Patents

Literature

47results about How to "Oil removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

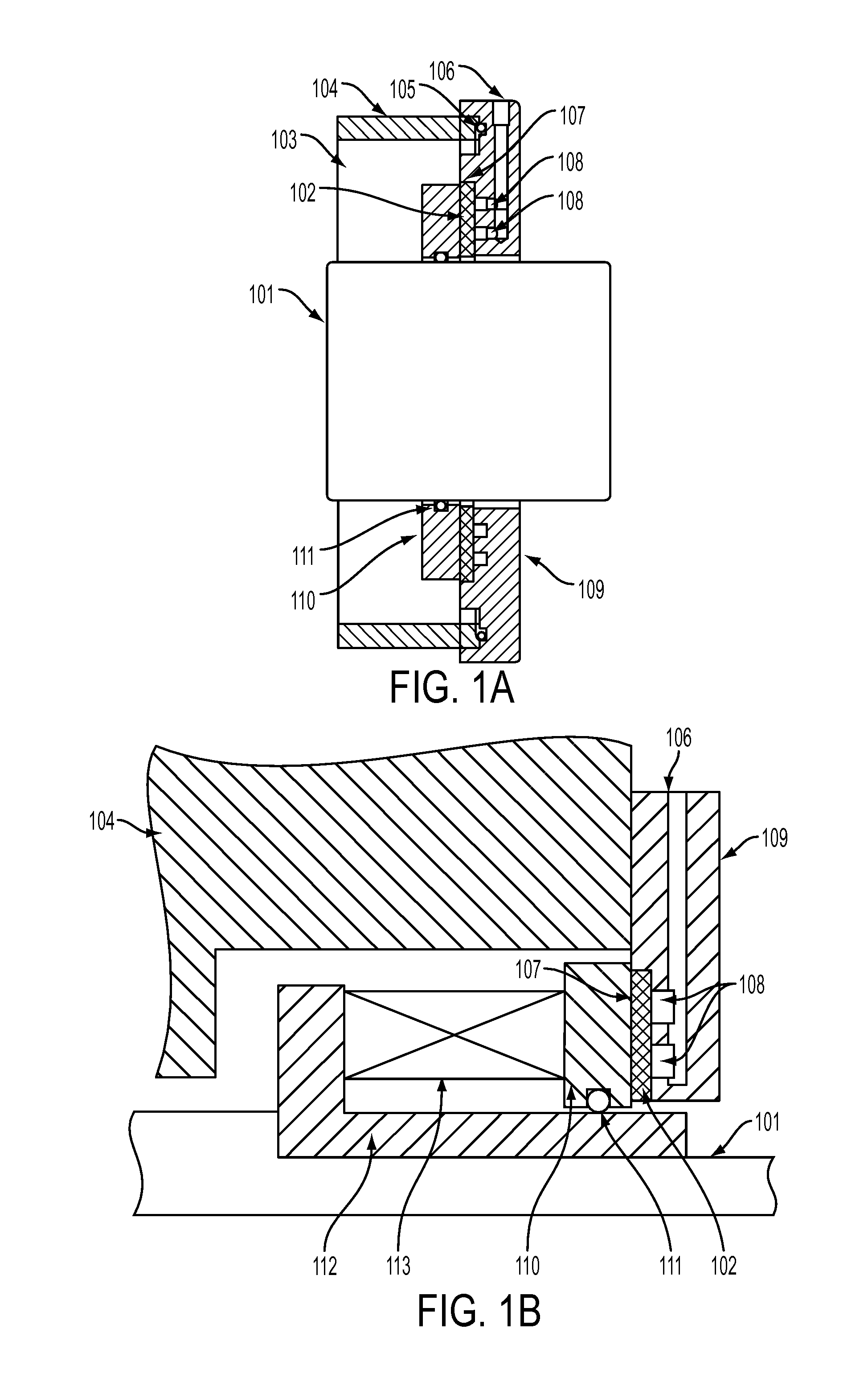

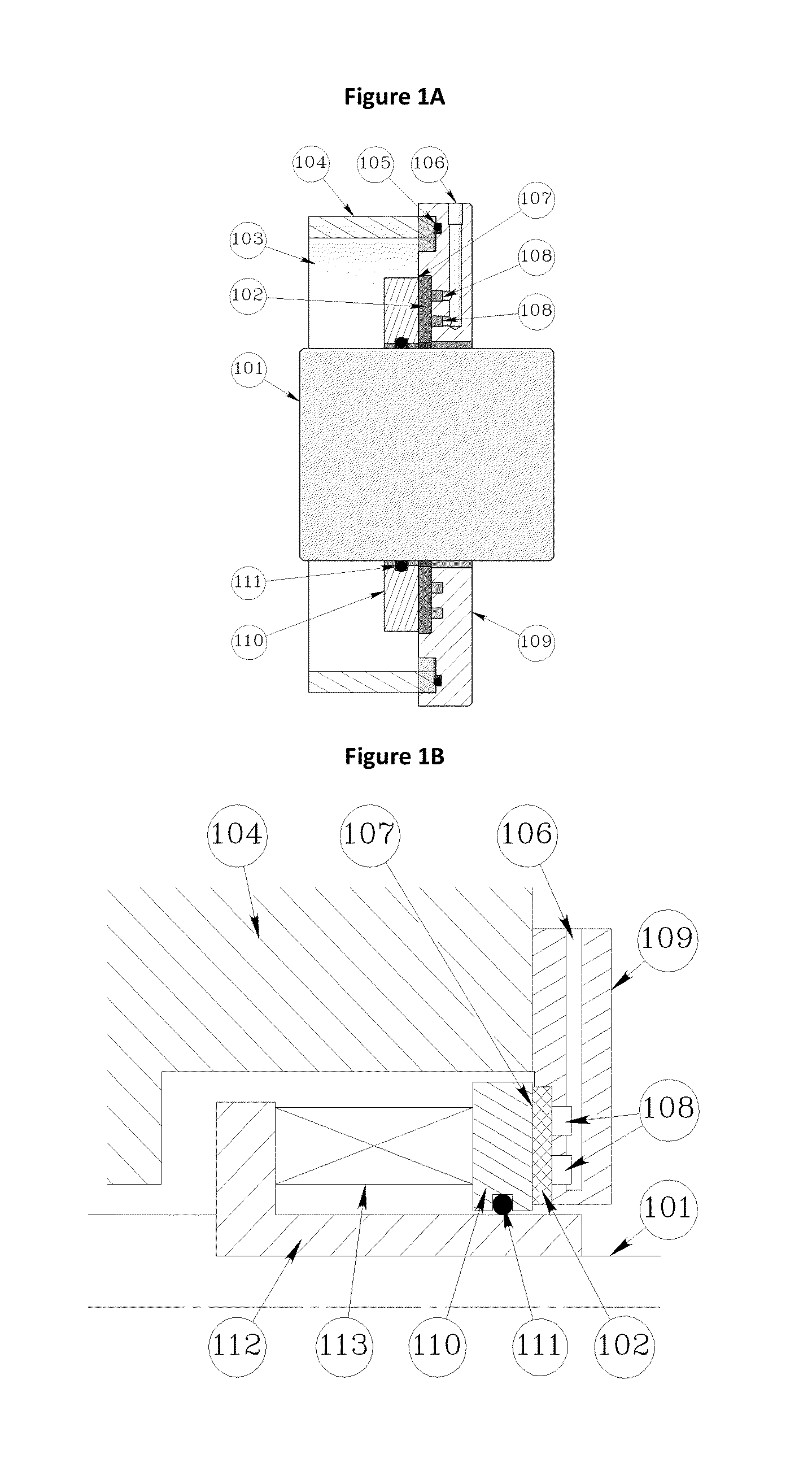

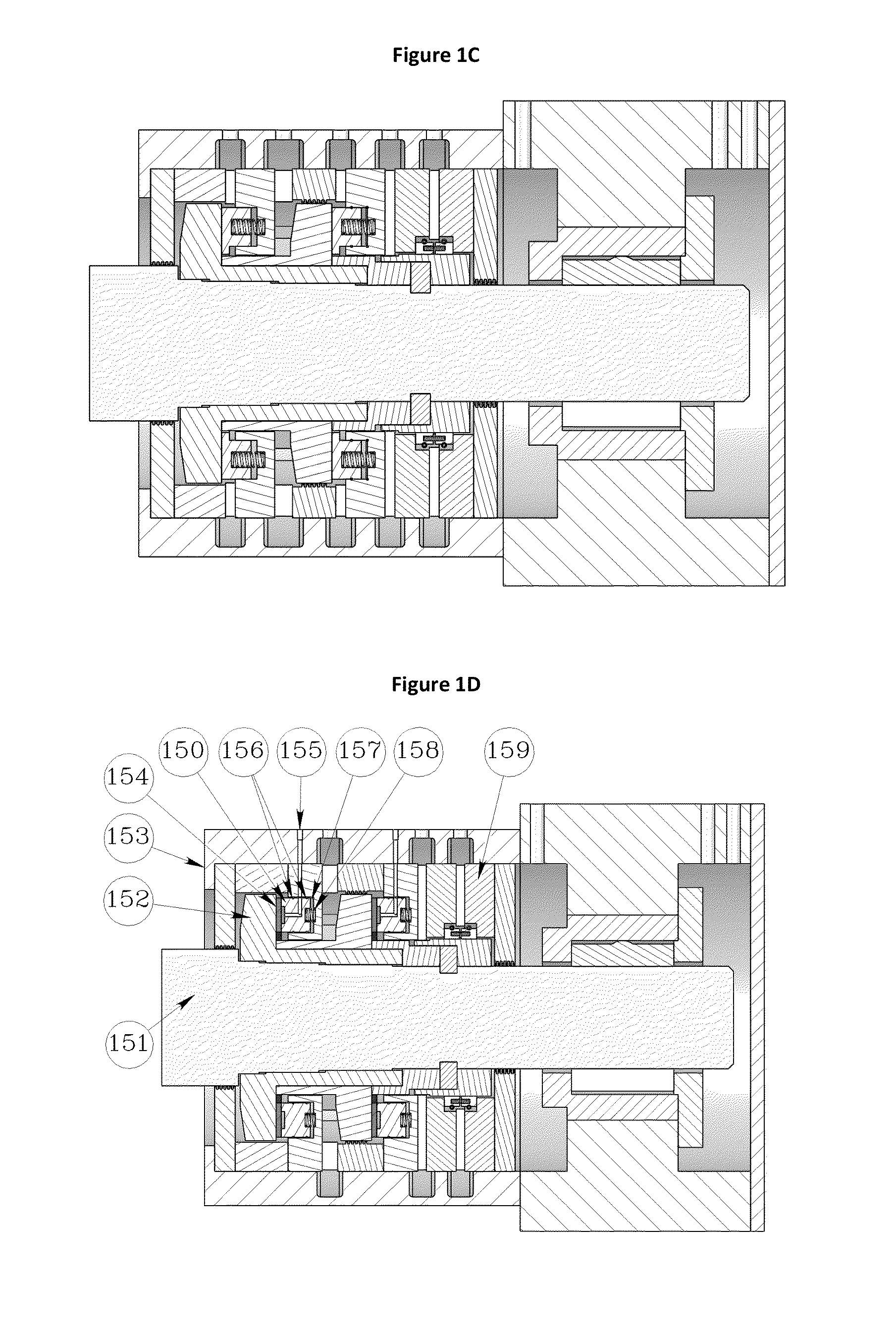

Air bearing for use as a seal

ActiveUS8753014B2Improve sealingReliable surfaceEngine sealsGas cushion bearingsAir bearingPressure difference

In order to effect a seal; a porous material which comprises one side of two opposing surfaces is used to restrict and evenly distribute externally pressurized gas, liquid, steam, etc. between the two surfaces, exerting a force which is opposite the forces from pressure differences or springs trying to close the two faces together and so may create a non contact seal that is more stable and reliable than hydrodynamic seals currently in use.

Owner:NEW WAY MACHINE COMPONENTS

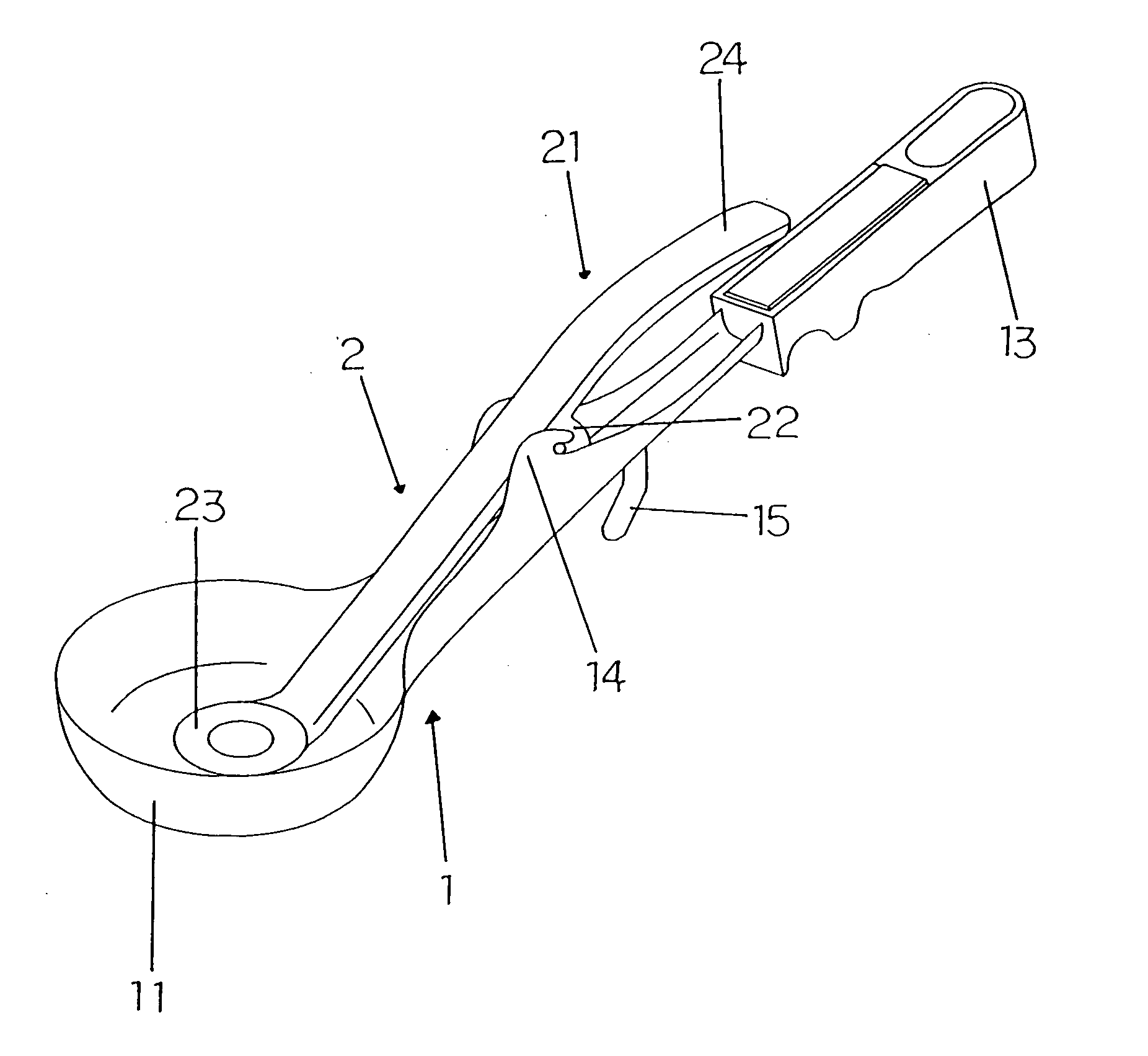

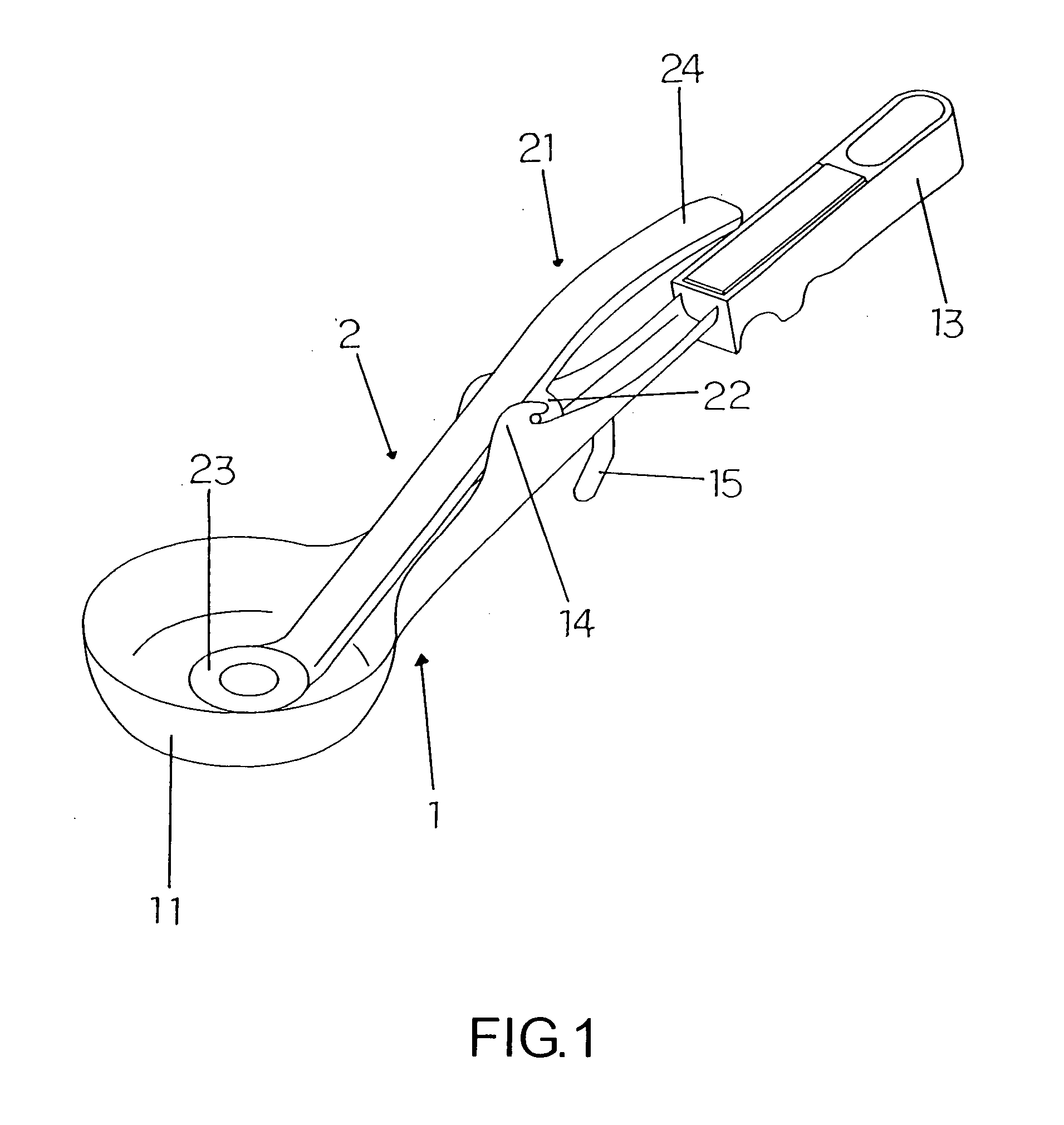

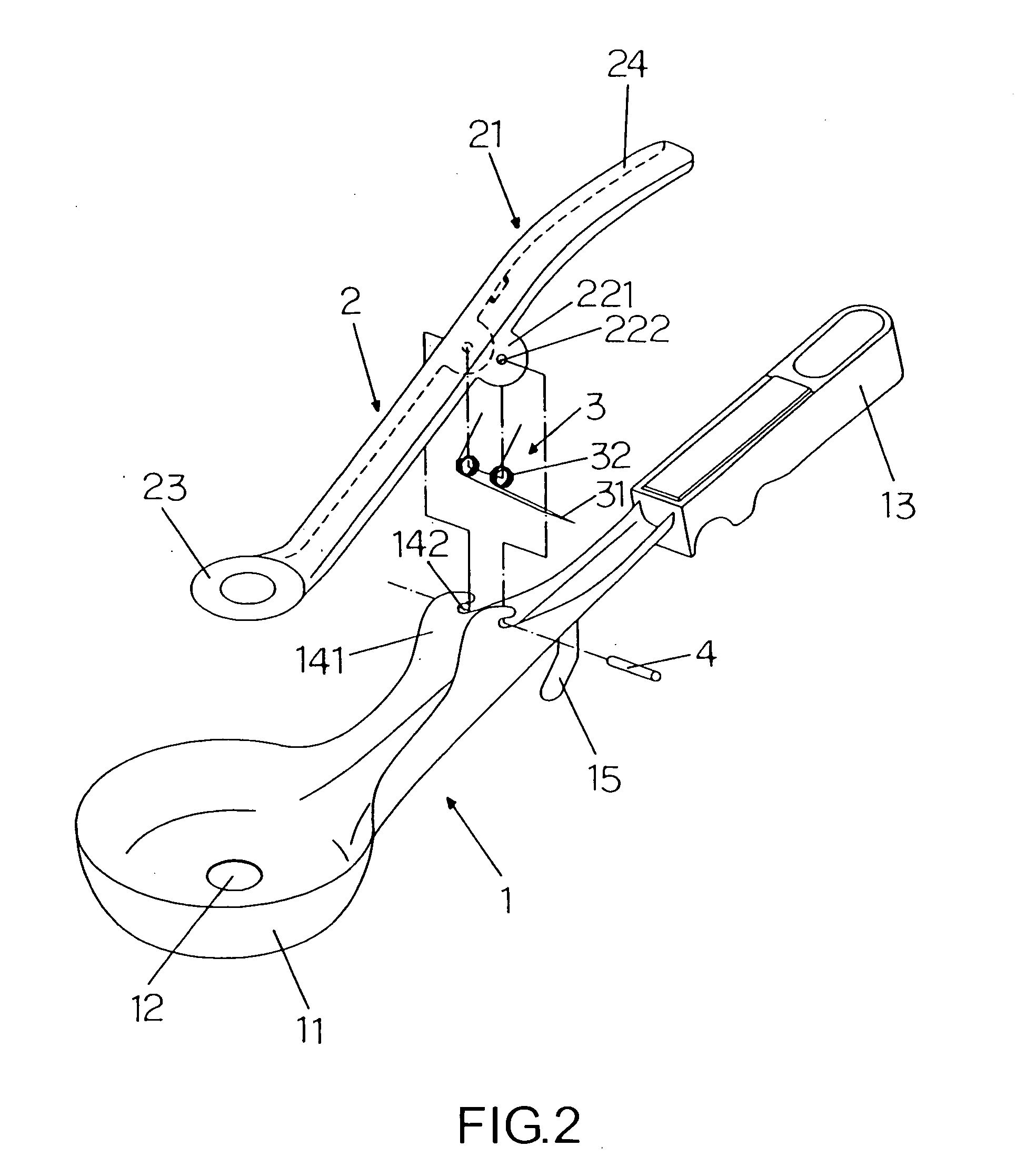

Multipurpose spoon structure

The invention herein relates to a multipurpose spoon structure, including a spoon, a flow-stopper and a springy element, wherein, one end of the spoon is a bowl-shaped part with a water outlet therein; at the other end is a handle holding a hanger hereunder used to hang the spoon to the rim of a pot. Moreover, the handle of spoon and the mobile handle of flow-stopper pegged together at a specific place is encompassed with a springy element, whereby enabling the flow-stopper to move up and down on the spoon, making a valve held at one end of the flow-stopper covering up the water outlet. When pressing a trigger, the valve subsequently lifts up, thus opening the water outlet. When being released, the trigger is sprung back in place by the strength of the springy element, and the valve go down and cover up the water outlet.

Owner:HO CHEN LUNG

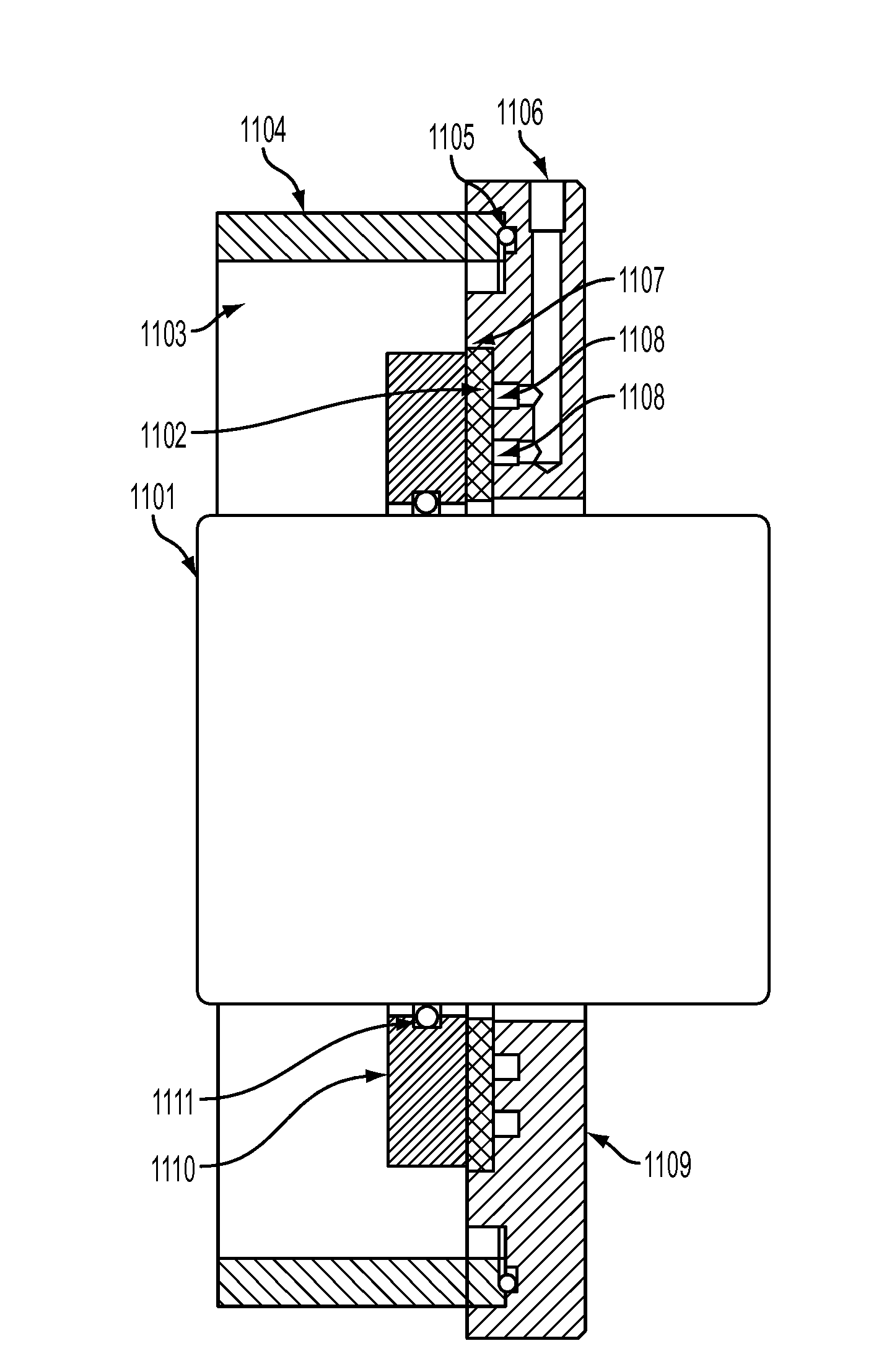

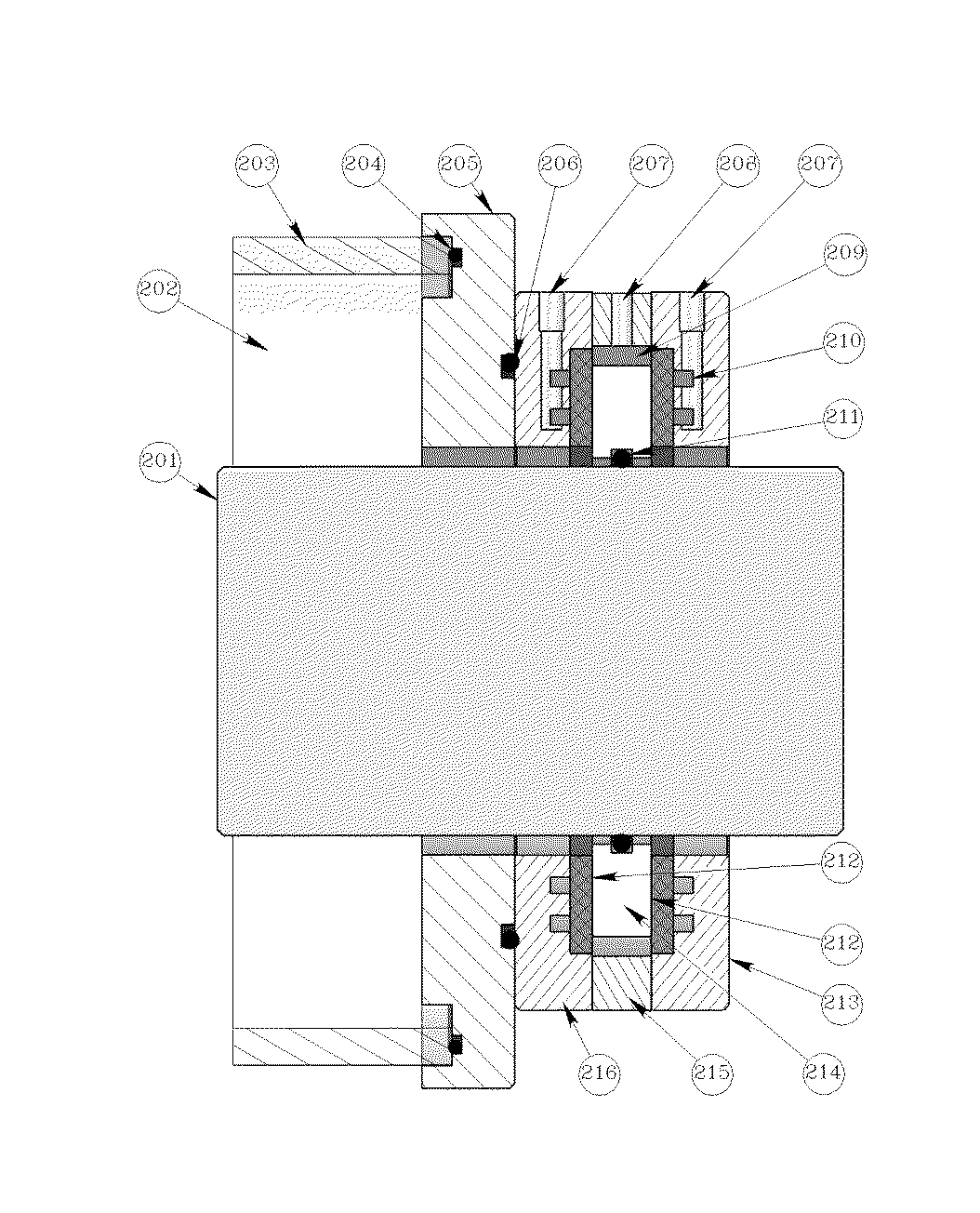

Air bearing for use as seal

ActiveUS20130188895A1Easy to adjustReduce wareEngine sealsGas cushion bearingsAir bearingEngineering

In order to effect a seal; a porous material which comprises one side of two opposing surfaces is used to restrict and evenly distribute externally pressurized gas, liquid, steam, etc. between the two surfaces, exerting a force which is opposite the forces from pressure differences or springs trying to close the two faces together and so may create a non contact seal that is more stable and reliable than hydrodynamic seals currently in use.

Owner:NEW WAY MACHINE COMPONENTS

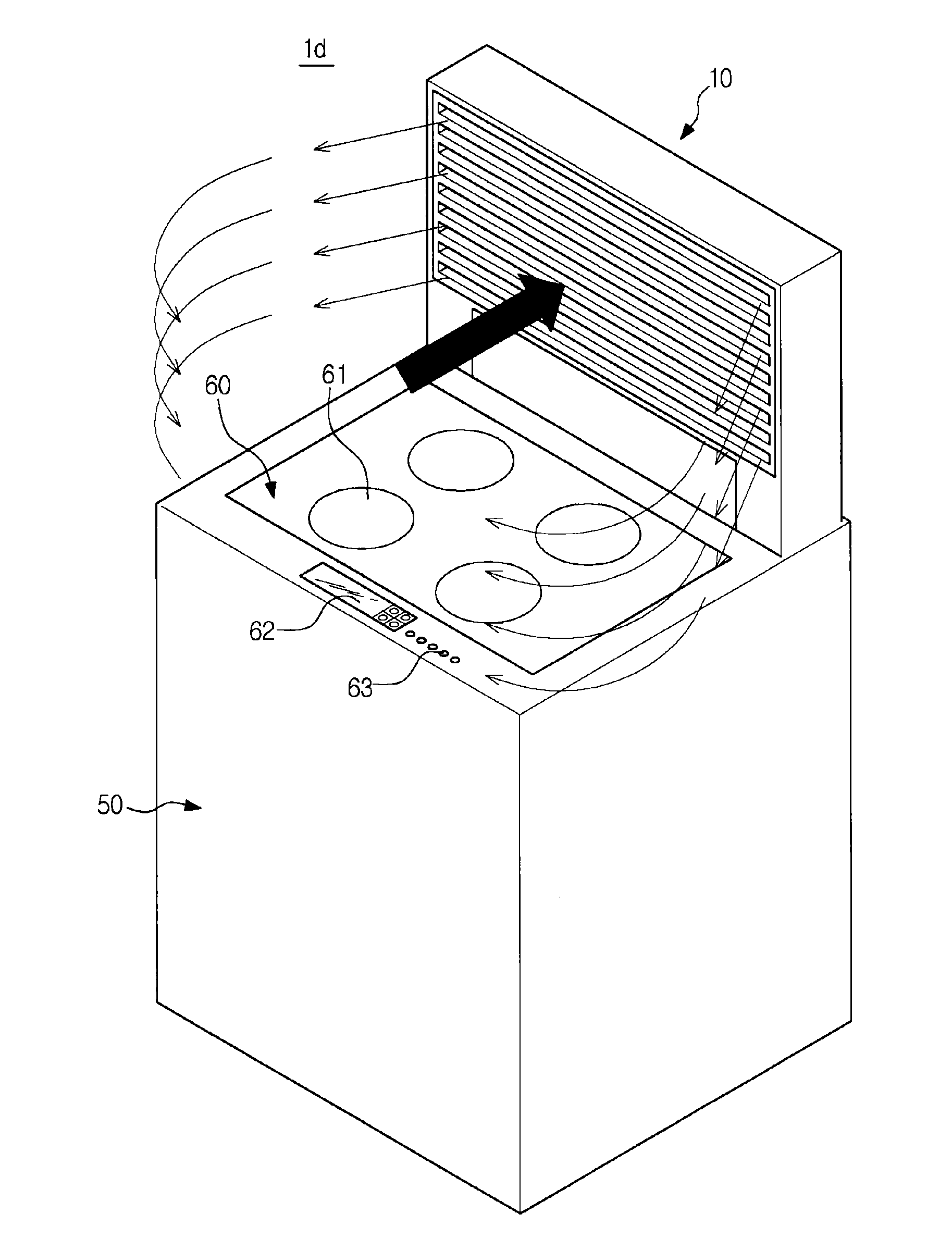

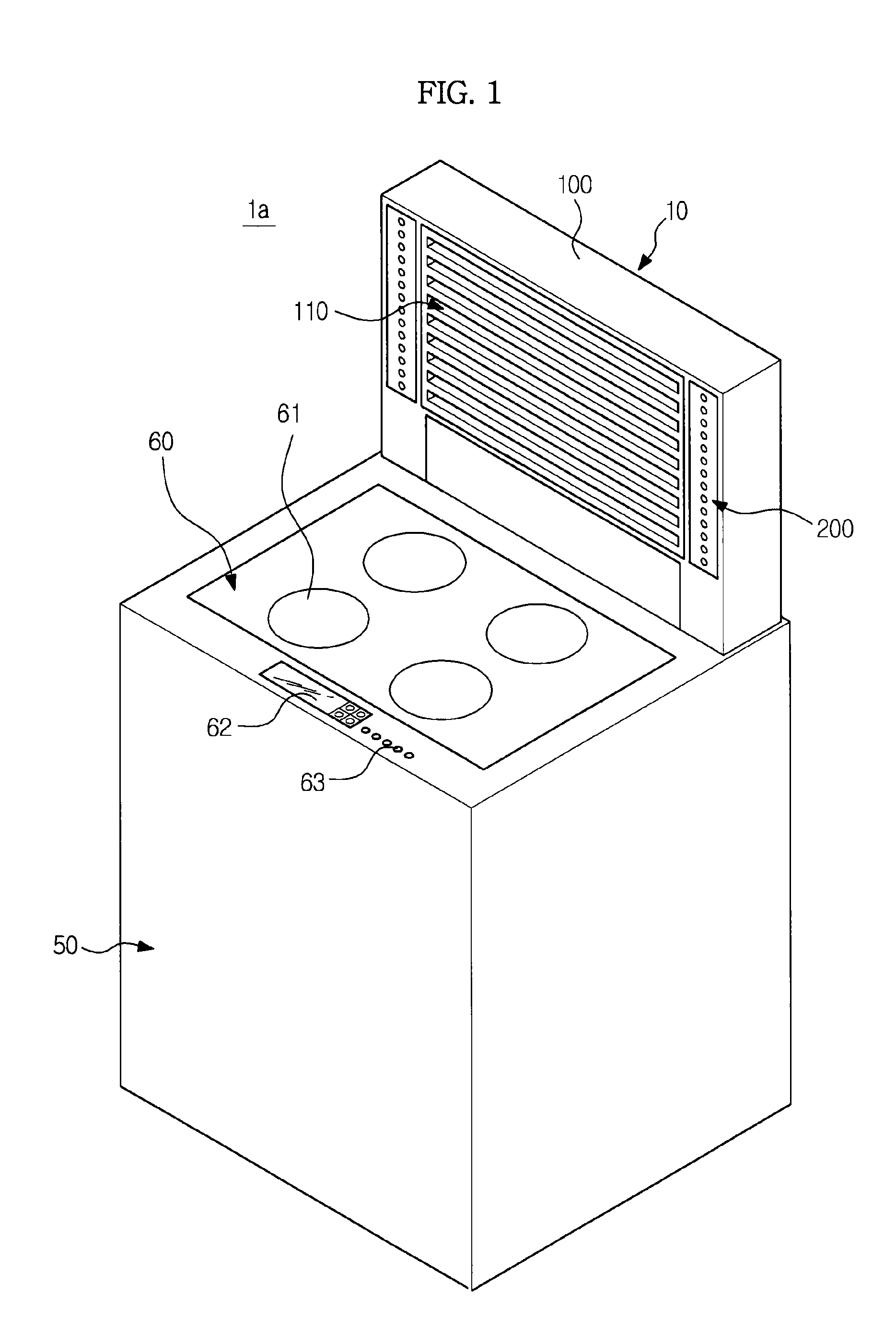

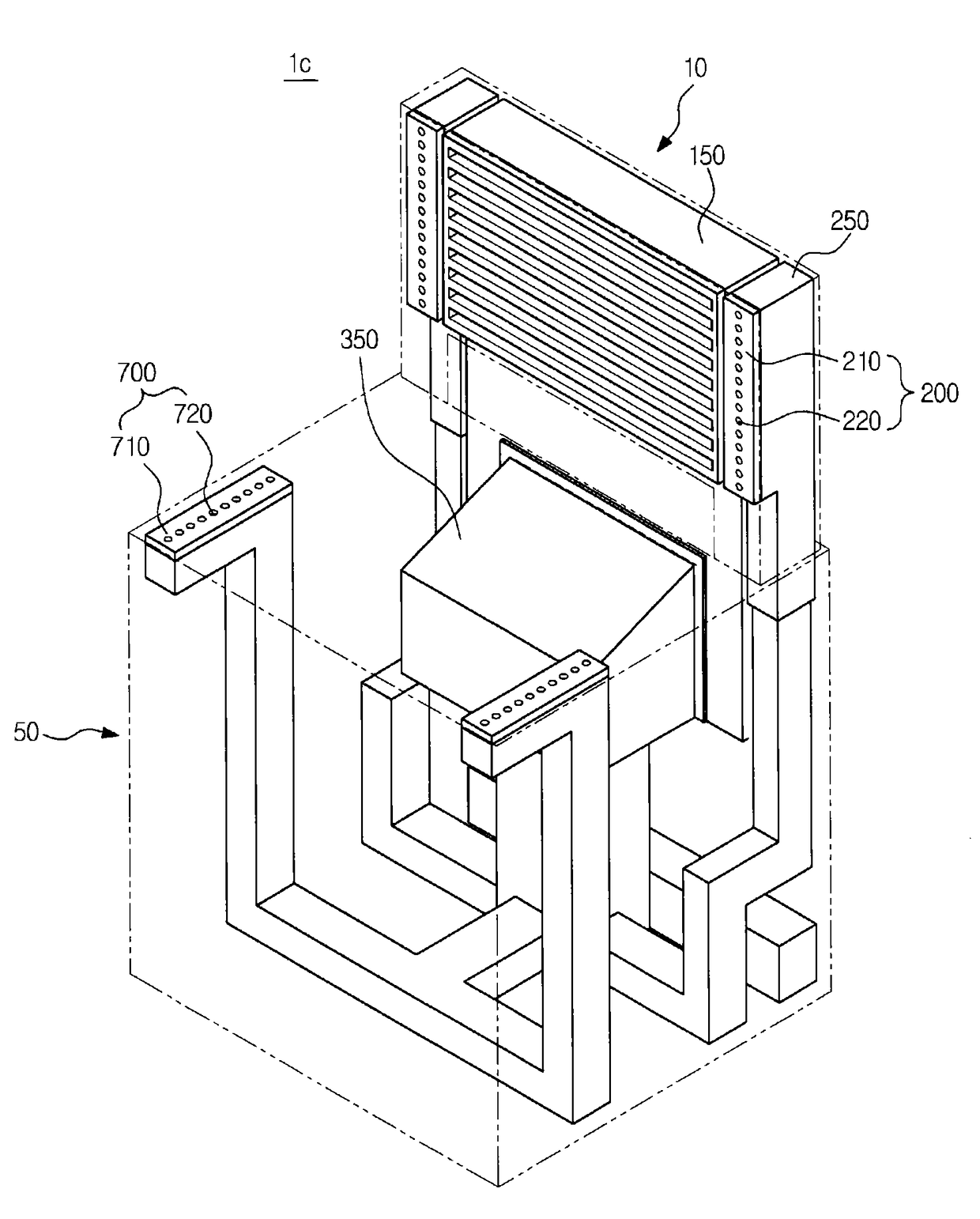

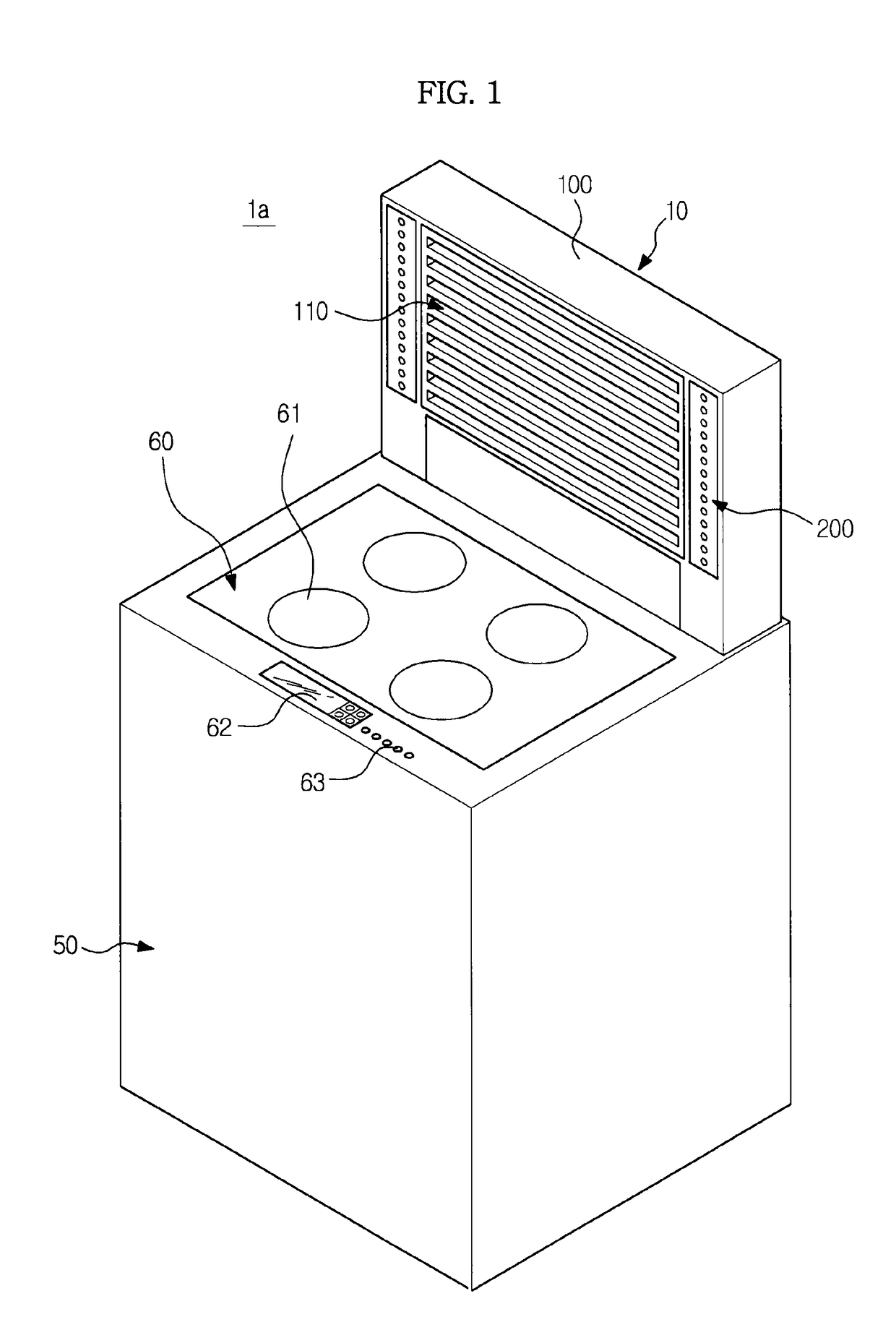

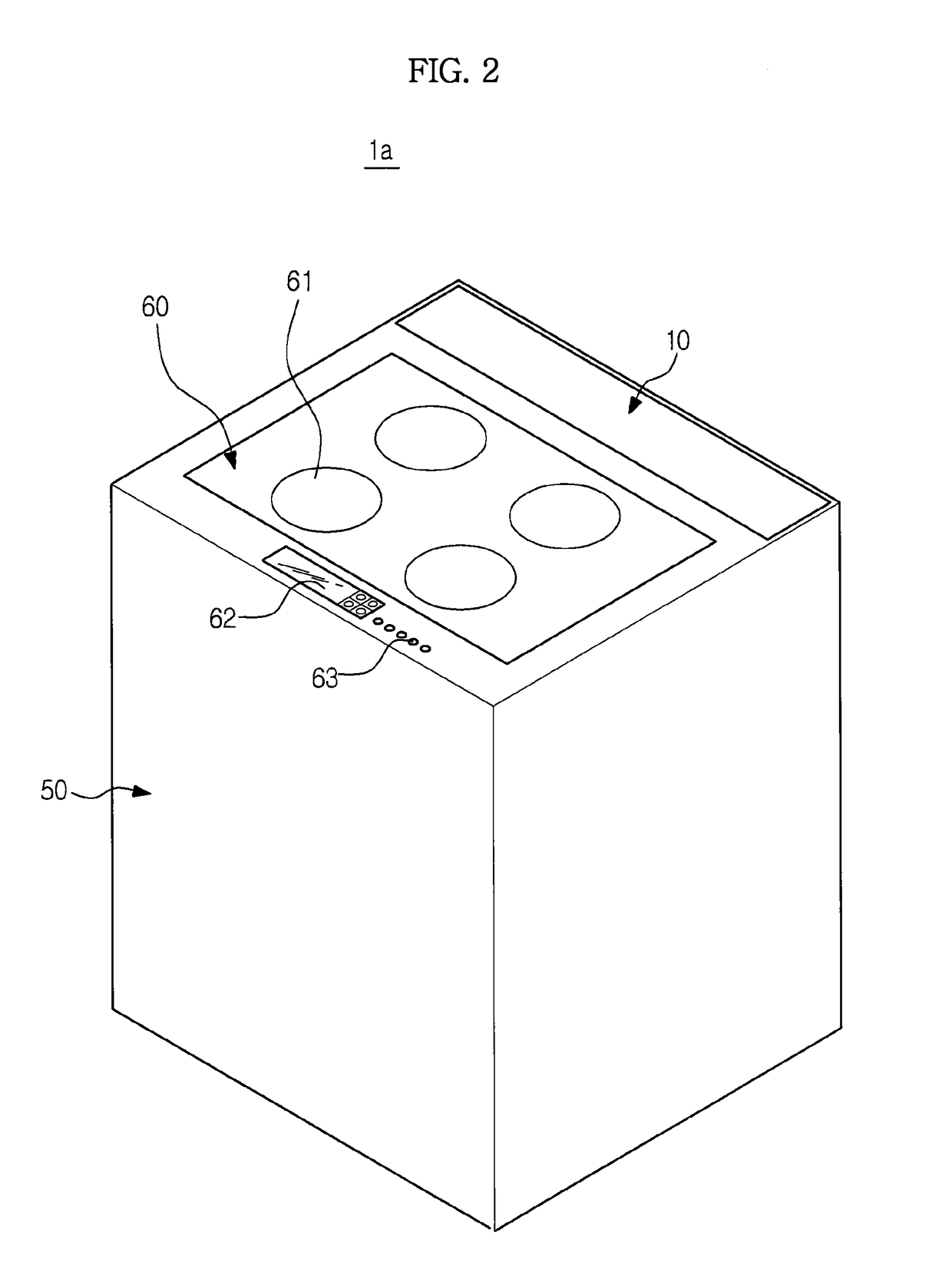

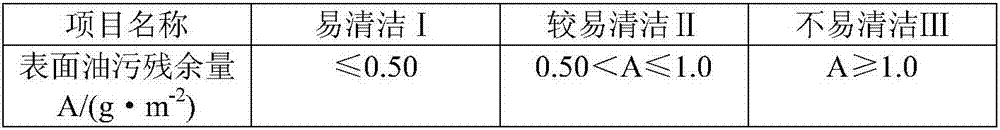

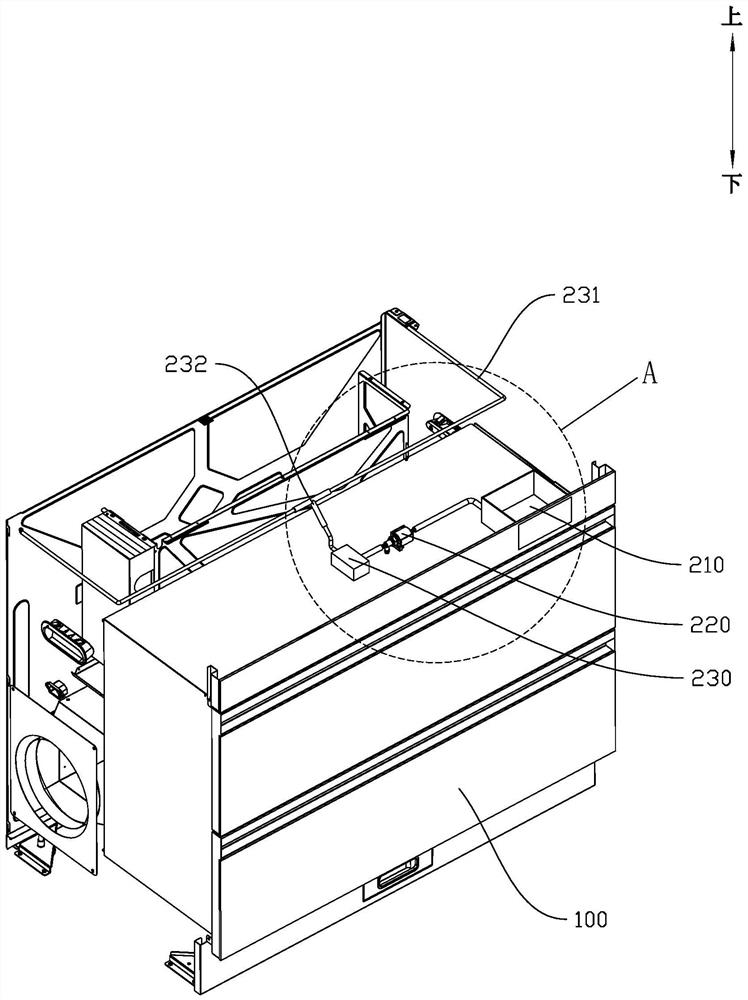

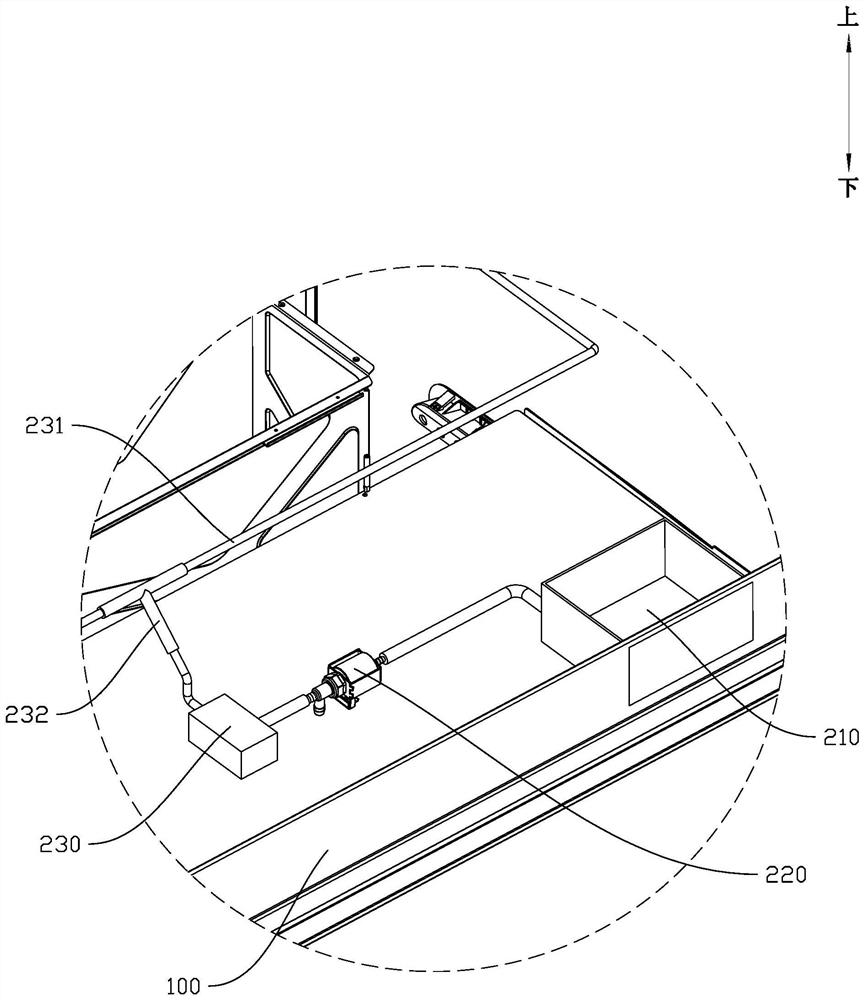

Ventilation apparatus and cooking system having the same

ActiveUS20130125764A1Simple structureImprove utilization efficiencyCombination devicesDomestic stoves or rangesSuction forceEngineering

A ventilation system that allows air to be directly discharged indoors, a the ventilation system including a body and a ventilation apparatus provided at an edge of an upper surface of the body and configured to take in polluted air generated during cooking, wherein the ventilation apparatus includes a suction port configured to take in the polluted air, a suction fan provided at an inside the body and configured to generate a suction force for the polluted air to be taken in through the suction port, a passage through which the air taken in through the suction port passes, at least one filter mounted at an inside the passage and configured to purify the air passing through the passage, and an exit port communicating with one end portion of the passage and configured to discharge the air purified by the at least one filter indoors.

Owner:SAMSUNG ELECTRONICS CO LTD +1

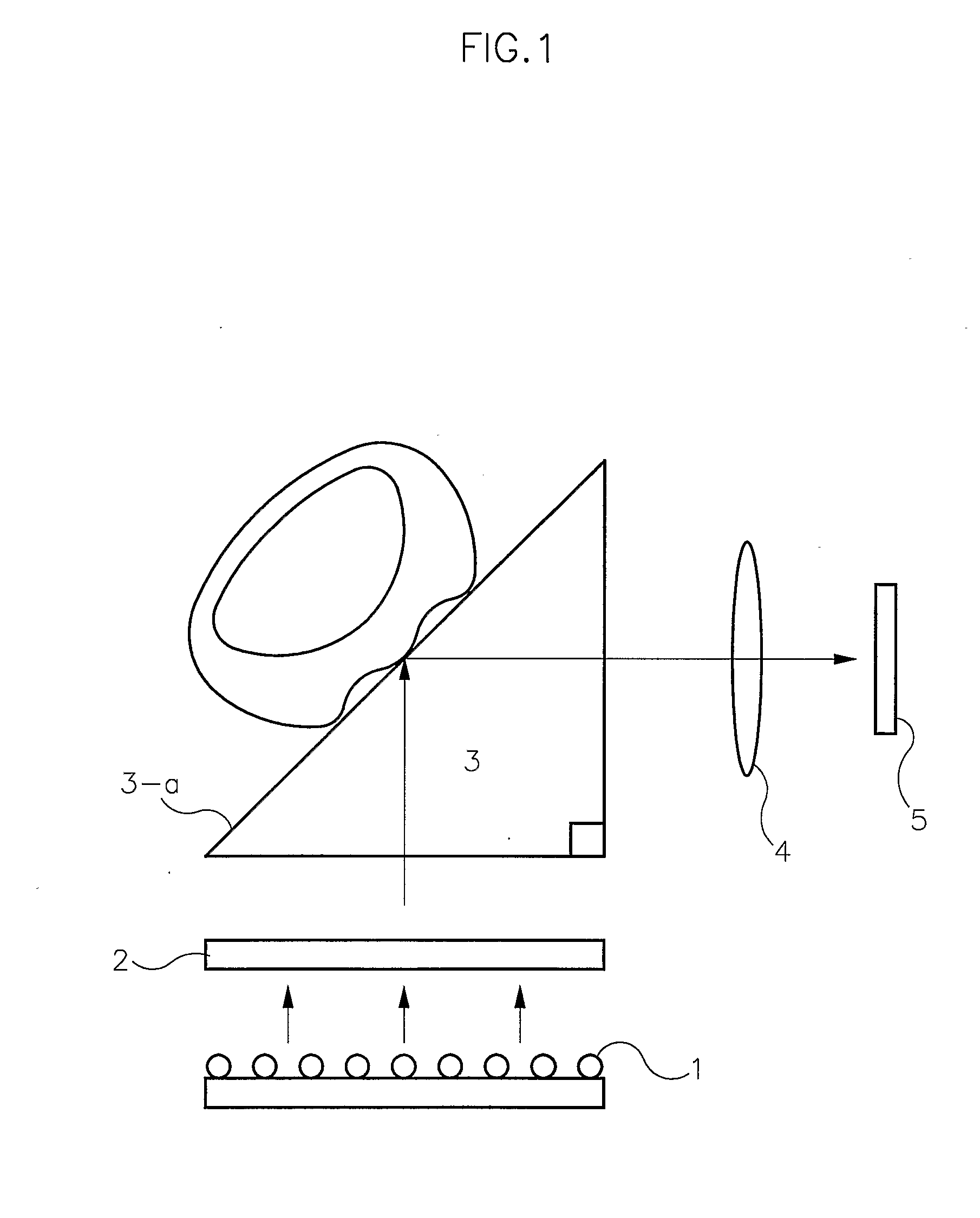

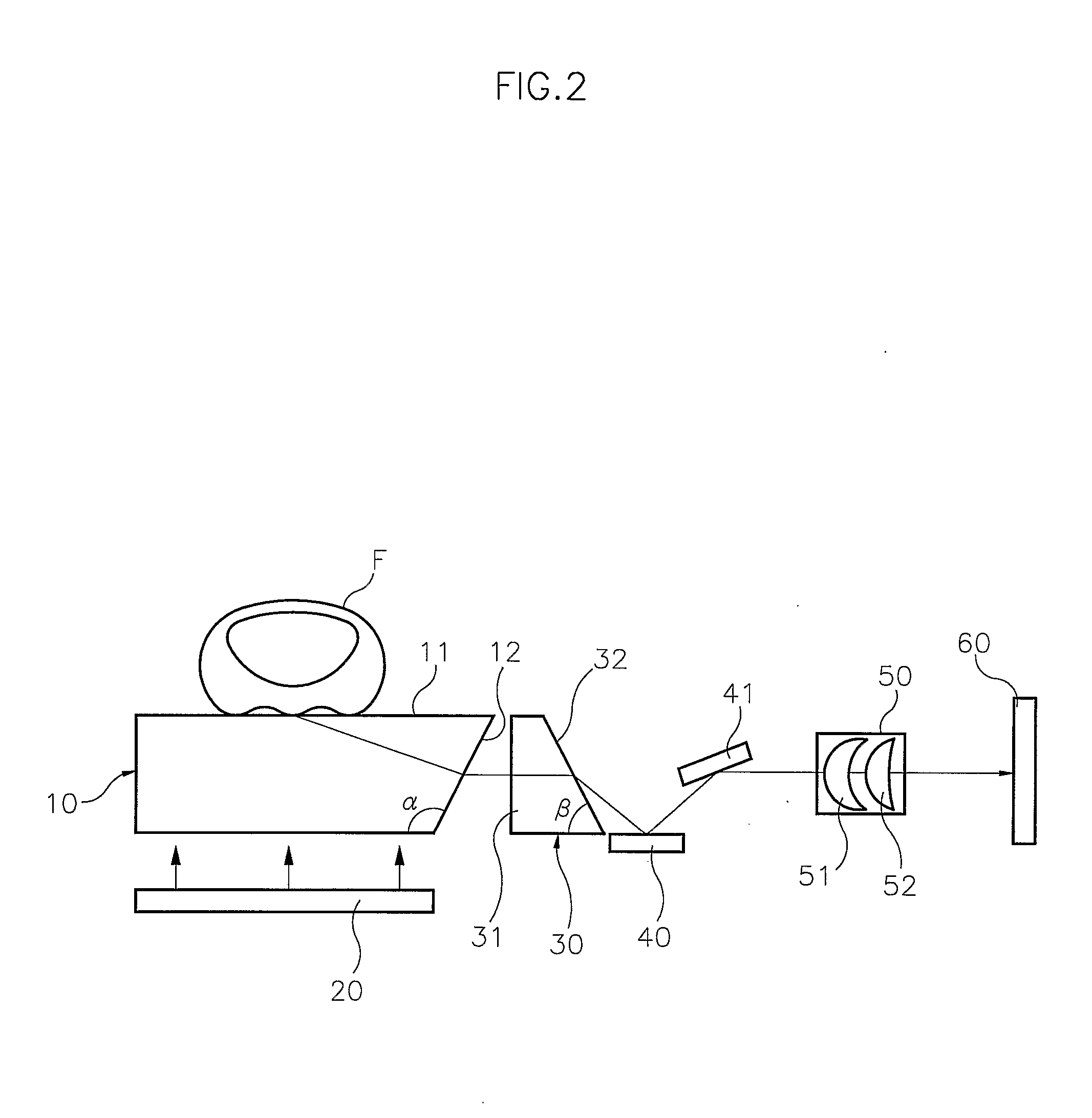

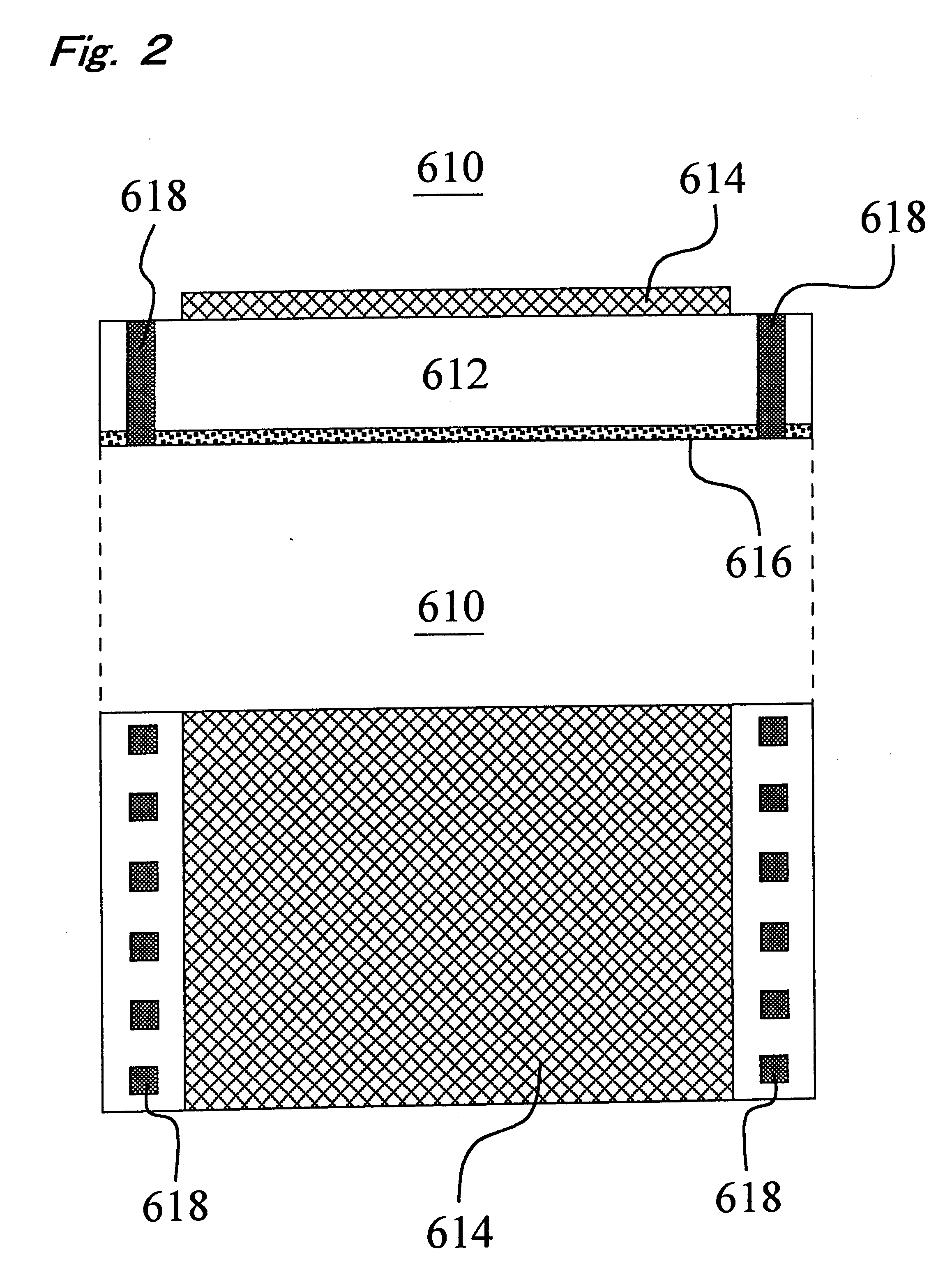

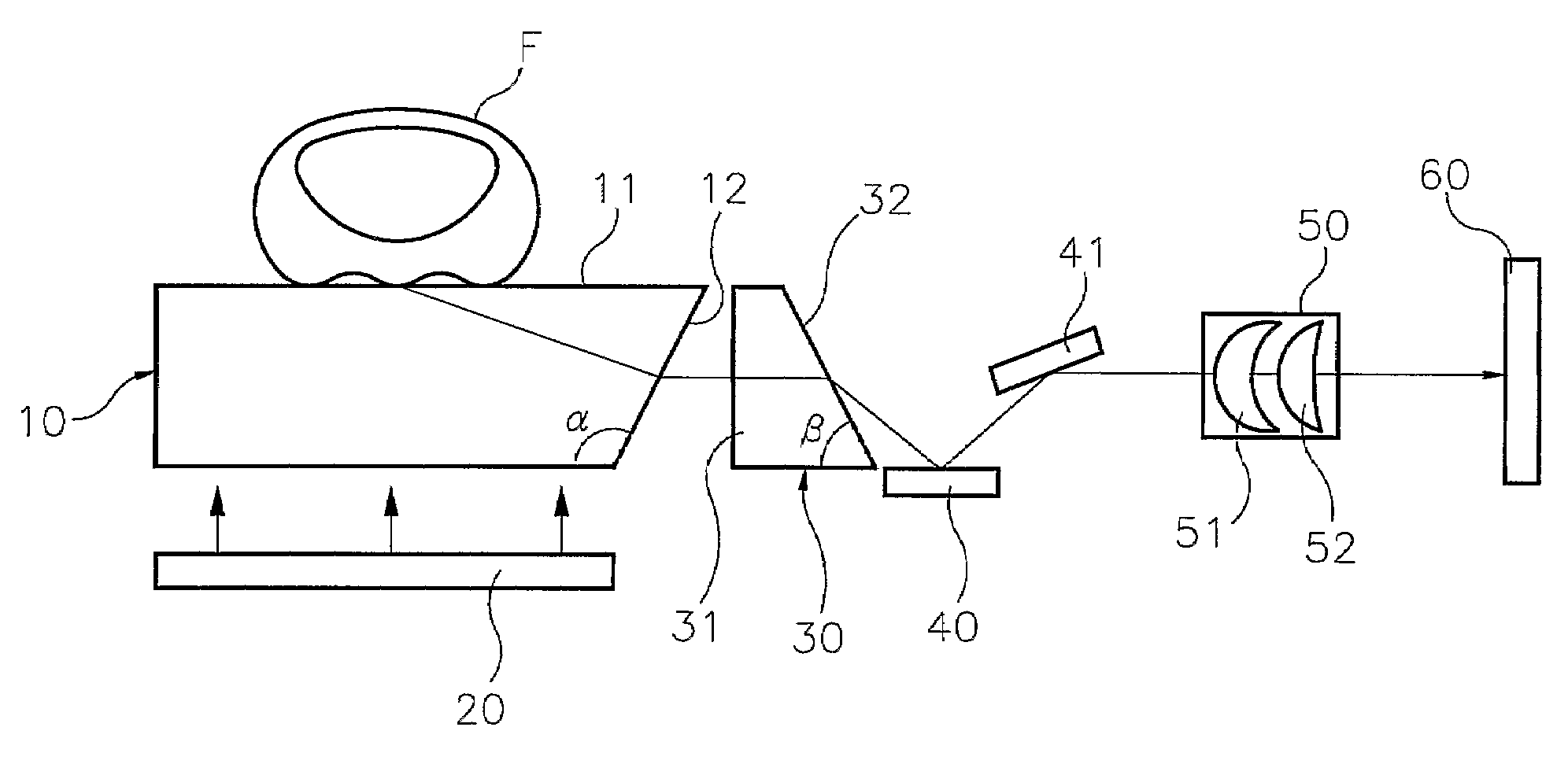

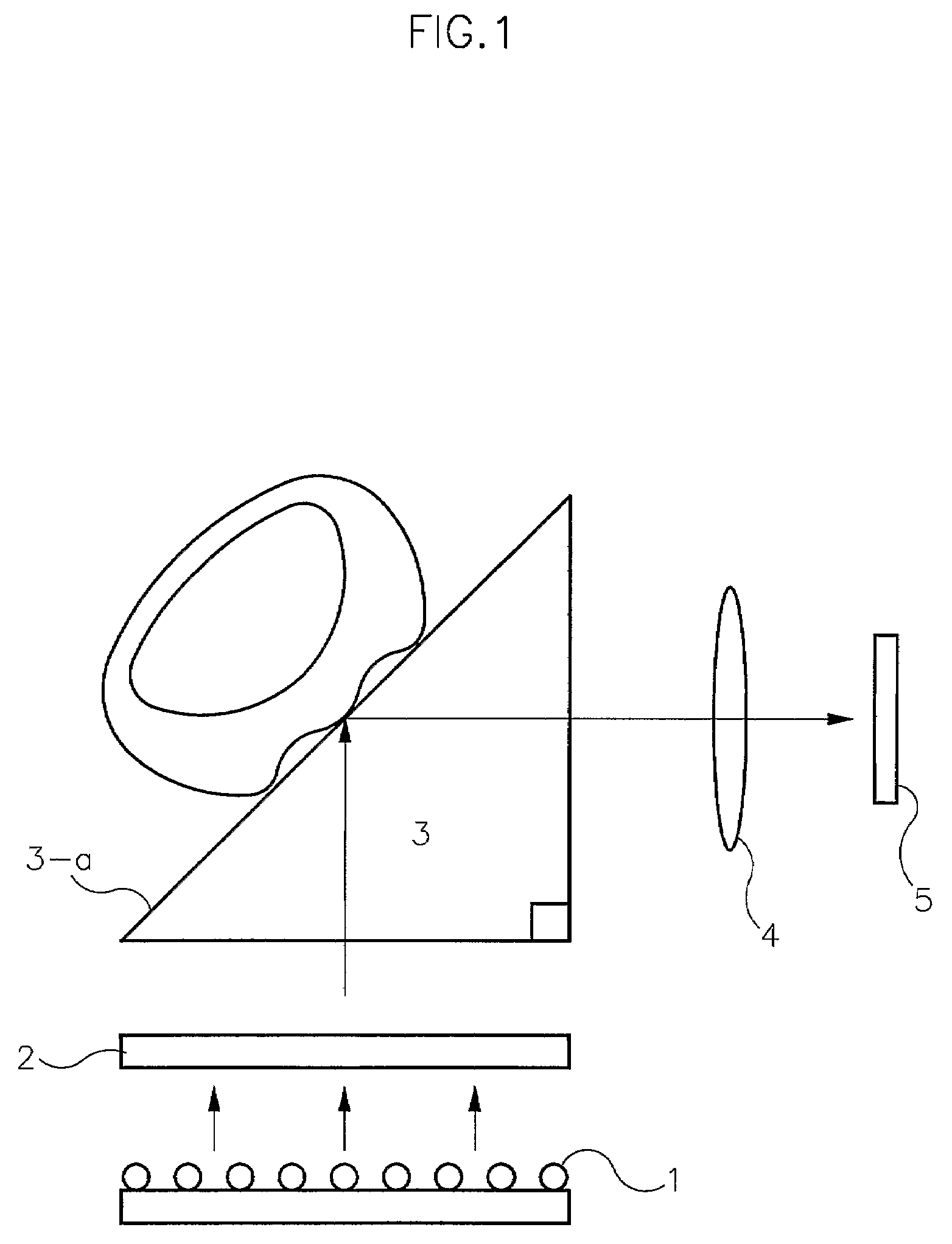

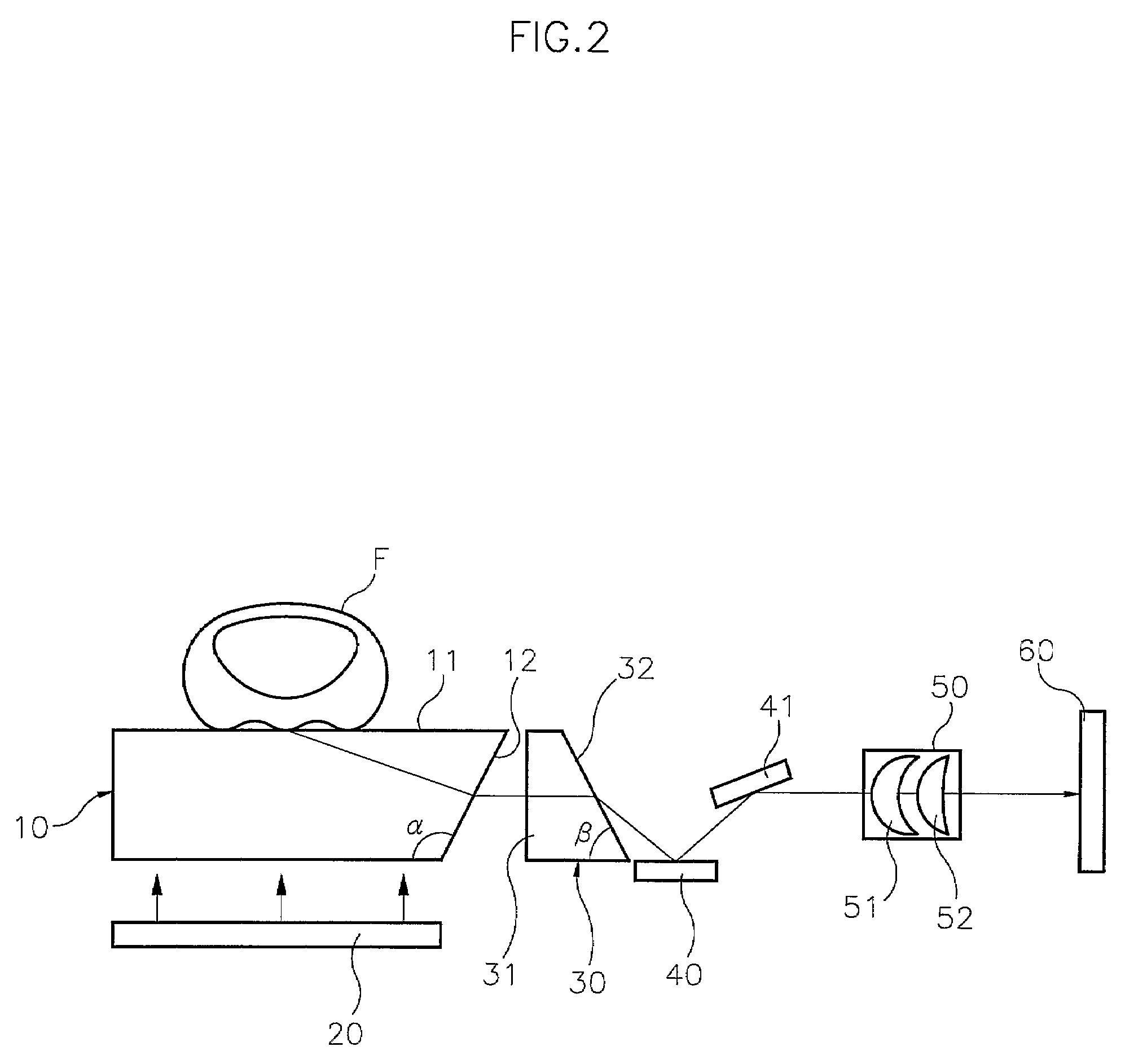

Optical finger print input device for mobile apparatus

InactiveUS20070189588A1Efficient use ofOil removalCharacter and pattern recognitionSecurity arrangementLiquid-crystal displayMobile device

An optical fingerprint image input device for a mobile apparatus includes: a plate-shaped fingerprint contact member; a distortion correcting member for correcting distortions; light sources disposed at both sides of the fingerprint contact member, other than an inclined surface or a back light source in a liquid crystal display element; focusing means disposed at an inclined surface side of the distortion correcting member; and an image sensor. In other words, the fingerprint contact member and the distortion correcting member having respective set-up inclined angles are disposed to discern sweat, water or oil and to correct a trapezoidal distortion which is a disadvantage that occurs when a thin fingerprint contact medium is used, and to form a lens system comprised of a cylindrical lens and a spherical lens for adjustment of a ratio of transversal to longitudinal widths of an image. By this configuration, problems generated by the thin optical fingerprint input device can be overcome to minimize the loss of information necessary for fingerprint verification and a region of used image sensor can be established in consideration of a design to be capable of obtaining fingerprint information of a high resolution. Furthermore, as a thin optical fingerprint input device can be embodied, the present invention can be applied to a mobile apparatus like a cellular phone, and a conventional secrecy-maintaining function performed by a secret number can be replaced by fingerprint information to thereby increase the secrecy of the mobile apparatus.

Owner:HANSL

Metal polishing solution

The invention discloses metal polishing solution, which comprises the following components in percentage by weight: 15-20% of sodium oleate, 2-5% of citric acid, 5-7% of sodium tripolyphosphate, 3-4% of sodium dodecyl benzene sulfonate, 1-2% of 2-(heptadecene)-4,5-dihydro-1H-imidazole-1-ethanol, 8-10% of quartz sand and the balance of water. According to the metal polishing solution disclosed by the invention, greasy dirt and rust spots on the surface of a metal appliance, such as steel, iron, copper and aluminum can be effectively removed, and metallic luster of the appliance is kept and the appliance is bright as new, and the appliance is prevented from being rusted again for more than one year after cleaning one time.

Owner:深圳市永霖科技有限公司

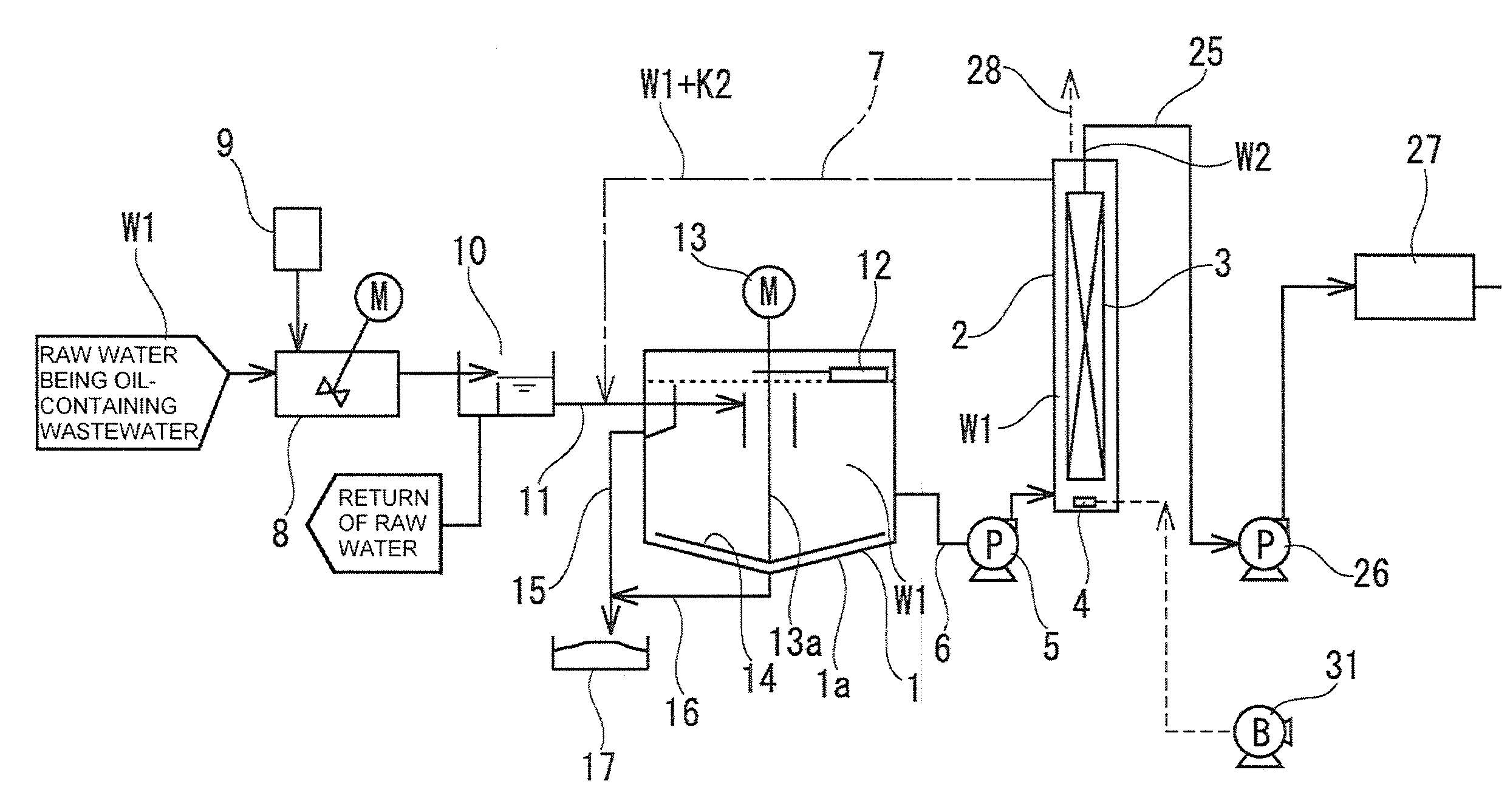

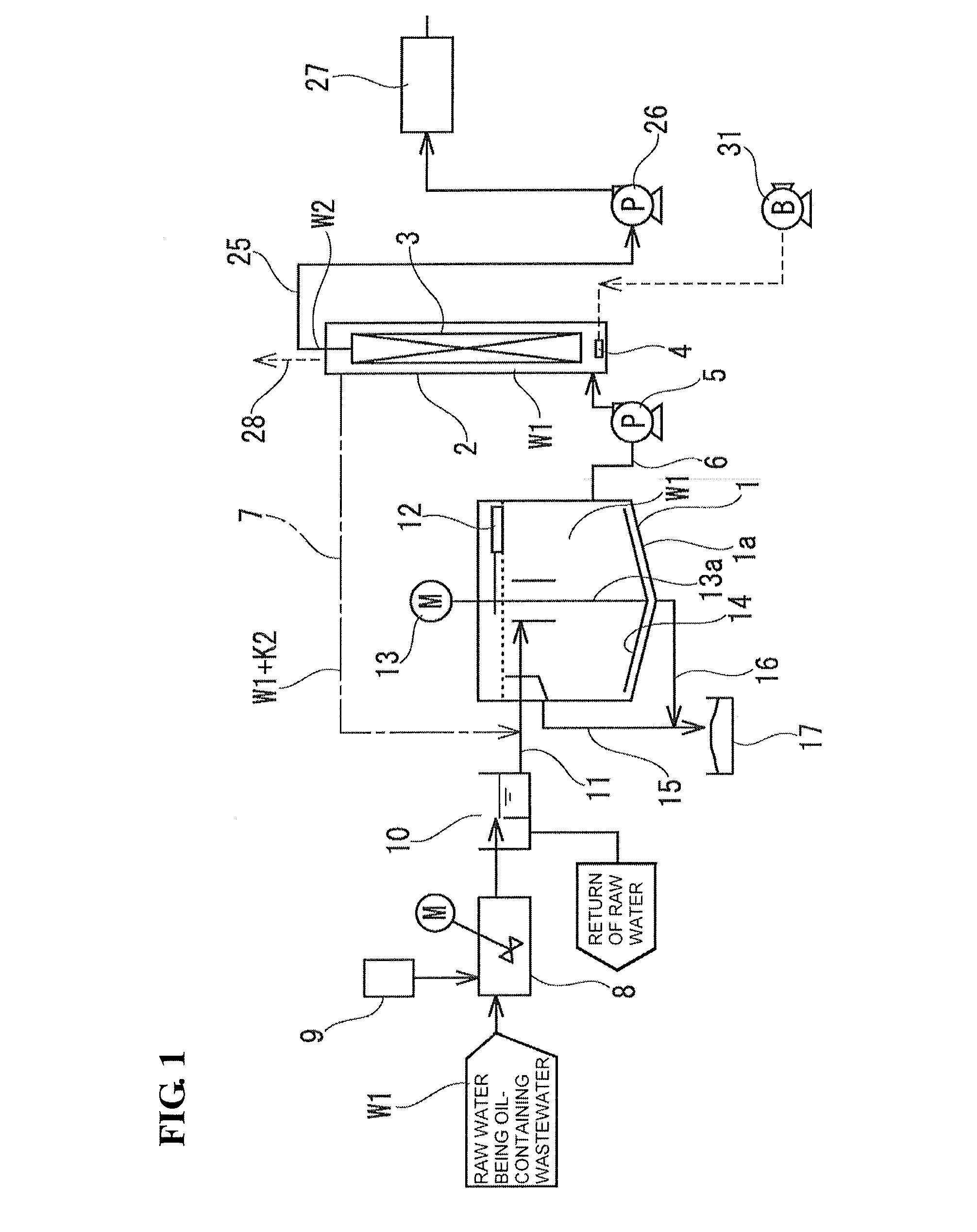

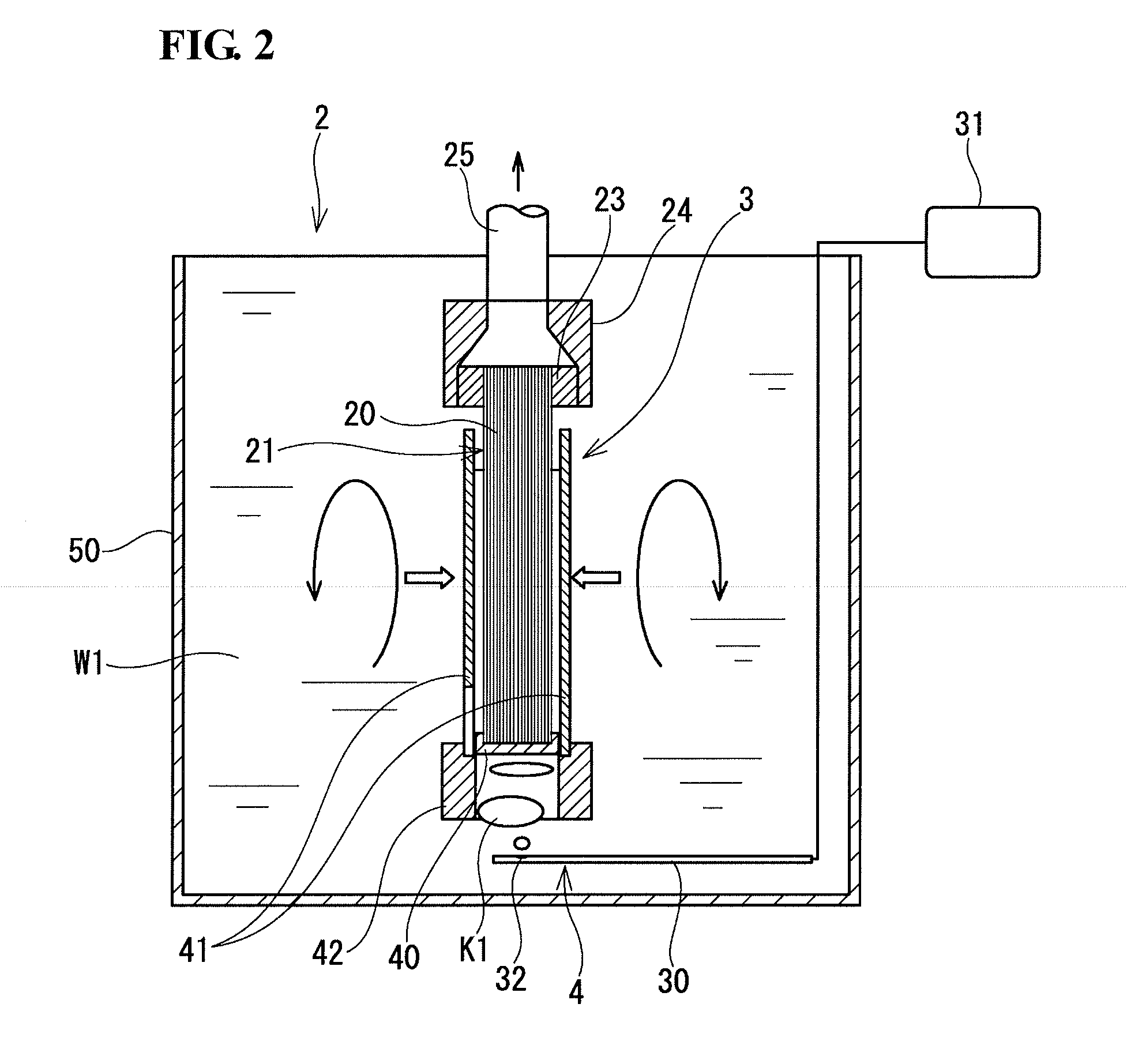

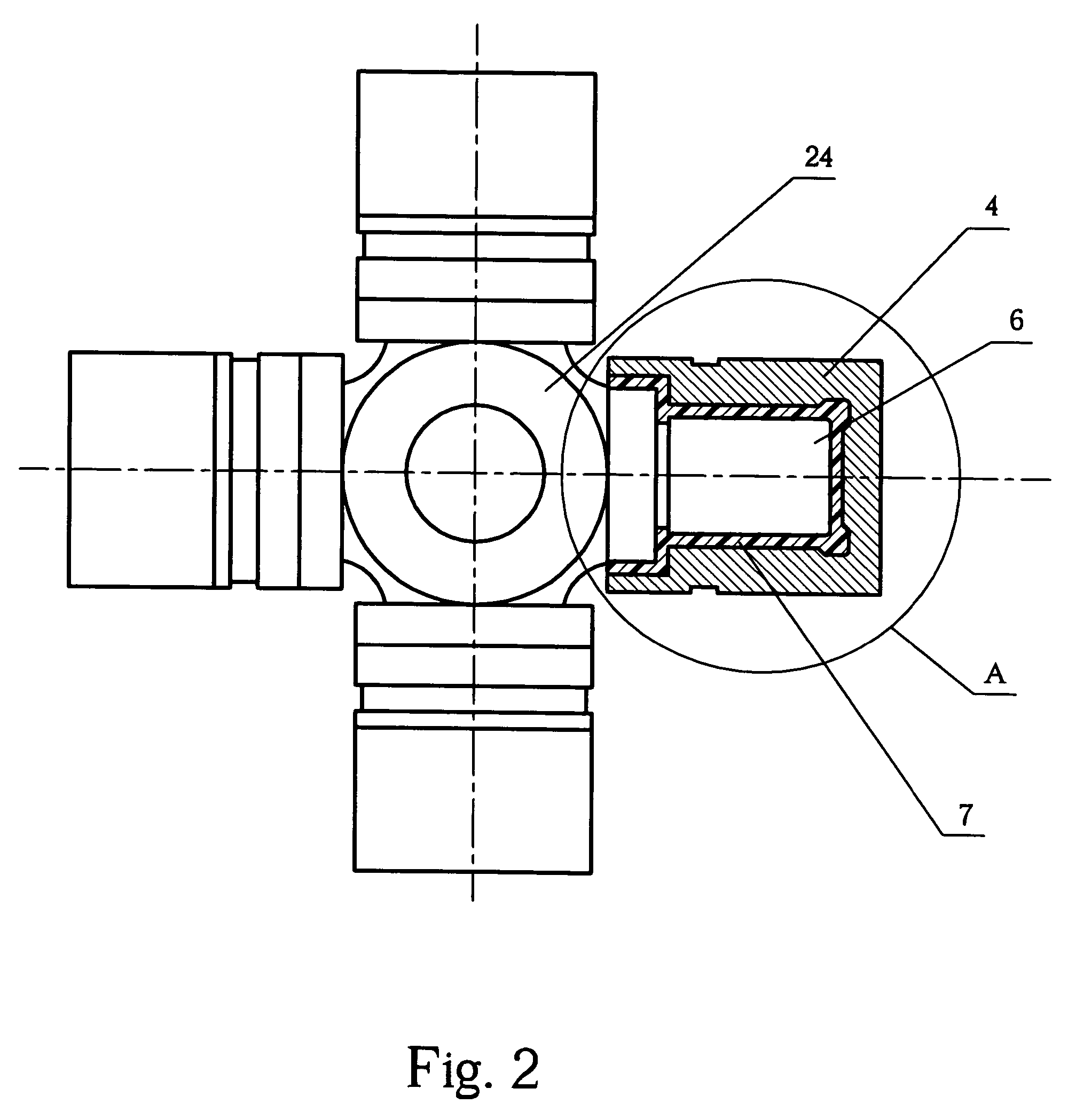

Oil-containing wastewater treatment system

InactiveUS20130264254A1Stable filtration performanceSimplify processMembranesFatty/oily/floating substances removal devicesRaw waterAir bubble

Devices used in an oil-containing wastewater treatment system are simplified by efficiently combining differences in processes used in the system.The oil-containing wastewater treatment system includes a separation tank that separates oil by flotation, the separation tank being arranged in a supply path of raw water which is oil-containing wastewater; a membrane filtration tank that is arranged on the downstream of the separation tank and that includes therein a membrane separation module including a hollow fiber membrane or a flat sheet membrane, and a diffuser for generating air bubbles, the diffuser being disposed below the membrane separation module; a supply pipe that supplies the raw water from the separation tank to the membrane filtration tank through a circulating pump; and a return pipe that returns unfiltered water containing the oil and air bubbles from the membrane filtration tank to the separation tank.

Owner:SUMITOMO ELECTRIC IND LTD

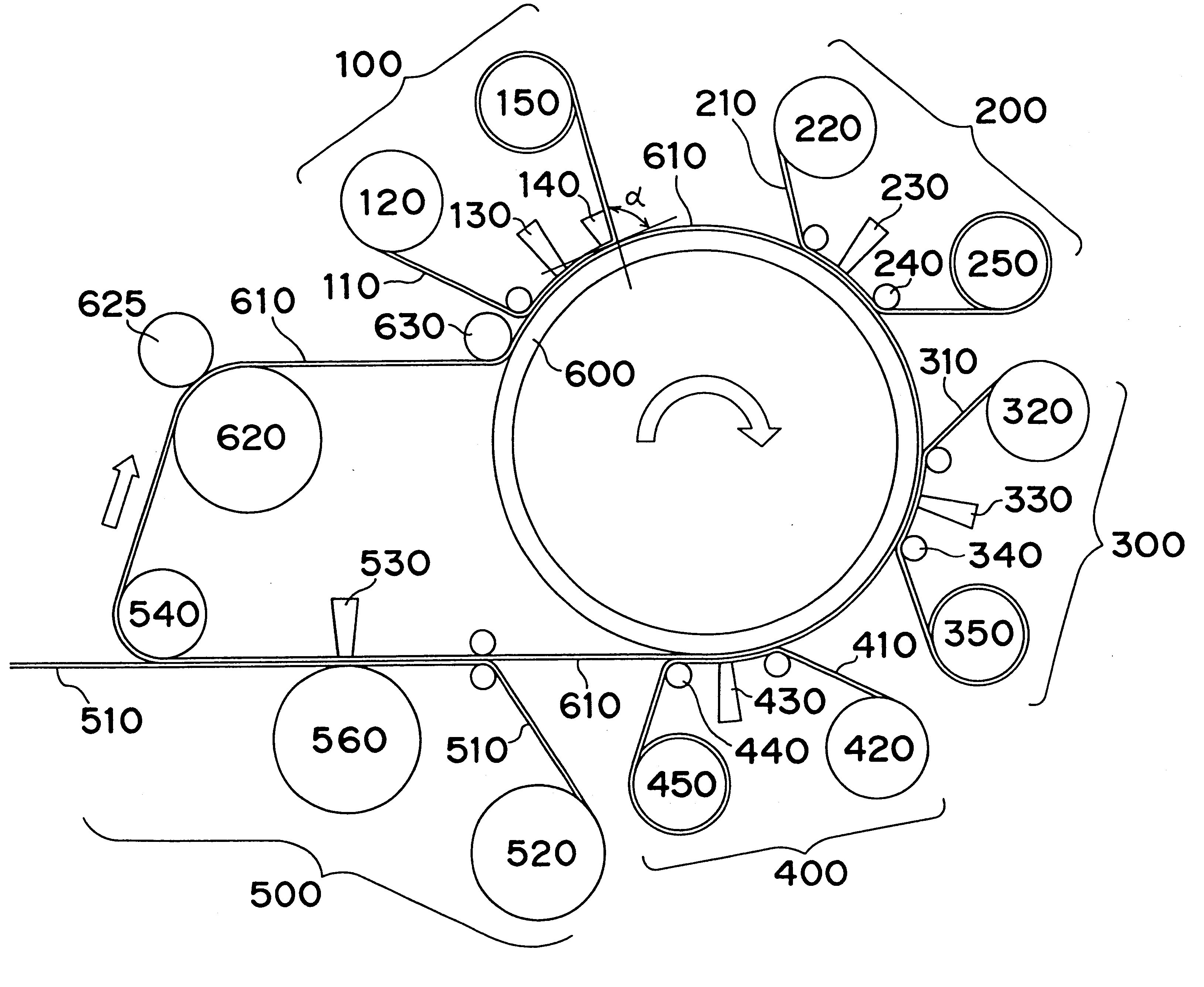

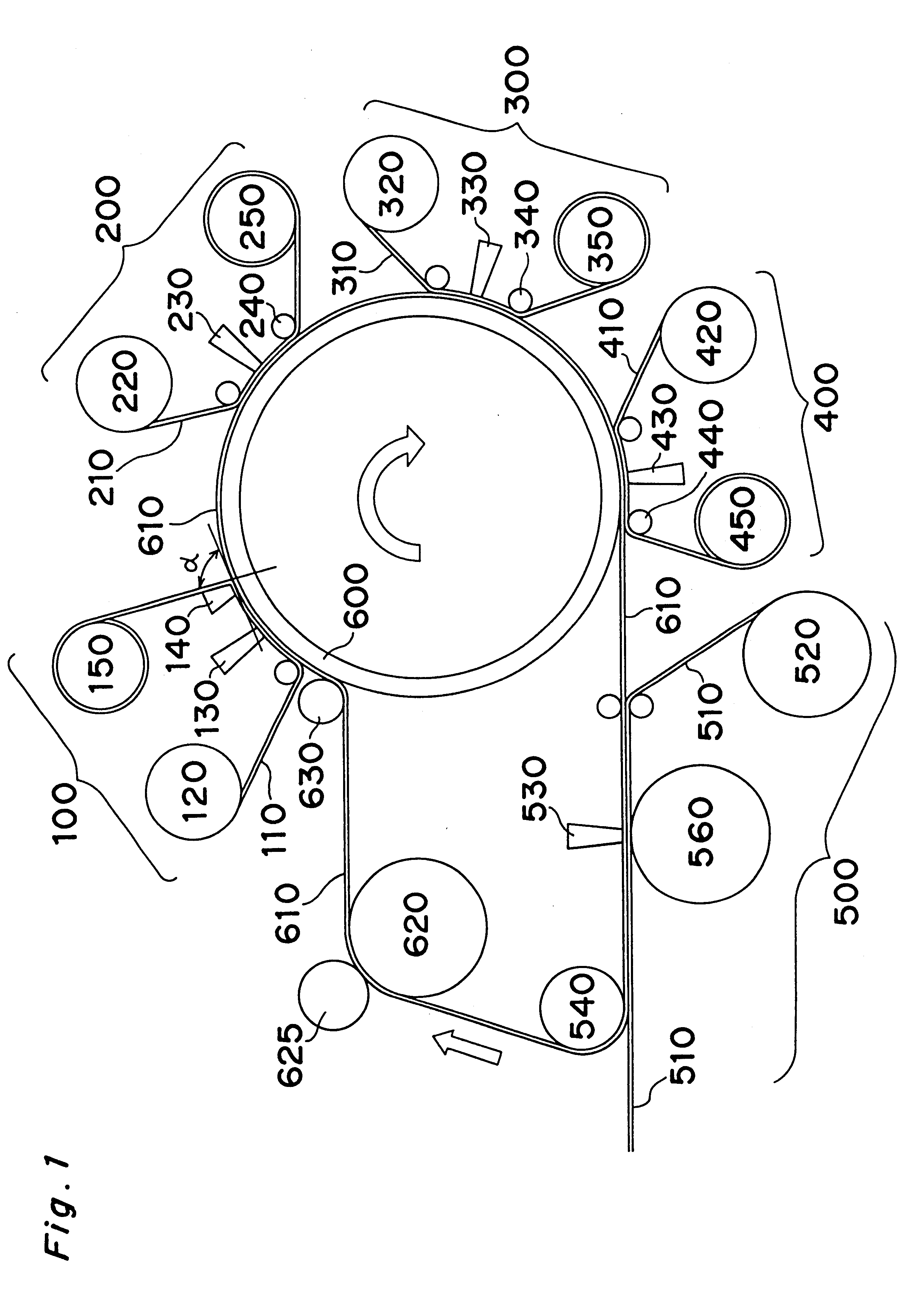

Thermal transfer recording apparatus and thermal transfer recording method using the same

InactiveUS6704037B1Increase speedEasy to controlRecording apparatusInk ribbonsImage transferImage recording

A thermal transfer recording apparatus for recording a glossy and high quality image alleviates or substantially solves at least one of the problems of low recording speed of the image, poor stability of recording, and high running cost of recording. The thermal transfer recording apparatus has an intermediate record support which forms a closed loop and extends over a plurality of drums which are placed separately, and a dye receiving layer transfer section having a dye receiving layer transfer head which faces a part of the intermediate record support on an outer periphery of one drum of the plurality of the drums. The thermal transfer recording apparatus also has an image recording section having at least one image recording head which faces a part of the intermediate record support on an outer periphery of the one drum, and an image transfer section having an image transfer head which faces the intermediate record support inside of the closed loop.

Owner:PANASONIC CORP

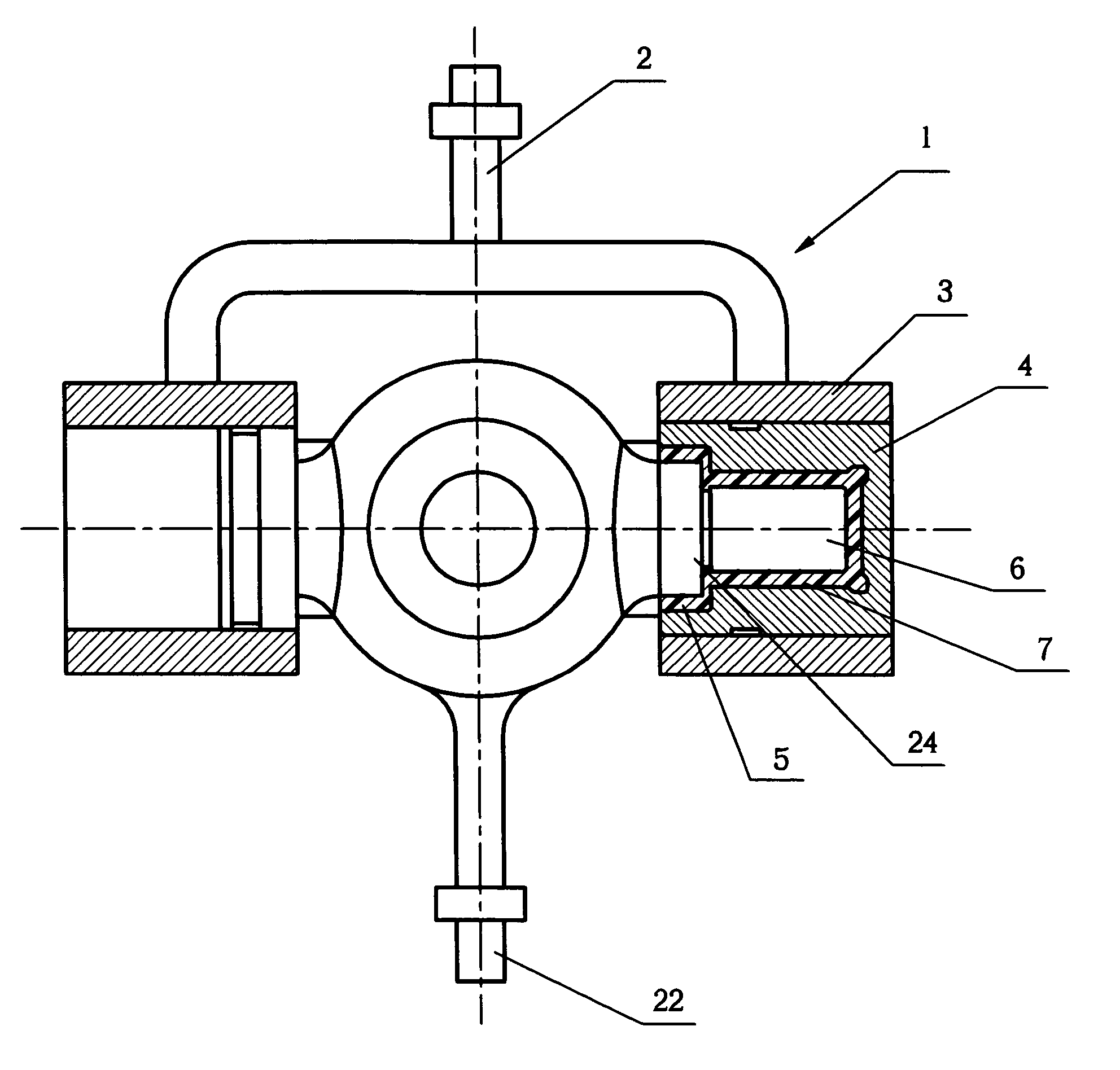

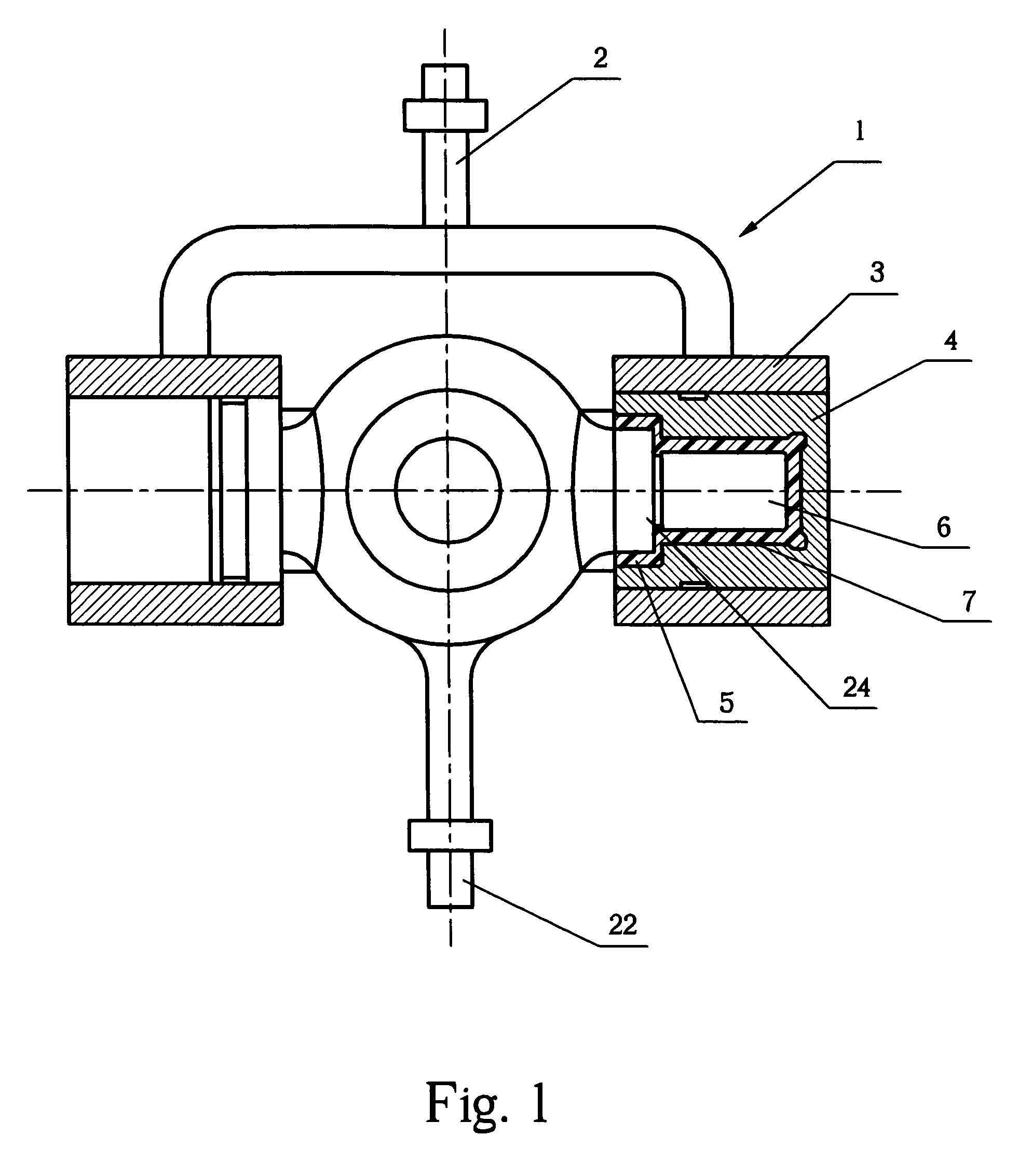

Yoke-trunnion universal joint without needle bearings

InactiveUS20060135269A1Increase production capacitySimple structureClutchesYielding couplingNeedle roller bearingUniversal joint

A yoke-trunnion universal joint has a plastic anti-wear coating disposed between the sleeve and trunnion for lubrication, anti wear and absorbing vibration. A combining means combines the plastic ant-wear coating with sleeve or trunnion tightly. The plastic anti-wear coating is made by nylon or polytetrafluoroethylene. The universal joint has a simple structure, long working life, low operating noise and cheap manufacture cost. The most advantage is that the universal joint needs not oil or grease for whole working life. It is an oil or grease free and maintenance free universal joint.

Owner:WANXIANGQIANCHAO CO LTD

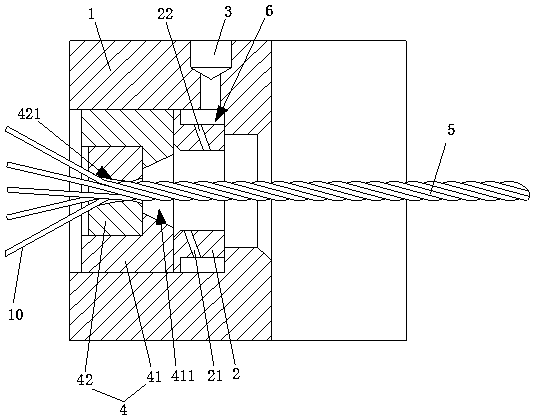

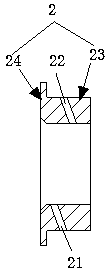

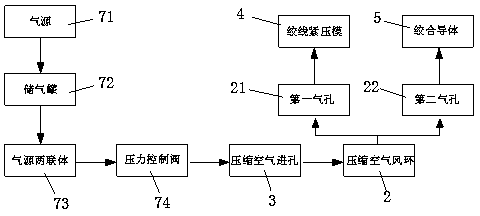

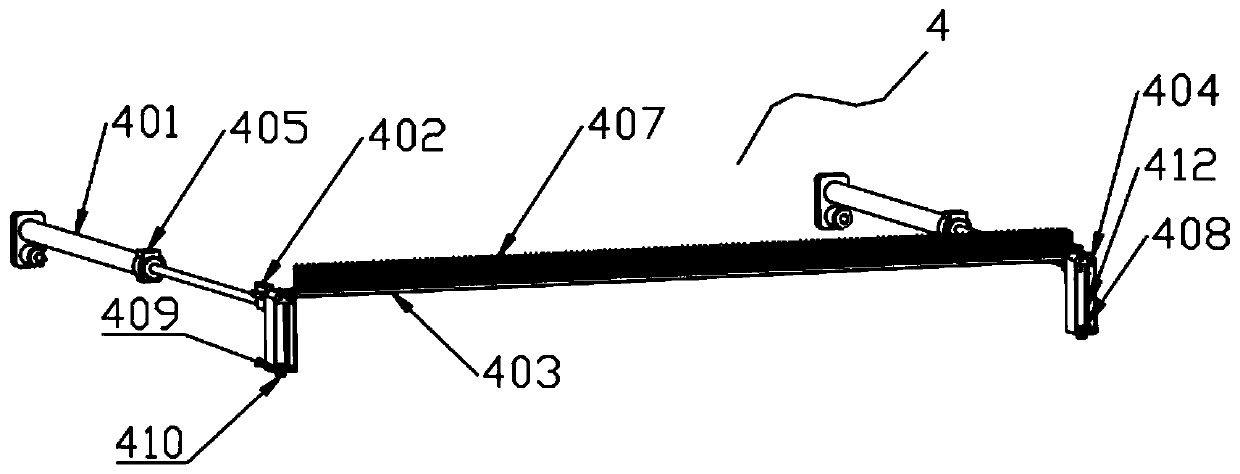

Pressed stranded conductor stranding die for aluminum alloy cable

ActiveCN104269229AIncrease packing densityImprove conductor surface roughnessCable/conductor manufactureElectrical conductorAluminium alloy

The invention relates to a pressed stranded conductor stranding die for an aluminum alloy cable. The die comprises a die base, wherein the die base is internally provided with a pressed stranding die body, a compressed air ring and a compressed air inlet hole, and the pressed stranding die body comprises an outer layer die sleeve and a die core assembled in the die sleeve; a first channel of a pressed stranded conductor stranding wire is formed in the die core; the outlet of the first channel is connected with a second channel formed in the die sleeve; the compressed air ring is arranged on the outlet of the second channel, and a first set of air holes blowing air to the pressed stranding die body and a second set of air holes blowing air to a stranded conductor are formed in the compressed air ring. Due to the technical scheme, the first set of air holes and the second set of air holes in the compressed air ring perform cooling and pressure blowing around the stranded conductor and the pressed stranding die body, and therefore the filling density of the stranded conductor and the surface roughness of the conductor are improved, and meanwhile aluminum skimmings and aluminum powder generated in the spiral stranding pressing process and greasy dirt on the surface of an original alloy single wire are removed.

Owner:安徽省惠尔电气有限公司

Ventilation apparatus and cooking system having the same

ActiveUS9874356B2Improve suction efficiencyOil removalCombination devicesDomestic stoves or rangesSuction forceEngineering

Owner:SAMSUNG ELECTRONICS CO LTD +1

Cleaning device for computer keyboard

ActiveCN111515153ARealize automatic fixed limitEasy to operateCleaning using toolsCleaning using gasesKey pressingEngineering

The invention discloses a cleaning device for a computer keyboard, and relates to the technical field of computer hardware cleaning. The cleaning device comprises a rack, a mounting frame, a positioning mechanism, a longitudinal cleaning mechanism, a transverse cleaning mechanism and a cap cleaning mechanism, wherein the mounting frame is mounted at the upper end of the rack, the mounting frame isof a hollow structure, the lower end of the mounting frame is provided with two symmetrically-arranged laying rails, two symmetrically-arranged mounting cavities are formed in the upper end of the mounting frame, and two corresponding symmetrically-arranged guide plates arranged on the rack in a sliding mode are fixed to the lower end of each laying rail. The cleaning device is convenient to operate, sweat stains and oil stains attached to the surfaces of keys are effectively removed through the arrangement of the longitudinal cleaning mechanism and the inverted arrangement of the keyboard, meanwhile, cleaning liquid and clear water on a towel or wet cloth are prevented from entering the keyboard, through the arrangement of the transverse cleaning mechanism and the cap cleaning mechanism,bidirectional cleaning operation is automatically conducted on the keyboard, the positions where keycaps are removed can be cleaned, and the keycaps can be further cleaned.

Owner:ANQING NORMAL UNIV

Hydrogen-rich facial mask with antioxidant function and using method thereof

InactiveCN110420126ABlock oxidative damageEasy to operateCosmetic preparationsToilet preparationsHydrogenSkin type

The invention discloses a hydrogen-rich facial mask with an antioxidant function and a using method thereof, and belongs to the technical field of cosmetics. The hydrogen-rich facial mask consists ofa soft mask and essence, wherein the soft mask includes hydrogenated coral powder. According to the hydrogen-rich facial mask, the soft mask and the essence can be mixed and stirred to release hydrogen continuously during using, excess free radicals can be effectively removed from skin when the facial mask is applied to the skin, the antioxidant function is played, at the same time the deep cleaning effect can further be achieved, preparation is simple, using is convenient, stimulation is avoided, the experience feeling is good, and the hydrogen-rich facial mask is suitable for people with various skin types.

Owner:盛世荣恩生物科技有限公司

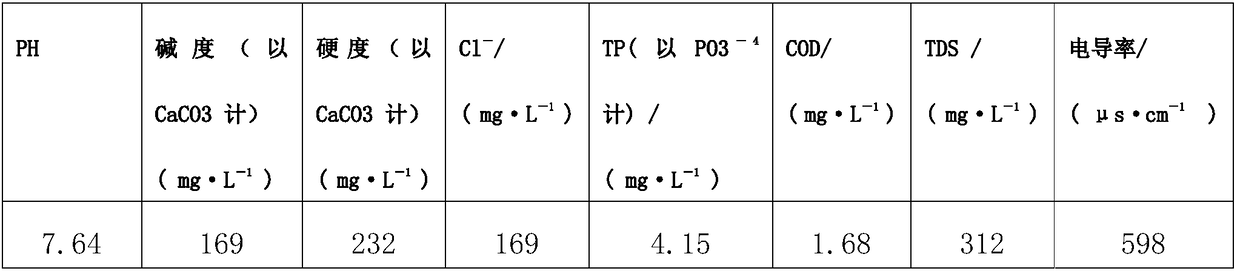

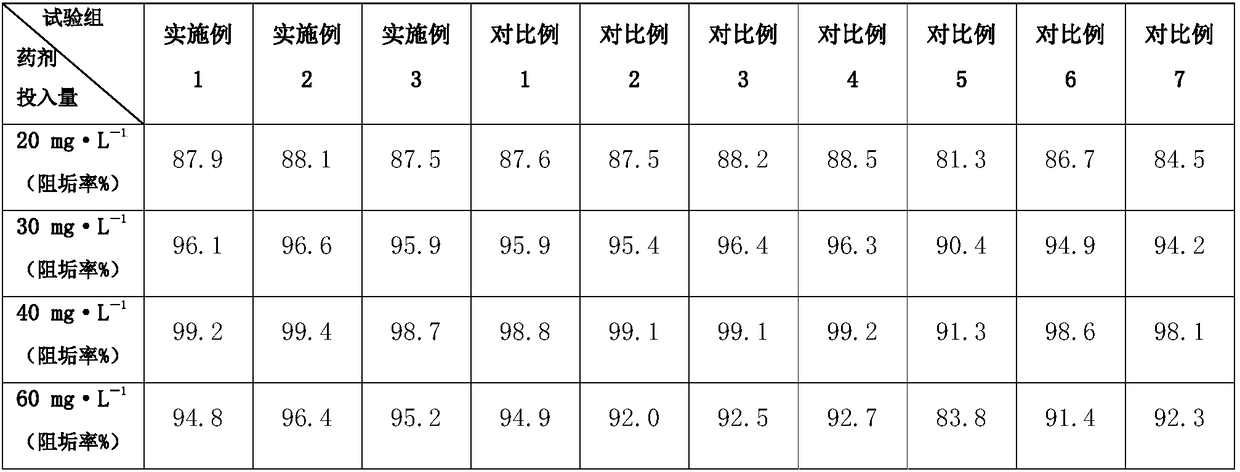

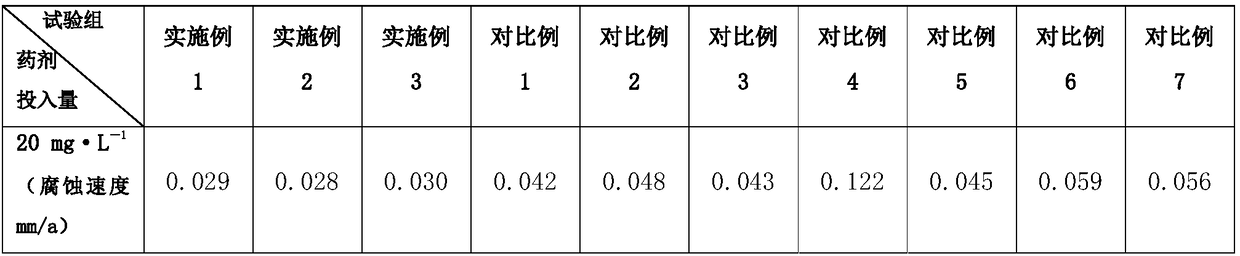

Industrial circulating water treatment agent

ActiveCN109293015AGood solubility and stabilityShorten speedSpecific water treatment objectivesWater softeningChemistrySodium erythorbate

The invention belongs to the technical field of sewage treatment and particularly discloses an industrial circulating water treatment agent. The industrial circulating water treatment agent comprises,by mass, 0.5-2 parts of a surfactant, 20-35 parts of a compound corrosion inhibitor, 12-25 parts of a scale inhibitor, 1-8 parts of a bactericide and 30-60 parts of water. The compound corrosion inhibitor comprises imidazoline, oxalyl hydrazide, sodium erythorbate and a zinc salt. The circulating water treatment agent can be used in the water treatment process to realize better scale inhibition,sustained release and sterilization effects, and does not produce phosphorus pollution.

Owner:CHONGQING CECEP SANFENG ENERGY

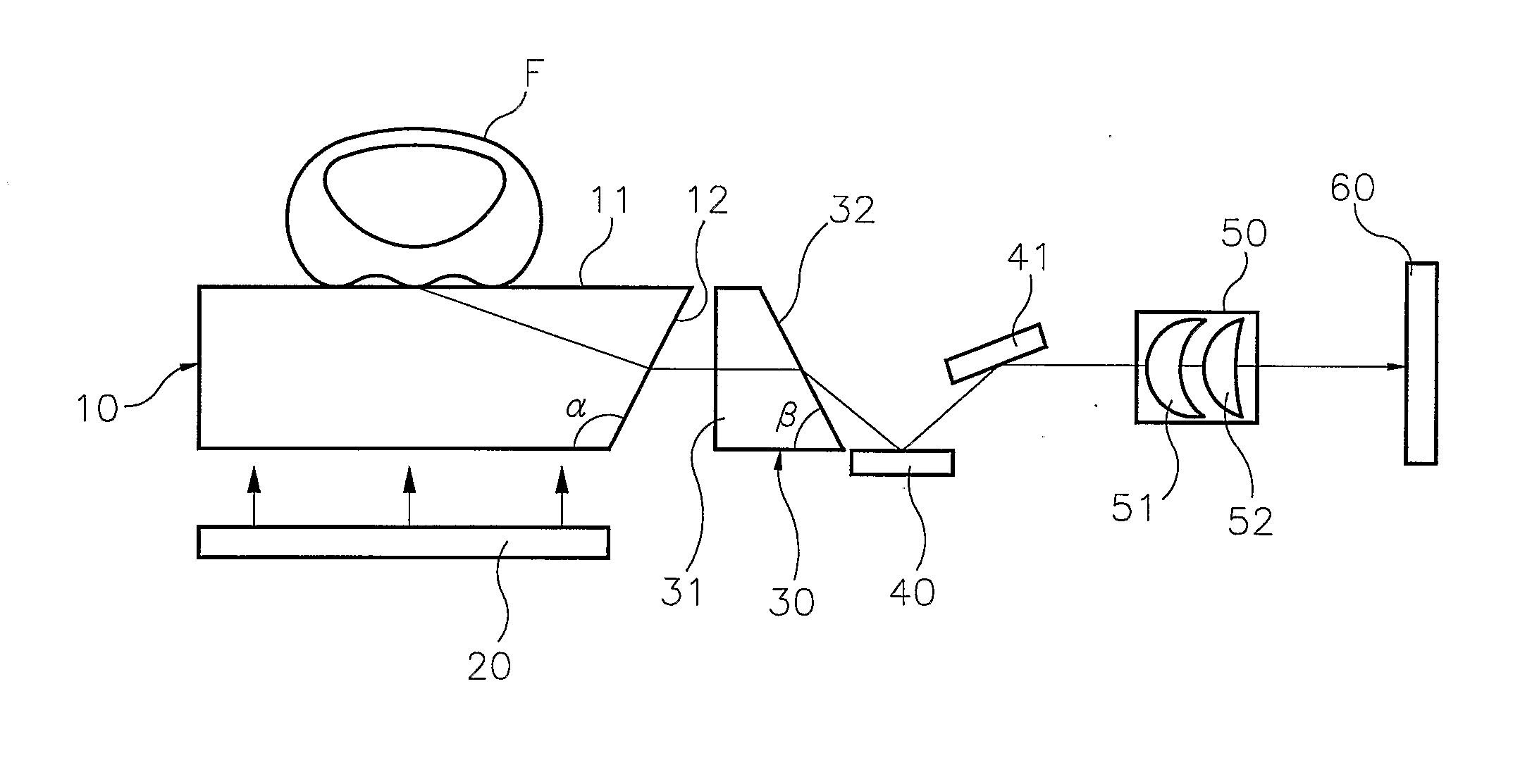

Optical finger print input device for mobile apparatus

InactiveUS7403271B2Oil removalRemoving sweatCharacter and pattern recognitionSecurity arrangementLiquid-crystal displayMobile device

An optical fingerprint image input device for a mobile apparatus includes: a plate-shaped fingerprint contact member; a distortion correcting member for correcting distortions; light sources disposed at both sides of the fingerprint contact member, other than an inclined surface or a back light source in a liquid crystal display element; focusing means disposed at an inclined surface side of the distortion correcting member; and an image sensor. In other words, the fingerprint contact member and the distortion correcting member having respective set-up inclined angles are disposed to discern sweat, water or oil and to correct a trapezoidal distortion which is a disadvantage that occurs when a thin fingerprint contact medium is used, and to form a lens system comprised of a cylindrical lens and a spherical lens for adjustment of a ratio of transversal to longitudinal widths of an image.

Owner:HANSL

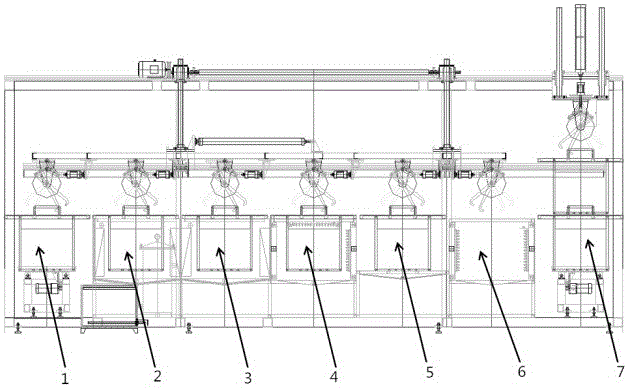

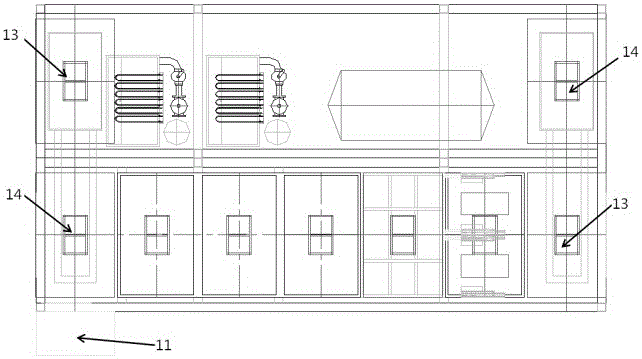

Automatic cleaning line

InactiveCN106216320ADry fastFully automatic production processDrying gas arrangementsCleaning using liquidsMegasonic cleaningMechanical equipment

The invention relates to the field of mechanical equipment, in particular to an automatic cleaning line. The automatic cleaning line comprises a conveying feed inlet, a conveying discharge outlet and a working conveying system, and further comprises an ultrasonic cleaning device, a compressed air water cutting device and a cold-hot air drying and cooling device; the conveying feed inlet, the ultrasonic cleaning device, the compressed air water cutting device, the cold-hot air drying and cooling device and the conveying discharge outlet are sequentially connected through the working conveying system. According to the automatic cleaning line disclosed by the invention, the ultrasonic cleaning device, the compressed air water cutting device and the cold-hot air drying and cooling device are arranged for enabling the cleanliness of automotive parts to meet requirements, and also deep mounting holes can be fast dried after being cleaned; and the full-automatic production process greatly saves time and quickens the production progress.

Owner:GUANGDONG HONGTAI TECH HLDG

Putty composition and method

ActiveUS20070114726A1Reduced staining qualityEasy to optimizeSleeve/socket jointsEngine sealsOligomerMedicine

Generally speaking, in accordance with the invention, a putty is provided that can include many or all of the handling characteristics of a traditional plumber's putty, but with reduced staining qualities. Such putty can facilitate substantially stain free installations. Putties in accordance with the invention can contain combinations of polymers or oligomers, solvents, fillers and optional rubbery materials. A composition according to the invention is preferably sufficiently stain-free to be used on porous stone, such as marble and granite, without damaging the appearance of the stone. This is achieved by eliminating oil completely, or at least substantially, or restricting their ability to cause stains sufficiently. Because compositions of the invention can be made to be free of oils, they can also have the effect of eliminating the greasy feeling to the hands, which can occur when handling traditional putty. Putties in accordance with preferred embodiments of the invention can provide a degree of tackiness for adhesion and gap fill purposes during installation, as well as a degree of abrasiveness so that pressure from the tightening process will not cause the putty to slip. Of these benefits, one particularly important advantage is the lack of staining on most, if not all, surfaces traditionally used to finish kitchens and baths, including porous stones and other porous materials, such as unglazed ceramics.

Owner:HERCULES CHEM

Salted meat and preparation method thereof

InactiveCN107811224AUnique flavorFull of nutritionFood ingredient as taste affecting agentFood ingredient as flavour affecting agentFiberMeat fibers

The invention relates to salted meat and a preparation method thereof and belongs to the technical field of food processing. The salted meat is prepared from the following food raw materials in partsby weight: 1000-1500 parts of fresh meat, 50-100 parts of radish leaves or pumpkin leaves, 3-5 parts of dried orange peel, 1-2 parts of amomum fruits, 5-8 parts of ginger, 0.5-1 part of aniseed, 0.2-0.5 part of fennel, 15-30 parts of table salt, 1-2 parts of vinegar, 50-100 parts of sweet wine liquid, 300-500 parts of oil and 50-150 parts of sugarcane juice. The preparation method comprises the steps: (1) cleaning, (2) boiling in water, (3) frying in oil, (4) pickling, and (5) vacuum packaging. The salted meat provided by the invention is unique in flavor, fat but not greasy, soft and tender in meat fibers, digestible, red in color, salty and sweet in mouthfeel, crisp, soft, delicious, fragrant, delicate, smooth, juicy, chewy and strong in fragrance, the flavor leaves in the mouth and on the lips for a long time after the salted meat is eaten and the salted meat has a lingering aftertaste.

Owner:施俊

Mild cleansing milk

InactiveCN102860931AEffectively remove oilOil removalCosmetic preparationsToilet preparationsCoconut oilGlycerol

The invention relates to a mild cleansing milk which comprises the components based on parts by weight: 13-18 parts of coconut oil hydroxyethyl sulfonate, 9-13 parts of xanthan gum, 8-14 parts of ethylene glycol distearate, 6-9 parts of glycerol, 8-10 parts of propyl paraben, 2-8 parts of glycerol and the balance of water. The mild cleansing milk is capable of thoroughly cleaning the dirt on the face and in pores as well as supplementing the nutrient needed by the skin; and after the face is washed by the mild cleansing milk, the skin is moistened, bright, clean, soft and smooth.

Owner:JIANGSU ZHENGTAI PHARMA CHEM

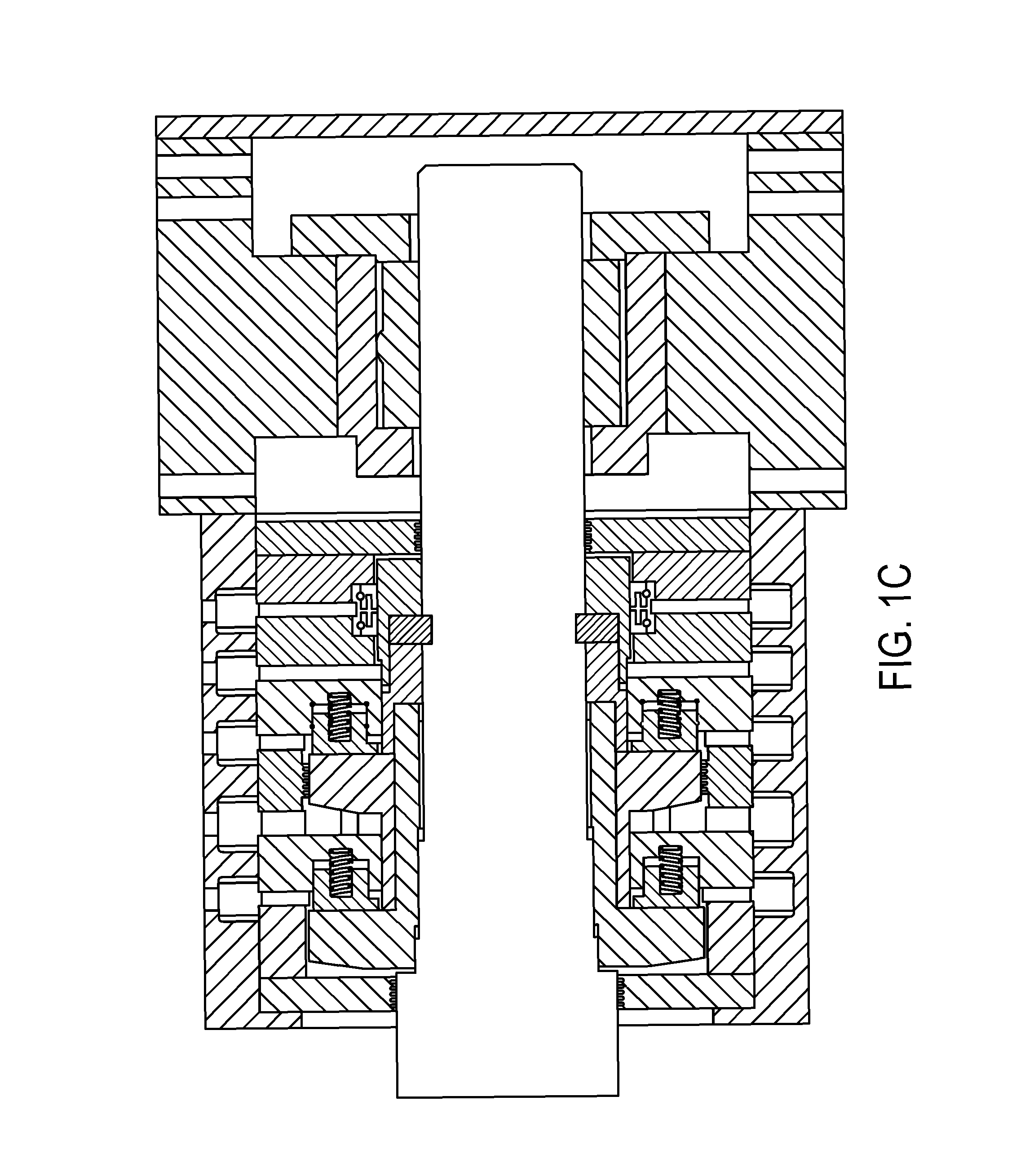

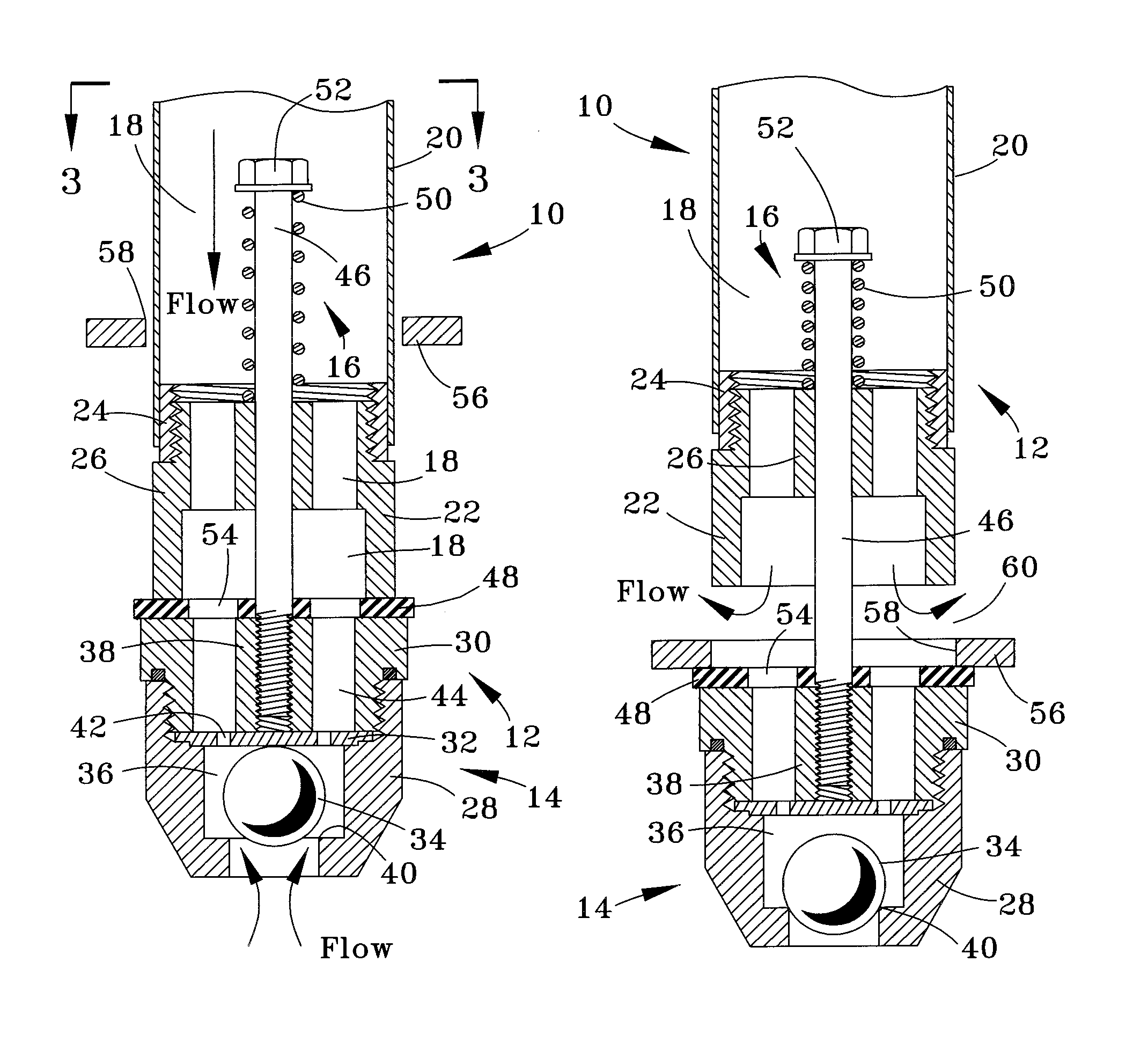

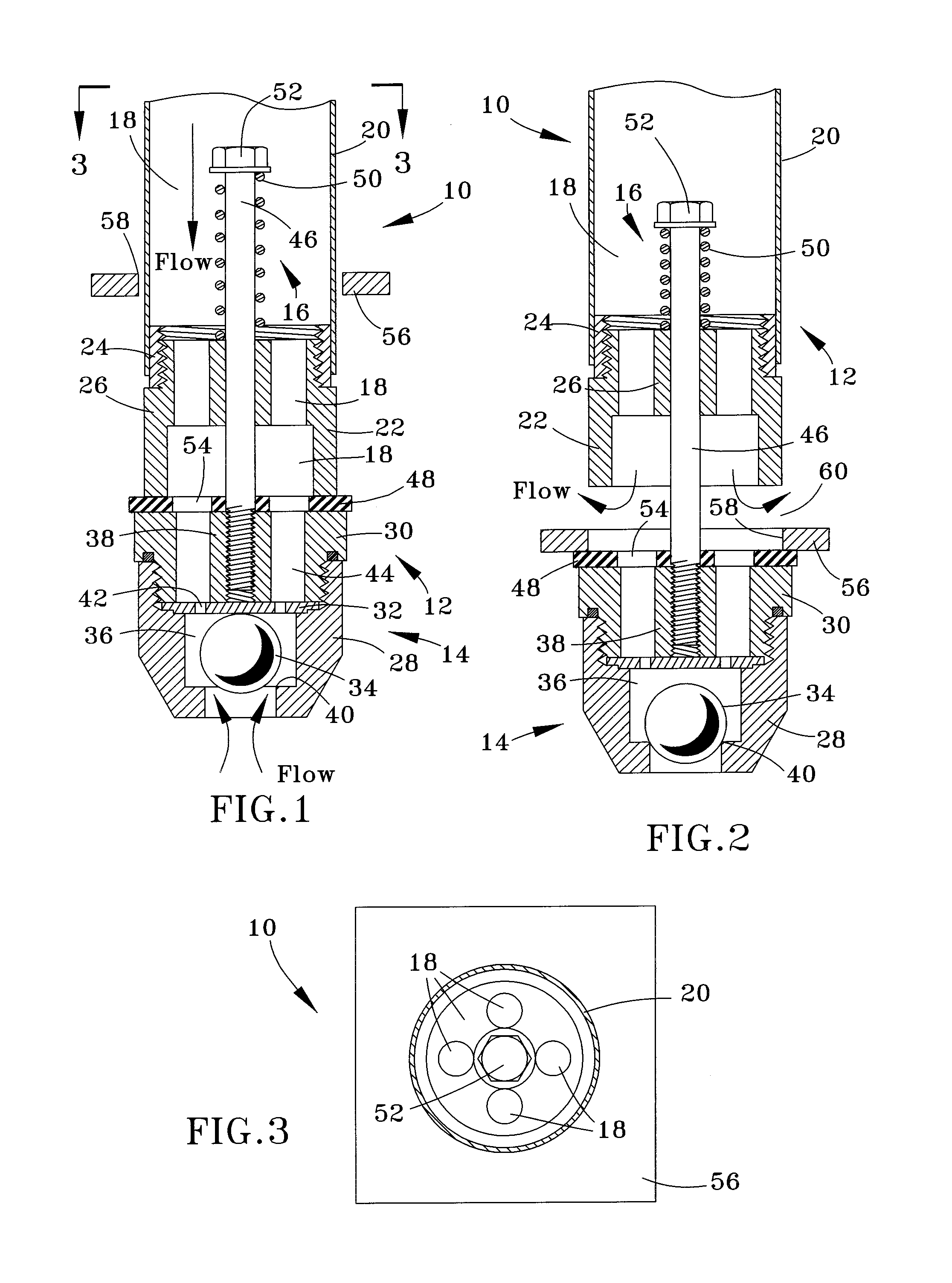

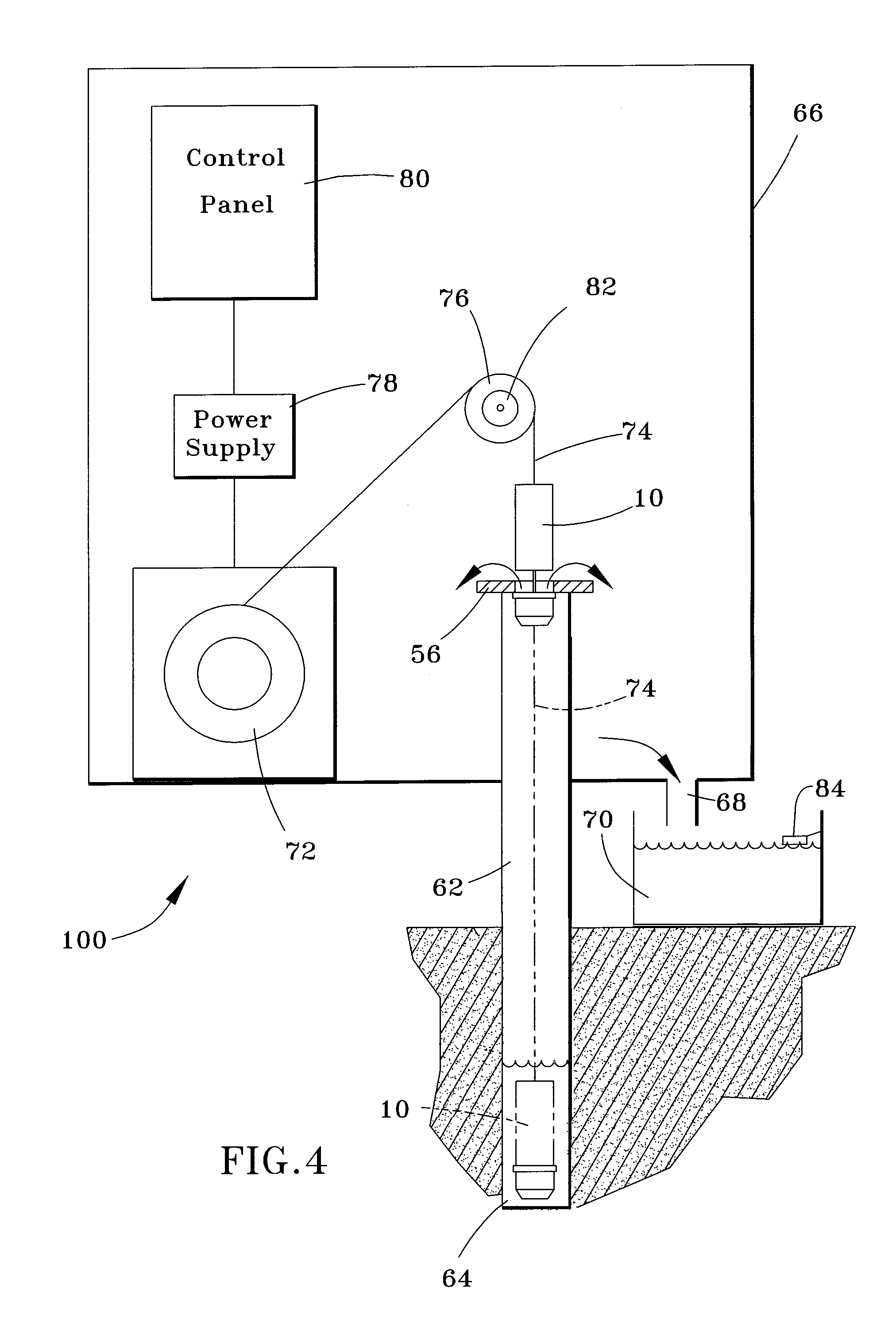

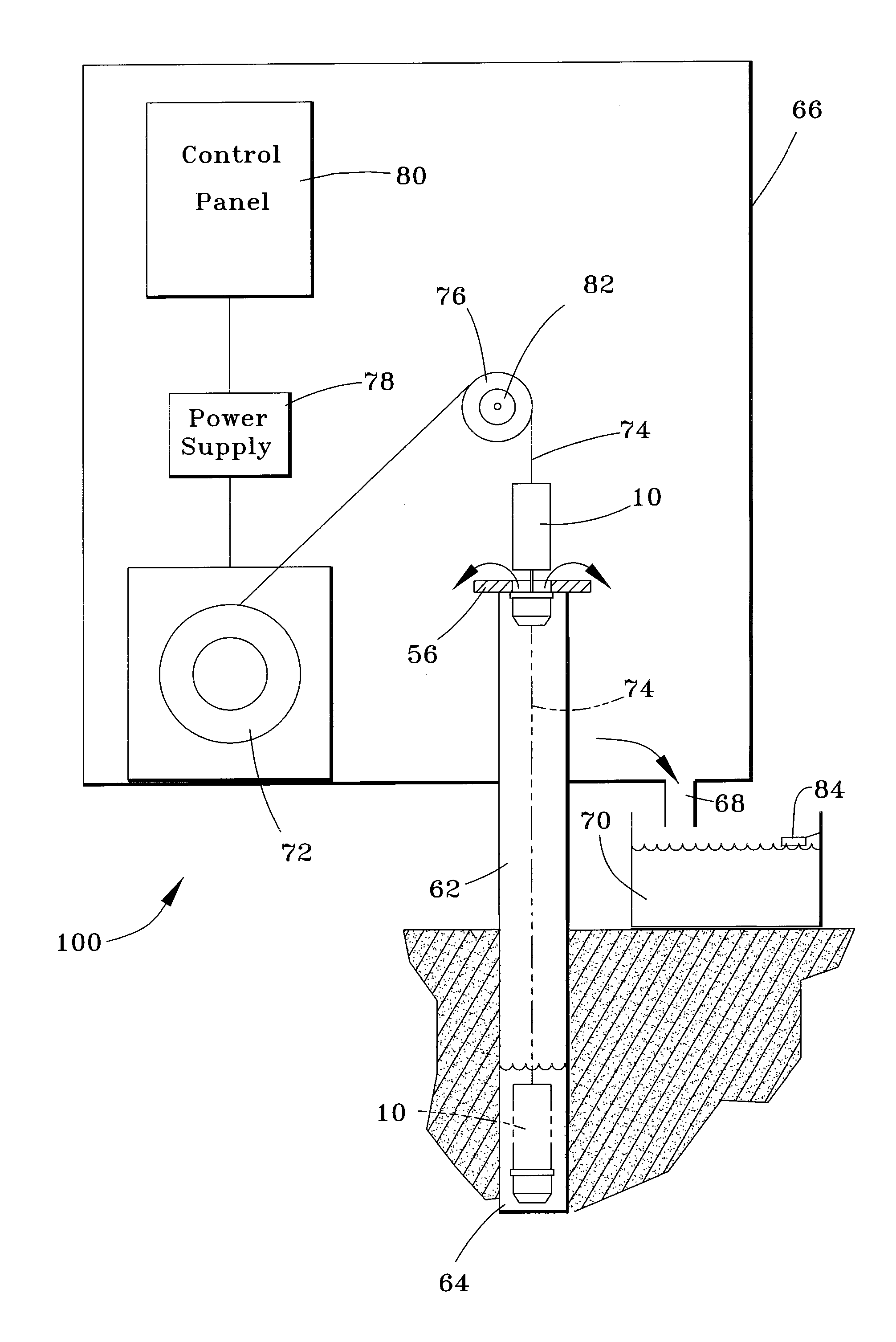

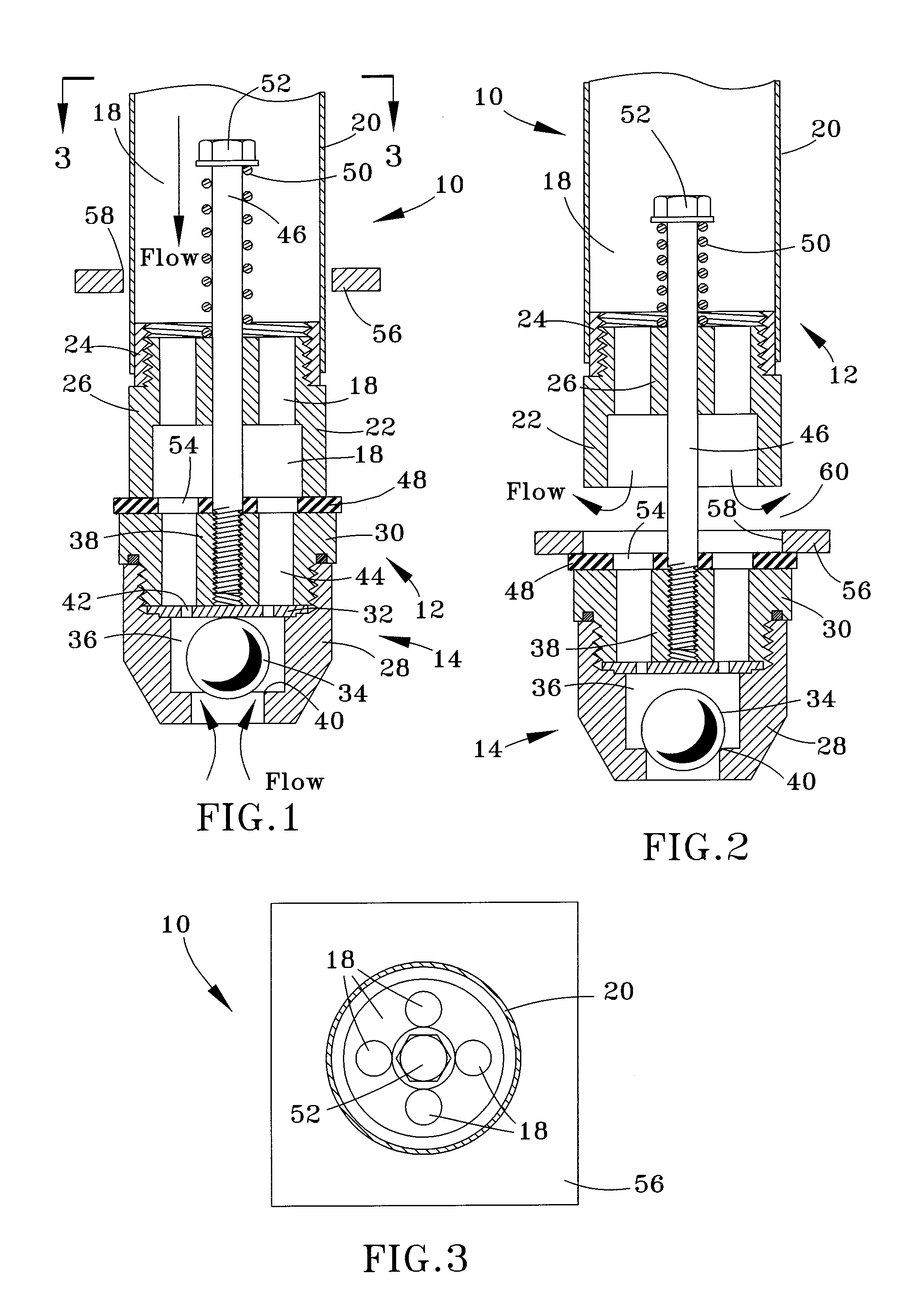

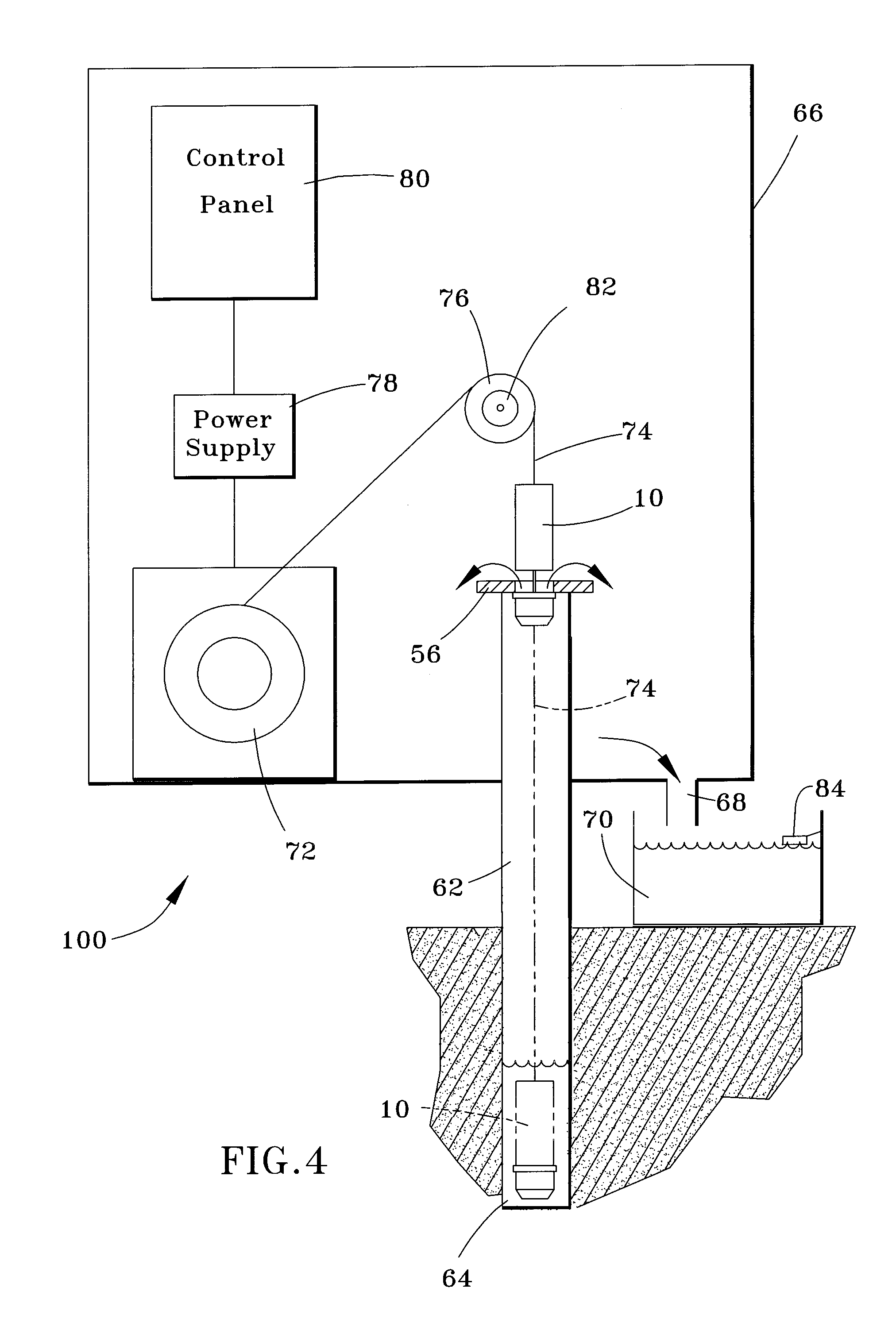

Liquid removal system and method

A method and system capable of economically removing a liquid from a liquid reservoir, such as oil from an oil reservoir, by withdrawing limited quantities of the liquid in discrete steps. The system includes a dipping unit sized to be received in a passage to the reservoir, such as a casing of an oil well, and a unit for lowering and raising the dipping unit within the passage. The dipping unit is configured and oriented to have an upper end portion and a lower end portion when within the passage. The dipping unit includes a chamber, a feature for enabling a liquid to enter the chamber when at least its lower end portion is submerged in the liquid within the reservoir, and a feature for releasing the liquid from the chamber. In use, the dipping unit is lowered within passage to a liquid reservoir to enable liquid to flow into the chamber of the dipping unit when at least a lower end portion of the dipping unit is submerged in the liquid within the reservoir, and then raising the dipping unit within the passage so that the liquid is released from the chamber.

Owner:UNDERWOOD JERRY

Method for extracting theanine from tea leaves

InactiveCN107033020AOil removalRelaxCosmetic preparationsHair cosmeticsChemistryCross-flow filtration

The invention belongs to the technical field of theanine extraction and production, and specifically relates to a method for extracting theanine from tea leaves; including extraction, cross-flow filtration, microfiltration, adsorption, concentration, drying and other steps; the tea leaves provided by the invention The method for extracting theanine in the invention can shorten the process steps, reduce the extraction cost, and have high product yield.

Owner:唐雪平

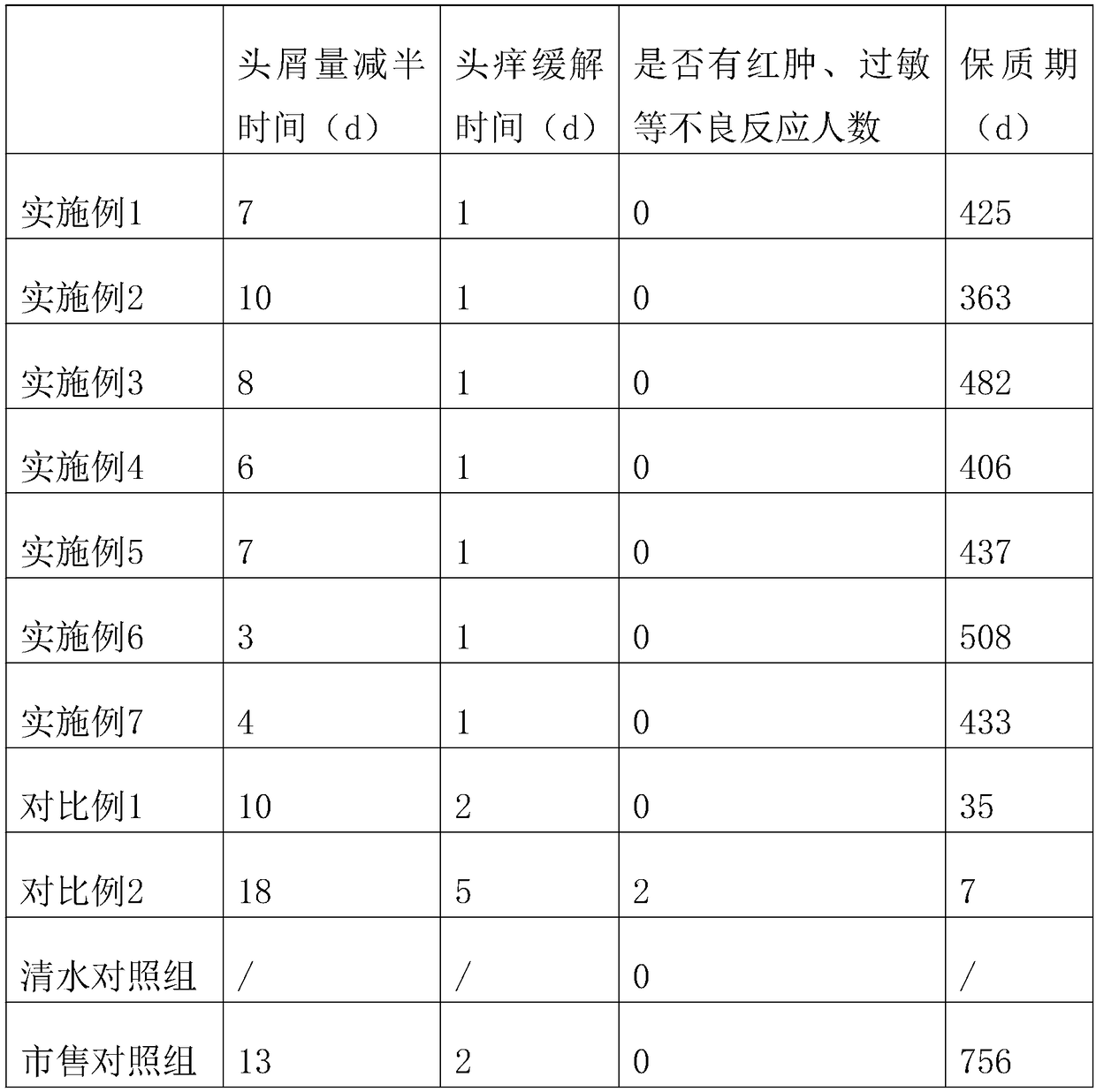

Long-shelf-life traditional Chinese medicinal honeylocust shampoo and preparation method thereof

InactiveCN108888555AGive full play to the antibacterial effectGood antibacterial effectCosmetic preparationsHair cosmeticsAsiatic pennywortHuman health

The invention belongs to the technical field of personal care products and particularly relates to long-shelf-life traditional Chinese medicinal honeylocust shampoo and a preparation method thereof. through reasonable compatibility and treatment, Chinese honeylocust, tea leaf, jasmine fruit, honeysuckle flower, asiatic pennywort herb, uniflower swisscentaury root and myrrh are reasonably blended in terms of property; the effects of the materials are given to full play. The reasonable ratio of the medicinal materials and suitable alcohol concentration enable the antibacterial effect of the shampoo herein to be optimal, the shampoo is ensured, and the long-shelf-life traditional Chinese medicinal honeylocust shampoo is finally attained. The long-shelf-life traditional Chinese medicinal honeylocust shampoo can effectively eliminate hair and scalp sebum stain and restore the clean environment of scalp follicles, thereby arriving at dandruff removal and itching elimination. The long-shelf-life traditional Chinese medicinal honeylocust shampoo made from pure natural traditional Chinese medicines has no chemical ingredients, has no impact on human health and has long shelf life.

Owner:GUIZHOU JIEYIKANG PLANT CHEM IND CO LTD

Oil-dissolving water purification material and preparation method thereof

InactiveCN107215907AHigh surface performanceReduce surface tensionWater/sewage treatment by irradiationWater treatment compoundsWastewaterDissolution

The invention provides an oil-dissolving water purification material and a preparation method thereof. On the basis of the total mass of the oil-dissolving water purification material, the oil-dissolving water purification material is prepared from the following components in percentage by mass: 4-15% of far-infrared ceramic powder, 35-45% of kaolin and 40-51% of a multi-element composite antibacterial material. The preparation method mainly comprises three steps of preparing the materials, performing pressing molding and performing firing. Water purified by using the oil-dissolving water purification material provided by the invention has an oil stain dissolution property, and oil stains can be removed to a certain extent; the water purified by using the material is harmless to human bodies and can be directly drunk and used in daily life; and the oil-dissolving water purification material is simple in preparation process, green and environmental-friendly in purification process and free of wastewater.

Owner:李明 +2

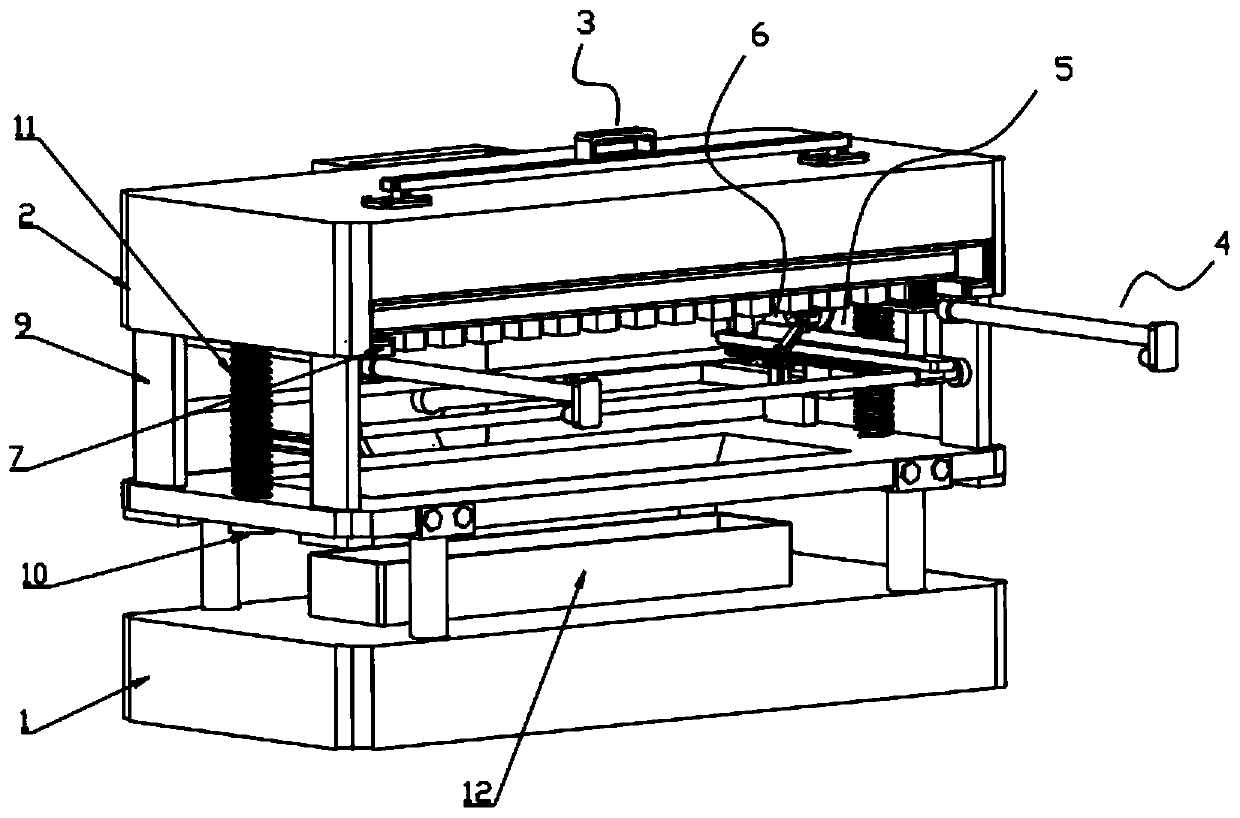

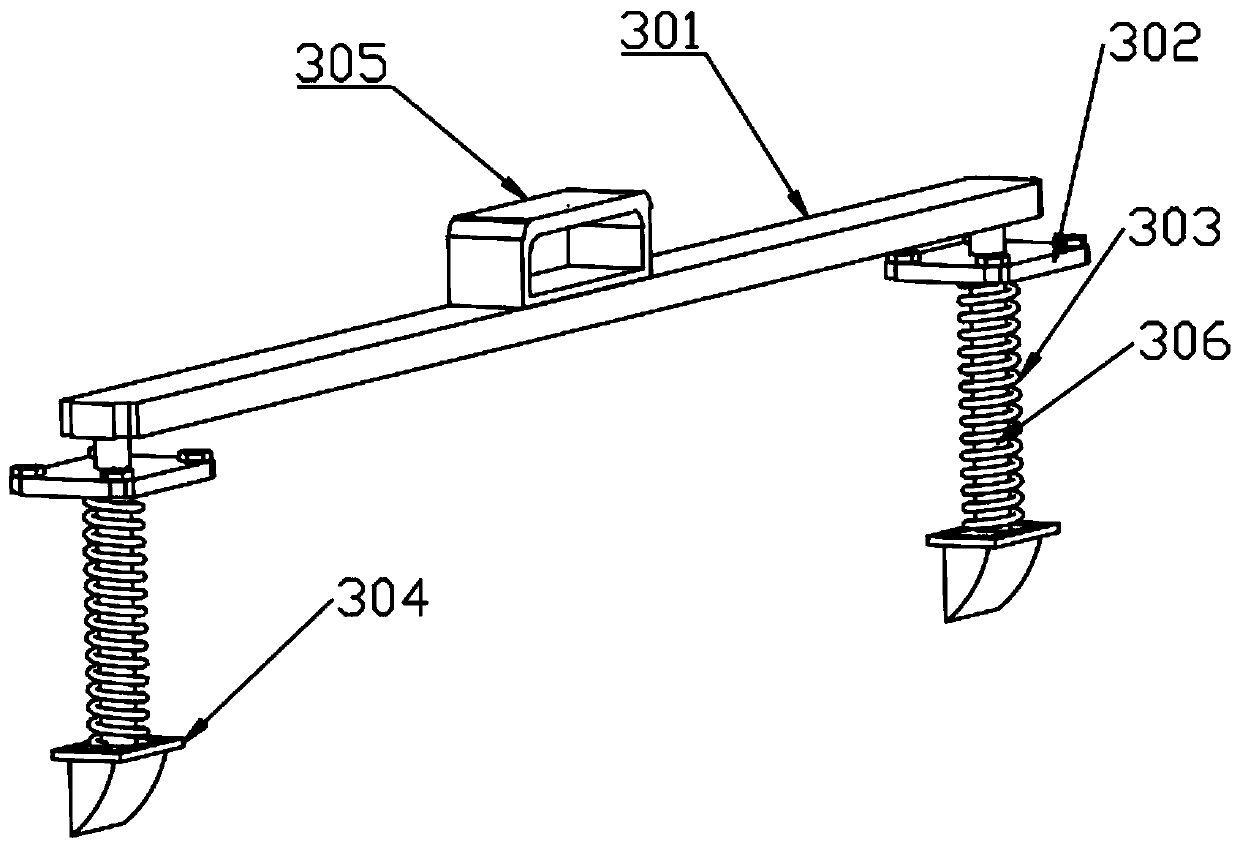

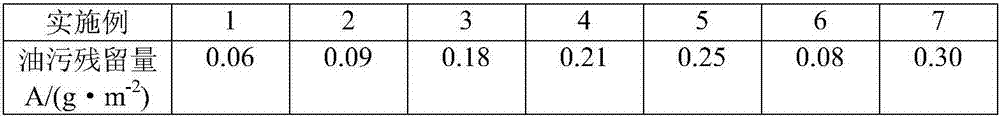

Integrated cooker and control method

PendingCN114234253AImprove decontamination abilityOil removalDomestic stoves or rangesLighting and heating apparatusProcess engineeringCooker

The invention discloses an integrated stove and a control method, the integrated stove comprises a machine body and a self-cleaning assembly, the upper end of the machine body is provided with a smoke exhaust assembly, an air duct is formed in the smoke exhaust assembly, and one side of the smoke exhaust assembly is provided with a smoke suction port communicated with the air duct; the self-cleaning assembly comprises a storage box, a delivery pump, a heater and a nozzle, the storage box is connected to the machine body, the inlet end of the delivery pump is connected with the storage box, and the outlet end of the delivery pump is connected with the heater which is connected with the nozzle through a pipeline. Wherein the air duct is provided with two opposite side walls, the two side walls are located on the two sides of the smoke suction opening, each side wall is provided with at least one spray head, and the spray heads on the two side walls are oppositely arranged. The nozzles on the two side walls of the air duct are oppositely arranged, the cleaning requirements of large long slits and large planes can be met in a hedging spraying mode, water and detergent are added into the storage box, steam or hot water is prepared, the physical cleaning effect and the chemical cleaning effect are achieved at the same time, and oil stains can be effectively removed.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG +1

Liquid removal system and method

A method and system capable of economically removing a liquid from a liquid reservoir, such as oil from an oil reservoir, by withdrawing limited quantities of the liquid in discrete steps. The system includes a dipping unit sized to be received in a passage to the reservoir, such as a casing of an oil well, and a unit for lowering and raising the dipping unit within the passage. The dipping unit is configured and oriented to have an upper end portion and a lower end portion when within the passage. The dipping unit includes a chamber, a feature for enabling a liquid to enter the chamber when at least its lower end portion is submerged in the liquid within the reservoir, and a feature for releasing the liquid from the chamber. In use, the dipping unit is lowered within passage to a liquid reservoir to enable liquid to flow into the chamber of the dipping unit when at least a lower end portion of the dipping unit is submerged in the liquid within the reservoir, and then raising the dipping unit within the passage so that the liquid is released from the chamber.

Owner:UNDERWOOD JERRY

Production process of high-strength rivet nuts

The invention provides a production process of high-strength rivet nuts, belongs to the technical field of rivet nut machining, and solves the technical problem that the strength of existing rivet nuts cannot be improved. The production process of the high-strength rivet nuts comprises the following steps that (1), raw material spheroidizing annealing is conducted, specifically, raw materials are selected and spheroidizing annealing treatment is carried out on the raw materials; (2), upsetting forming is conducted, specifically, the raw materials subjected to spheroidizing annealing are subjected to cold upsetting to form a blank; (3), oil is removed; (4), zone annealing is conducted, specifically, zone annealing is carried out on a designated position of the blank subjected to oil removal; (5), acid pickling is conducted, specifically, acid pickling is carried out on the blank obtained after zone annealing through an acid pickling solution; (6), tapping is conducted, specifically, tapping and tapping are carried out on the interior of the blank through a part machine to form rivet nuts; (7), surface treatment is conducted, specifically, treatment is carried out on the surfaces of the rivet nuts; (8), screening is conducted, specifically, testing is carried out on the rivet nuts, and the rivet nuts with qualified strength are screened out; and (9), packaging is carried out. The production process of the high-strength rivet nuts has the advantages that the overall strength of the rivet nuts is improved, and the production efficiency is high.

Owner:浙江坤厚汽车零部件股份有限公司

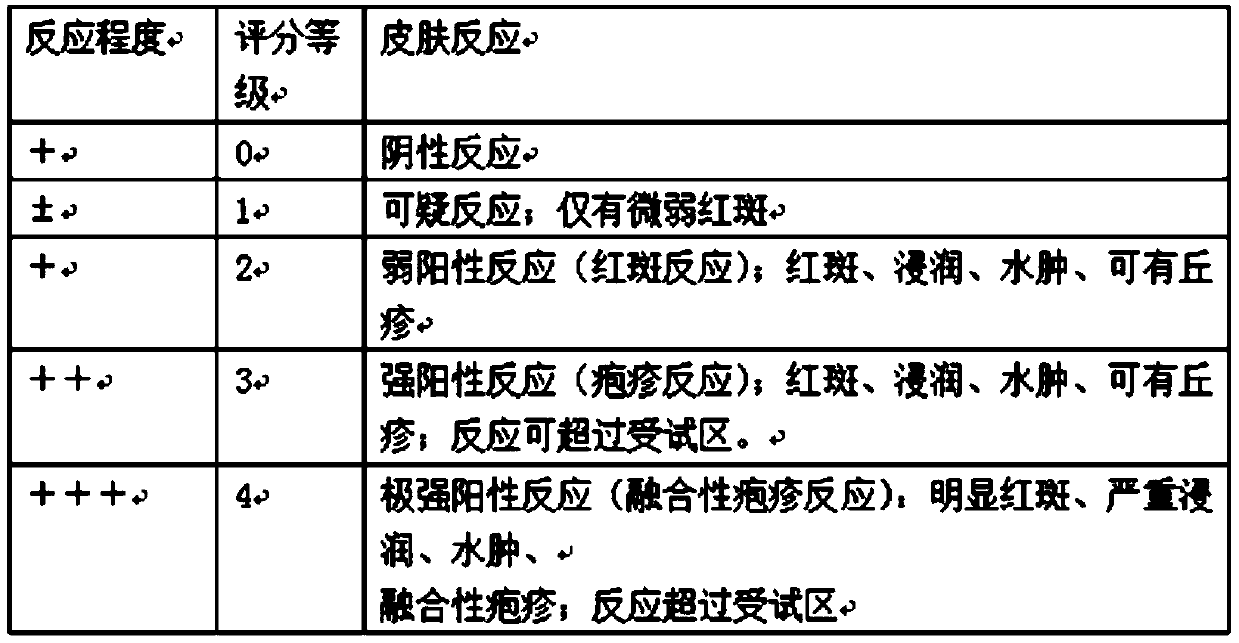

Exfoliating facial cleanser

InactiveCN108056954APrevent agingOil removalCosmetic preparationsToilet preparationsIrritationLanolin

The invention discloses an exfoliating facial cleanser. The exfoliating facial cleanser comprises, by mass, 3-5 parts of isopropyl palmitate, 5-7 parts of multivitamins, 1-3 parts of decyl glucoside,2-3 parts of xanthan gums, 3-7 parts of dried orange peel powder, 2-4 parts of Herba Leonuri powder, 3-5 parts of jasmine flowers, 6-8 parts of isopropyl palmitate, 4-7 parts of cocamidopropyl betaine, 2-4 parts of lanolin, 1-3 parts of butanediol, 5-8 parts of towel gourd extract, 7-10 parts of activated carbon and 30-34 parts of distilled water. The exfoliating facial cleanser has the advantagesof thoroughness in exfoliation, no residual, mildness and no irritation, can moisturize and balance grease without tightness, also has whitening, skin caring, pore shrinking and skin aging preventingeffects, and can effectively remove skin oil stains.

Owner:宋德强

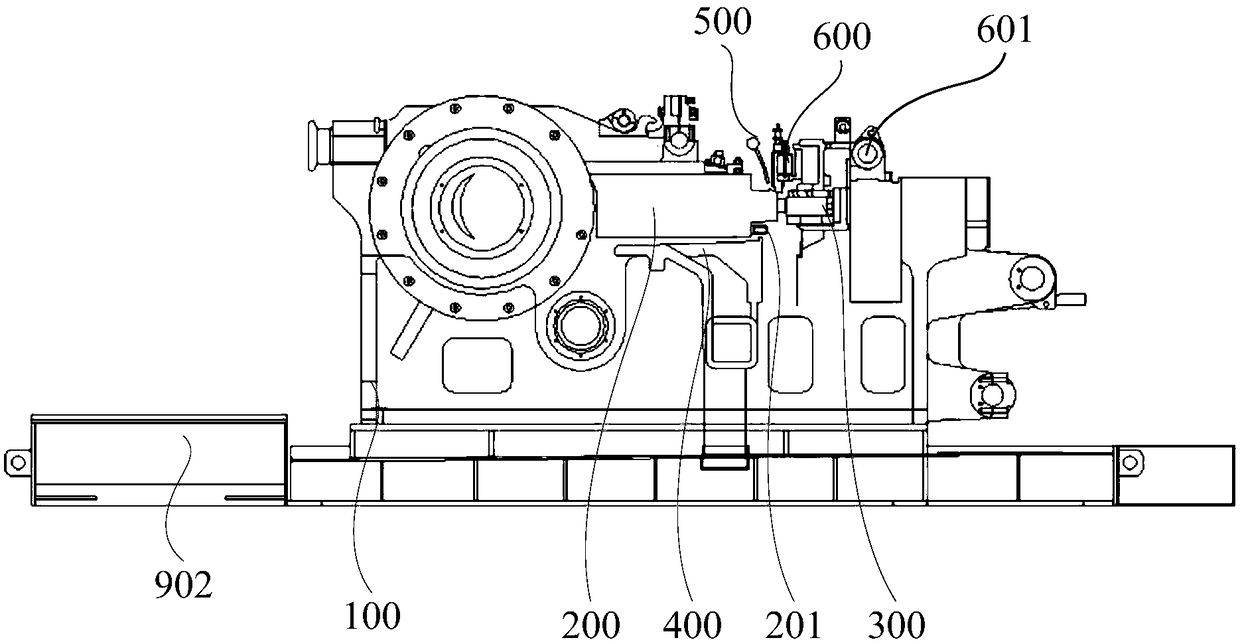

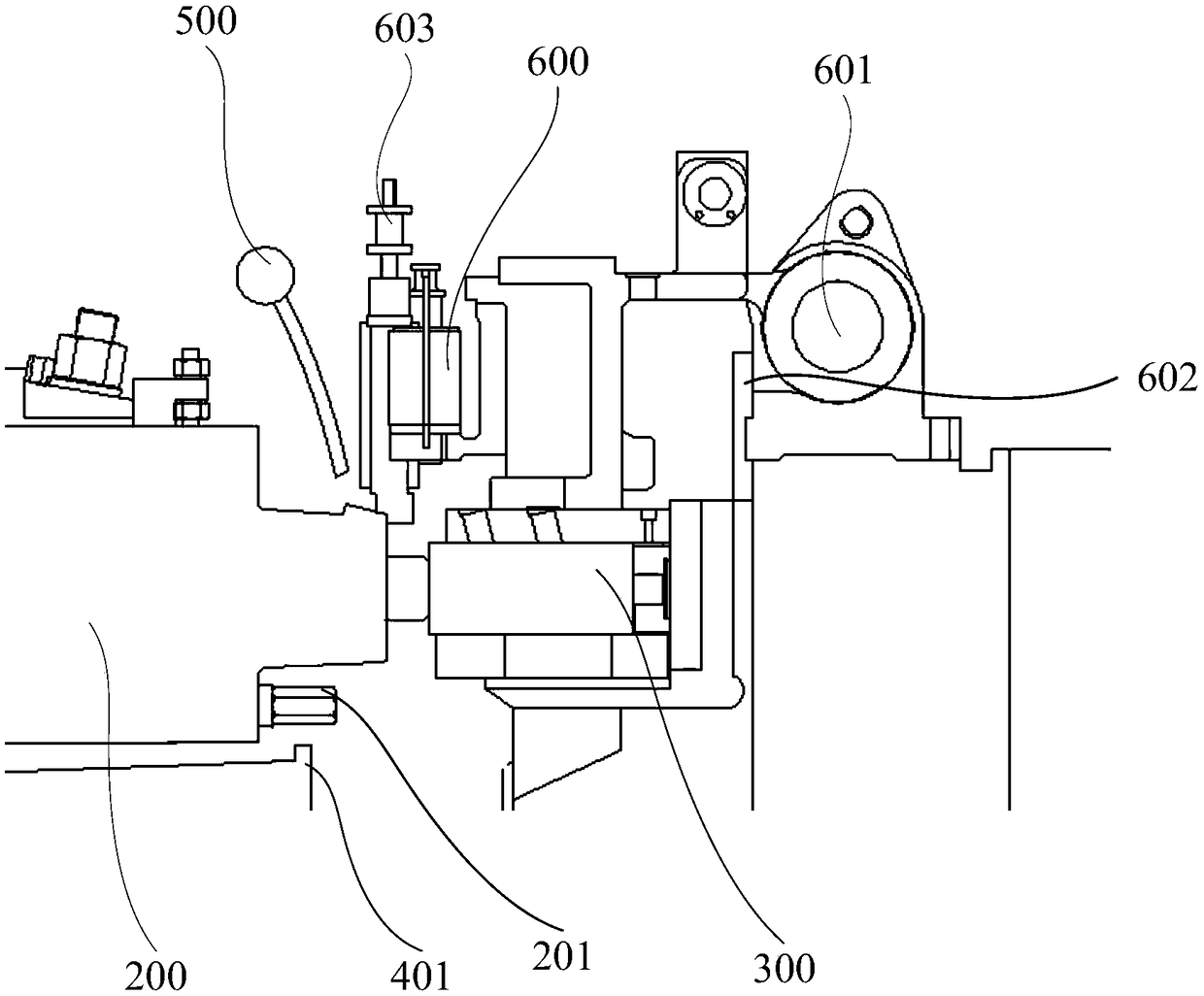

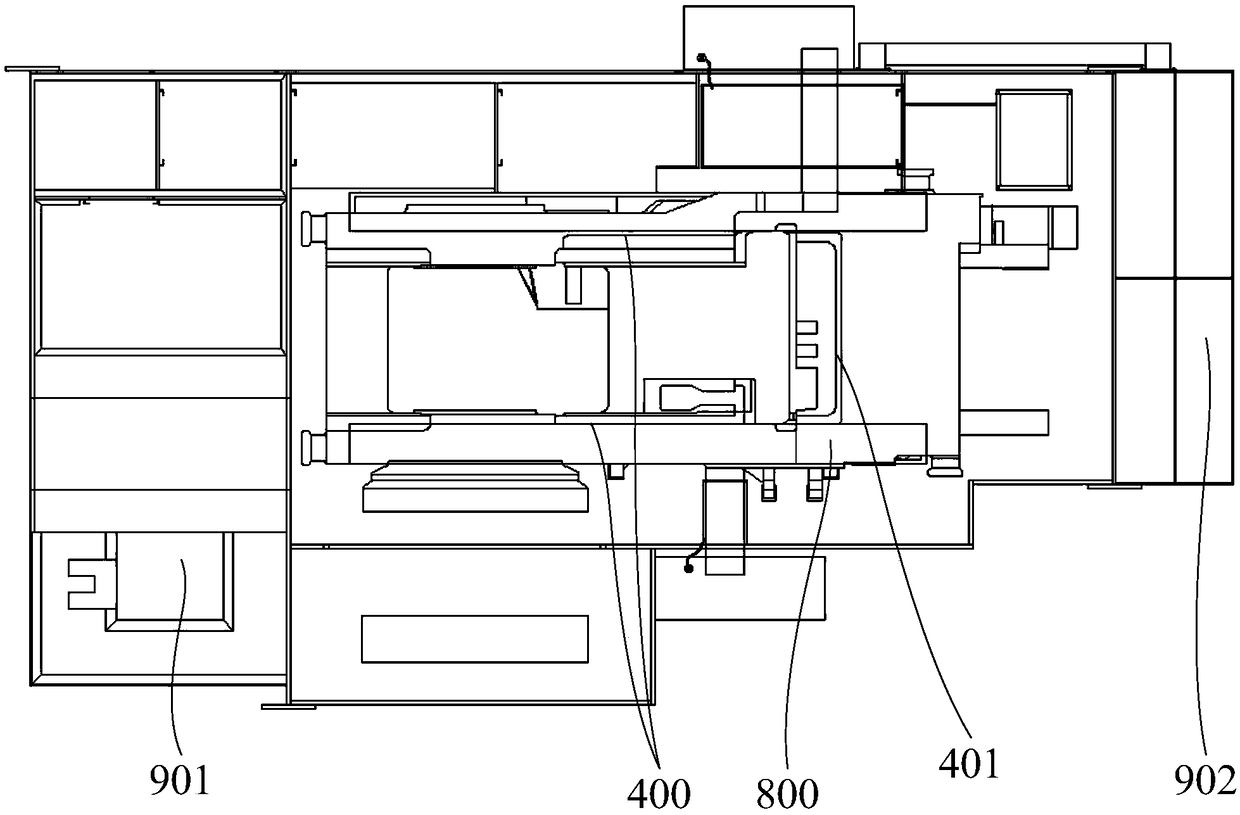

Multi-station cold-upsetting molding machine with oil-water separation function

PendingCN108971402AEliminate the effects ofEliminate oil stainsForging press detailsHeating/cooling devicesEngineeringOil water

The invention discloses a multi-station cold-upsetting forming machine with an oil-water separation function. The multi-station cold-upsetting forming machine comprises a cold-upsetting forming machine body, a cold-upsetting sliding table mounted on the cold-upsetting forming machine body, and a cold-upsetting mold, wherein the cold-upsetting mold and the cold-upsetting sliding table are mounted correspondingly. The cold-upsetting sliding table is mounted on a horizontally-arranged cold-upsetting sliding rail. One end of the cold-upsetting sliding rail is connected with the cold-upsetting forming machine body, and the other end of the cold-upsetting sliding rail extends towards the lower portion of the cold-upsetting mold. An oil collecting plate is arranged under the cold-upsetting sliding rail. The first edge of the oil collecting plate is fixed to the position, on the lower portion of the cold-upsetting sliding rail, of the cold-upsetting forming machine body. The second edge, except for the first edge, of the oil collecting plate is bent in the direction of the cold-upsetting sliding table to form an oil blocking step. The top of the oil blocking step corresponding to the edge,close to the cold-upsetting mold, of the oil collecting plate is located on the lower portion of the cold-upsetting sliding rail, and the projection of the cold-upsetting sliding table on the horizontal plane is located in the area defined by the oil blocking step and the first edge. By applying the multi-station cold-upsetting forming machine, oil contamination on the surface of a cold-upset product can be eliminated.

Owner:安徽阳天机械工业有限公司

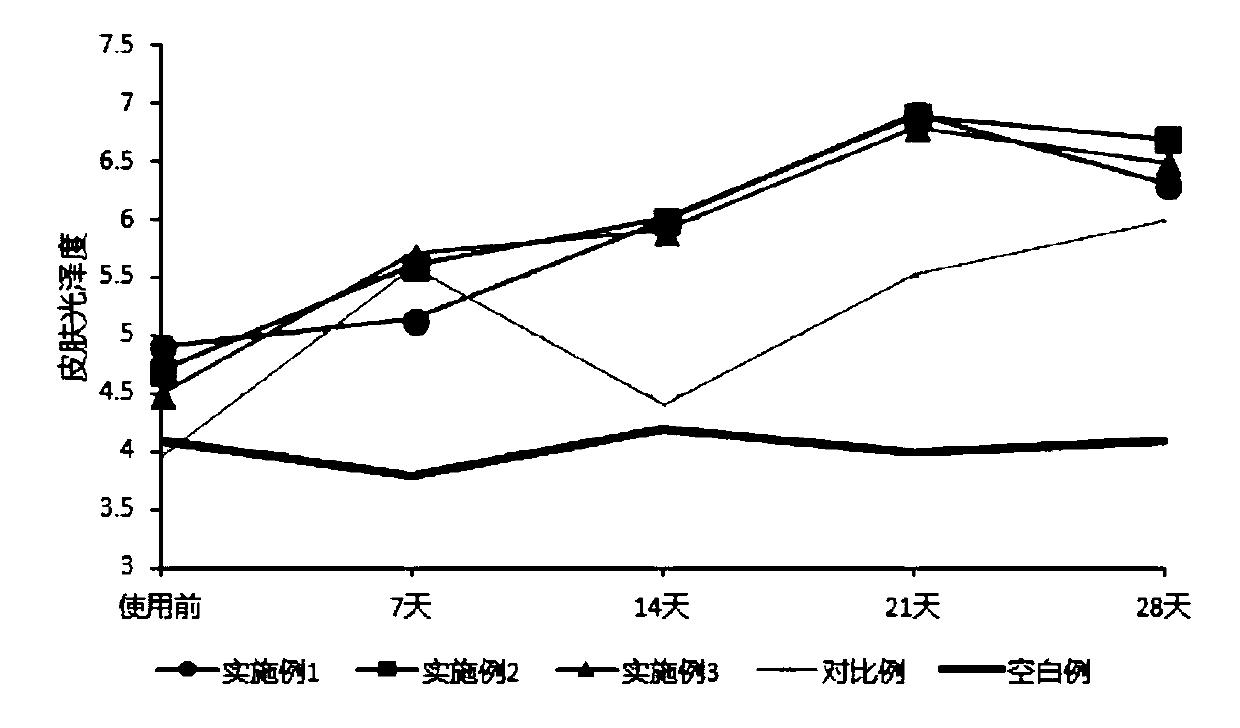

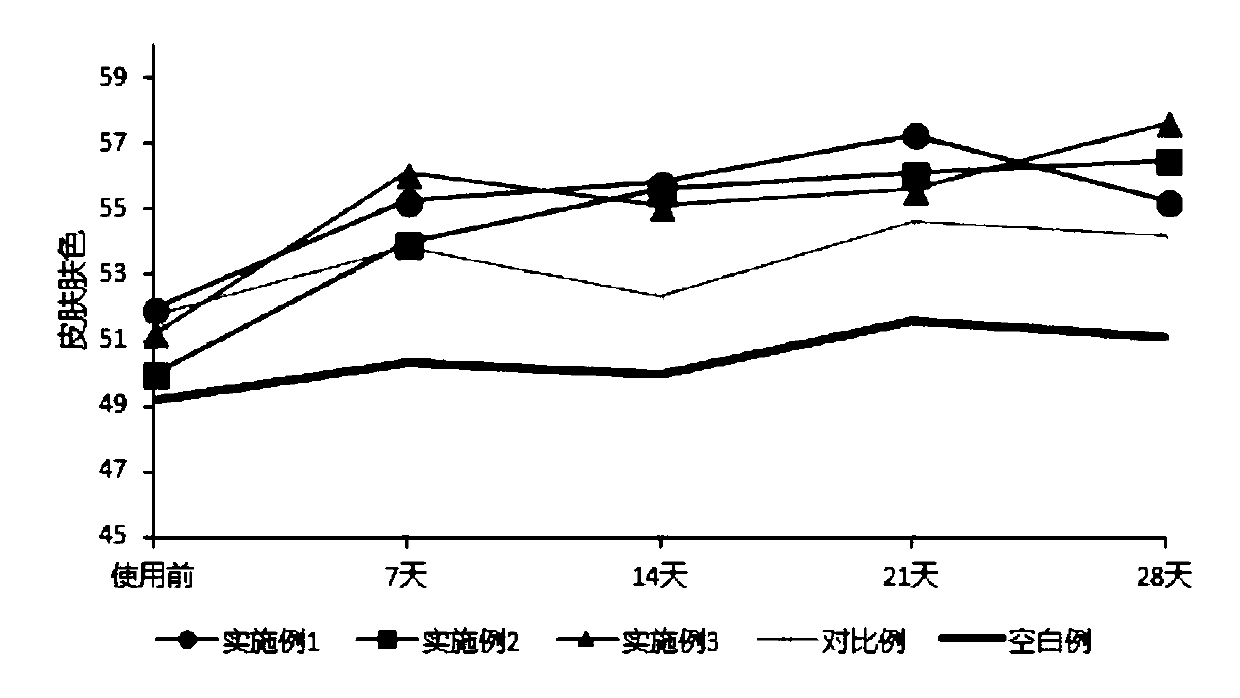

Gloss enhancer for household article leather

InactiveCN106148047AEasy to penetrateOil removalSurface-active non-soap compounds and soap mixture detergentsAqueous dispersionsSODIUM DODECYL BENZENE SULFONATESodium nitrate

The invention relates to a gloss enhancer for household article leather. The gloss enhancer for household article leather is prepared from orthosilicate, sodium nitrate, acetone, sodium dodecyl benzene sulfonate, sodium nitrate, nitrocellulose, sodium acetate, silicone oil, sodium phosphate and water. Compared with the prior art, the gloss enhancer for household article leather has the advantages that the gloss enhancer is oil-color water emulsion and can permeate the surface of leather easily and remove oil dirt effectively; meanwhile, after a solvent evaporates, the gloss enhancer is transformed into water-color oil emulsion and can remove water dirt.

Owner:CHENGDU FENGYA BUILDING MATERIAL

Traditional Chinese medicine Chinese honeylocust fruit shampoo and preparation method thereof

InactiveCN108653109AEliminate hair and scalp oilRestoring a clean environmentCosmetic preparationsHair cosmeticsHouttuynia cordataDandruff

The invention belongs to the technical field of wash supplies and particularly relates to traditional Chinese medicine Chinese honeylocust fruit shampoo and a preparation method thereof. Through reasonable matching and treatment, properties of Chinese honeylocust fruits, tea, willow roots, willow flowers, houttuynia cordata, table salt and alum are reasonably blended together, efficacies of all raw materials are sufficiently played, and the traditional Chinese medicine Chinese honeylocust fruit shampoo is finally obtained. The traditional Chinese medicine Chinese honeylocust fruit shampoo caneffectively eliminate hair and scalp grease dirt and recover the clean environment of scalp hair follicles to realize the effects of hair growth and hair blackening. The traditional Chinese medicine Chinese honeylocust fruit shampoo takes purely natural traditional Chinese medicines as raw materials, contains no chemical ingredients and cannot affect body health.

Owner:GUIZHOU JIEYIKANG PLANT CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com