Industrial circulating water treatment agent

A technology for industrial circulating water and treatment agents, applied in water/sludge/sewage treatment, special treatment targets, water softening, etc., can solve problems such as phosphorus pollution, achieve oil pollution elimination, corrosion inhibition, good solubility and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

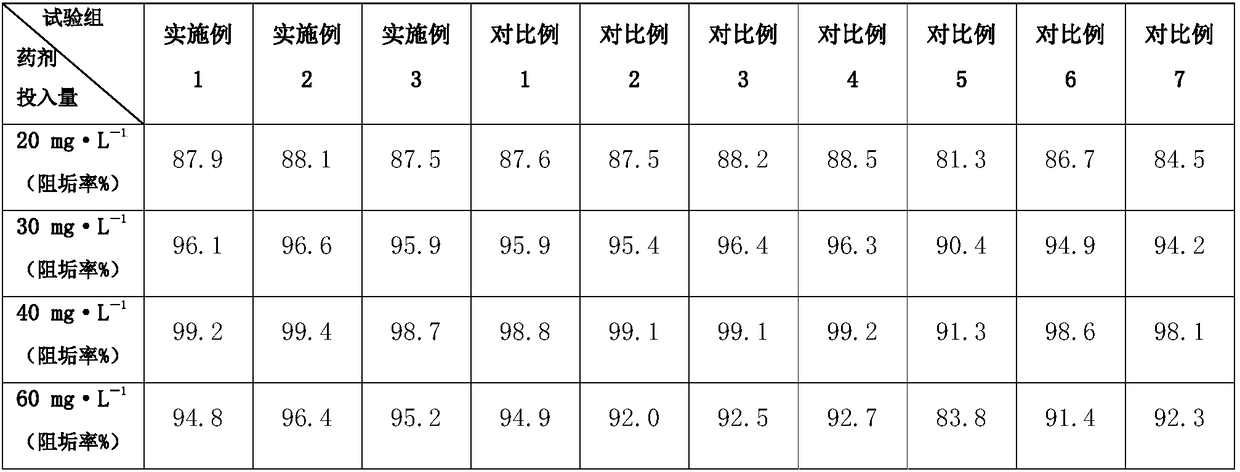

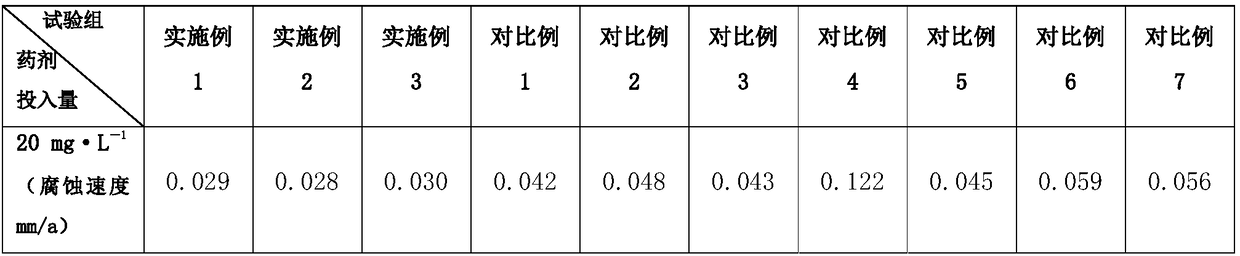

Examples

Embodiment 1

[0031]An industrial circulating water treatment agent, comprising the following raw materials in parts by mass: 1.2 parts of dodecyl dimethyl benzyl ammonium chloride, 29 parts of compound corrosion inhibitor, 21 parts of scale inhibitor, 5 parts of bactericide, 42 parts of water. The compound corrosion inhibitor includes the following raw materials in parts by mass: 25 parts of modified imidazoline, 10 parts of oxalazide compounds, 5 parts of sodium erythorbate, 7 parts of zinc sulfate and 10 parts of sodium D-gluconate; The agent includes the following raw materials in parts by mass: 9 parts of polyacrylic acid, 12 parts of tannic acid and 16 parts of acrylic copolymer; the bactericide includes the following raw materials in parts by mass: 7 parts of dithiocyanomethane and 10 parts of glutaraldehyde.

[0032] Modified imidazoline is prepared by the following steps in the present embodiment:

[0033] (1) Prepare raw materials: 1.4mol of lauric acid, 0.6mol of ricinoleic acid...

Embodiment 2

[0038] An industrial circulating water treatment agent, comprising the following raw materials in parts by mass: 1.5 parts of tetradecyl dimethyl benzyl ammonium chloride, 30 parts of compound corrosion inhibitor, 20 parts of scale inhibitor, 7 parts of bactericide, 45 parts of water. The compound corrosion inhibitor includes the following raw materials in parts by mass: 24 parts of modified imidazoline, 12 parts of oxalazide compounds, 4 parts of sodium erythorbate, 6 parts of zinc sulfate and 12 parts of sodium D-gluconate; The agent includes the following raw materials in parts by mass: 8 parts of polyacrylic acid, 10 parts of tannic acid and 15 parts of acrylic copolymer; the bactericide includes the following raw materials in parts by mass: 6 parts of dithiocyanomethane and 12 parts of glutaraldehyde.

[0039] Modified imidazoline is prepared by the following steps in the present embodiment:

[0040] (1) Prepare raw materials: 1.5mol of lauric acid, 0.8mol of ricinoleic ...

Embodiment 3

[0045] An industrial circulating water treatment agent, comprising the following raw materials in parts by mass: 1.8 parts of dodecyl dimethyl benzyl ammonium chloride, 30 parts of compound corrosion inhibitor, 21 parts of scale inhibitor, 8 parts of bactericide, 42 parts of water. The composite corrosion inhibitor includes the following raw materials in parts by mass: 25 parts of modified imidazoline, 10 parts of oxalazide compounds, 5 parts of sodium erythorbate, 6 parts of zinc molybdate and 10 parts of sodium D-gluconate; The scale agent includes the following raw materials in parts by mass: 10 parts of polyacrylic acid, 12 parts of tannic acid and 16 parts of acrylic copolymer; the bactericide includes the raw materials of the following parts by mass: 6 parts of dithiocyanomethane and 12 parts of glutaraldehyde .

[0046] Modified imidazoline is prepared by the following steps in the present embodiment:

[0047] (1) Prepare raw materials: 1.5 mol of lauric acid, 1 mol o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com