Film winding device and method for making optical film employing the same

A manufacturing method and technology of optical film, which are applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of insufficient winding device, increased jitter, and inability to prevent scratches and scratches, and achieve improved performance. The effect of attracting pressure and preventing winding misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

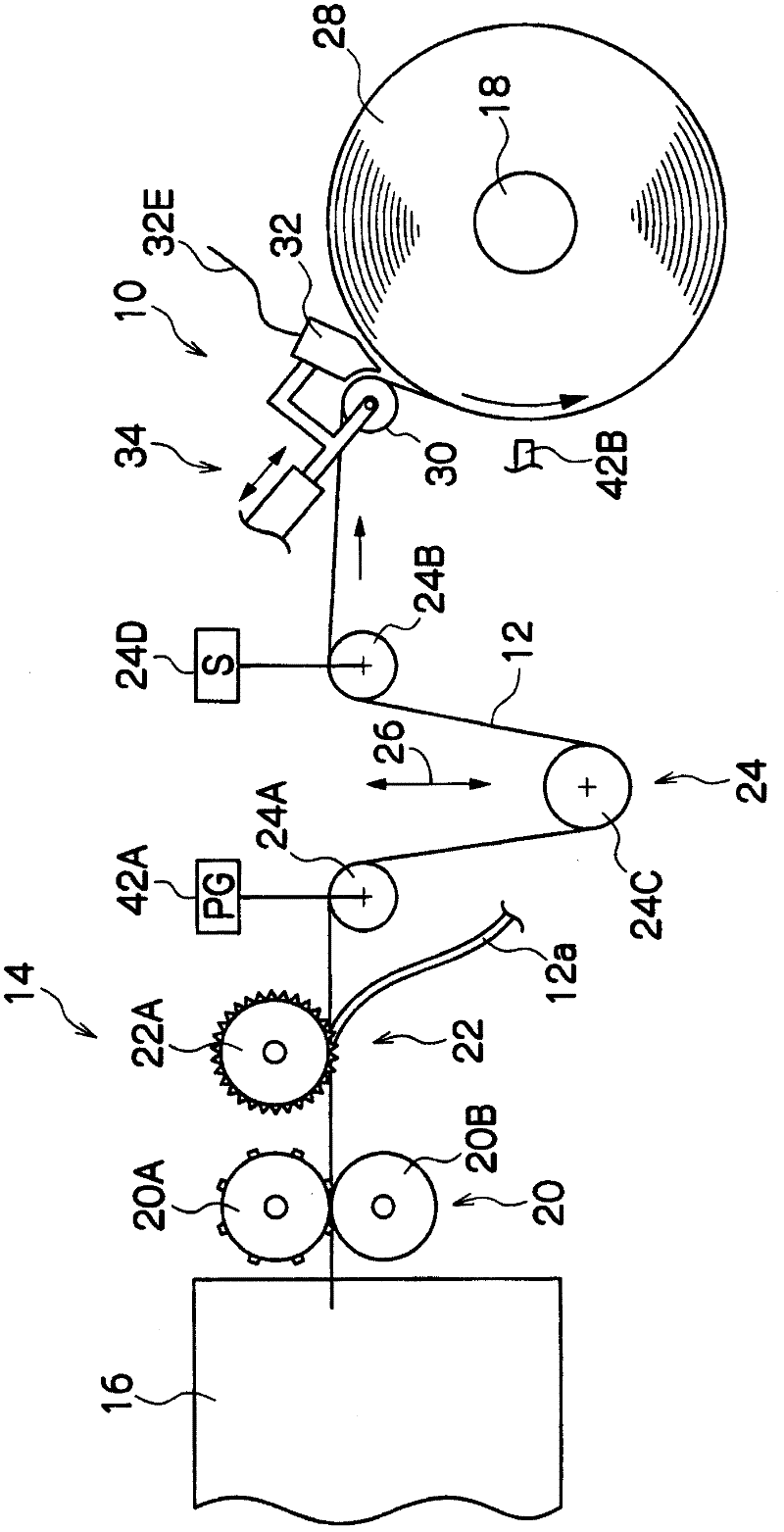

[0133] For the winding device that passed the conditions of the following experiments 1 to 3, the figure 1 A cellulose triacetate film with a width of 2000 mm and a thickness of 80 μm produced in the film production line of the company was wound up.

[0134] (winding condition)

[0135] Experiment 1... is the case of winding without using the backup roll 30 and the suction nozzle 32.

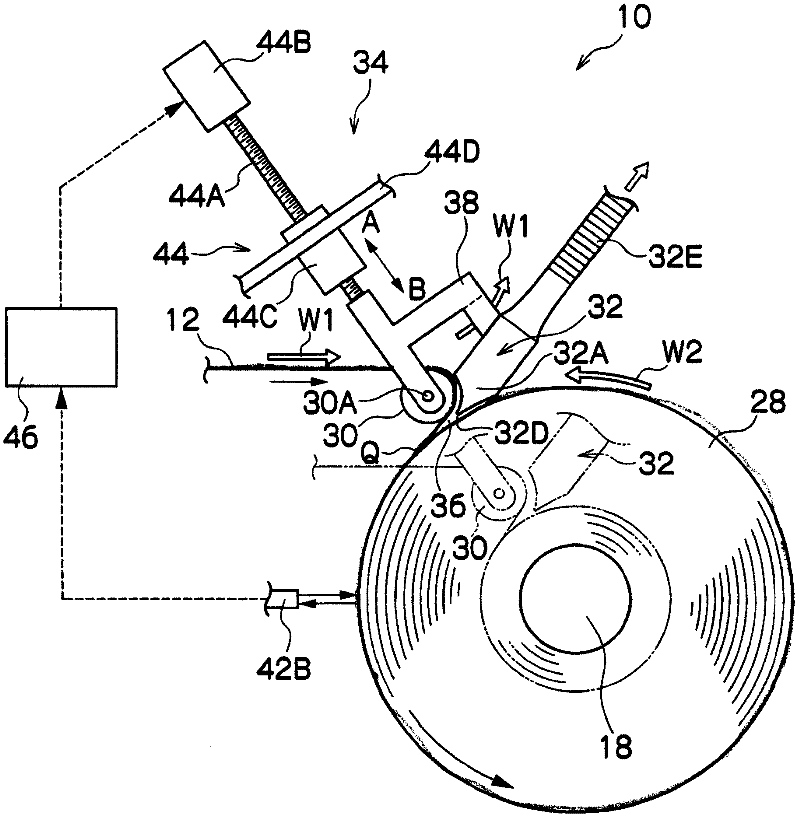

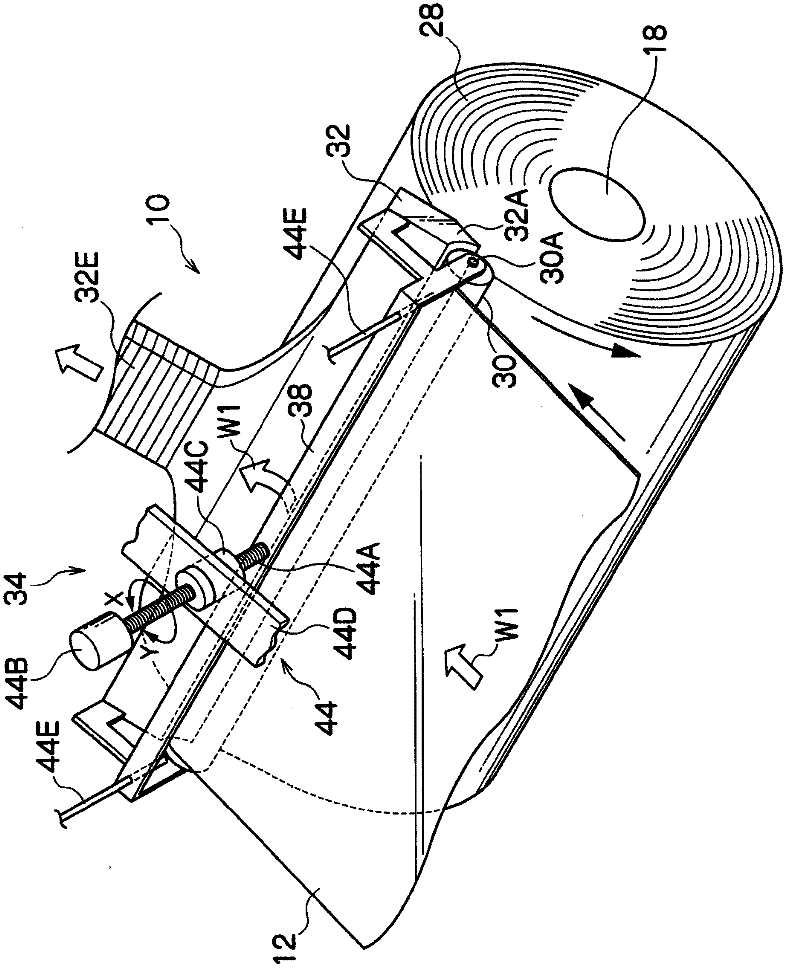

[0136] Experiment 2... is the case where the winding device 10 of this embodiment demonstrated above was used. The gap L1 between the support roll 30 surface and the wrapping roll 28 face is 3 mm, the gap L2 between the support roll 30 face and the side 32B of the support roll side of the suction nozzle 32 is 5 mm, and the side surface of the suction nozzle 32 surrounding the roll roll 28 side The gap L3 between 32C and the surface of the surrounding roll 28 is 5mm. Furthermore, the suction pressure of the suction nozzle 32 was set to 1100 Pa.

[0137] Experiment 3... is the case where the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com