Nitrogen-oxygen alloying ti-based amorphous alloy and preparation method thereof

A technology of amorphous alloy and nitrogen-oxygen alloy, which is applied in the field of designing metal materials and its preparation, to achieve the effects of convenient preparation, safe use, and excellent compression plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

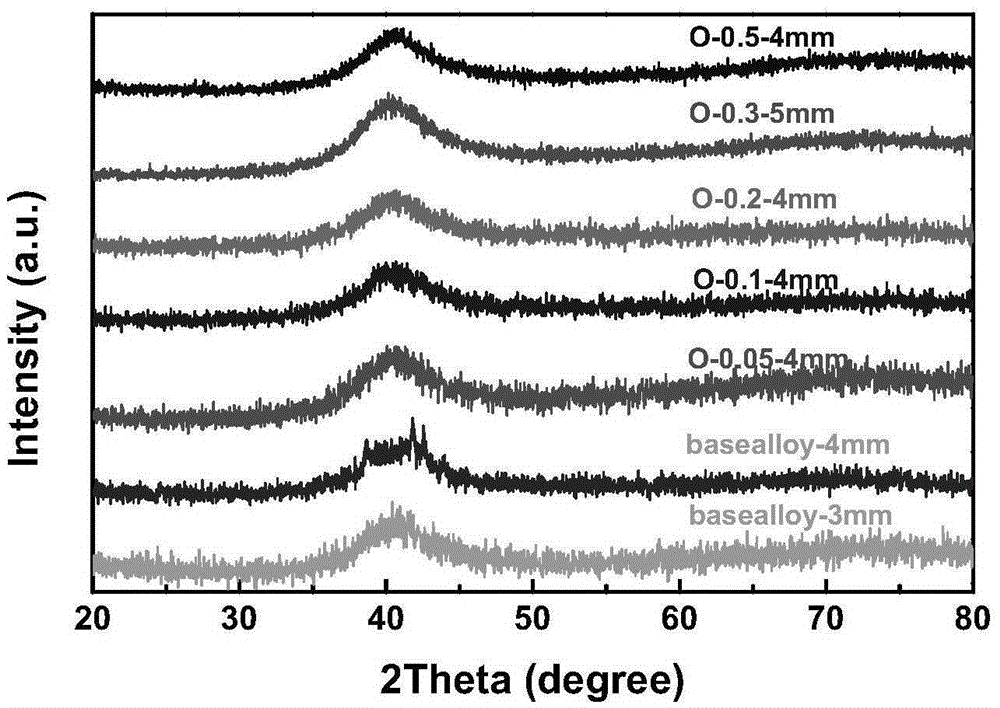

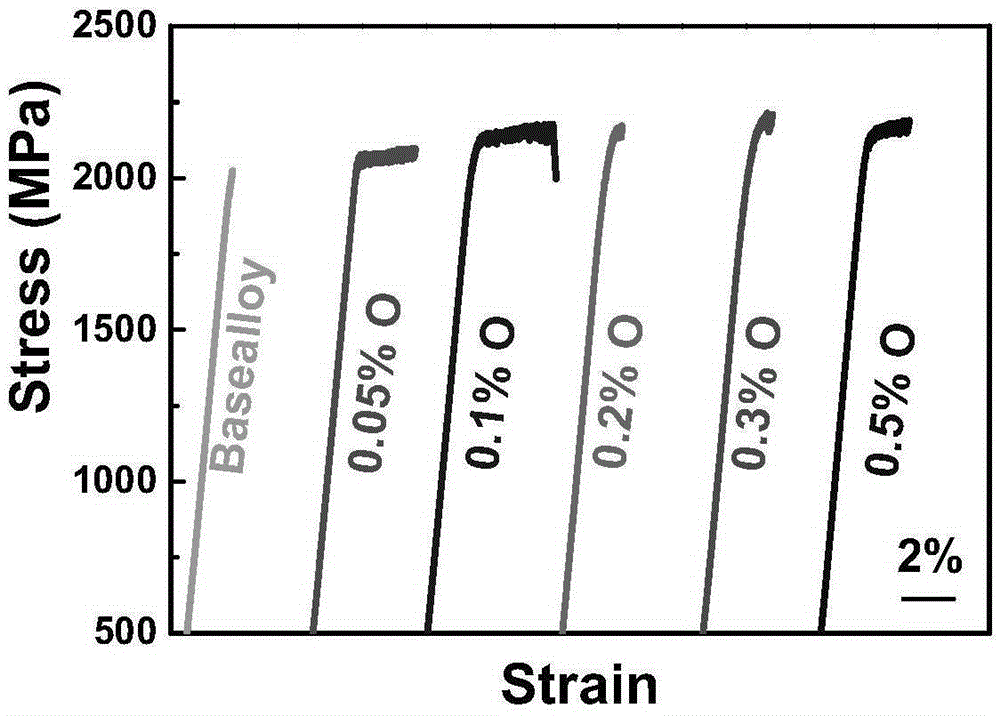

[0034] (Ti 42.5 Cu 40 Zr 10 Ni 5 sn 2.5 ) n o q Preparation and Properties of Amorphous Alloys

[0035] 1. Composition design and preparation of bulk amorphous alloys

[0036] Design (Ti 42.5 Cu 40 Zr 10 Ni 5 sn 2.5 ) n o q Amorphous alloy composition, where n = 99.95, 99.9, 99.8, 99.7, 99.5, corresponding to q = 0.05, 0.1, 0.2, 0.3 and 0.5, respectively, with O-0.05, O-0.1, O-0.2, O-0.3 and O-0.5 to represent. At the same time, in order to reflect the effect of adding oxygen on the amorphous alloy, the inventor also designed and prepared an oxygen-free Ti 42.5 Cu 40 Zr 10 Ni 5 sn 2.5 The alloy is used as a reference, which is expressed as Basealloy in this article. This alloy is only used as a reference alloy, but it is not within the scope of this patent requirement, and is hereby explained. The composition of the designed alloy is shown in Table 1.

[0037] (Ti 42.5 Cu 40 Zr 10 Ni 5 sn 2.5 ) n o q The preparation process of the amorphous alloy sy...

Embodiment 2

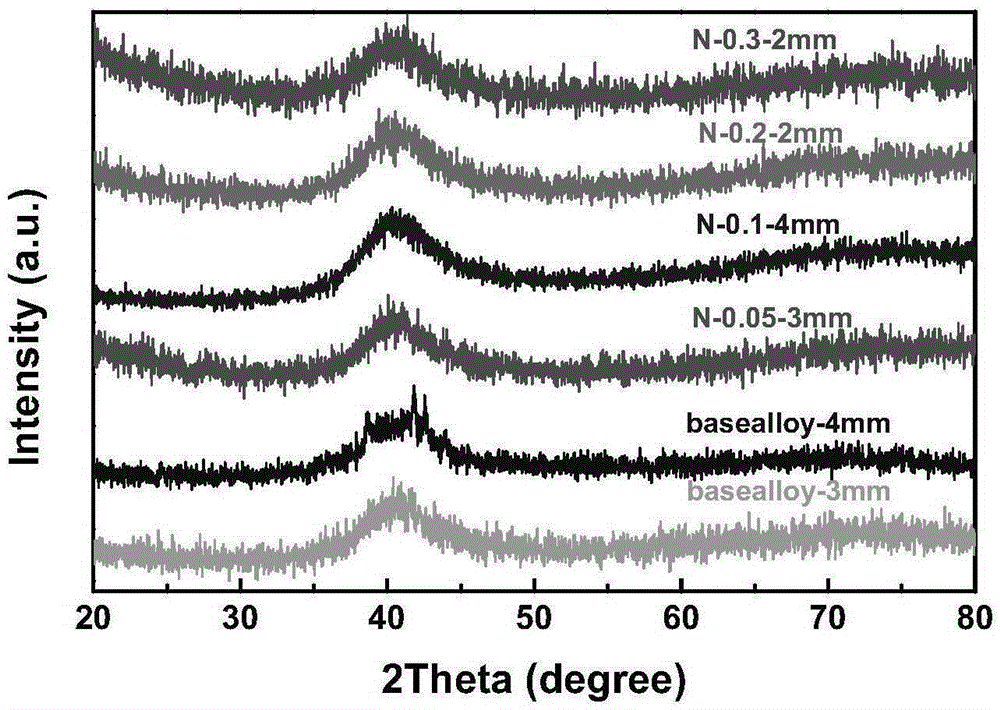

[0060] (Ti 42.5 Cu 40 Zr 10 Ni 5sn 2.5 ) n N p Preparation and Properties of Amorphous Alloys

[0061] 1. Composition design and preparation of bulk amorphous alloys

[0062] Design (Ti 42.5 Cu 40 Zr 10 Ni 5 sn 2.5 ) n N p The composition of the amorphous alloy, where n=99.95, 99.9, 99.8, 99.7, respectively correspond to p=0.05, 0.1, 0.2 and 0.3, are represented by N-0.05, N-0.1, N-0.2 and N-0.3 respectively. The composition of the designed alloy is shown in Table 4.

[0063] (Ti 42.5 Cu 40 Zr 10 Ni 5 sn 2.5 ) n N p The preparation process of the amorphous alloy system is as follows:

[0064] (1) raw material preparation: the smelting raw material that the present invention adopts is high-purity (≥99.9%) Ti, Zr, Cu, Ni and Sn element, removes the scale of raw material surface, carries out weighing proportioning according to molar ratio, in alcohol It is cleaned by ultrasonic vibration and used for smelting alloys. N element is directly added in the form ...

Embodiment 3

[0083] (Ti 42.5 Cu 40 Zr 10 Ni 5 sn 2.5 ) n N p o q The preparation and formation ability of amorphous alloy.

[0084] 1. Composition design and preparation of bulk amorphous alloys

[0085] Design (Ti 42.5 Cu 40 Zr 10 Ni 5 sn 2.5 ) n N p o q Amorphous alloy composition, where p+q=0.2, 0.3, 0.4 and 0.5, q:p=3:1, 4:1, 5:1 and 6:1, where n+p+q=100, respectively with O : N=3:1, 0.2; O: N=3:1, 0.3; O: N=3:1, 0.4; O: N=3:1, 0.5; O: N=4:1, 0.2; O :N=4:1,0.3,O:N=4:1,0.4,O:N=4:1,0.5,O:N=5:1,0.2,O:N=5:1,0.3,O : N=5:1,0.4, O:N=5:1,0.5, O:N=6:1,0.2, O:N=6:1,0.3, O:N=6:1,0.4 and O : N=6:1, 0.5 to represent.

[0086] (Ti 42.5 Cu 40 Zr 10 Ni 5 sn 2.5 ) n N p o q The preparation process of the amorphous alloy system is as follows:

[0087] (1) raw material preparation: the smelting raw material that the present invention adopts is high-purity (≥99.9%) Ti, Zr, Cu, Ni and Sn element, removes the scale of raw material surface, carries out weighing proportioning accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com