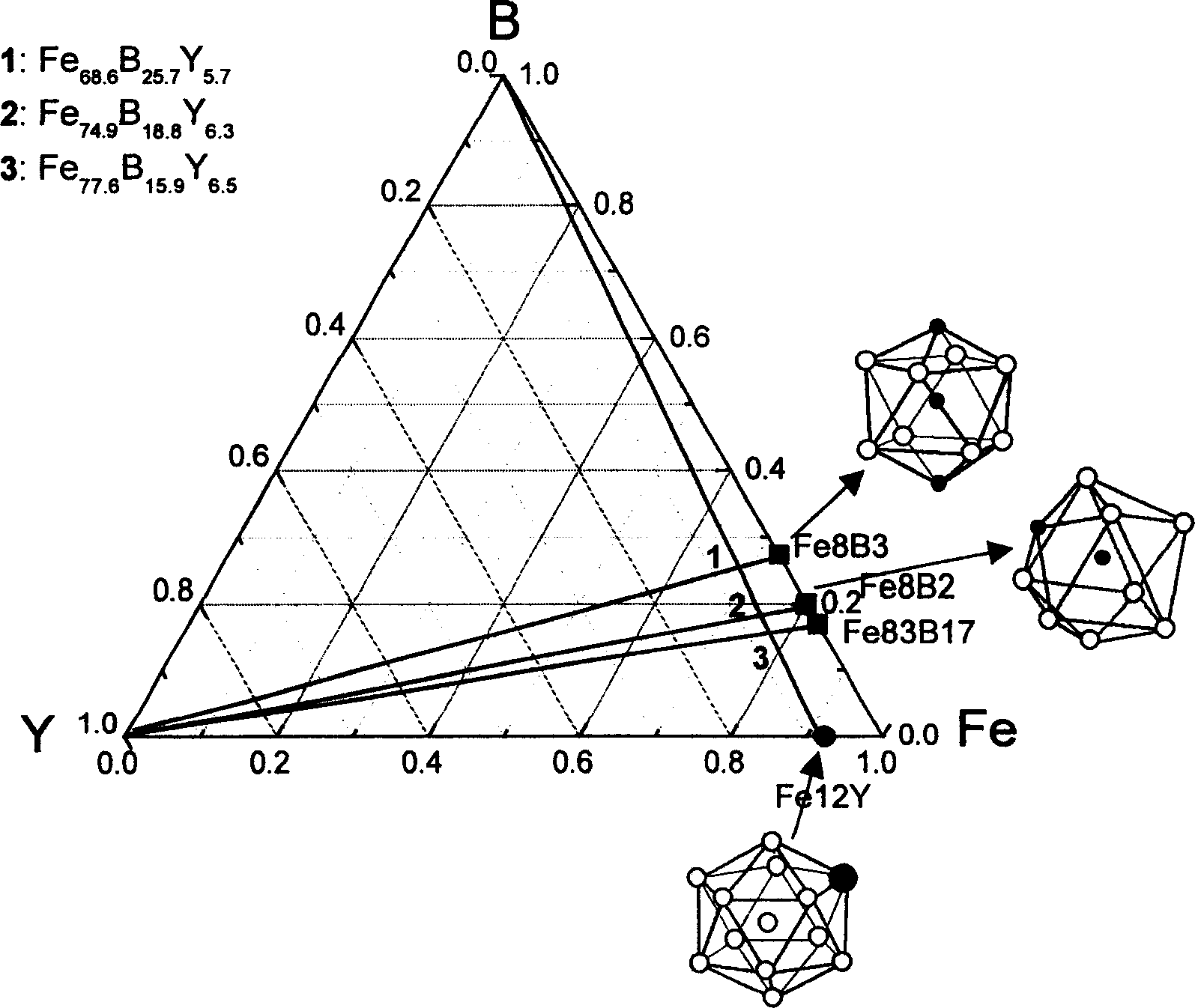

Fe base block amorphous alloy based on Fe-B-Y cluster

A technology of amorphous alloys and clusters, applied in the field of new materials, can solve problems such as difficulty in controlling volatilization of B elements, complex composition selection and optimization, subjectivity and randomness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment one, (Fe 68.6 B 25.7 Y 5.7 ) 0.96 Nb 2 Zr 2 Preparation of Bulk Amorphous Alloy and Its Properties Test

[0038] The first step, the weighing of the composition ratio

[0039] The composition is designed according to the atomic percentage. In the process of weighing the raw materials, the alloy atomic percentage (Fe 68.6 B 25.7 Y 5.7 ) 0.96 Nb 2 Zr 2 Converted to weight percent Fe 76.6 B 5.5 Y 10.2 Nb 3.9 Zr 3.8 , Weigh the raw materials of pure metal Fe, B, Y, Nb and Zr with a purity of 99.9% in proportion, and reserve; and add 10% more B in advance to compensate for the volatilization of the alloy during smelting;

[0040] The second step, the smelting of Fe-B master alloy ingot

[0041] First put the weighed mixture of metal Fe and non-metal B in the water-cooled copper crucible of the arc melting furnace, and use the non-consumable arc melting method to smelt under the protection of argon, and first vacuumize to 10 -2 Pa, then filled wit...

Embodiment 2

[0052] Embodiment two, (Fe 74.9 B 18.8 Y 6.3 ) 0.96 Nb 2 Zr 2 Preparation of Bulk Amorphous Alloy and Its Properties Test

[0053] The first step is to weigh the composition ratio

[0054] The composition is designed according to the atomic percentage. In the process of weighing the raw materials, the alloy atomic percentage (Fe 74.9 B 18.8 Y 6.3 ) 0.96 Nb 2 Zr 2 Converted to weight percent Fe 78.4 B 3.8 Y 10.6 Nb 3.6 Zr 3.6 , Weigh the raw materials of pure metal Fe, B, Y, Nb and Zr with a purity of 99.9% in proportion, and reserve; and add 10% more B in advance to compensate for the volatilization of the alloy during smelting;

[0055] The second step, the smelting of Fe-B master alloy ingot

[0056] After vacuuming, the pressure of filling argon is 0.07MPa, and the current density used for melting is 165A / cm 2 , other are all with the second step in the embodiment one (omitted);

[0057] The third step is to check the composition of Fe-B master alloy ingot ...

Embodiment 3

[0065] Embodiment three, (Fe 77.6 B 15.9 Y 6.5 ) 0.96 Nb 2 Zr 2 Preparation of Bulk Amorphous Alloy and Its Properties Test

[0066] The first step, the weighing of the composition ratio

[0067] The composition is designed according to the atomic percentage. In the process of weighing the raw materials, the alloy atomic percentage (Fe 77.6 B 15.9 Y 6.5 ) 0.96 Nb 2 Zr 2 Converted to weight percent Fe 79.3 B 3.2 Y 10.5 Nb 3.5 Zr 3.5 , Weigh the raw materials of pure metal Fe, B, Y, Nb and Zr with a purity of 99.9% in proportion, and reserve; and add 10% more B in advance to compensate for the volatilization of the alloy during smelting;

[0068] The second step, the smelting of Fe-B master alloy ingot

[0069] After vacuuming, the pressure of filling argon is 0.06MPa, and the current density used for melting is 175A / cm 2 , other are all with the second step in the embodiment one (omitted);

[0070] The third step is to check the composition of Fe-B master all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com