CIGS/CdTe dual-junction laminated thin-film solar cell and preparation method thereof

A solar cell and thin film technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low utilization rate of the solar spectrum, loss, and the inability of photons to convert photogenerated carriers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The present invention provides a method for preparing a thin-film solar cell described in the above scheme, comprising the following steps:

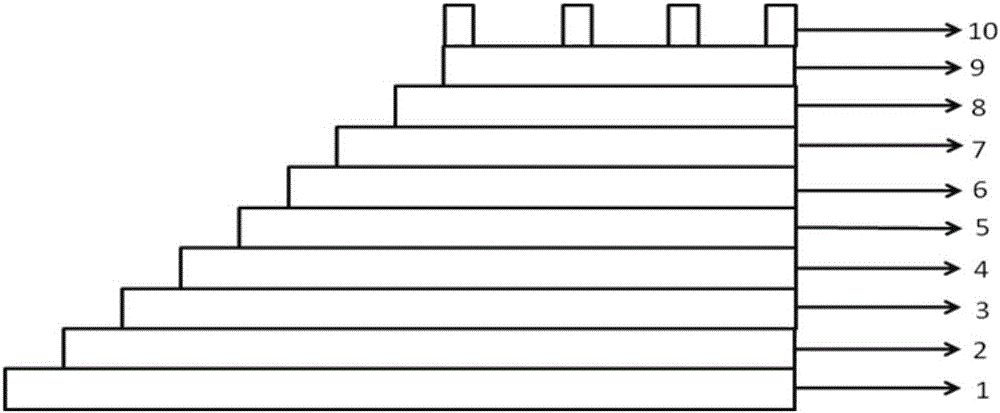

[0040] Prepare conductive electrodes, p-type CIGS absorber layer, bottom cell n-type CdS buffer layer, bottom cell intrinsic zinc oxide insulating layer, conductive connection layer, top cell intrinsic zinc oxide insulating layer, n-type CdS buffer on the substrate material layer, p-type CdTe absorber layer and copper-gold alloy electrode.

[0041] The present invention prepares conductive electrodes on the substrate material. In the present invention, the conductive electrode is preferably sputtered on the surface of the substrate by magnetron sputtering. In the present invention, the target material used in the magnetron sputtering is consistent with the above-mentioned scheme, and will not be repeated here; the diameter of the target is 75mm; the purity is preferably more than 99.99%; the magnetron sputtering The cathode magn...

Embodiment 1

[0084] Step 1: Prepare conductive electrodes by magnetron sputtering.

[0085] The Mo electrode is used as the conductive electrode, the target is a 3-inch forged fine-grained Mo target with a purity of 99.99%, the sputtering cathode magnetic field is an unbalanced field, and the back and bottom vacuum is pumped to 5.0×10 -3 Pa, the sputtering atmosphere is high-purity argon, the sputtering pressure is 0.1Pa, the sputtering power is 200W, the target base distance is 100mm, the sputtering time is 20min, and the thickness of the obtained Mo electrode is 800nm; The bottom surface is cleaned, the ion acceleration voltage is 250eV, the particle beam current is 80mA, and the cleaning time is 5min;

[0086] Step 2: Three-step co-evaporation method to deposit p-type CIGS absorber layer

[0087] Back vacuum to 5.0×10 -5 Pa, heat the bottom temperature, indium source, gallium source, and selenium source to 400°C, 800°C, 900°C, and 270°C respectively, wait for each evaporation source t...

Embodiment 2

[0108] Step 1: Preparation of conductive electrodes by magnetron sputtering

[0109] The Mo electrode is used as the conductive electrode, the target is a 3-inch forged fine-grained Mo target with a purity of 99.99%, the sputtering cathode magnetic field is an unbalanced field, and the back and bottom vacuum is pumped to 4.0×10 -3 Pa, the sputtering atmosphere is high-purity argon, the sputtering pressure is 0.5Pa, the sputtering power is 300W, the target base distance is 120mm, the sputtering time is 15min, and the thickness of the obtained Mo electrode is 1000nm; The bottom surface is cleaned, the ion acceleration voltage is 250eV, the particle beam current is 80mA, and the cleaning time is 5min;

[0110] Step 2: Three-step co-evaporation method to deposit p-type CIGS absorber layer

[0111] Back vacuum to 5.0×10 -5 Pa, heat the bottom temperature, indium source, gallium source, and selenium source to 450°C, 850°C, 950°C, and 300°C respectively, wait for each evaporation s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com