Oil-dissolving water purification material and preparation method thereof

A technology of dissolving oil and purifying water, applied in the field of water purification, can solve the problems of high COD content, high operating cost, environmental hazards, etc., and achieve the effects of improving penetration and dissolving power, simple preparation process, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

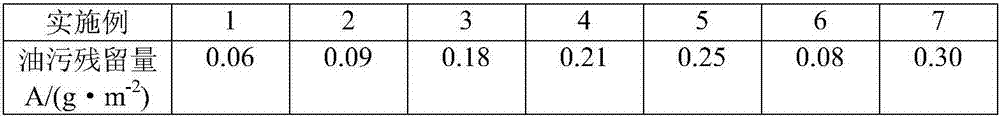

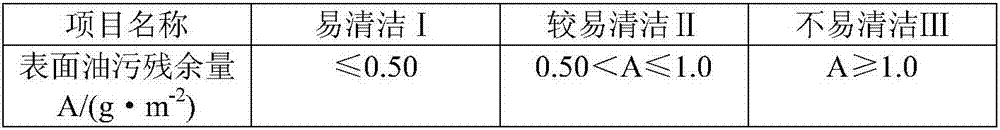

Examples

Embodiment 1

[0029] (1) Based on the total mass of oil-soluble water purification materials, weigh 4% of far-infrared ceramic powder, 45% of calcined kaolin (100 mesh, Fe≤0.5%), and 51% of multi-component composite antibacterial materials for batching, after fully mixing Obtain the mixed mud of oil-soluble material; Wherein, based on the total mass of multi-component composite antibacterial material, multi-component composite antibacterial material is made up of the following components: 20% silver-zeolite, 15% silver-activated carbon, 45% carboxymethyl shell Glycans and 20% ZnO;

[0030] (2) The oil-dissolving material mixing mud obtained in step (1) is mixed with water according to a water content of 15%, and pressed into oil-dissolving purification balls with a particle diameter of 0.5 mm by a press, and the working pressure of the press is 58.0 MPa;

[0031] (3) Place the soluble oil purification ball obtained in step (2) in a ceramsite roasting furnace, raise the temperature from room...

Embodiment 2

[0033] (1) Based on the total mass of oil-soluble water purification materials, weigh 15% of far-infrared ceramic powder, 35% of calcined kaolin (150 mesh, Fe≤0.5%), and 50% of multi-component composite antibacterial materials for batching, after fully mixing Obtain the mixed mud of oil-soluble material; Wherein, take multivariate composite antibacterial material gross mass as benchmark, multivariate composite antibacterial material is made up of following components: 25% silver-phosphate, 10% silver-silica gel, 50% TiO 2 / Ag + Composite material and 15% ZnO;

[0034] (2) The oil-dissolving material mixing mud obtained in step (1) is mixed with water according to a water content of 20%, and pressed into oil-dissolving purification balls with a particle diameter of 1.5 mm by a press, and the working pressure of the press is 62.0 MPa;

[0035] (3) Place the soluble oil purification ball obtained in step (2) in a ceramsite roasting furnace, heat up from room temperature to 200°C...

Embodiment 3

[0037](1) Based on the total mass of oil-soluble water purification materials, weigh 15% of far-infrared ceramic powder, 45% of calcined kaolin (120 mesh, Fe≤0.5%), and 40% of multi-component composite antibacterial materials for batching, after fully mixing Obtain the mixed mud of oil-soluble material; Wherein, take multi-component composite antibacterial material gross mass as benchmark, multi-component composite antibacterial material is made up of following components: 35% silver-zeolite, 45% carboxymethyl chitosan and 20% ZnO ;

[0038] (2) The oil-soluble material mixing mud obtained in step (1) is mixed with water according to a water content of 16%, and pressed into oil-soluble purification balls with a particle diameter of 2mm by a press, and the working pressure of the press is 59.0MPa;

[0039] (3) Place the oil-dissolved purification ball obtained in step (2) in a ceramsite roasting furnace, heat up from room temperature to 195°C at 2°C / min, and keep warm for 58 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com