Low-cost bulk amorphous alloy

An amorphous alloy, low-cost technology, applied in the field of low-cost bulk amorphous alloys, can solve the problems of difficulty in forming bulk amorphous and high sensitivity to oxygen content, and achieve the advantages of reduced sensitivity, low cost and reduced production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

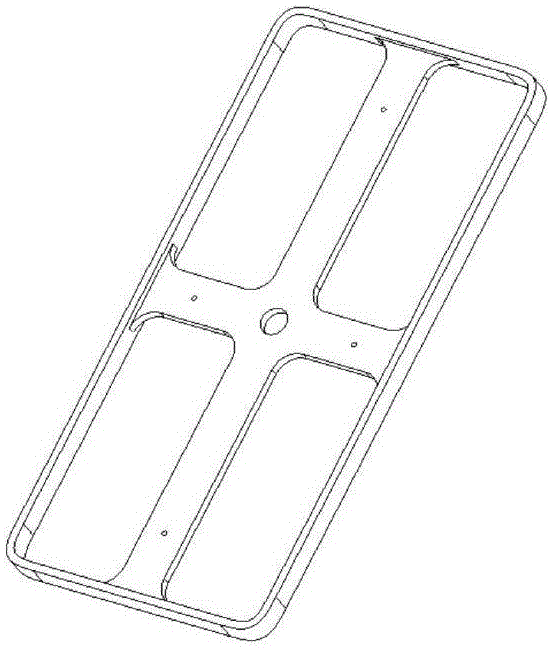

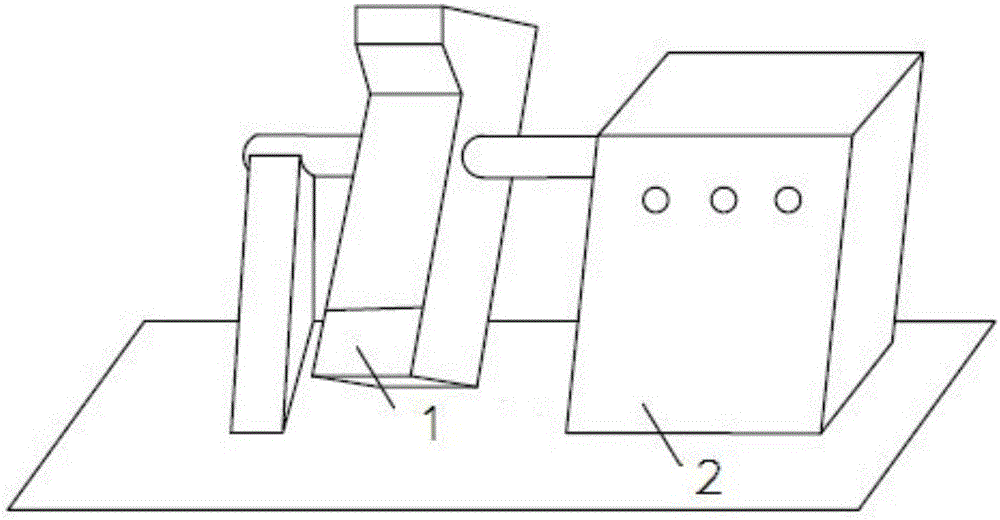

Image

Examples

preparation example Construction

[0014] The preparation technology of bulk amorphous alloy in the present invention is as follows:

[0015] The raw materials Hf, Al, Cu, Ni, Ag, Re, Li, Na, K, Si, Mg, and Ca used in this example are metals of industrial grade purity, Zr and Ti metals are sponge zirconium, sponge titanium, Hf You can also choose sponge zirconium containing a certain amount of Hf. O can be oxygen brought in by metal oxides or other impurities. After the raw materials are prepared according to the atomic percentage, the master alloy ingot is prepared by arc melting or induction melting under the protection of argon. In order to ensure the uniformity of the smelted alloy ingot, when the master alloy ingot is smelted by electric arc, it needs to be turned over 3 to 4 times, and then cast through a Cu mold, the induction heating temperature is about 1000 ℃, and the vacuum degree is 10 -1 ~10 -2 Pa.

specific Embodiment

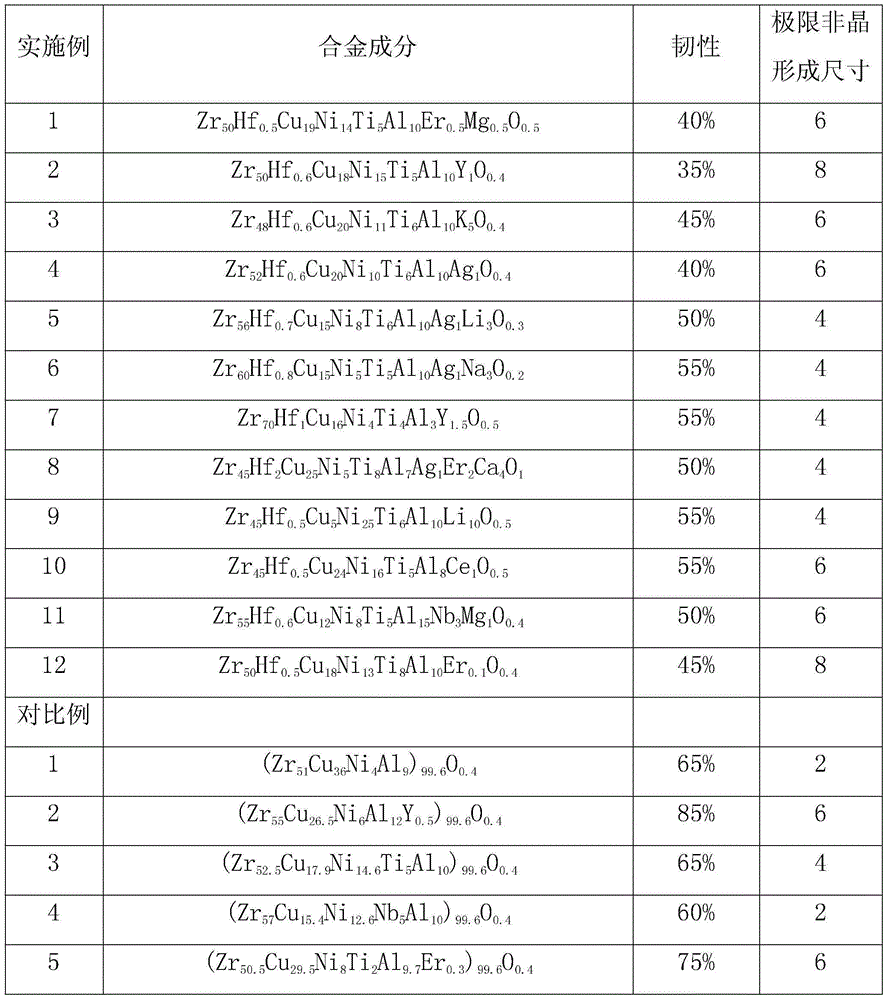

[0016] Specific examples are shown in the following table:

[0017]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com