Fe-based soft magnetic amorphous alloy with high corrosion resistance and preparation method thereof

An amorphous alloy, high corrosion resistance technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of alloy saturation magnetic induction intensity and Curie temperature reduction, loss of ferromagnetism, etc., and achieve the effect of low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

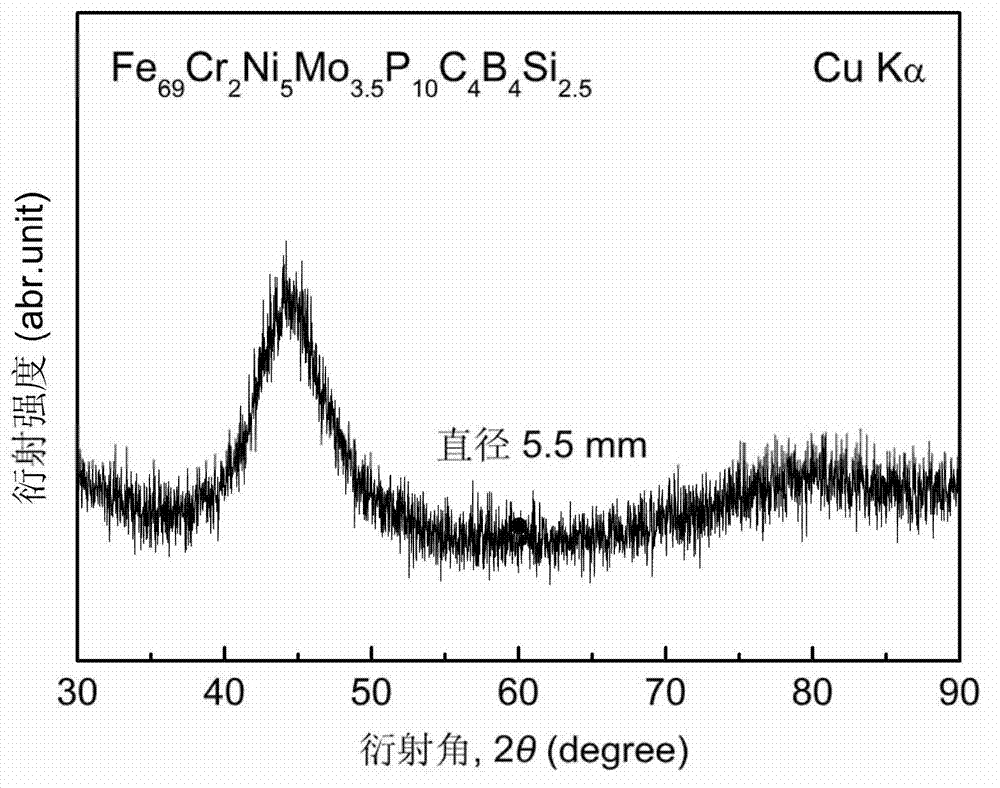

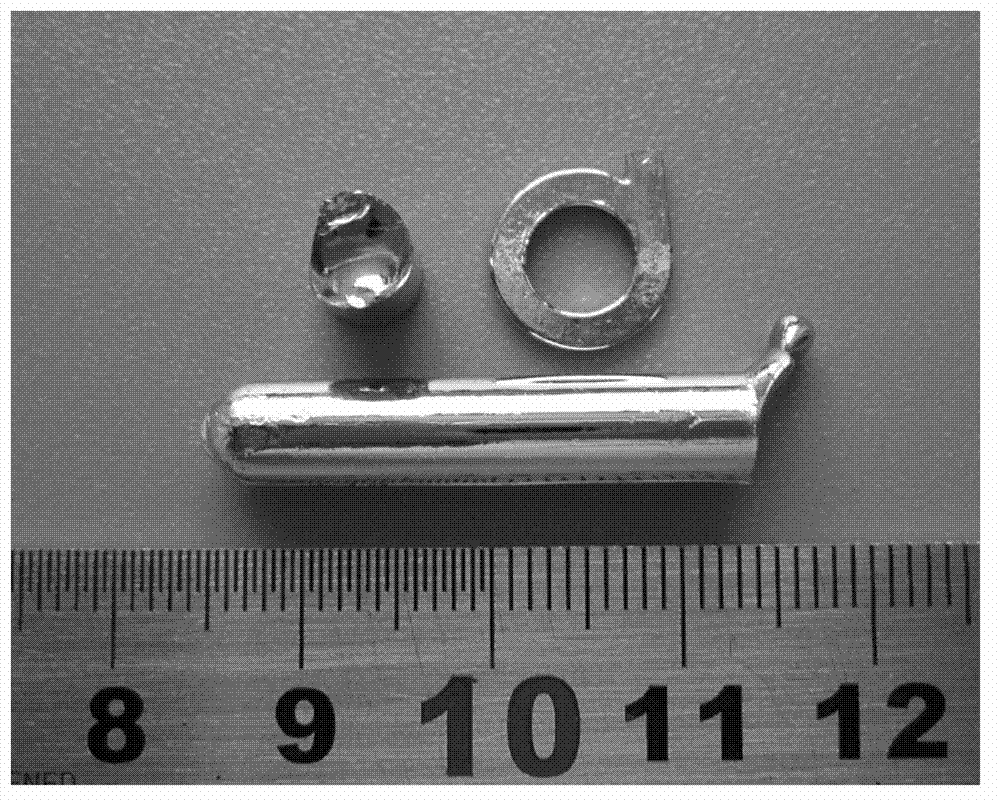

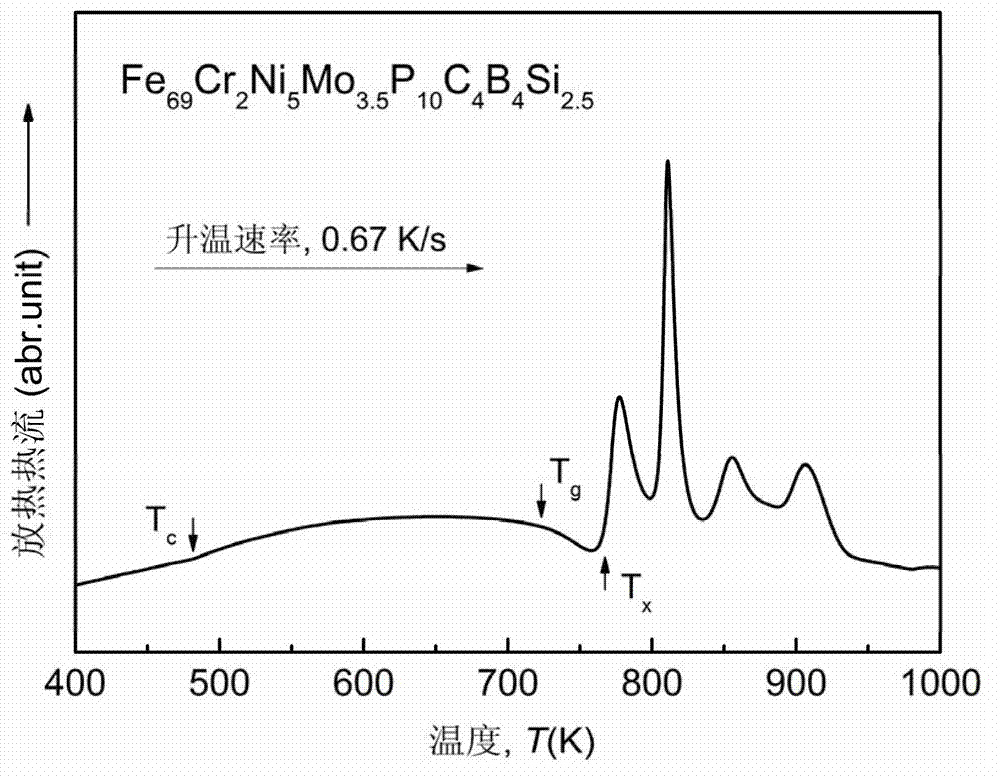

[0036] In the present embodiment 1-5, the iron-based soft magnetic amorphous alloy is an amorphous alloy strip or an amorphous alloy rod, and its molecular formula is Fe 71-x Cr x Ni 5 Mo 3.5 P 10 C 4 B 4 Si 2.5 , where x is 0, 1, 2, 3 or 4, see Table 1 below.

[0037] The specific preparation method of the above-mentioned iron-based soft magnetic amorphous alloy is as follows:

[0038] Step 1: According to the molecular formula Fe 71-x Cr x Ni 5 Mo 3.5 P 10 C 4 B 4 Si 2.5 (x=0,1,2,3,4) Raw materials Fe, Cr, Ni, Mo, P, C, B and Si are batched, specifically: convert the alloy atomic percentage to mass percentage, and weigh Fe in proportion , Cr, Ni, Mo, FeP, FeC, B, Si, where P and C are added in the form of FeP and FeC alloys respectively, and the purity of the rest of the raw materials is greater than 99%;

[0039] Step 2: Put the raw materials prepared in step 1 into the high-frequency induction melting furnace, and vacuumize to 5×10 -3 Pa, fill in an approp...

Embodiment 6

[0053] This embodiment adopts 1J36 alloy. Its performance was measured according to the measurement method in Examples 1-5, and the results were shown in the table above.

[0054] It can be seen from the above table that compared with the 1J36 alloy, the iron-based soft magnetic amorphous alloys in Examples 2-5 of the present invention have high corrosion resistance, high amorphous forming ability and excellent magnetic properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com