High-entropy bulk amorphous alloy and preparation method thereof

A technology of amorphous alloys and blocks, which is applied in the field of amorphous alloys and high-entropy alloy materials, can solve the problems of low amorphous forming ability and specific strength, and achieve the effects of reducing density, good amorphous forming ability, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

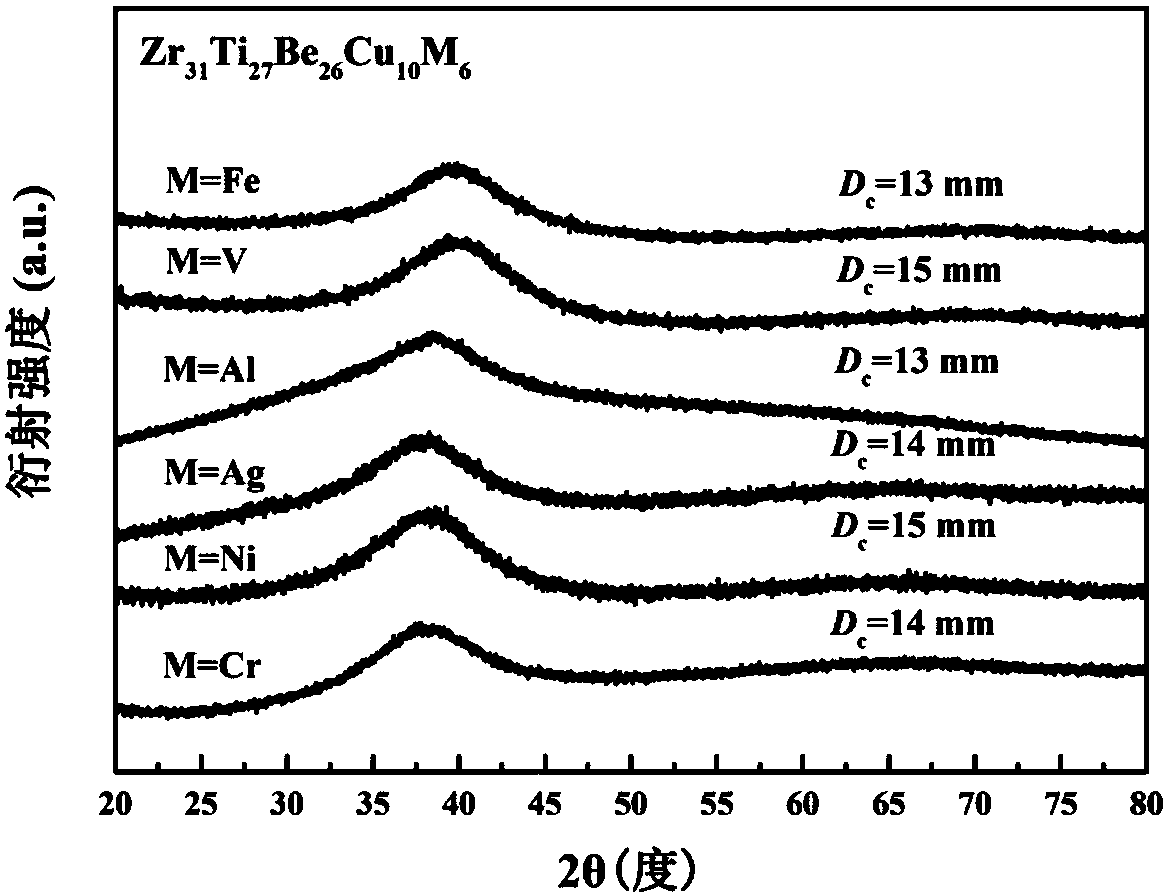

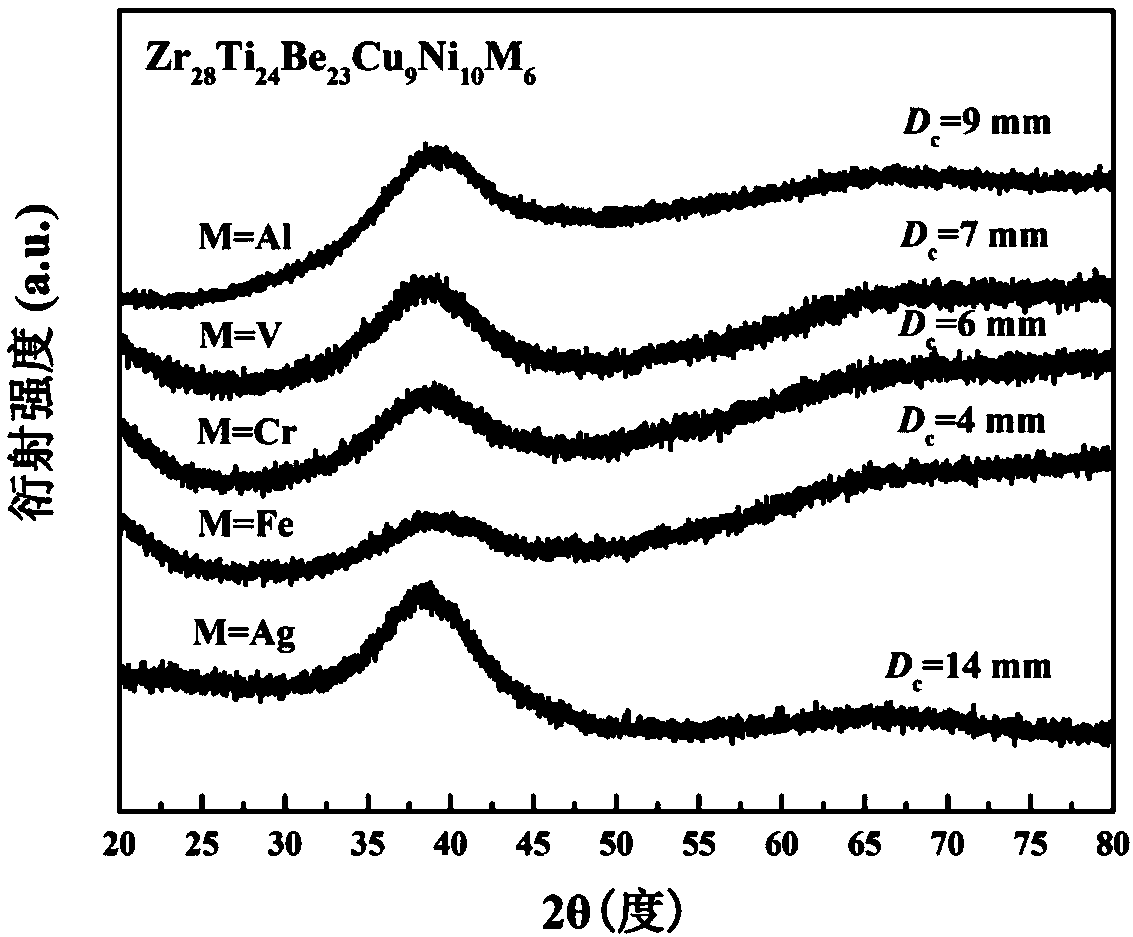

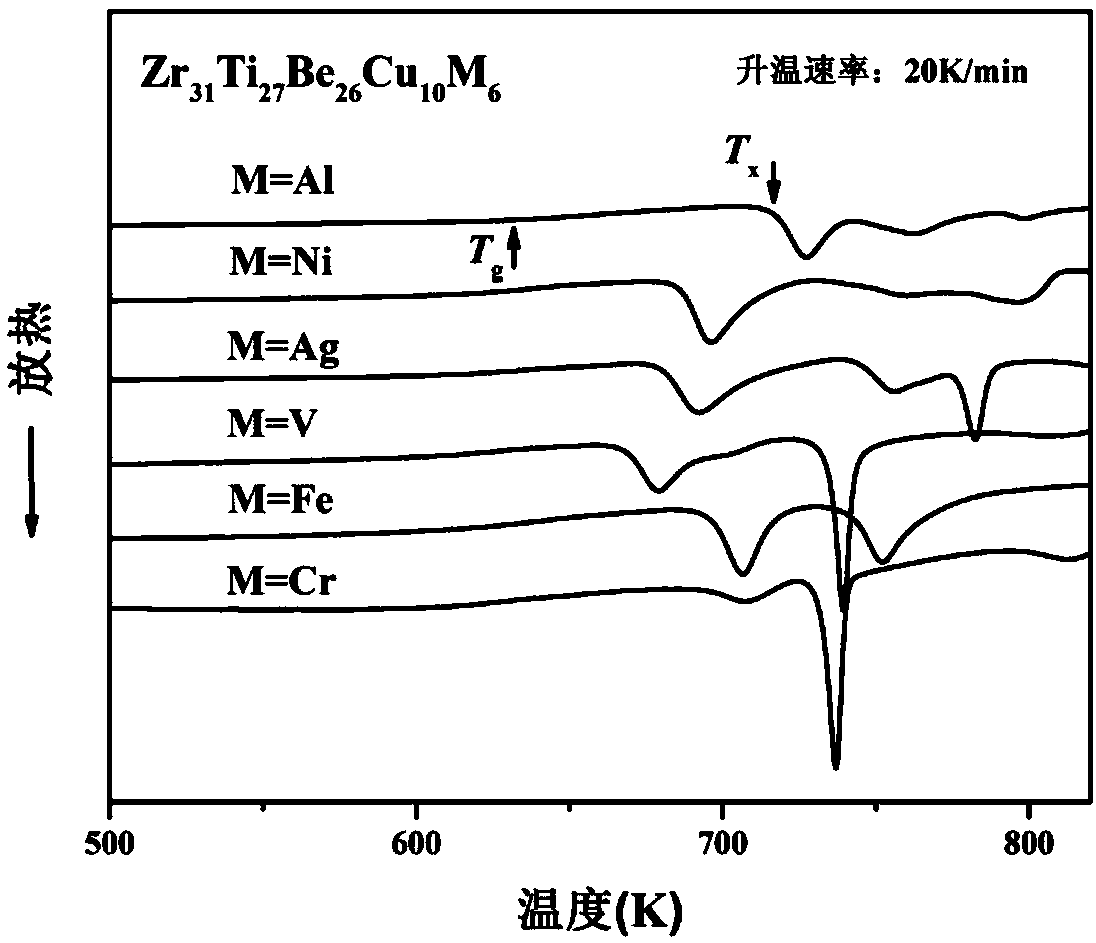

[0033] Embodiment 1 prepares Zr 31 Ti 27 be 26 Cu 10 Fe 6 bulk amorphous alloy material

[0034] The specific steps are as follows: the first step is to convert the atomic percentage composition of the alloy into mass percentage, and select high-purity zirconium rods, titanium rods, beryllium blocks, copper sheets, nickel blocks and iron blocks (purity not less than 99.95%) as raw materials , after polishing the scale, ultrasonically clean with acetone or alcohol, and use a high-precision balance with an accuracy of 0.0001g for batching; the second step is to prepare master alloy ingots under vacuum and argon protection conditions by arc melting, and each ingot is repeatedly Smelt at least 4 times, and carry out magnetic stirring during the smelting process to ensure that the composition of the alloy ingot is uniform; the third step is to melt the master alloy and suction cast it into a water-cooled oxygen-free copper mold to obtain an alloy rod; the fourth step is to prep...

Embodiment 2

[0035] Embodiment 2 prepares Zr 31 Ti 27 be 26 Cu 10 Al 6 bulk amorphous alloy material

[0036] The specific steps are as follows: the first step is to convert the atomic percentage composition of the alloy into mass percentage, and select high-purity zirconium rods, titanium rods, beryllium blocks, copper sheets, nickel blocks and aluminum blocks (purity not less than 99.95%) as raw materials , after polishing the scale, ultrasonically clean with acetone or alcohol, and use a high-precision balance with an accuracy of 0.0001g for batching; the second step is to prepare master alloy ingots under vacuum and argon protection conditions by arc melting, and each ingot is repeatedly Smelt at least 4 times, and carry out magnetic stirring during the smelting process to ensure that the composition of the alloy ingot is uniform; the third step is to melt the master alloy and suction cast it into a water-cooled oxygen-free copper mold to obtain an alloy rod; the fourth step is to ...

Embodiment 3

[0037] Embodiment 3 prepares Zr 31 Ti 27 be 26 Cu 10 Ag 6 bulk amorphous alloy material

[0038] The specific steps are as follows: the first step is to convert the atomic percentage composition of the alloy into mass percentage, and select high-purity zirconium rods, titanium rods, beryllium blocks, copper sheets, nickel blocks and silver blocks (purity not less than 99.95%) as raw materials , after polishing the scale, ultrasonically clean with acetone or alcohol, and use a high-precision balance with an accuracy of 0.0001g for batching; the second step is to prepare master alloy ingots under vacuum and argon protection conditions by arc melting, and each ingot is repeatedly Smelt at least 4 times, and carry out magnetic stirring during the smelting process to ensure that the composition of the alloy ingot is uniform; the third step is to melt the master alloy and suction cast it into a water-cooled oxygen-free copper mold to obtain an alloy rod; the fourth step is to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com