Cobalt iron base block body metal glass with super-large super-cooling interval and preparation method thereof

A bulk metal, cobalt-iron-based technology, applied in the field of amorphous alloys, can solve the problems of restricted application, limited application, high raw material cost, etc., and achieve excellent mechanical properties, good superplastic forming processability, and excellent comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, the molecular formula of the cobalt-iron-based bulk metallic glass is (Co 0.5 f 0.5 ) 62 Nb 6 Dy 2 B 30 , its preparation method is as follows:

[0042] Co, Fe, Nb, Dy and B components with a raw material purity of not less than 99.5wt% are prepared in a molar ratio of 31:31:6:2:30, mixed and smelted in an electric arc furnace with an argon atmosphere 3 to 4 times, after cooling to get (Co 0.5 Fe 0.5 ) 62 Nb 6 Dy 2 B 30 Master alloy ingot; then using vacuum copper mold casting method, this ingot is re-melted to obtain master alloy melt, and then the master alloy melt is pressed into the copper mold to obtain the composition (Co 0.5 Fe 0.5 ) 62 Nb 6 Dy 2 B 30 , bulk metallic glass amorphous rod samples with diameters of 2mm and 3mm, and amorphous sheet samples with a size of 17mm×10mm×1mm.

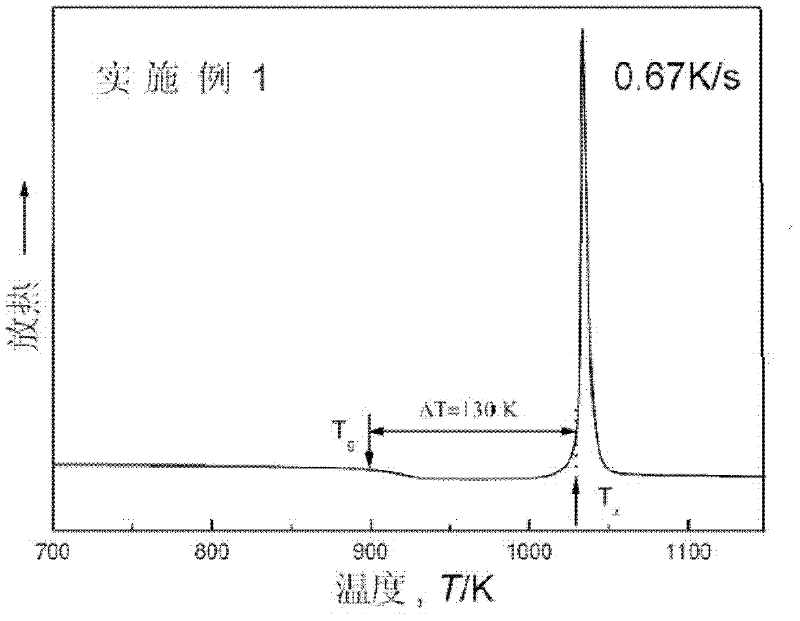

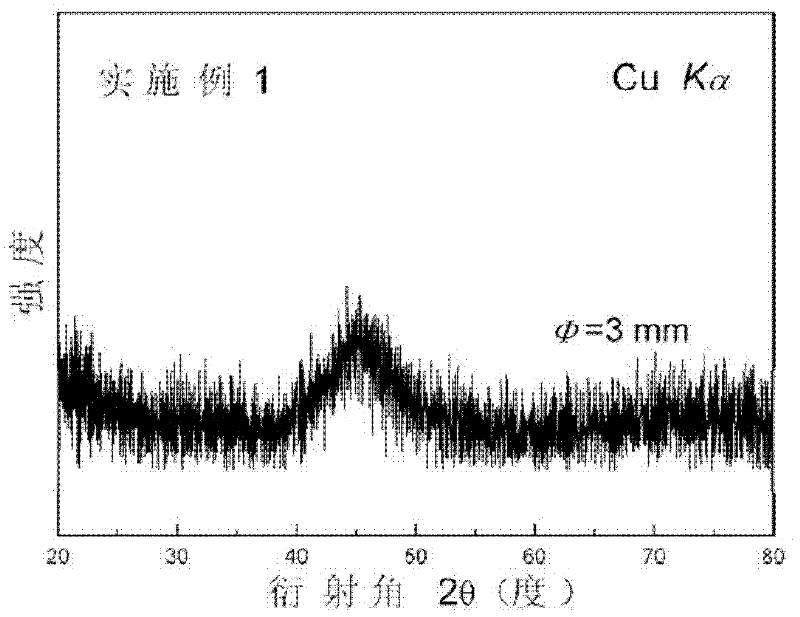

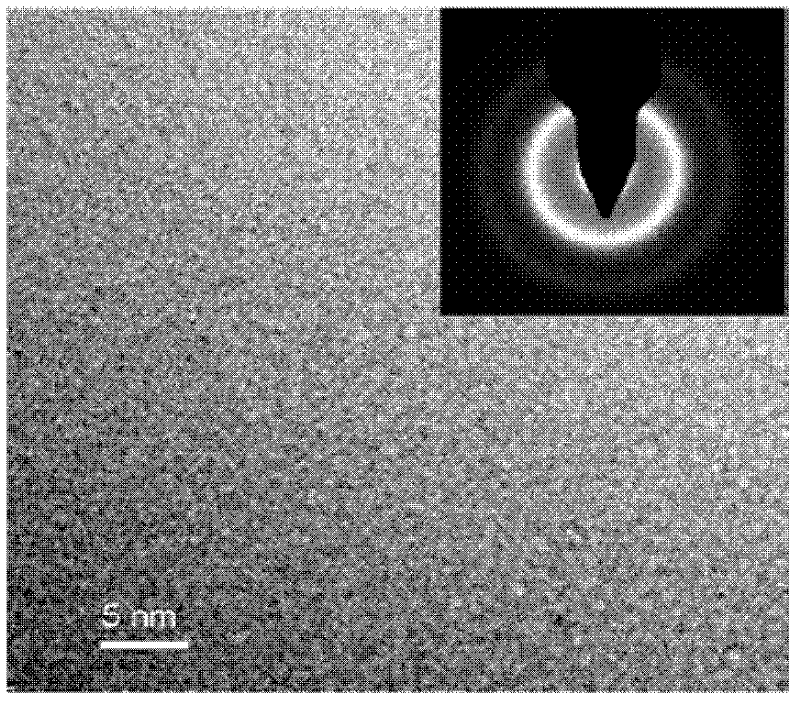

[0043] The above bulk metallic glass amorphous samples were tested as follows:

[0044] X-ray diffraction (XRD) was used to analyze the structur...

Embodiment 2

[0056] In this embodiment, the molecular formula of the cobalt-iron-based bulk metallic glass is (Co 0.5 Fe 0.5 ) 61 Nb 6 Dy 3 B 30 , its preparation method is substantially the same as in Example 1, specifically as follows:

[0057] Co, Fe, Nb, Dy and B components with a raw material purity of not less than 99.5wt% are prepared in a molar ratio of 30.5:30.5:6:3:30, mixed and smelted in an electric arc furnace with an argon atmosphere 3 to 4 times, after cooling to get (Co 0.5 Fe 0.5 ) 62 Nb 6 Dy 2 B 30 Master alloy ingot; then using vacuum copper mold casting method, this ingot is re-melted to obtain master alloy melt, and then the master alloy melt is pressed into the copper mold to obtain the composition (Co 0.5 Fe 0.5 ) 61 Nb 6 Dy 3 B 30 , bulk metallic glass amorphous rod samples with diameters of 3mm and 4mm, and amorphous sheet samples with a size of 17mm×10mm×1mm.

[0058] The same method and equipment as in Example 1 were used to test the bulk metalli...

Embodiment 3~23

[0064] Similar to Example 1, the molecular formulas of the alloy components of the cobalt-iron-based bulk metallic glasses in Examples 3 to 23 are the molecular formulas shown in the following table, respectively. Its preparation method is basically the same as Example 1. The same method and equipment as in Example 1 were used to test the above bulk metallic glass amorphous samples respectively. The critical dimensions, thermodynamic parameters, mechanical properties and soft magnetic properties of the tested samples are shown in Table 1.

[0065] The symbols in Table 1 have the following meanings:

[0066] D——sample diameter under the experimental conditions; T g ——Glass transition temperature; ΔT——Width of supercooled liquid phase region; T 1 ——liquidus temperature; σ——compression fracture strength; H V - Vickers hardness; H c ——coercive force; μ e ——Effective magnetic permeability (1A / m, 1kHz); M s - Saturation magnetization.

[0067] Table 1: Alloy composition, cri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com