Mould powder for continuous casting of steel

A powder and mold technology, applied in the field of mold powder for continuous casting, can solve the problems of poor lubrication and unstable heat removal of the mold, and achieve the effect of stable heat removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

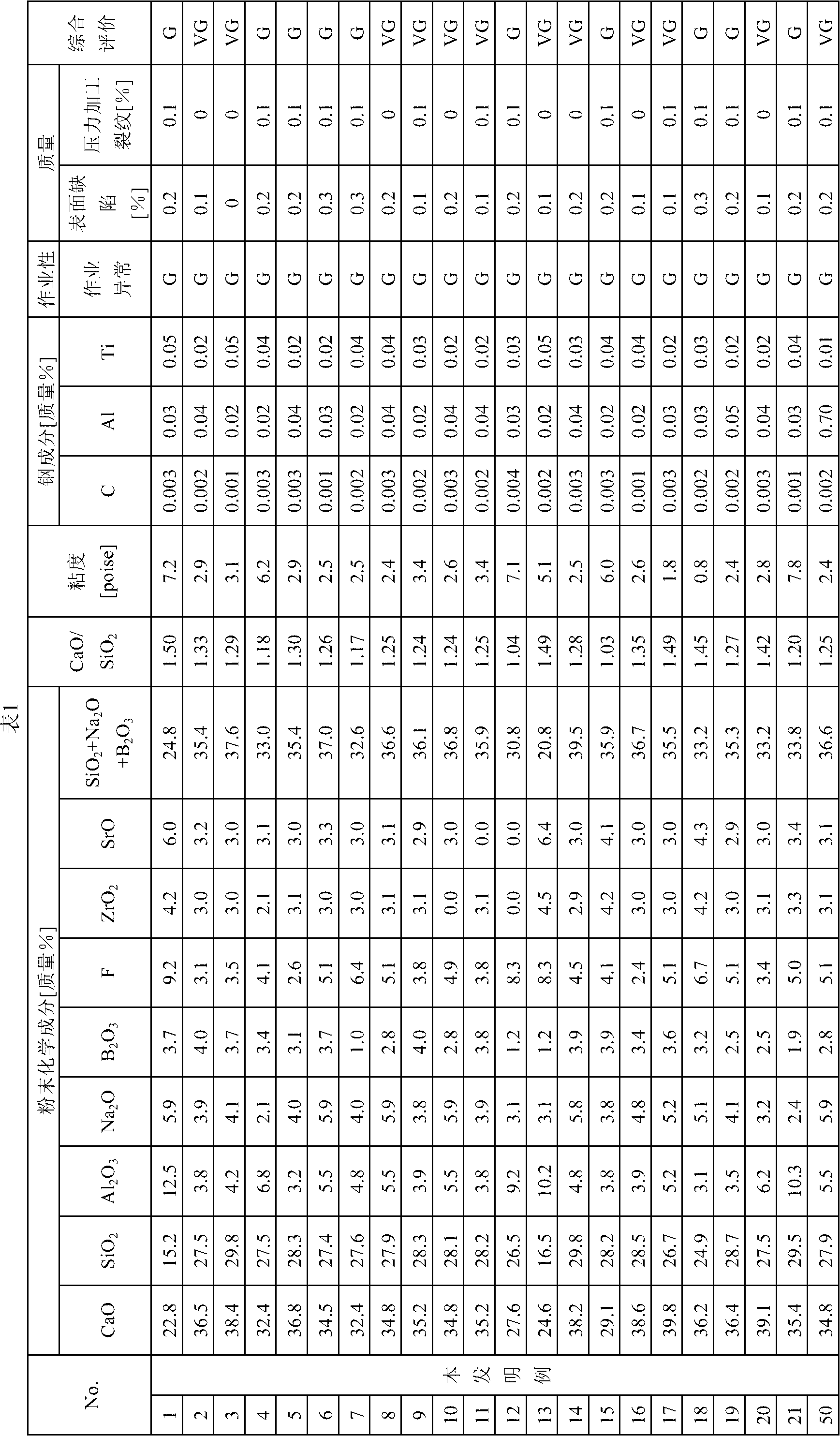

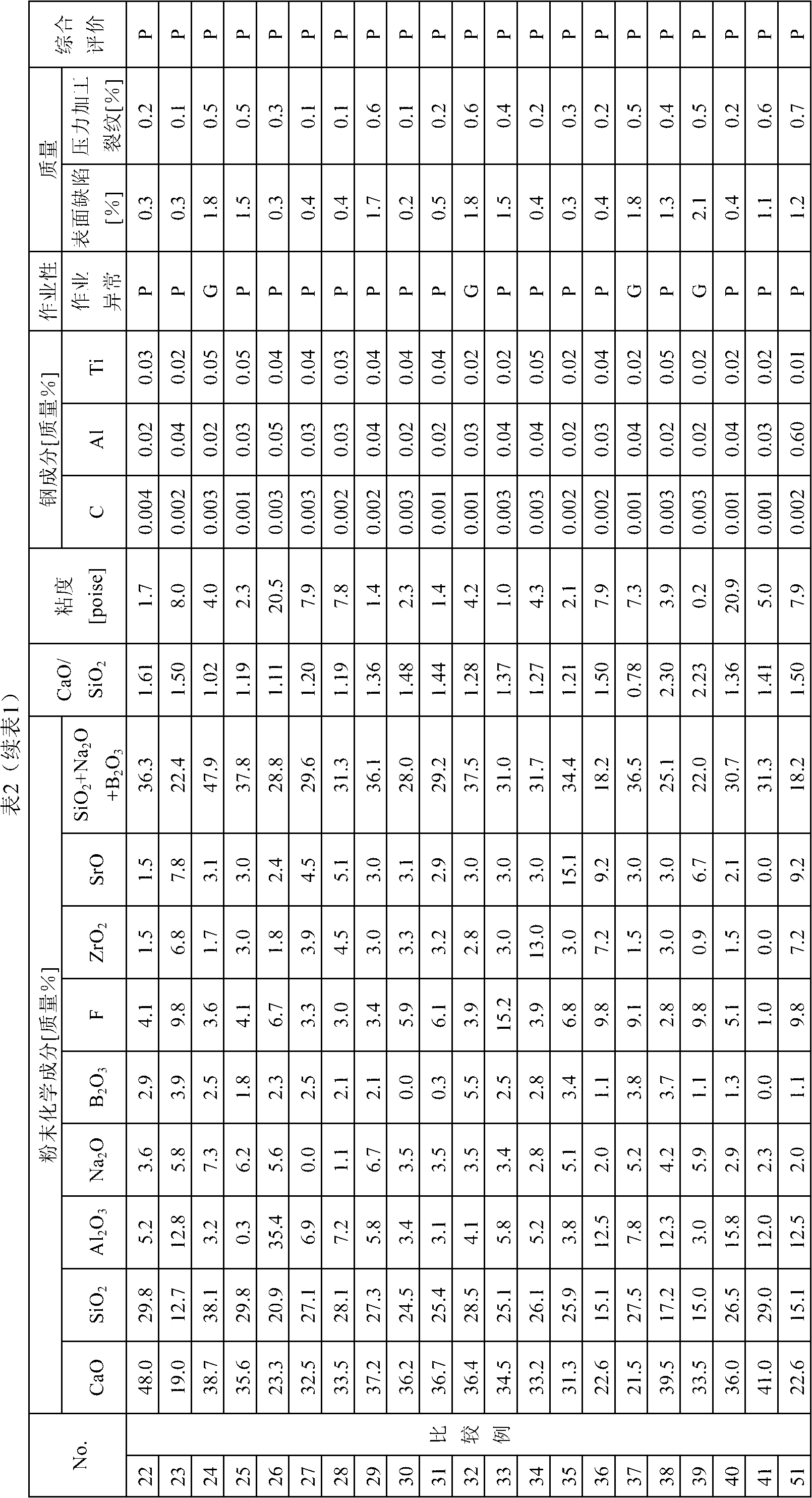

[0093] Examples are given below to describe the present invention in detail.

[0094] In the vacuum refining furnace (RH), 300 tons of molten steel smelted in a converter is adjusted to a specified component concentration, and the molten steel of ultra-low carbon steel obtained in this way is passed through a tundish and a submerged nozzle, and cast with a vertical curved continuous casting machine A slab with a thickness of 250mm and a width of 1600mm was formed. The casting speed was set at 1.8 m / min.

[0095] Table 1 and Table 2 (continued from Table 1) show the powder composition, physical property values, and Al and Ti concentrations in the cast molten steel. Powder Nos. 1 to 21 and 50 are examples of the present invention. Nos. 22 to 41 and 51 are comparative examples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com