Surface treatment process of a cast iron product

A technology for cast iron products and surface treatment, which is applied to special surfaces, pre-treated surfaces, and devices for coating liquid on surfaces, etc. It can solve problems such as complex anti-rust treatment processes, achieve no odor, simple process operation, and prevent surface rust. rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The present invention provides a surface treatment process for cast iron products. In order to make the objectives, technical solutions and effects of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

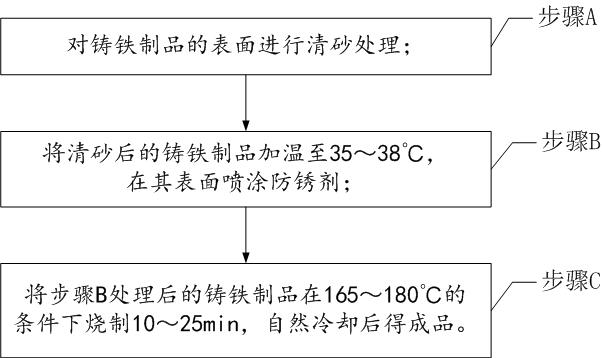

[0020]Seefigure 1, The present invention provides a surface treatment process for cast iron products, including the following steps:

[0021]A. Clean the surface of cast iron products; cast iron products are processed from casting or forging blanks, and the blanks are cast with sand during the casting or forging process, so there are often sticky sand residues on the blanks that need to be cleaned and cleaned up the cast iron products The sticky sand on the surface can make subsequent operations go smoothly.

[0022]B. Heat the cast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com