Preparation method of magnesium alloy surface colorless transparent film

A magnesium alloy and transparent film technology, which is applied to the device for coating liquid on the surface, special surface, pretreatment surface, etc., can solve the problems of high cost and inability to obtain magnesium alloy, and achieve low cost, low resistance value, and durability good corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

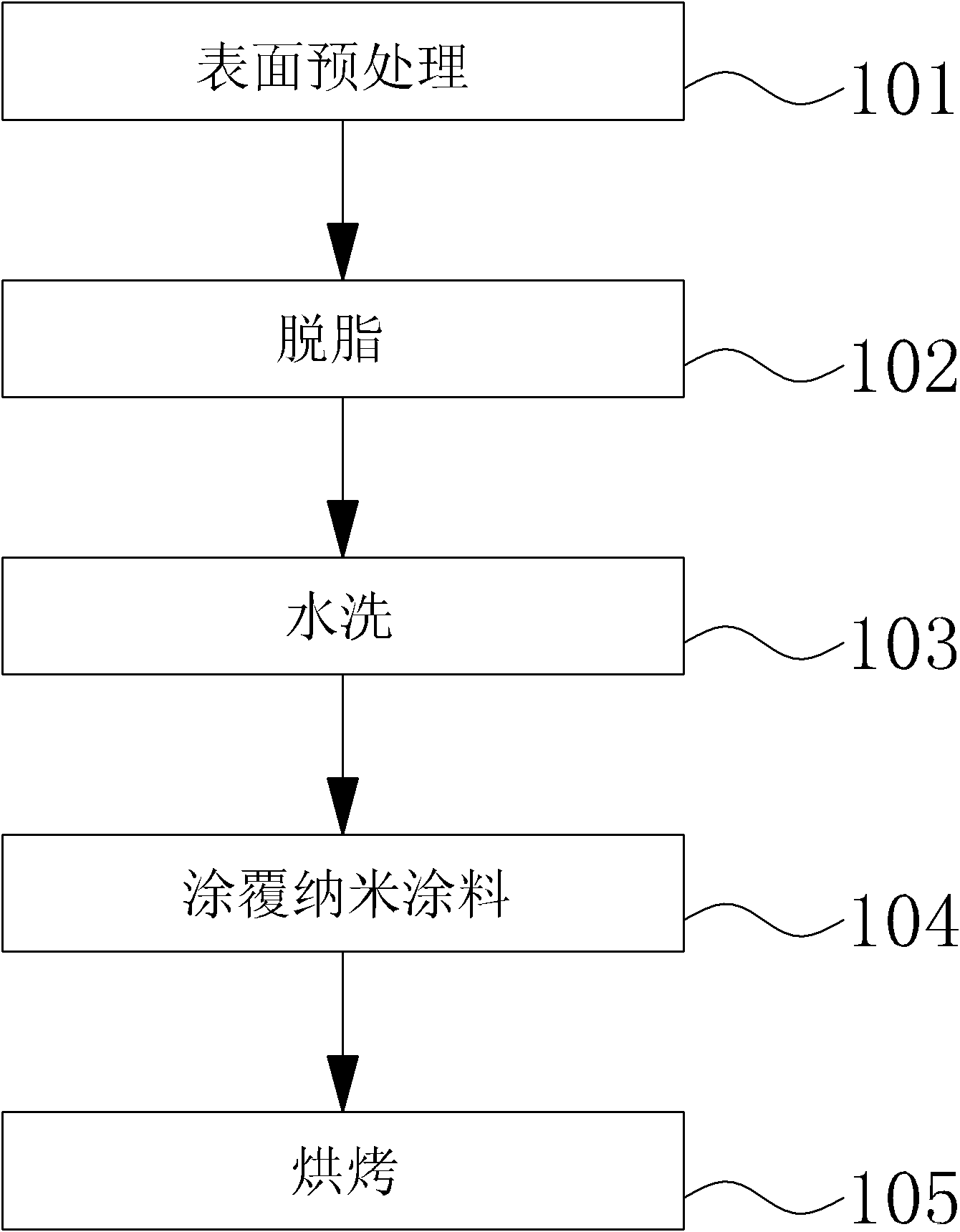

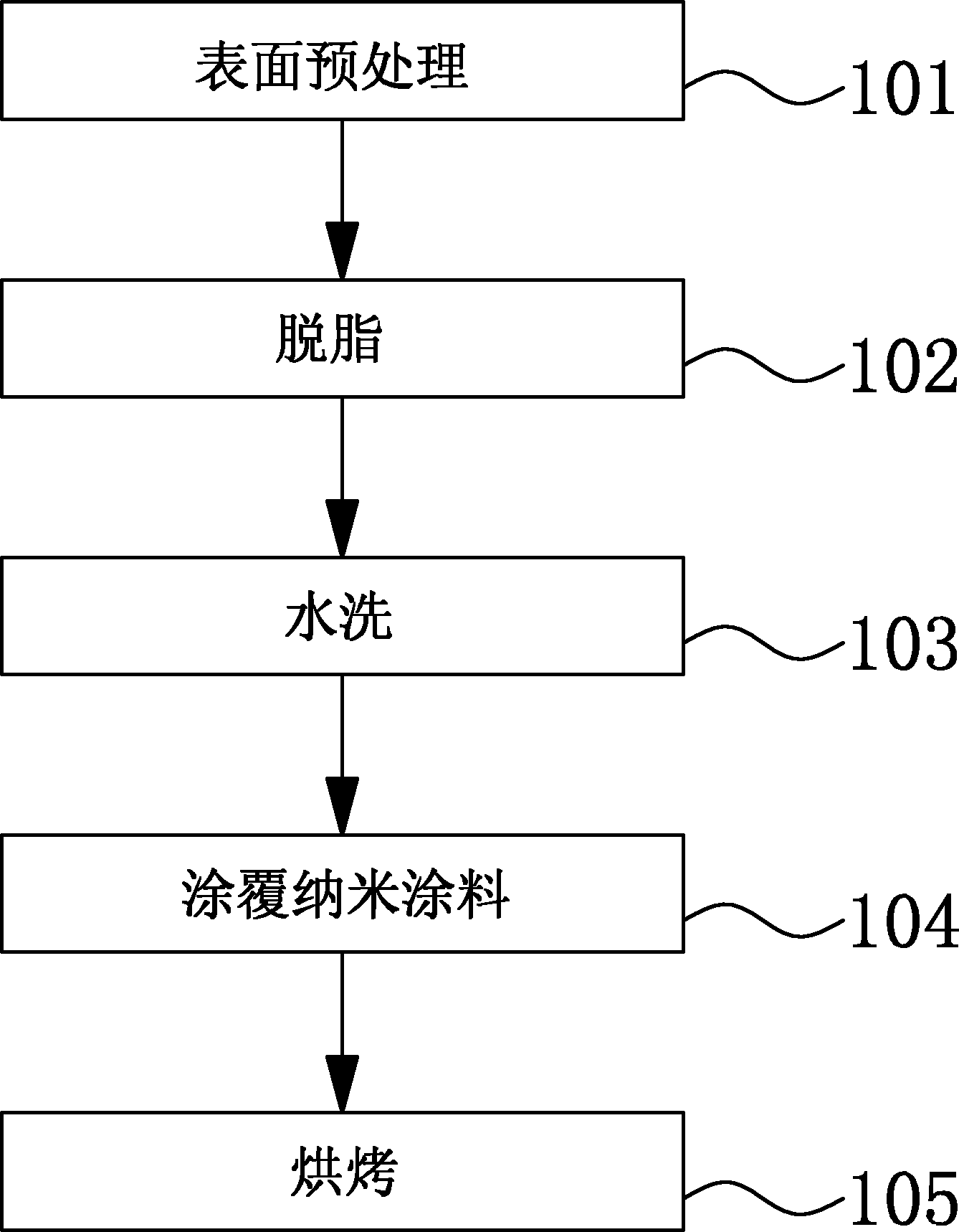

[0022] The preparation method of the colorless transparent film on the surface of the magnesium alloy of the present invention is obtained by coating a layer of nano-coating on the surface of the magnesium alloy after surface pretreatment, degreasing and water washing, and then baking and curing the nano-coating on the surface of the magnesium alloy. Colorless transparent film. Wherein, the formula of this nano-coating mainly comprises by weight percentage:

[0023] Isobutanol 20-50%;

[0024] Ethylene glycol butyl ether 40-70%;

[0025] Nano sol gel 5-20%.

Embodiment 1

[0028] Step 101: Brushing the surface of the magnesium alloy workpiece to enhance the metal texture and brightness of the surface.

[0029] Step 102: degreasing the magnesium alloy workpiece after surface drawing to remove oil stains on its surface.

[0030] Step 103: Rinse the degreased magnesium alloy workpiece with clean water first, and then with deionized water to remove the residual agent on the surface.

[0031] Step 104: Spraying a layer of nano-coating on the surface of the washed magnesium alloy workpiece to prepare a colorless and transparent film, wherein the formula of the nano-coating mainly includes by weight percentage:

[0032] Isobutanol 50%;

[0033] Ethylene glycol butyl ether 40%;

[0034] Nano Sol Gel N7111 10%.

[0035] Step 105: Baking the magnesium alloy workpiece with the nano-coating film on the surface at 150 degrees Celsius for 30 minutes to dry and solidify the nano-coating film.

[0036] The surface of the product obtained by the above steps ...

Embodiment 2

[0038] Step 101: Vibrating and grinding the magnesium alloy workpiece to enhance the metal texture and brightness of its surface.

[0039] Step 102: degreasing the magnesium alloy workpiece after surface vibration grinding to remove oil stains on its surface.

[0040] Step 103: Rinse the degreased magnesium alloy workpiece with clean water first, and then with deionized water to remove the residual agent on the surface.

[0041] Step 104: Spraying a layer of nano-coating on the surface of the washed magnesium alloy workpiece to prepare a colorless and transparent film, wherein the formula of the nano-coating mainly includes by weight percentage:

[0042] Isobutanol 25%;

[0043] Ethylene glycol butyl ether 70%;

[0044] Nano Sol Gel N7111 5%.

[0045] Step 105: Baking the magnesium alloy workpiece with the nano-coating film on the surface at 150 degrees Celsius for 30 minutes to dry and solidify the nano-coating film.

[0046] The surface of the product obtained by the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com