthesis process of product purity, and few reports on catalyzing the growth of two-dimensional black phosphorus crystals. Accelerates the nucleation and growth process and promotes the effect of rapid generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

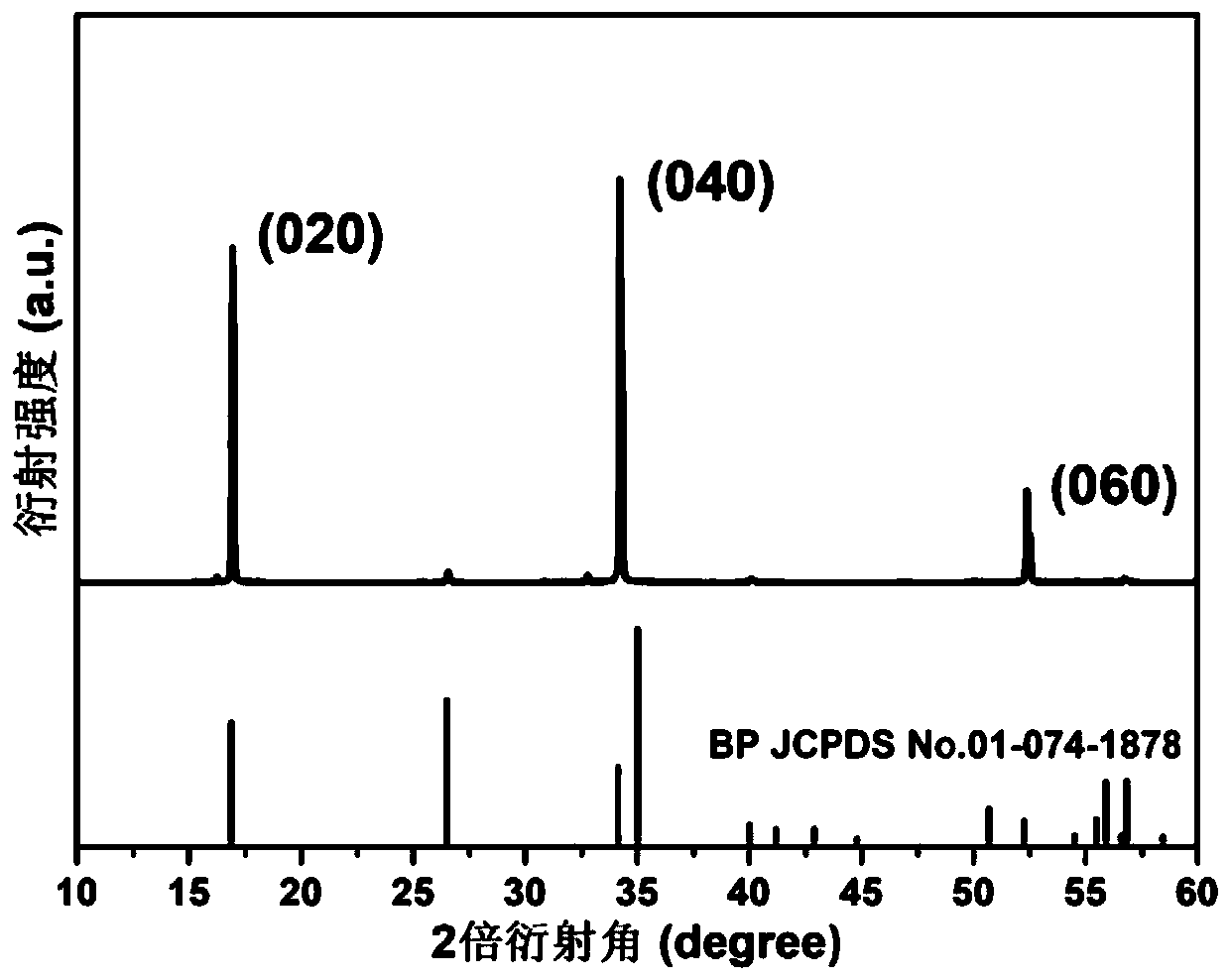

[0043] A tin-phosphorous compound (SnP 3 ) is a method for efficiently preparing two-dimensional black phosphorus crystals as a catalyst, and the specific preparation steps are as follows:

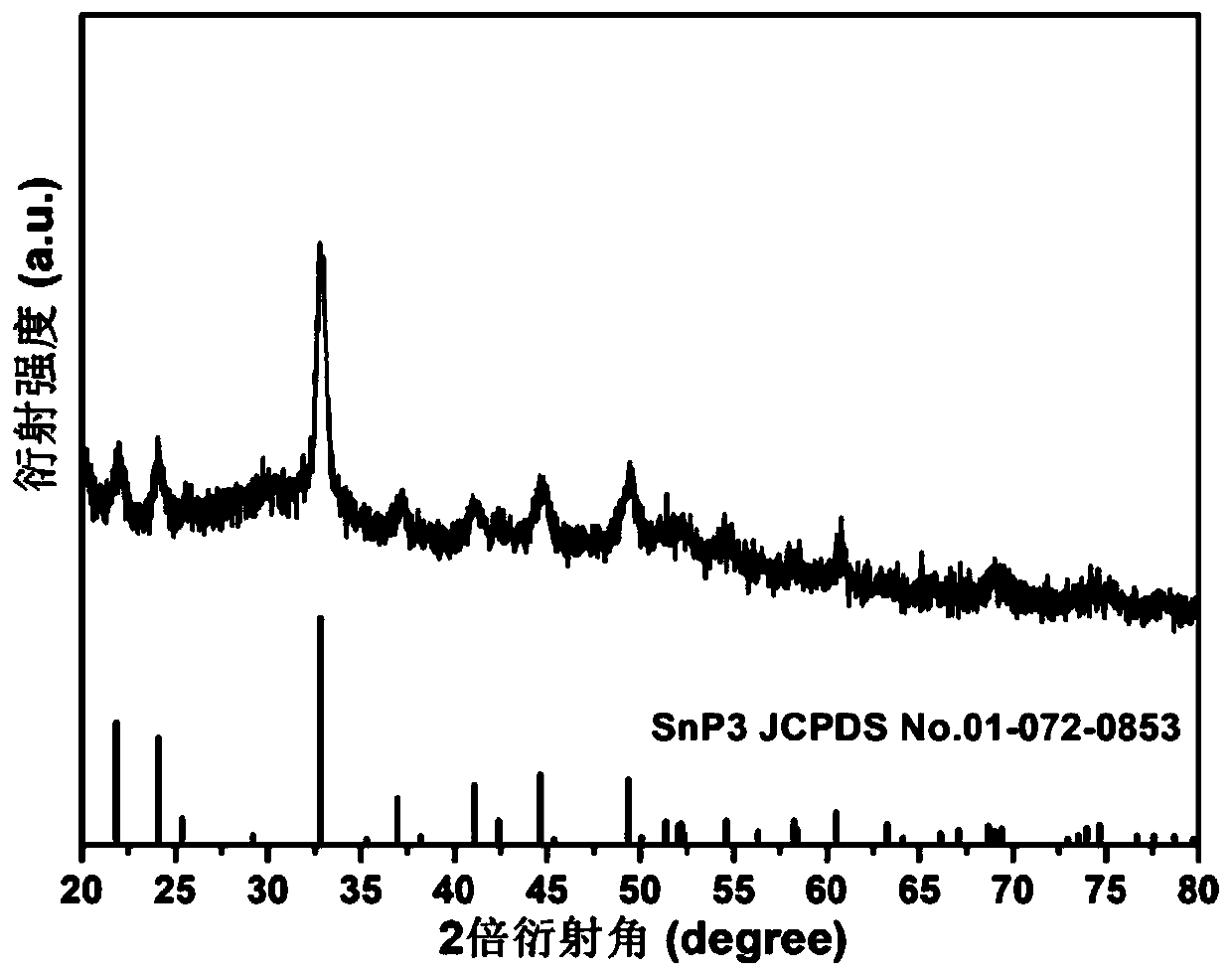

[0044] 1) Weigh 86.7 mg of red phosphorus raw material and 118.7 mg of metal elemental tin into a ball mill jar, and perform high-energy ball milling under an inert atmosphere. The specific parameters are: the ball milling material (including ball milling pot and balls) is agate, the particle size of the balls is 0.5cm, the ball-to-material ratio is 90:1, the ball milling time is 36h, and the milling speed is 300r / min. After ball milling, get SnP 3 powder and take it out for later use.

[0045] 2) Under an inert atmosphere, weigh 3100 mg of red phosphorus raw material, SnP 3 210mg of powder and 60mg of transport agent I2 were placed at the bottom of a single-head sealed quartz tube, and the opening was sealed with parafilm for later use.

[0046] 3) Remove the sealing film, and quickly...

Embodiment 2

[0050] A tin-phosphorous compound (SnP 3 ) is a method for efficiently preparing two-dimensional black phosphorus crystals as a catalyst, and the specific preparation steps are as follows:

[0051] 1) Weigh 99.1 mg of red phosphorus raw material and 118.7 mg of metal elemental tin into a ball mill jar, and perform high-energy ball milling under an inert atmosphere. The specific parameters are: the ball milling material (including the ball mill jar and balls) is zirconia, the particle size of the balls is 1cm, the ball-to-material ratio is 100:1, the milling time is 60h, and the ball milling speed is 500r / min. After ball milling, get SnP 3 powder and take it out for later use.

[0052] 2) Under an inert atmosphere, weigh 3100 mg of red phosphorus raw material, SnP 3 Powder 210mg and Transport Agent SnI 2 60mg is placed at the bottom of a single-head sealed quartz tube, and the opening is sealed with parafilm for later use.

[0053] 3) Remove the sealing film, and quickly ...

Embodiment 3

[0057] A tin-phosphorous compound (SnP 3 ) is a method for efficiently preparing two-dimensional black phosphorus crystals as a catalyst, and the specific preparation steps are as follows:

[0058] 1) Weigh 92.9 mg of red phosphorus raw material and 118.7 mg of metal elemental tin into a ball mill jar, and perform high-energy ball milling under an inert atmosphere. The specific parameters are: the ball milling material (including ball milling pot and balls) is zirconia, the particle size of the balls is 0.8cm, the ball-material ratio is 95:1, the ball milling time is 48h, and the milling speed is 400r / min. After ball milling, get SnP 3 powder and take it out for later use.

[0059] 2) Under an inert atmosphere, weigh 3100 mg of red phosphorus raw material, SnP 3 Powder 210mg and Transport Agent SnI 4 60mg is placed at the bottom of a single-head sealed quartz tube, and the opening is sealed with parafilm for later use.

[0060] 3) Remove the sealing film, and quickly use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com