Non-nickel and non-copper zirconium-based bulk amorphous alloy

An amorphous alloy and zirconium-based technology, which is applied in the field of nickel-free and copper-free zirconium-based bulk amorphous alloys, can solve the problems of reducing the ability of the system to form amorphous and the inability to prepare large-sized amorphous alloys, and achieve biological toxicity The effect of reducing, excellent corrosion resistance, and strong pitting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

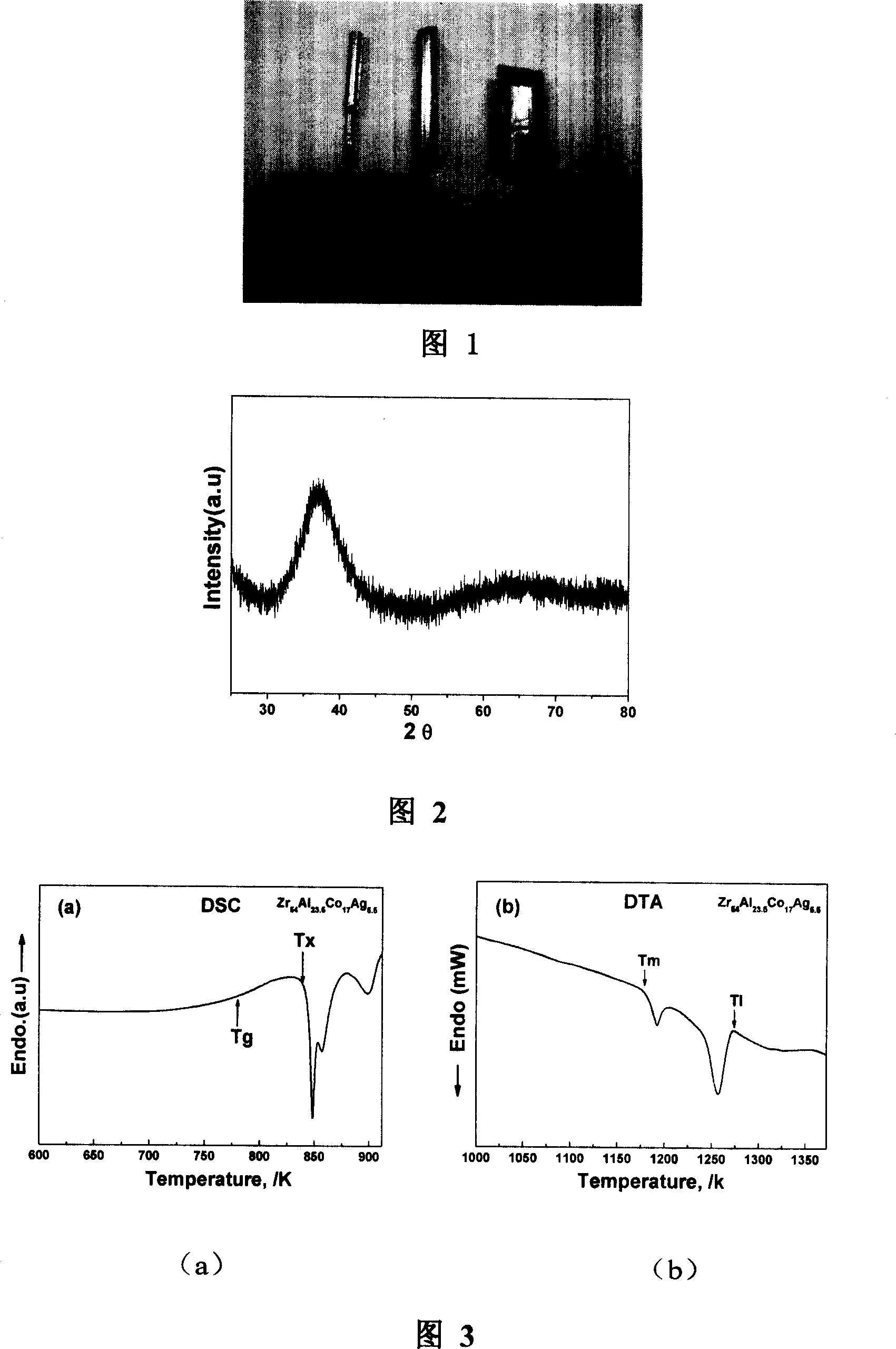

[0020] The atomic percentage of each component in the zirconium-based bulk amorphous alloy is: Zr 53%, Al 23.5%, Co 22.5%, Ag 1%. The formed Zr 53 Al 23.5 co 23.5 Ag 1 It has strong amorphous forming ability, and can obtain bulk amorphous alloy with critical size not less than φ3mm under the condition of arc melting copper mold suction casting.

Embodiment 2

[0022] The atomic percentage of each component in the zirconium-based bulk amorphous alloy is: Zr 54%, Al 23.5%, Co 17%, Ag 5.5%. The formed Zr 54 Al 23.5 co 17 Ag 5.5 It has super strong amorphous forming ability, and can obtain bulk amorphous alloy with critical size not less than φ10mm under the condition of arc melting copper mold suction casting.

Embodiment 3

[0024] The atomic percentage of each component in the zirconium-based bulk amorphous alloy is: Zr 57%, Al 23.5%, Co 14%, Ag 5.5% formed Zr 57 Al 23.5 co 14 Ag 5.5 It has strong amorphous forming ability, and can obtain bulk amorphous alloy with critical size not less than φ5mm under the condition of arc melting copper mold suction casting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com