Pressed stranded conductor stranding die for aluminum alloy cable

A technology of stranded conductors and aluminum alloys, which is used in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of high insulation breakdown rate, decreased cable insulation performance, and no solution to temperature rise molds, stranded wire effects, etc. Achieve the effect of improving conductor surface roughness, increasing packing density, production efficiency and quality of stranded conductors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

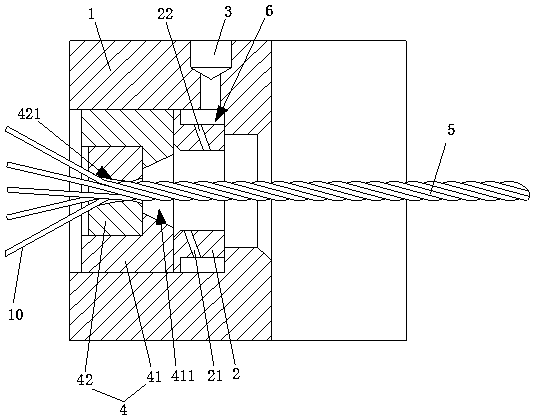

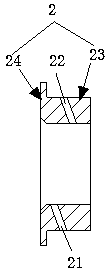

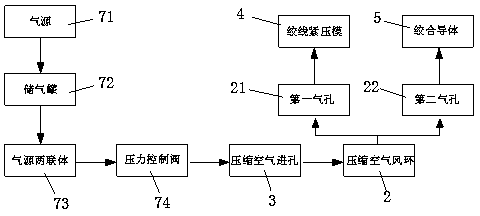

[0015] like figure 1 , figure 2 The shown a kind of aluminum alloy cable compression stranded conductor stranded wire mold, comprises mold base 1, and mold base 1 is provided with stranded wire compression mold 4, compressed air wind ring 2 and the compressed air that communicates with compressed air wind ring 2. The air inlet hole 3; the stranded wire compression mold 4 includes an outer mold cover 41 and a mold core 42 assembled in the mold cover 41; After entering the first channel 421, an aluminum alloy single wire is tightly compressed and twisted in the first channel 421 to form a stranded conductor 5; the outlet of the first channel 421 is connected to the second channel 411 provided inside the mold cover 41; the compressed air wind ring 2 is set at the exit of the second channel 411, and the compressed air air ring 2 is provided with a first group of air holes 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com