Patents

Literature

40results about How to "Simplify the forging process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

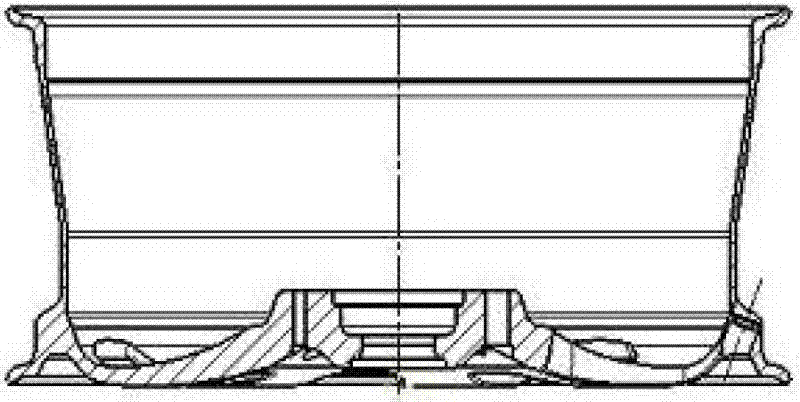

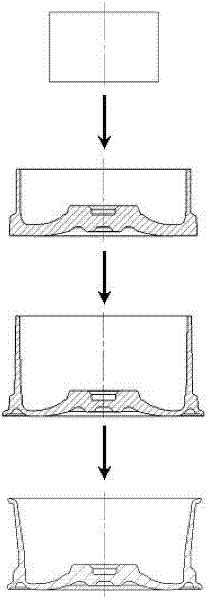

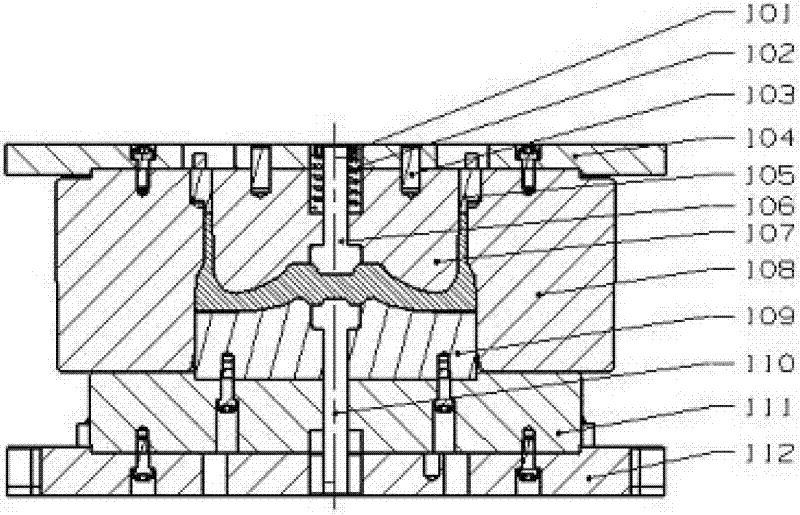

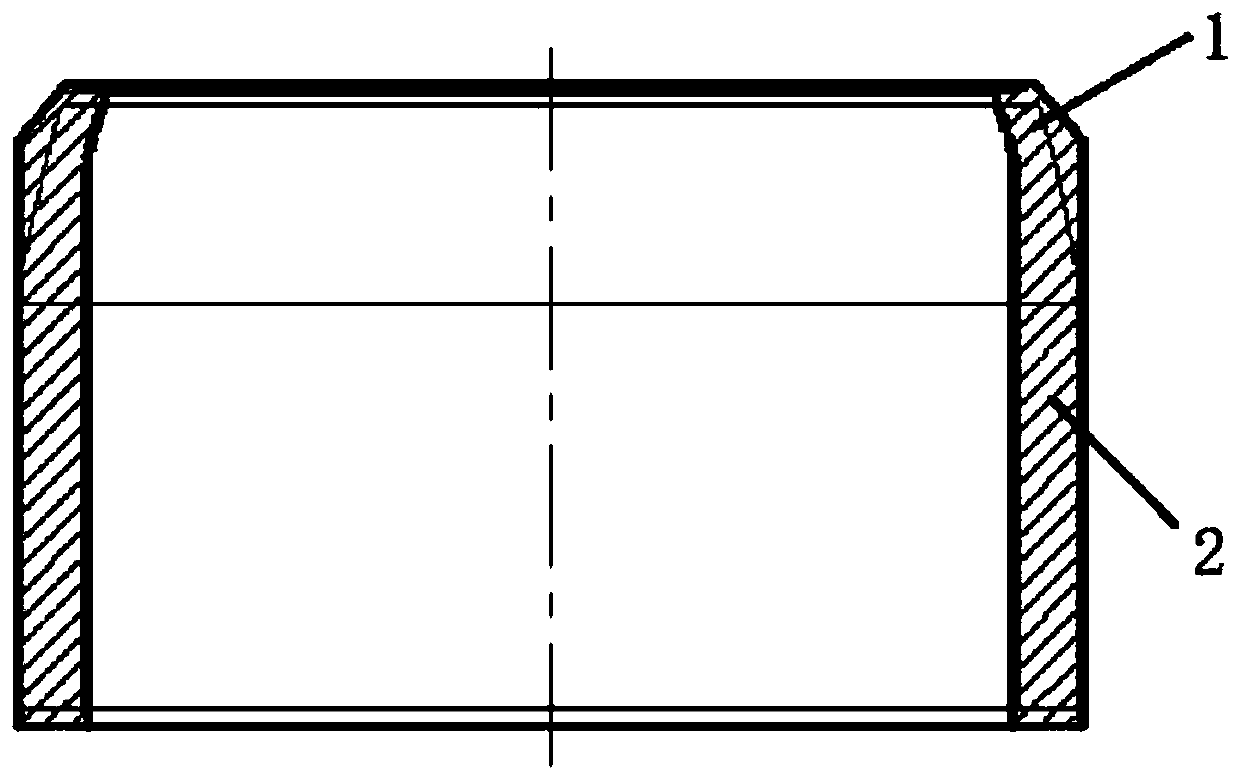

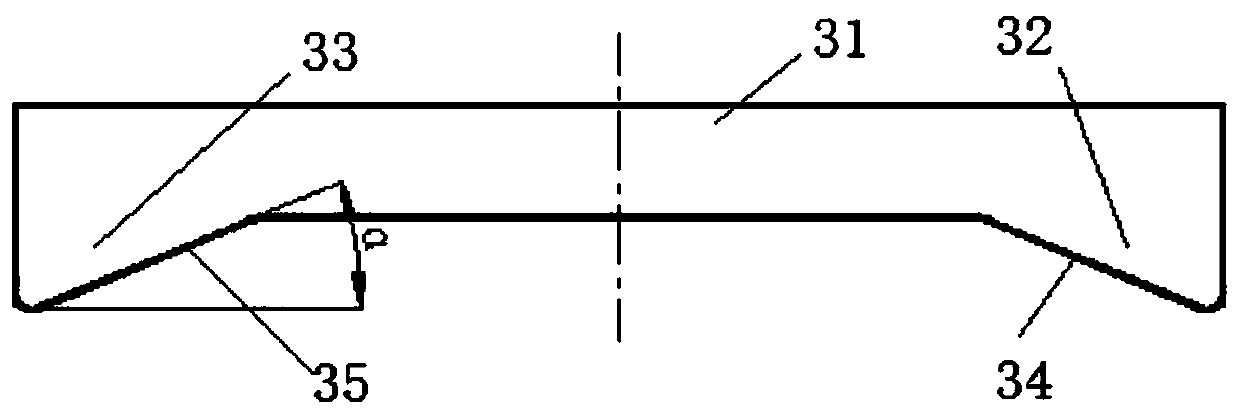

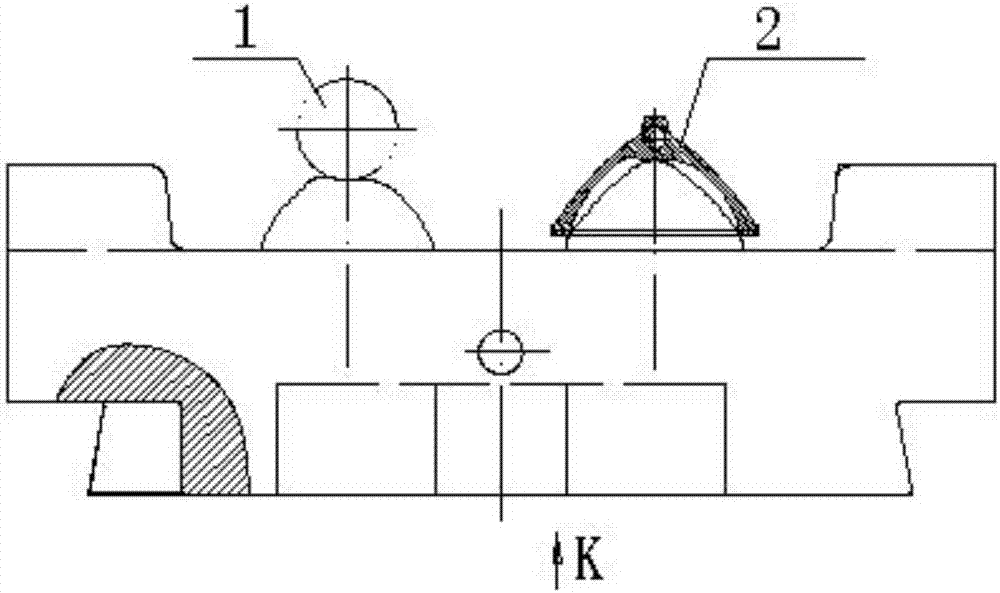

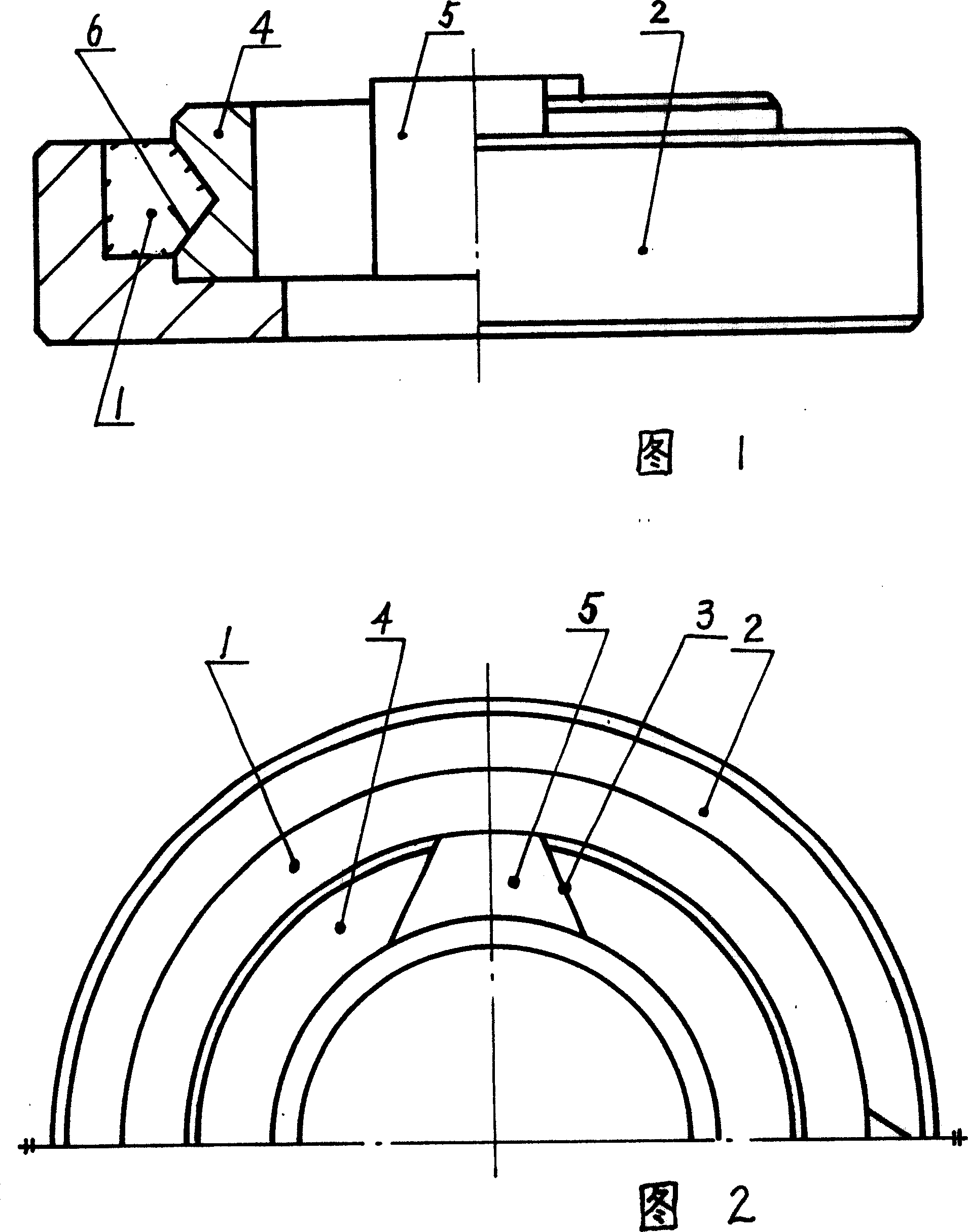

Magnesium alloy wheel forging forming method and die

InactiveCN102632185ASimplify the forging processThe mold is simple and efficientForging/hammering/pressing machinesWheelsForgingForming processes

The invention discloses a magnesium alloy wheel forging forming method and a die, belonging to magnesium alloy wheel forging forming process and process equipment. The method comprises pre-forging, final-forging and flaring forming; and the used die comprises a pre-forging die, a final-forging die and a flaring forming die. According to the method, in the pre-forging, formation of a hub of a wheel and pre-formation of a wheel arm and a felloe are carried out; in the final-forging, the wheel arm, an outer wheel rim and a cylindrical felloe having an inner wall with a certain taper and a vertical outer wall; and in the flaring forming, the final shape of the felloe of the wheel and a formed inner rim are obtained. The magnesium alloy wheel forging forming method provided by the invention has the advantages that process is simple, the surface and interior quality of the wheel forging piece are good, the mechanical property of the wheel forging piece is excellent, industrial large-scale production is easy to realize, and the like; and the die disclosed by the invention is reliable in work, convenient to regulate and long in service life.

Owner:秦皇岛燕大现代集成制造技术开发有限公司

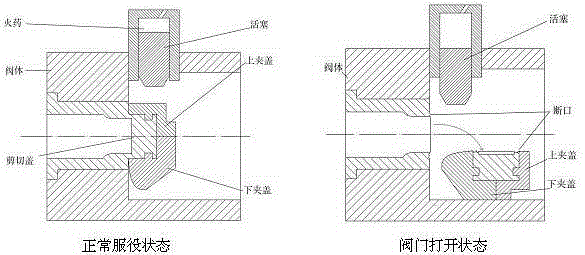

Crystalline grain control method for GH690 alloy shear cover of explosion valve

ActiveCN105170865AAddressing inhomogeneitySolve the problem of abnormal grain growthValve arrangementsMetal-working apparatusAlloyMaterials processing

The invention discloses a crystalline grain control method for a GH690 alloy shear cover of an explosion valve and belongs to the technical field of material machining. The method aims to solve the problems that the structure of a forge piece of the GH690 alloy material shear cover of the explosion valve is not even, and crystalline grains abnormally grow up. A heat treatment machining is organically combined with a forging machining, and the machining method that large deformation free forging is implemented at a high temperature (1020 DEG C to 1150 DEG C), small deformation foetal die forging is implemented at a medium temperature (710 DEG C to 850 DEG C), and the inhibition function of carbide second-phase particles on moving of a grain boundary is used for restraining the abnormal growth of the crystalline grains in forging machining of the shear cover in an auxiliary mode is provided. According to the crystalline grain control method for the GH690 alloy shear cover of the explosion valve, the forging piece forming and crystalline grain refinement are conducted synchronously, and the shear cover forge piece is obtained through heating twice; the machining limitation that a forging piece with the simple structure is subjected to high-temperature multiple-time hierarchical forging machining at present is overcome; the forging heating number is reduced; the follow-up heating treatment of the forging piece of the GH690 nickel-based alloy sheer cover is avoided. The structure with even carbides and refined crystalline grains of the GH690 alloy shear cover of the explosion valve forged through the method can be obtained.

Owner:DALIAN UNIV OF TECH +1

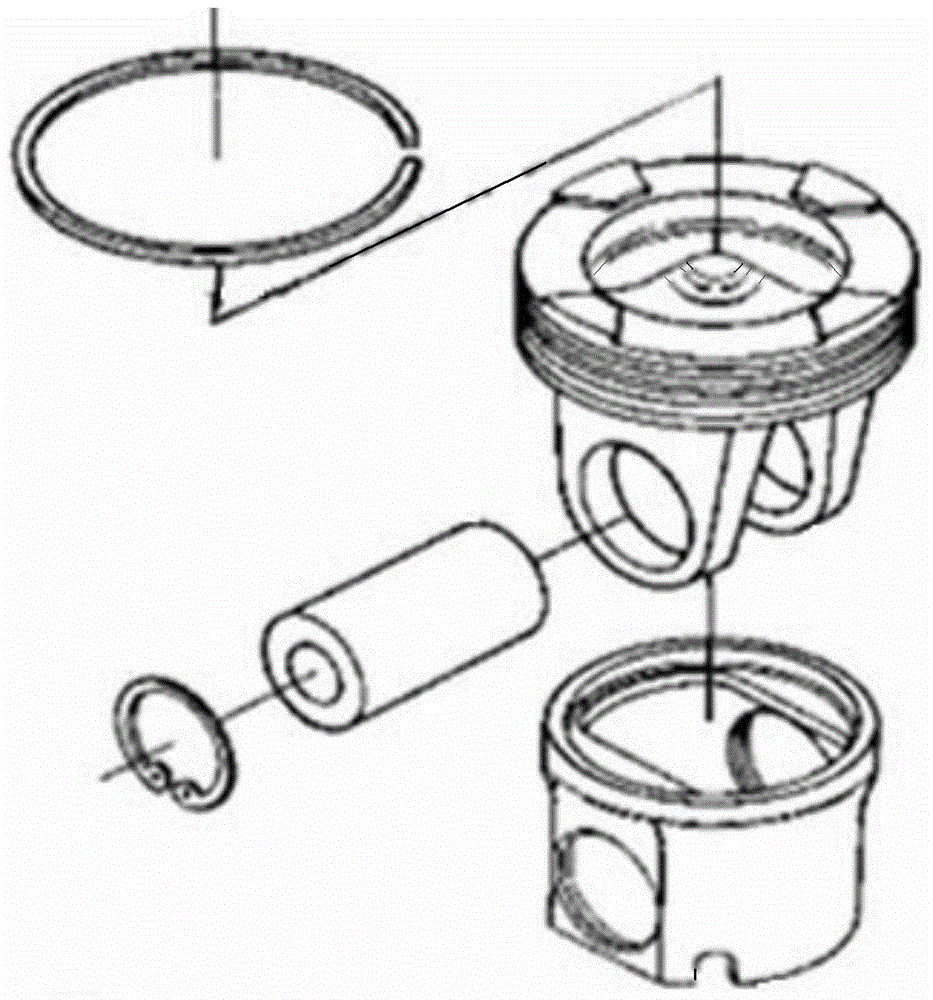

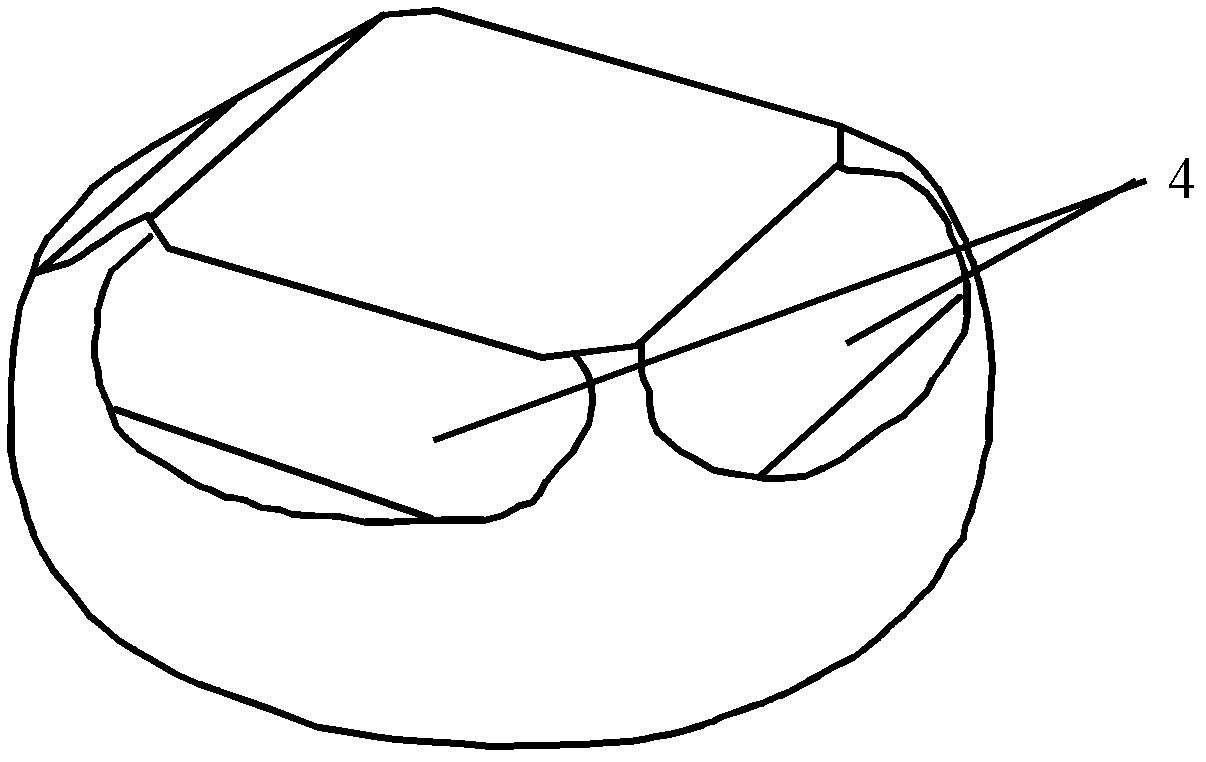

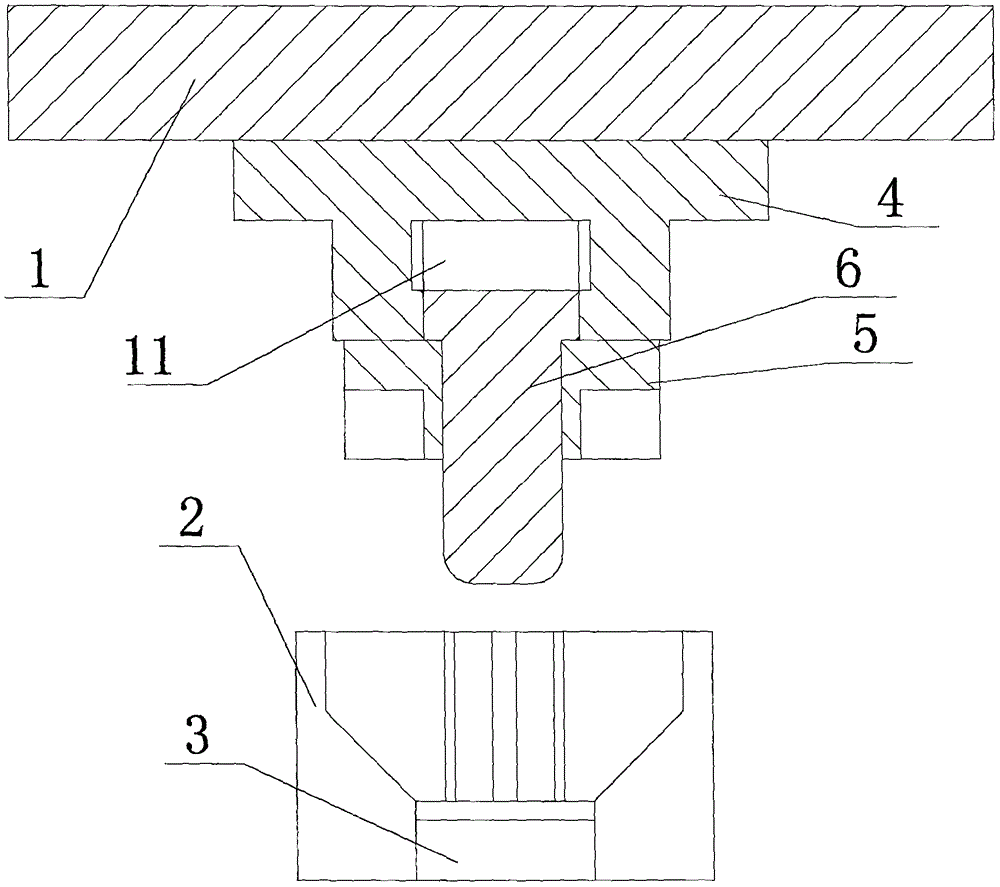

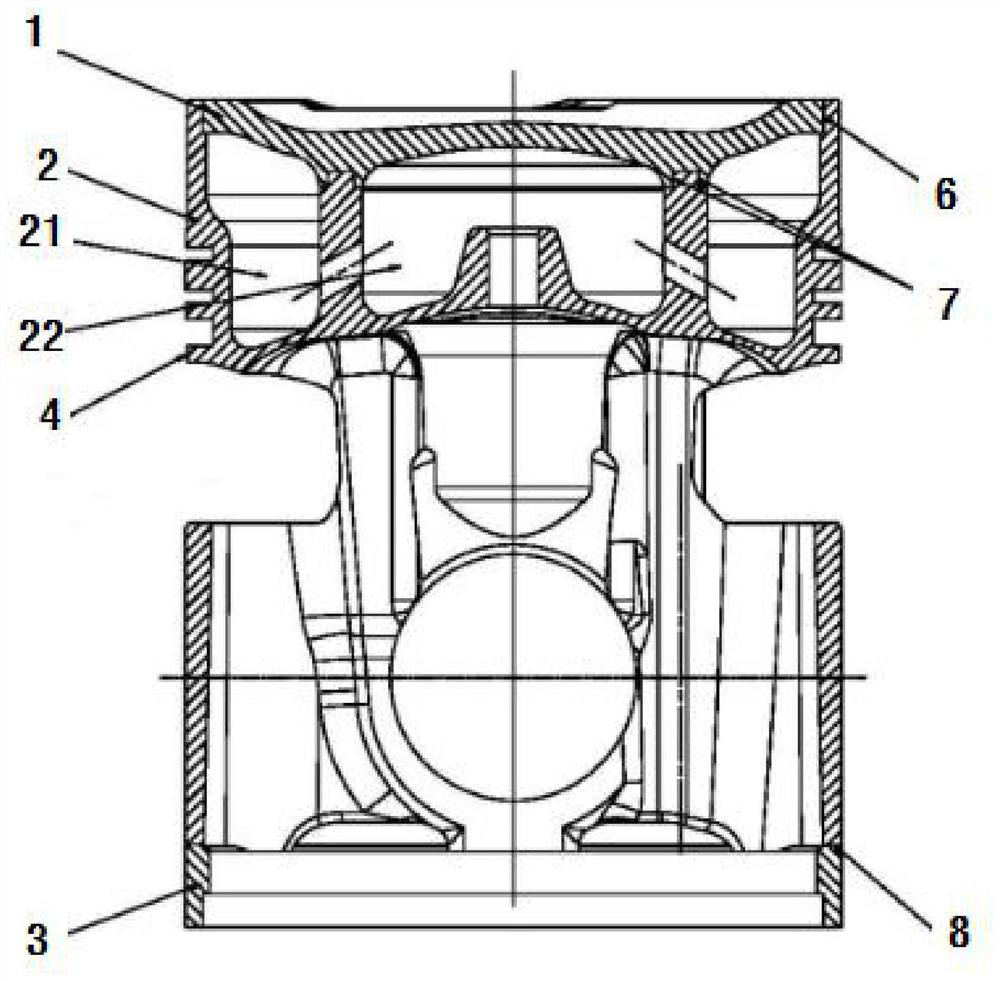

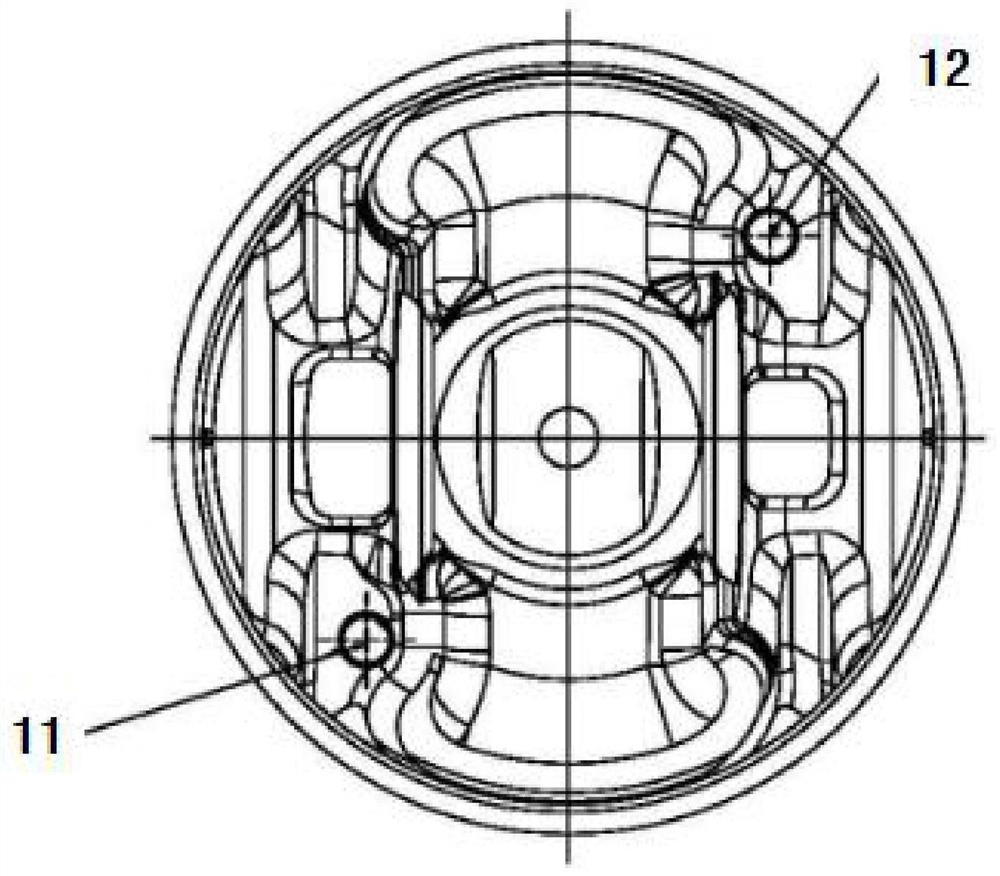

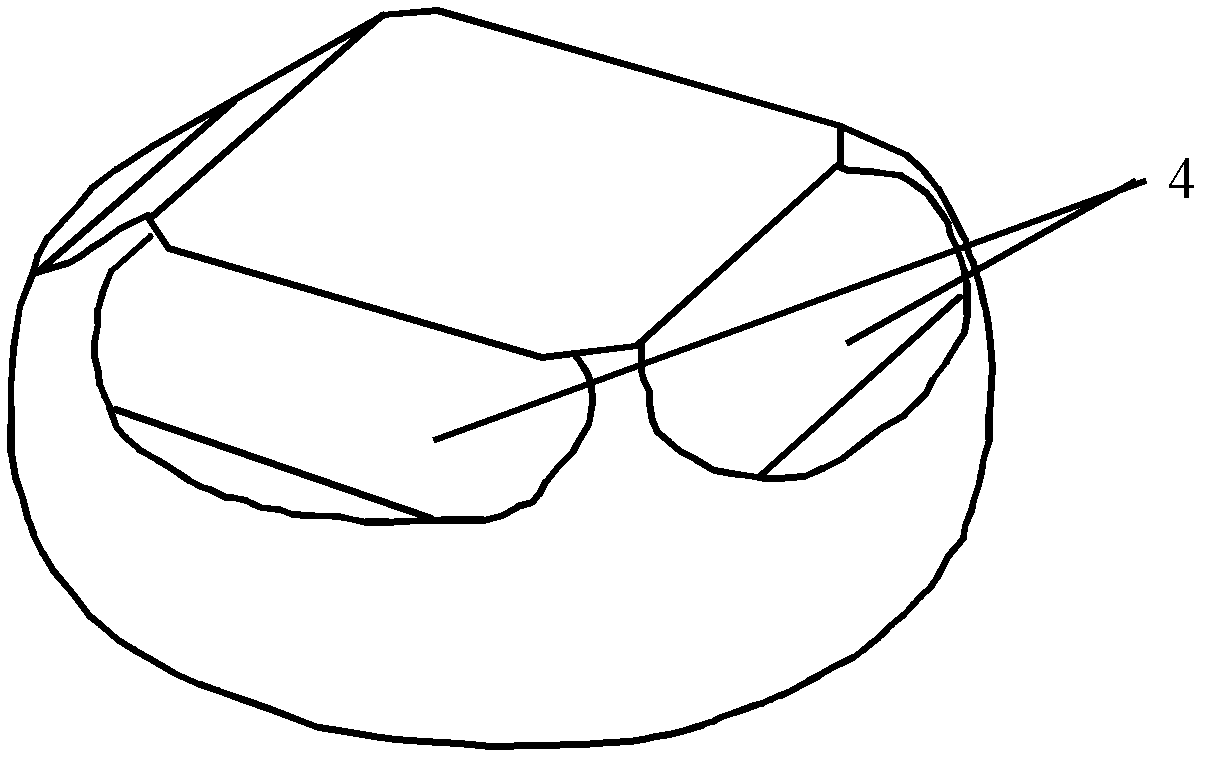

Engine piston

InactiveCN105332813ASmall heightReduce weightMachines/enginesPistonsCombustion chamberControl theory

The invention relates to the technical field of structural design of engine components, in particular to an engine piston. The engine piston comprises a piston head (1) and a piston skirt (2) which are of split structures; an annular groove (4), a burning chamber (5) and an inner cooling oil channel (6) are machined in the piston head (1), and a single middle-mounted pin base (7) is arranged in the middle of a cavity of the piston head (1); a pin hole (11) perpendicular to the axis of the piston head (1) is machined in one end, far away from the piston head (1), of the middle-mounted pin base (7); the piston skirt (2) is in a barrel shape; the middle-mounted pin base (7) of the piston head (1) penetrates the barrel-shaped inner cavity from one end of the piston skirt (2); and the piston skirt (2) relatively penetrates into the middle-mounted pin base (7) in the inner cavity, a pin base hole (8) coaxial with a pin hole (11) of the middle-mounted pin base (7) is formed in the lateral wall, and pin connection of a three-pin-base structure is achieved by the piston head (1) and the piston skirt (2) through the above structure.

Owner:强道前

Forging and forming method of integral hinge beam

InactiveCN102513482AImprove performanceExtended service lifeMetal-working apparatusUltra high pressureDiameter ratio

The invention belongs to the field of the forging and forming of the large forging and particularly relates to a forging and forming method of an integral hinge beam in a cubic press used for ultra-high pressure synthesis. A steel ingot is heated to the initial forging temperature according to the heating specification, wherein, reheating according to the heating specification during each work procedure is needed, and the initial forging temperature is not lower than 900 DEG C; after the steel ingot is upset to have the height-diameter ratio of 1, the billet is upset by using a swage into a round disc with an inclined surface at the bottom; after the round-disc shaped billet is drawn out into the cross-shaped billet, tong handles are cut off, a central hole is punched, and the billet is mechanically processed. Due to the adoption of the forging and forming method of the integral hinge beam, the problem on the central compaction of the hinge beam in the forging process is solved, the performance of the product is improved, the service life of the product is prolonged, the process of forging for producing is simplified, the utilization rate of the steel ingot is improved, the production efficiency is enhanced, and the production cost is reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

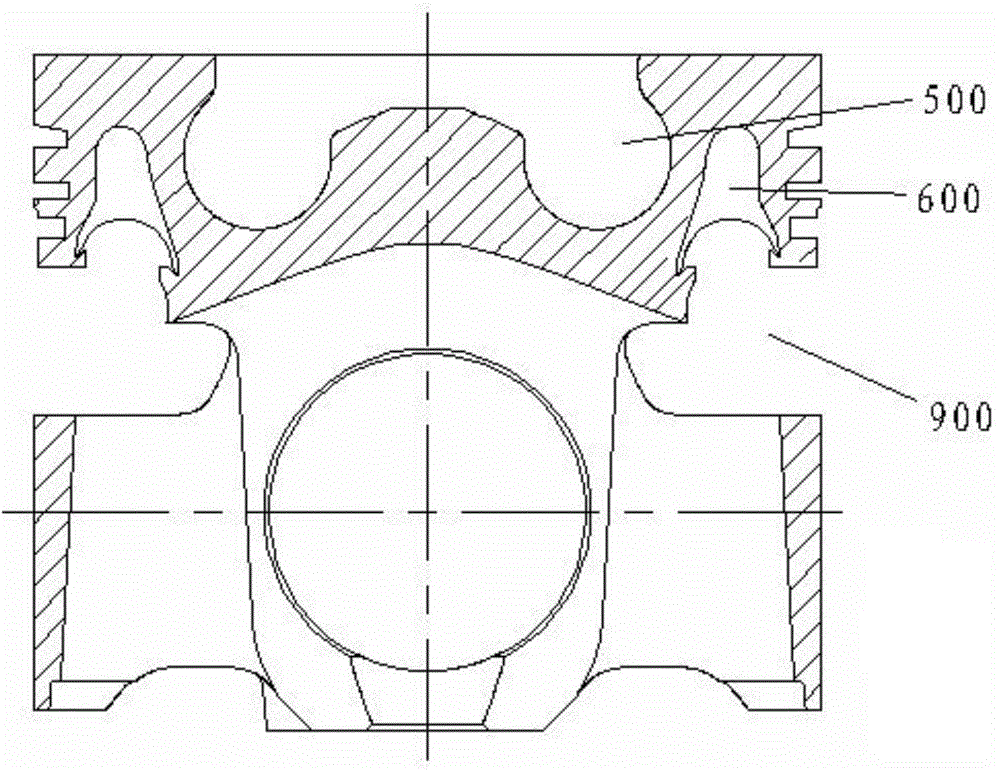

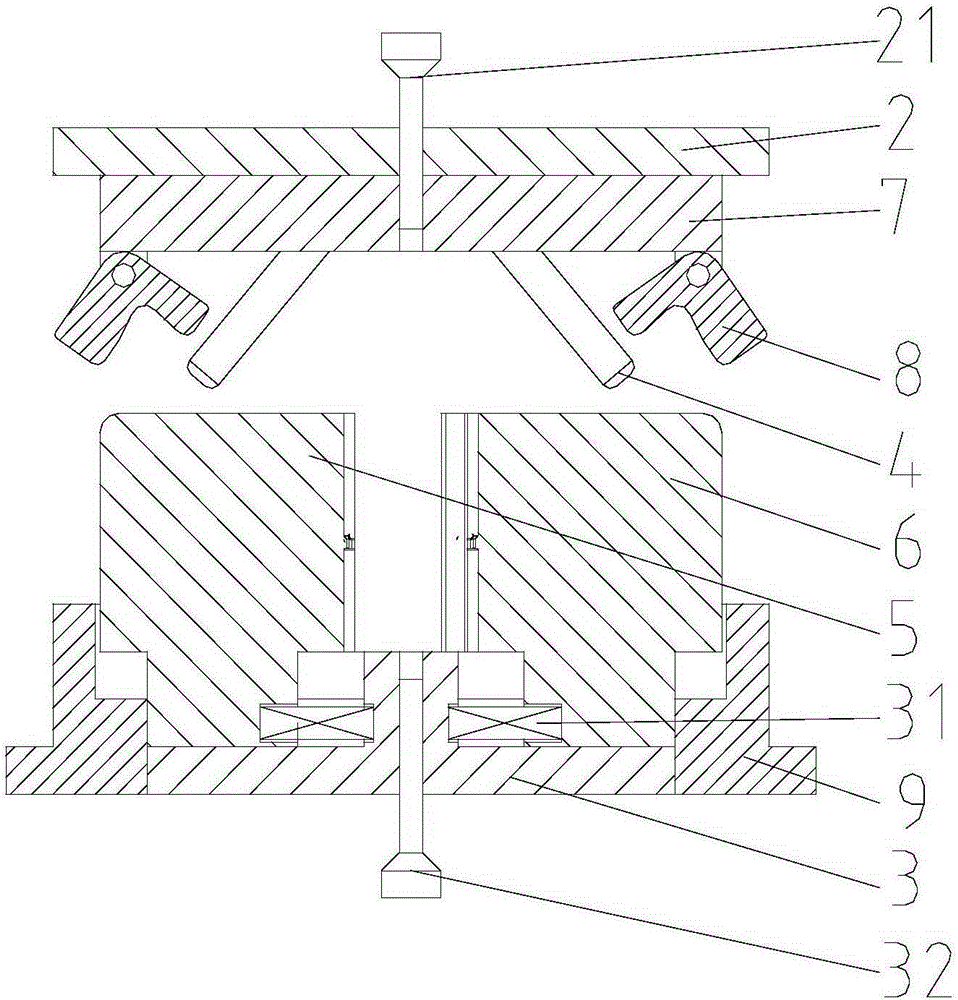

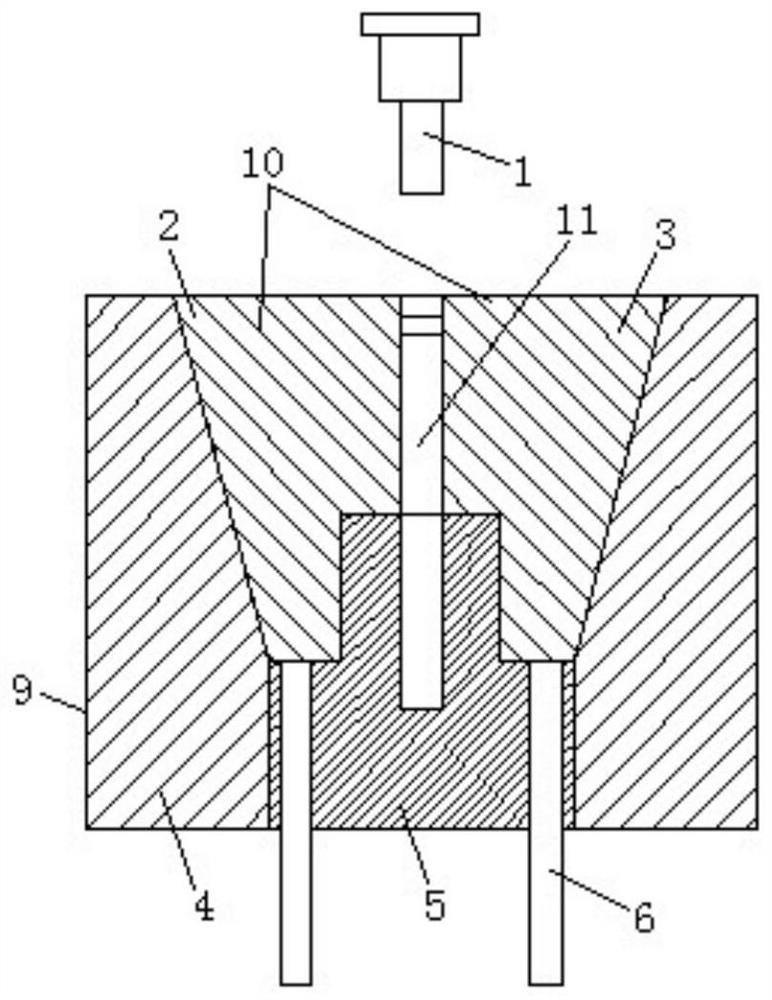

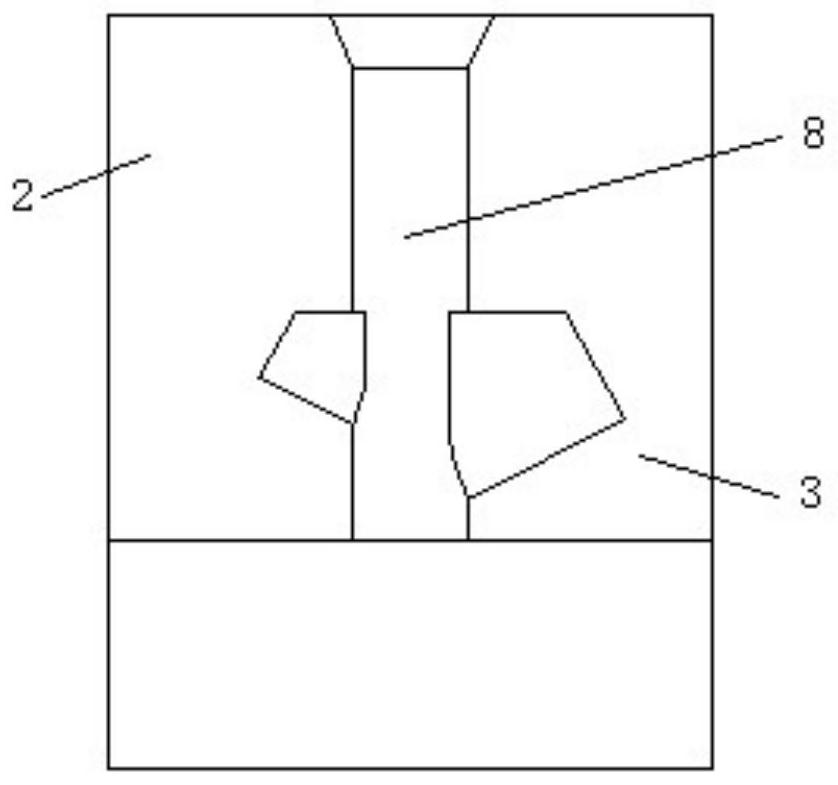

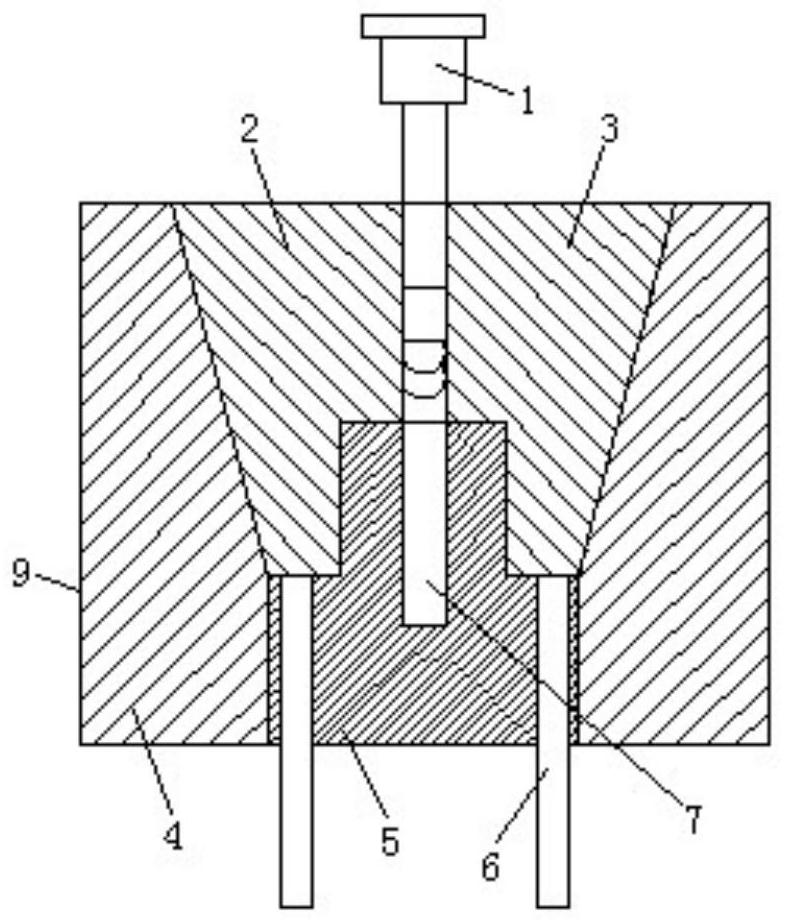

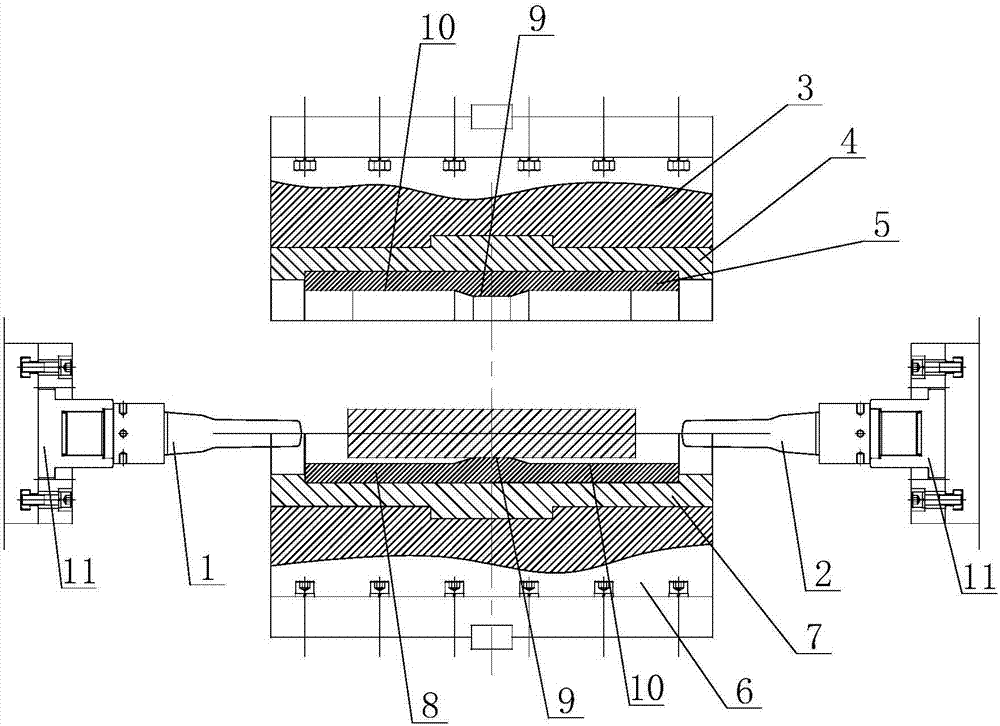

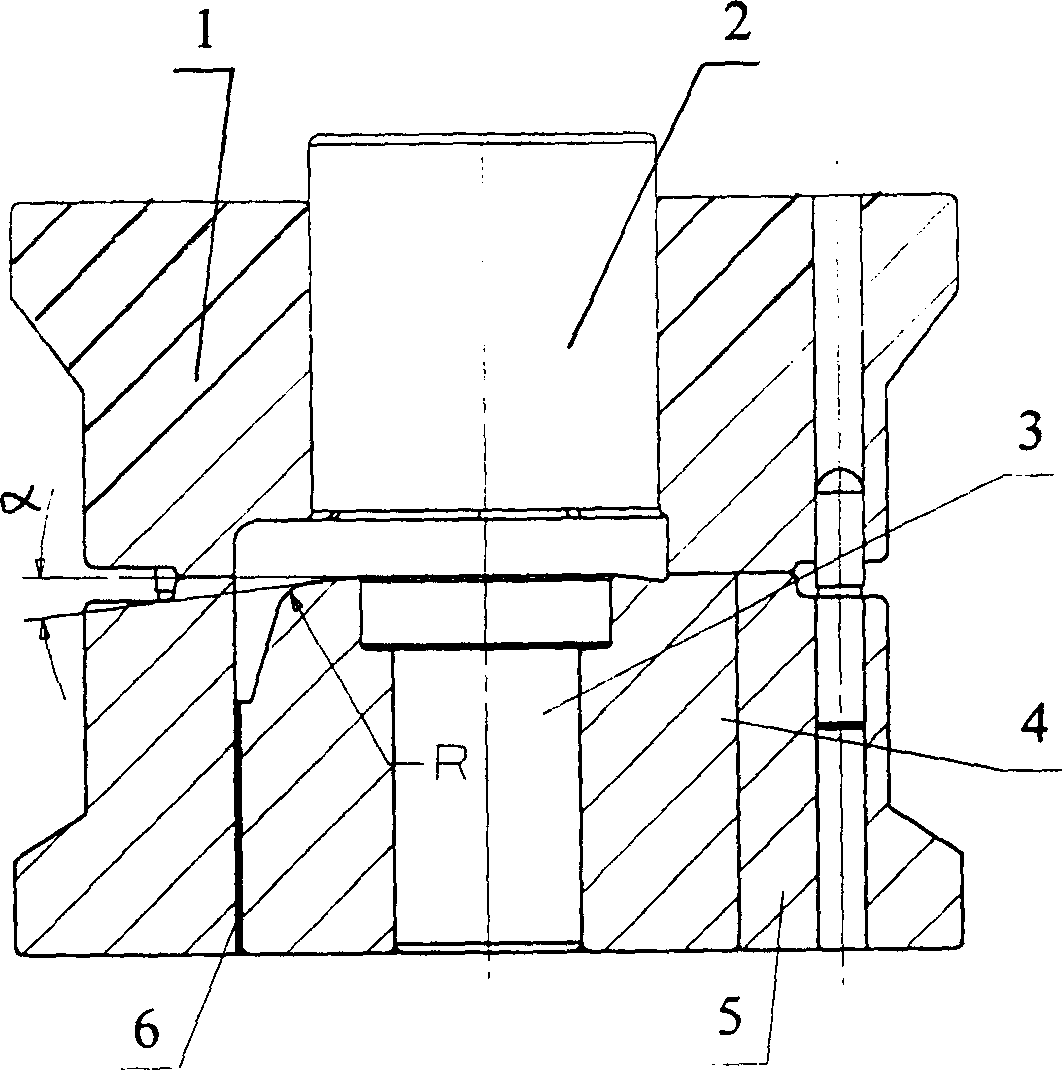

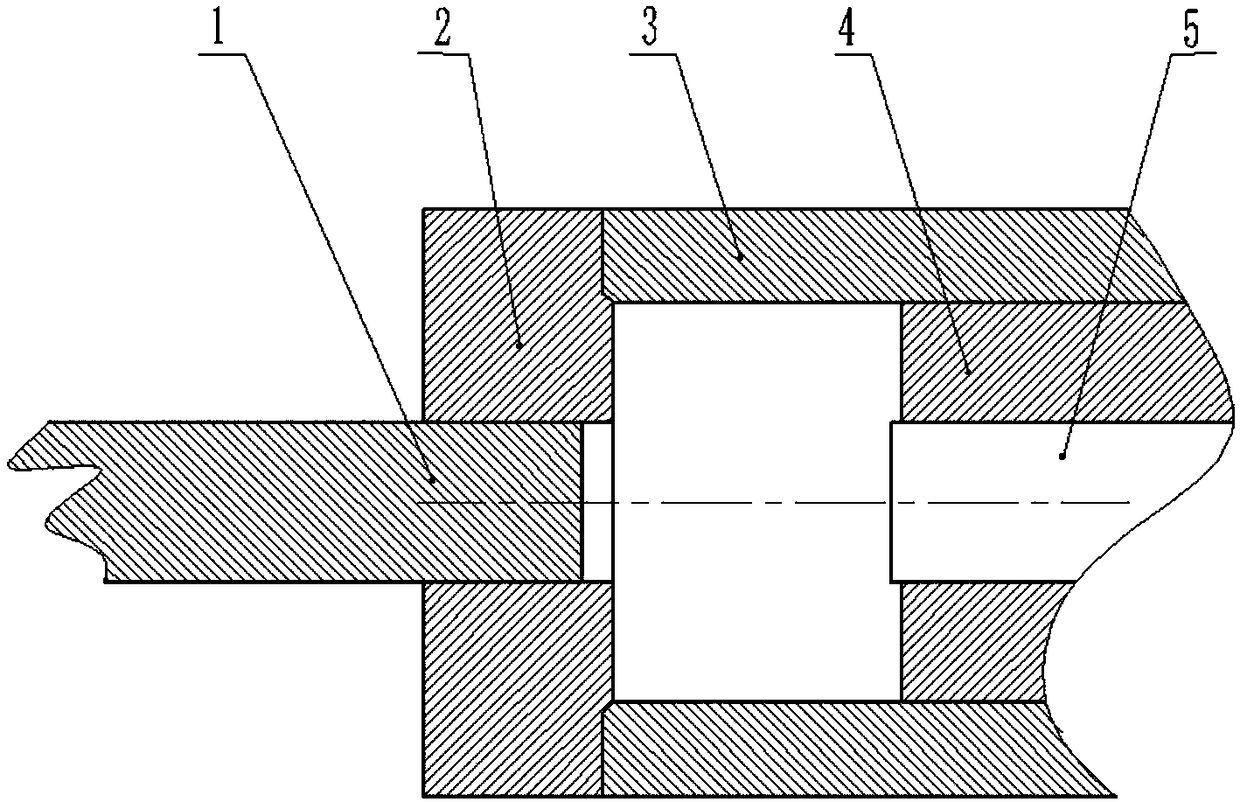

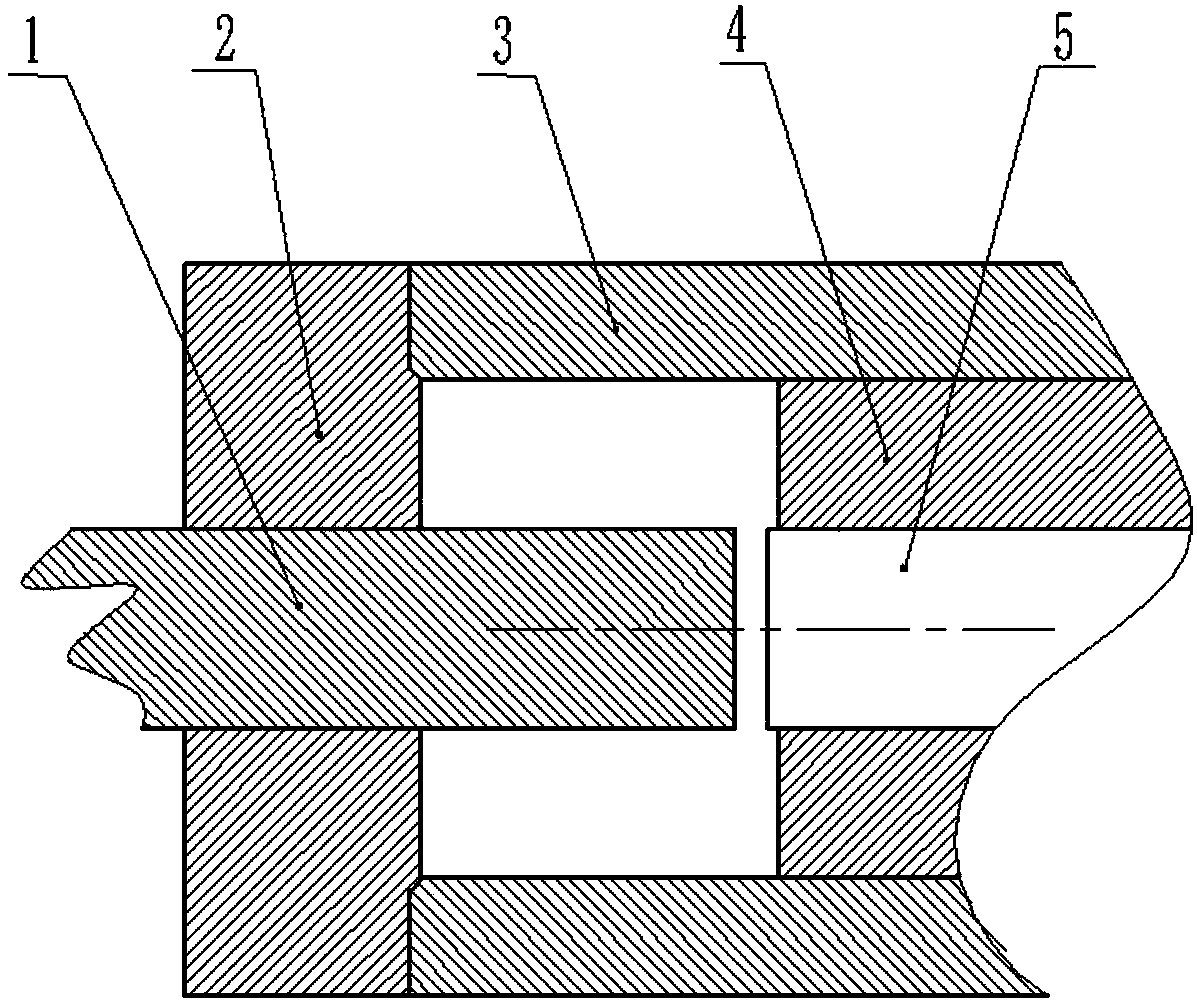

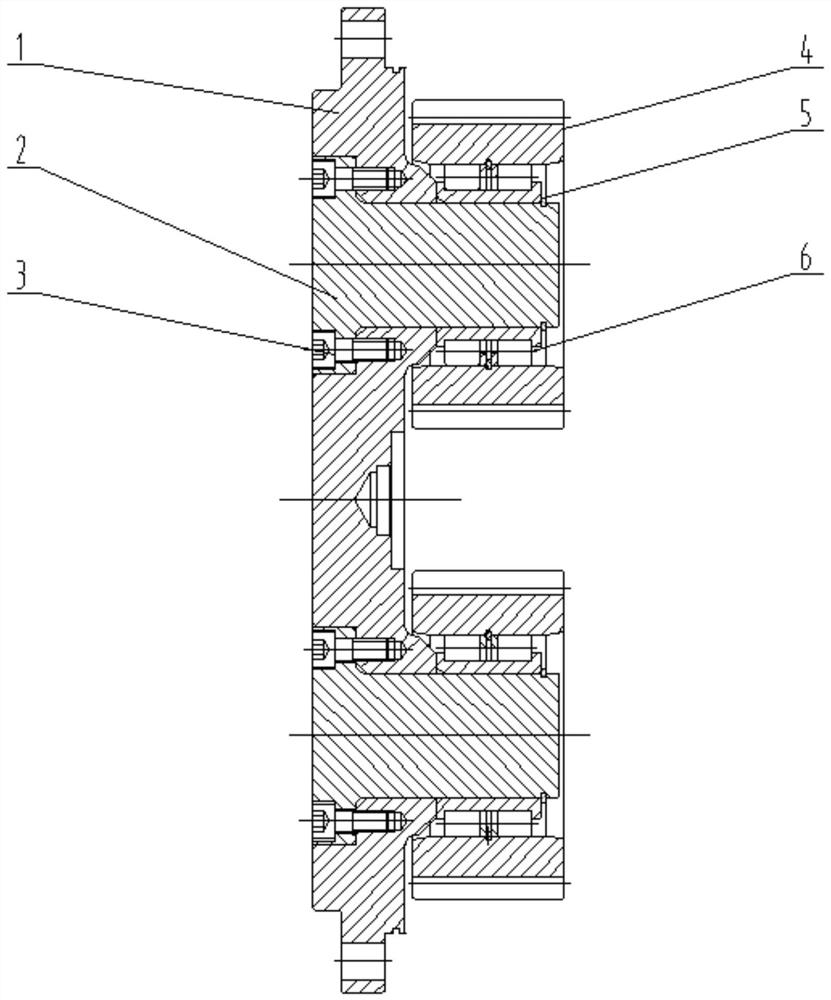

Integral type hinge beam closed-die forging and pressing forming die and hinge beam manufacturing method

ActiveCN106216585AReduced deformed cross-sectional areaIncreased pressure tonnageForging/hammering/pressing machinesEngineeringExtrusion

The invention belongs to an integral type hinge beam closed-die forging and pressing forming die and a hinge beam manufacturing method. The integral type hinge beam closed-die forging and pressing forming die comprises a mold punch connected to a pressing machine sliding block, a shaping female mold and an ejection block arranged at the inner bottom of the shaping female mold, wherein the mold punch comprises an upper mold base connected to the pressing machine sliding block, a male mold connected to the upper mold base and a piercing puncher chip arranged in the upper mold base and passing through the male mold; the forming female mold is of a top-to-bottom through hole structure, and the shape of the cavity of the interior of the forming female mold is matched with a hinge beam; and the ejection block is movably arranged at the inner bottom of a through hole of the forming female mold. The integral type hinge beam closed-die forging and pressing forming die has the advantages of one-time heating, closed-die hot extrusion forming, compacted and impregnable four lug parts of a workpiece, guaranteed product quality, small allowance for machining, high utilization rate of materials, high production efficiency and low production cost.

Owner:邓州市良机锻压设备制造有限公司

Integrated forging method for transition section and barrel body of hydrogenation reactor

The invention relates to an integrated forging method for a transition section and a barrel body of a hydrogenation reactor, and belongs to the field of machining and forging. For solving the problemsthat the transition section and the barrel body of the hydrogenation reactor are difficult to close in the prior art, and for cutting manufacturing cost and improving product quality, the forging method comprises the following steps that firstly, the characteristic dimension parameters of the barrel transition section are determined, and a special close-up hammer head for a shell close-up is manufactured according to the characteristic dimension; secondly, the barrel body is forged, a steel ingot is subjected to upsetting and punching, core rod drawn-out is conducted, and then hole-expandingis conducted to the size of a part; and finally, the close-up is pressed for a plurality of times, the special close-up hammer head is used for pressing a workpiece to perform local close-up on a port, and the workpiece is rotated and pressed for multiple times so as to complete forging forming of the transition section of the barrel body. According to the integrated forging method, the integratedforging of the transition section and the adjacent barrel body of the hydrogenation reactor is realized, the production cost is reduced, the production efficiency is improved, the number of welding lines of the whole hydrogenation reactor is reduced, and the working stability of the hydrogenation reactor is improved.

Owner:TIANJIN HEAVY EQUIP ENG RES +1

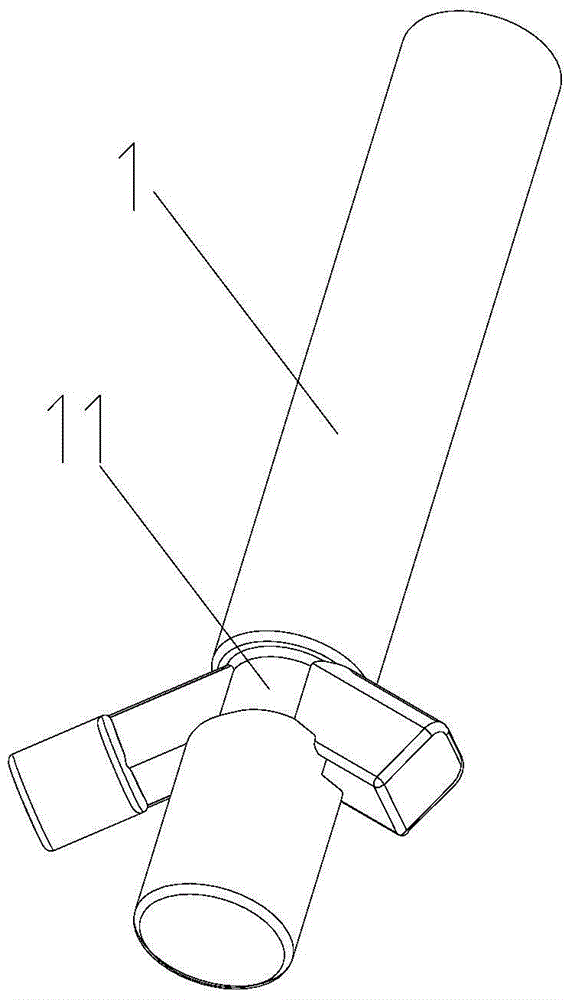

Guide-pin-based multidirectional closed forging device and technology for special-shaped oil sprayer body

ActiveCN105195659ASimplify the forging processIncrease productivityForging/hammering/pressing machinesSprayerMedium frequency

The invention belongs to the technical field of oil sprayer body forging, and discloses a guide-pin-based multidirectional closed forging technology and device for a special-shaped oil sprayer body. The technology includes the steps that a bar with the diameter slightly smaller than the minimum diameter of a forge piece is adopted to be fed, and the blank is heated to the forging temperature through a medium-frequency induction furnace and placed into the closed forging device; the device can perform lateral mold assembling under the effect of guide pins, the whole closed forging device moves downwards after a left female mold and a right female mold are locked through locking blocks, and the blank is molded under the effect of an upper male mold and a lower male mold; in the process that the closed forging device moves upwards after molding, the upper male mold is released, the left female mold and the right female mold are opened, and a workpiece is jacked out through the lower male mold. According to the technology and device, due to multidirectional parting, one-step closed forging molding of the special-shaped oil sprayer body is achieved, the forging technology is simplified, production efficiency and product performance are improved, and mechanization and automation can be easily achieved.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

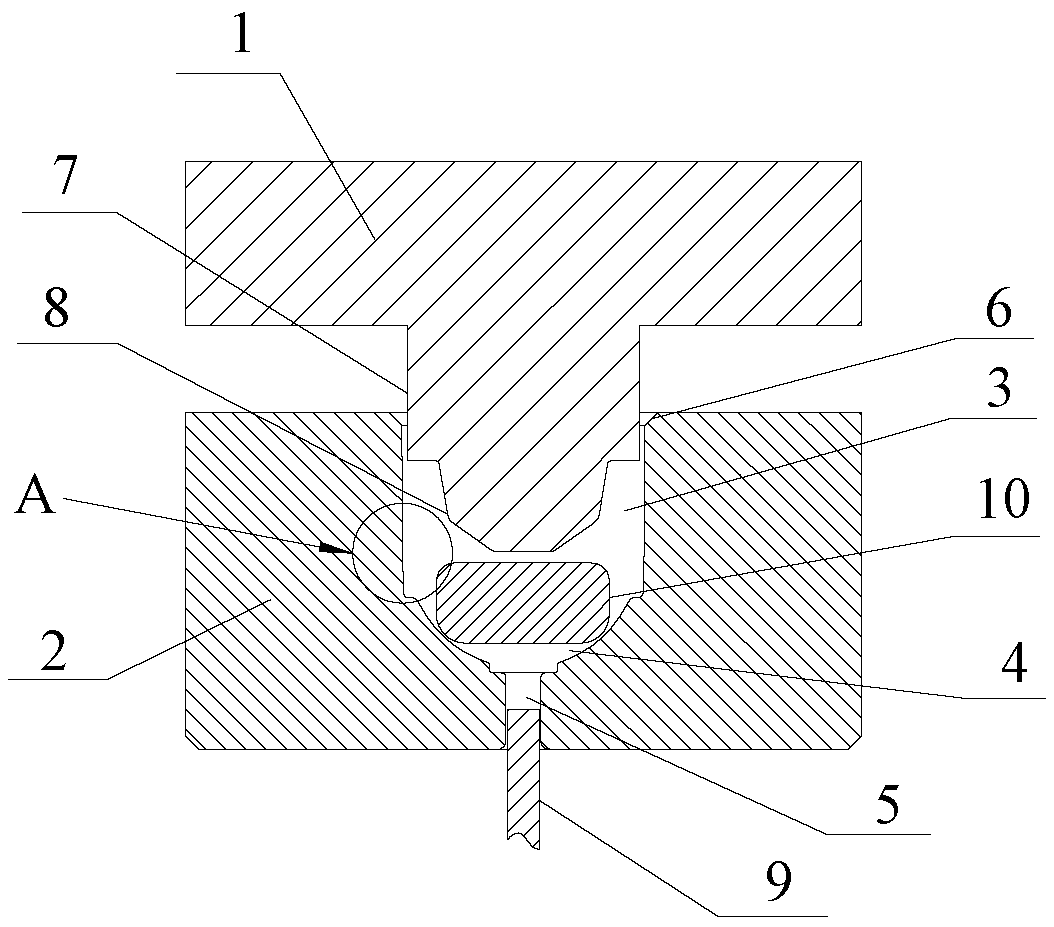

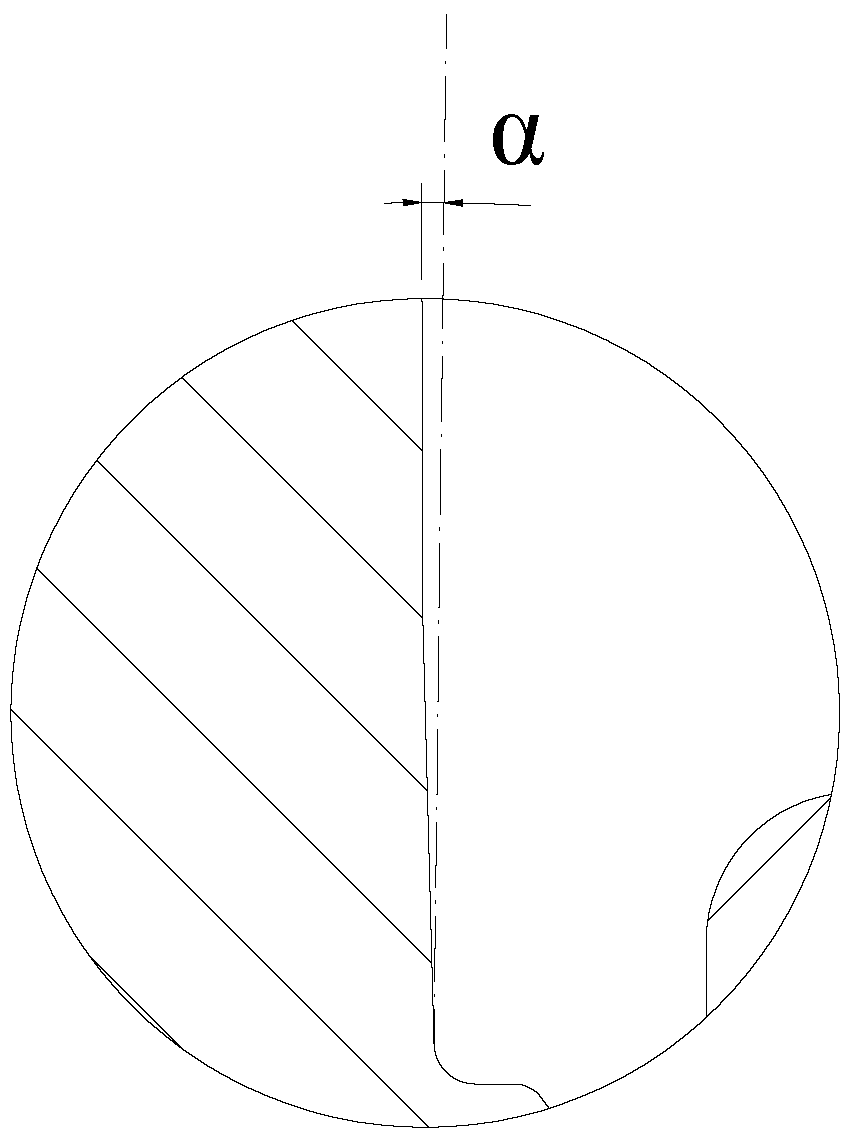

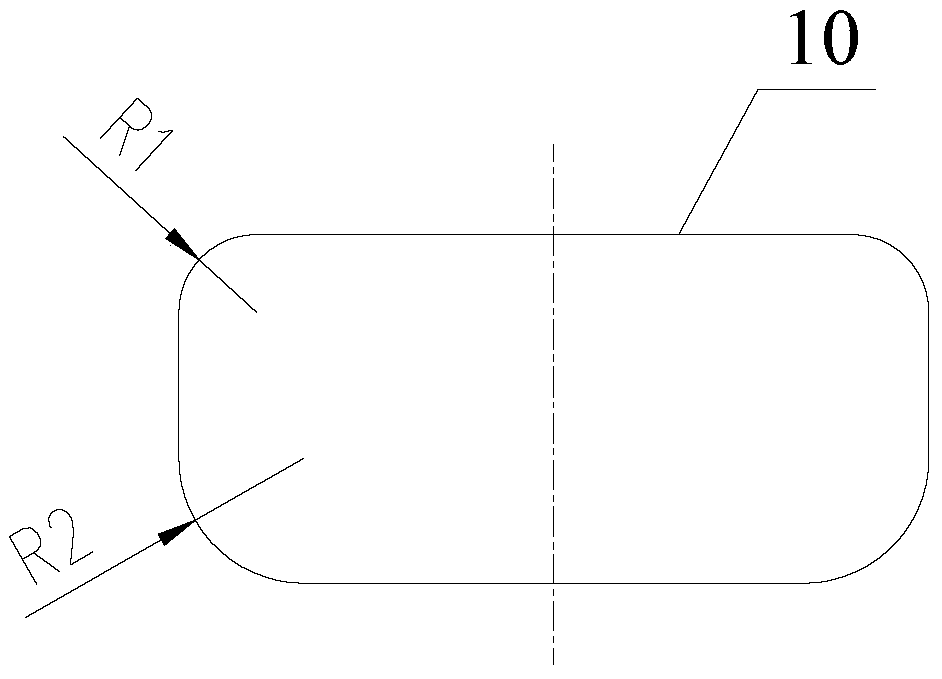

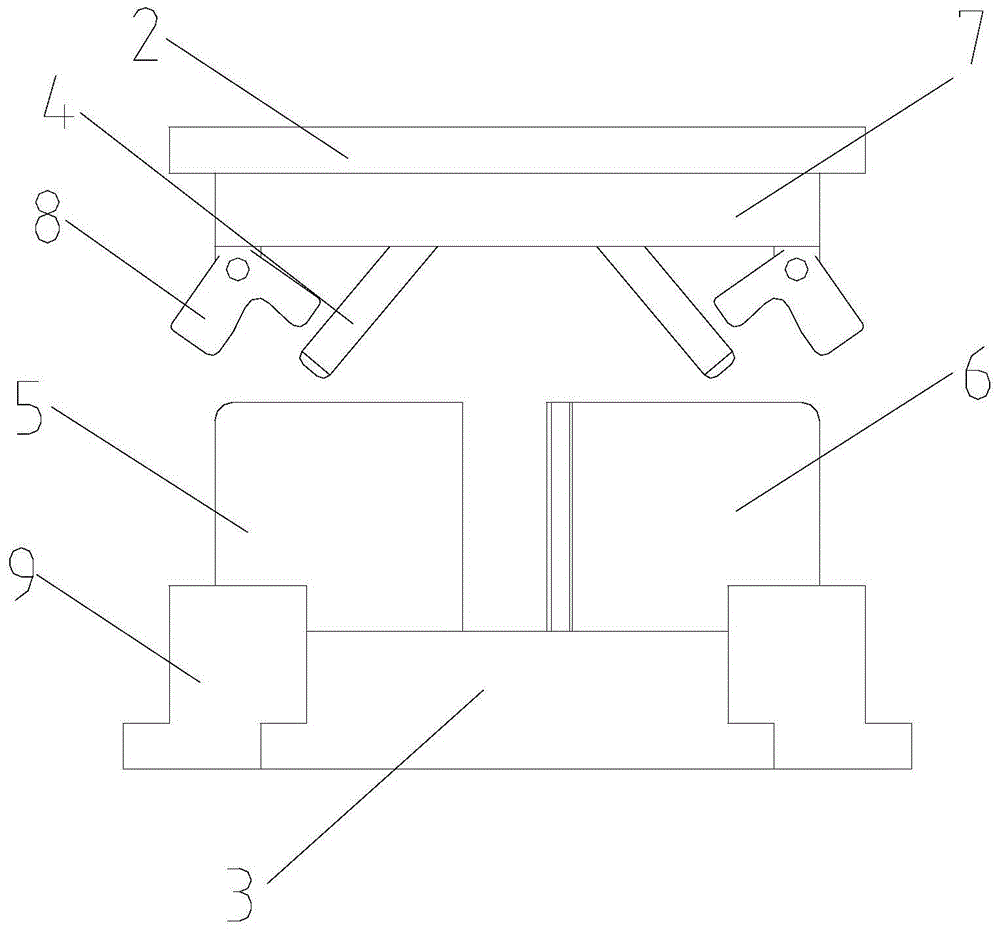

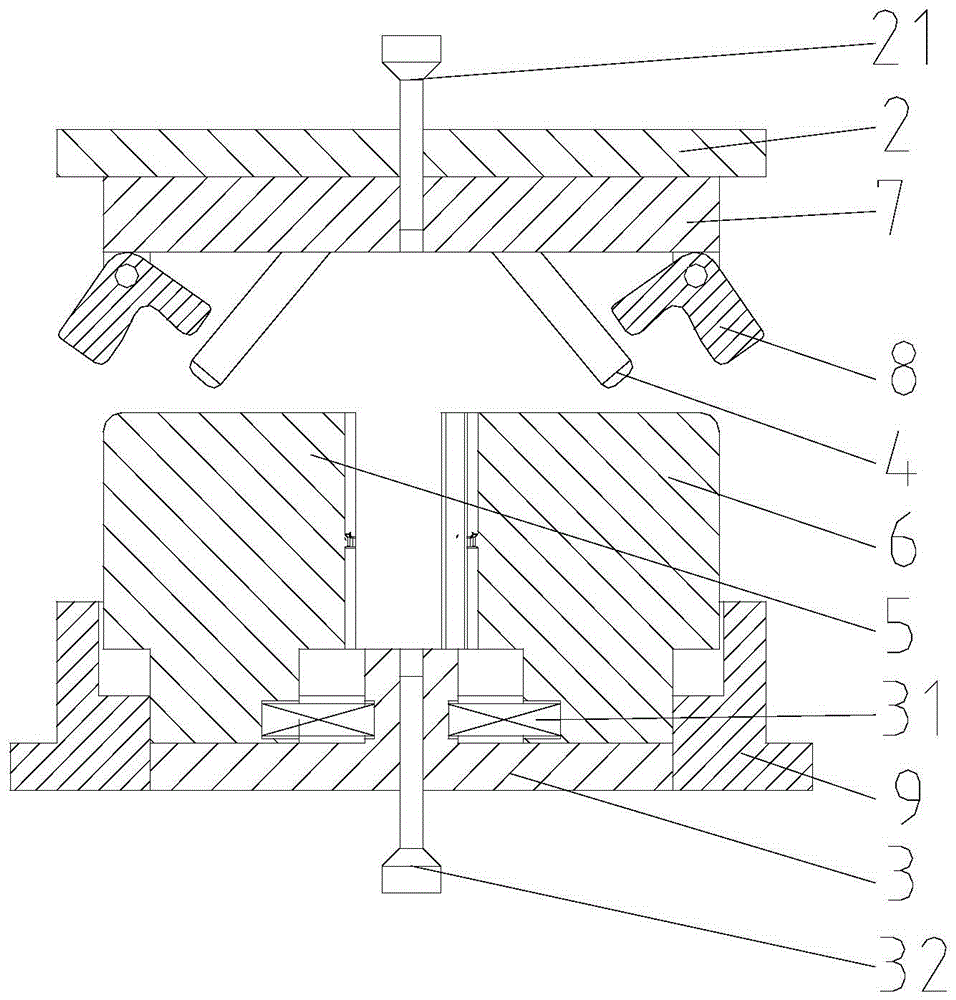

Blocking forging device and forging process for special-shaped fuel injector body

PendingCN111745107ASimple structureImprove reliabilityForging/hammering/pressing machinesEngineeringMold removal

The invention discloses a blocking forging device for a special-shaped fuel injector body. The device comprises an upper mold and a lower mold for blank forming, wherein the lower mold comprises a lower mold sleeve, and a base is arranged inside the lower mold sleeve; the upper end of the base is provided with a sliding mold which is in sliding connection with the inner side face of the lower moldsleeve, and the lower end of the base is provided with movable ejection rods capable of ejecting the sliding mold out; and the sliding mold is composed of a left half mold and a right mold half whichare oppositely arranged. Forming of a cavity is achieved by the oblique sliding of the left half mold and the right half mold, and under the action of self-locking angles, the space positions of thehalf molds are kept stable without additional mechanism maintenance; and a forged piece can be simultaneously demolded from a shape hole of the base and the cavity of the half molds during ejection, so that one-step blocking forging forming of the fuel injector body is achieved, the forging process and the mold structure are simplified, mold parts are reduced, the parting surface is flat and freeof step surfaces, the unbalance loading phenomenon does not exist during forging, and the forming force is lower. The invention further provides a blocking forging process for the special-shaped fuelinjector body, and the blocking forging device is included in the blocking forging process.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

Hot forging method of wetland track plate and hot forging die thereof

ActiveCN107096863AReduce power consumptionMeet lightweight requirementsRailway componentsForging/hammering/pressing machinesSlagMechanical property

The invention discloses a hot forging method of a wetland track plate and a hot forging die thereof. According to the hot forging method of the wetland track plate and the hot forging die thereof, casting forming is changed into forging forming, round steel or square steel is forged and formed, the forged structure is compact, various mechanical properties are remarkably improved, the tensile strength is 1095 Mpa, the yield strength is 1042 Mpa, the hardening and tempering hardness is HRC30-36, the impact toughness value is 128, the cross sectional area is reduced by 31.5%, the power consumption during walking of a main machine is greatly reduced, and the light weight requirement of parts is met; the hot forging belongs to solid forming, waste gas and waste sand generated by casting smelting and casting are avoided, and the defects such as air holes, sand holes, surface cracks, slag inclusion, micro-cracks and the like influencing the mechanical properties are avoided; and the forging process is simplified, the time for each step of the forging is shortened, the problem that large areas and thin walls are difficult to form is solved, the working environment is improved, the production efficiency of each shift is 400-450 pieces, the rejection rate is not more than 0.1%, and the batch production is balanced and stable.

Owner:大连金雕铸锻工业有限公司

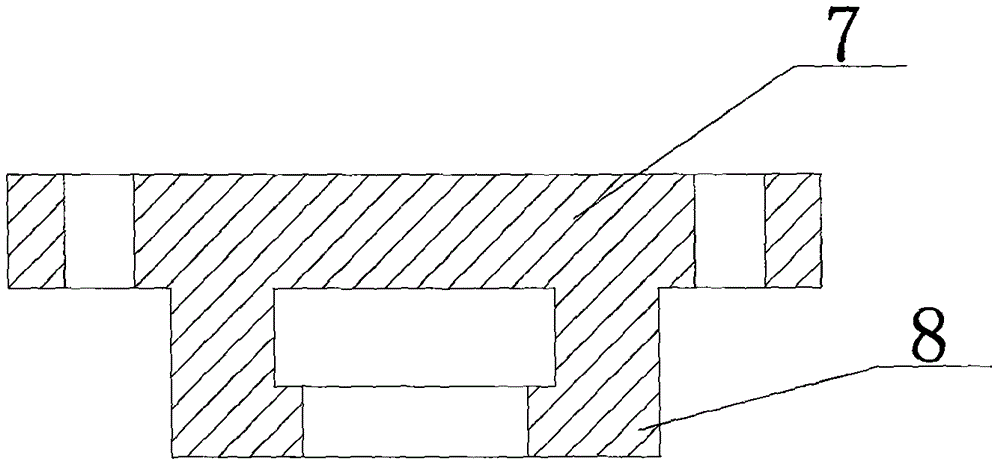

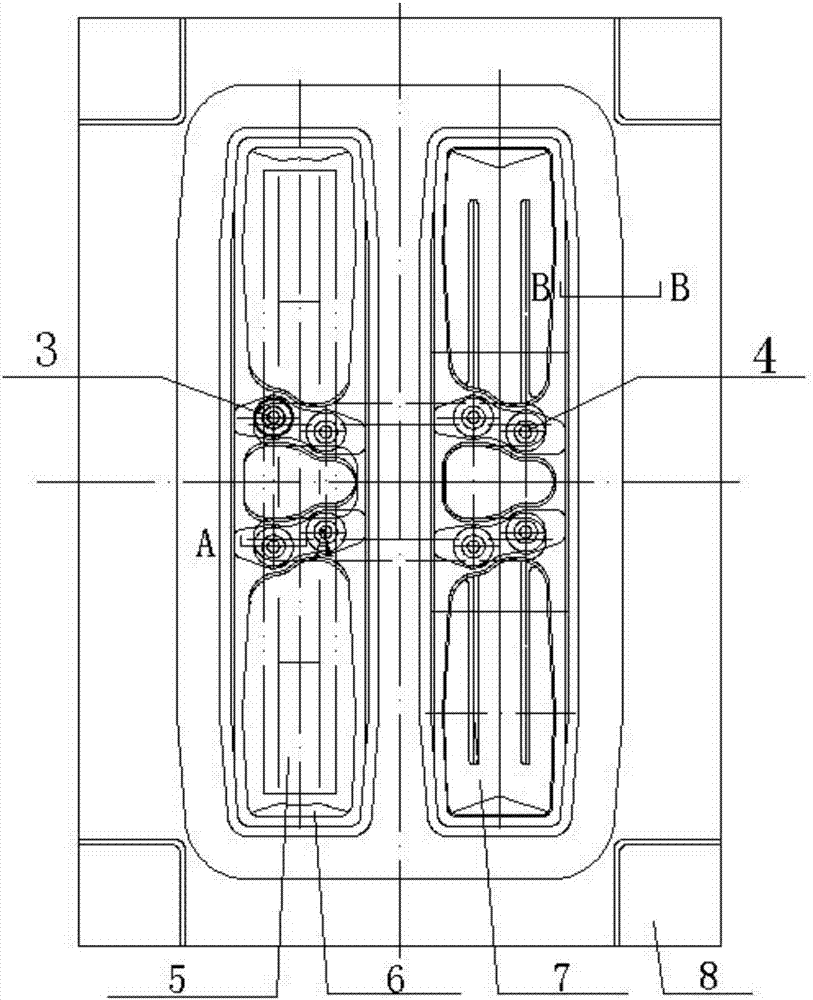

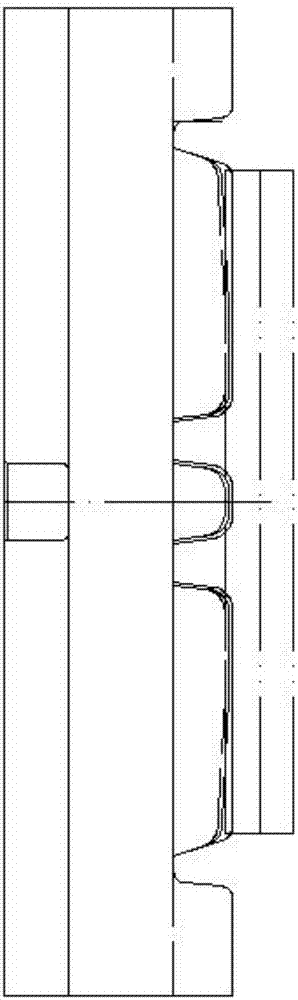

One-mold two-piece forging mold and method for drill pipe joint

ActiveCN107186149ASimplify the forging processImprove processing efficiencyForging/hammering/pressing machinesEngine componentsEngineeringMachining

The invention discloses a one-mold two-piece forging mold and method for a drill pipe joint. The mold comprises an upper mold, a lower mold, a first upsetting punch and a second upsetting punch, wherein the lower mold is located right below the upper mold; the first upsetting punch and the second upsetting punch can be correspondingly arranged on the two sides of the lower mold in a horizontal moving manner; the upper mold comprises an upper mold seat, an upper mold sleeve and an upper mold core; the lower mold comprises a lower mold seat, a lower mold sleeve and a lower mold core; molding bosses are correspondingly arranged in middles of the upper mold core and the lower mold core, and molding cavities matched with the shape of the drill pipe joint are arranged on the upper mold core and the lower mold core and located on the two sides of the molding bosses. The one-mold two-piece forging mold can be used for performing one-mold two-piece forging on the appropriate drill pipe joint, so that the forging process of the drill pipe joint is simplified, the machining efficiency is improved, and the machining cost is reduced.

Owner:WUXI DOUBLE HORSE DRILLING TOOLS

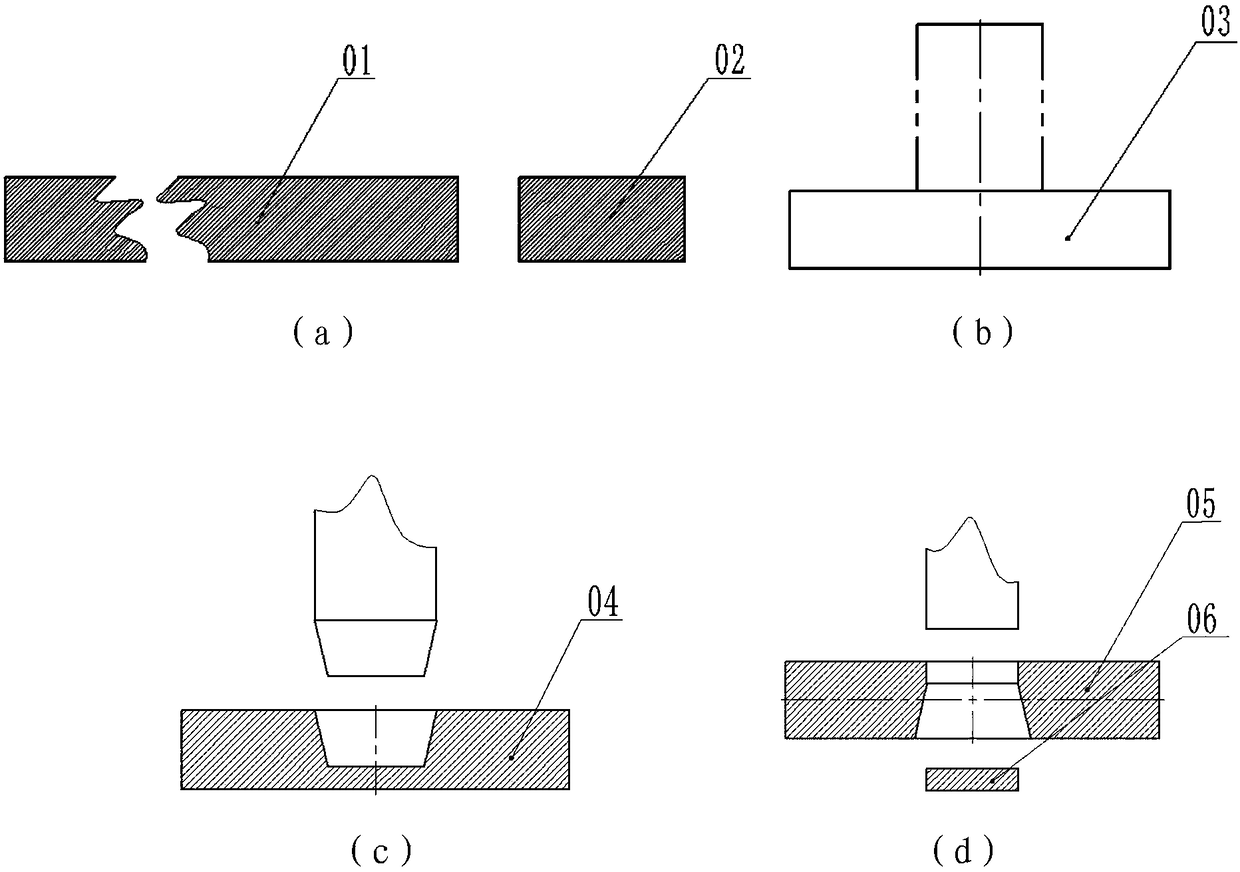

Fine forging technology for automobile claw pole forging

InactiveCN1166471CImprove deformationEasy to shapeMetal-working apparatusMetal formingPower consumption

The present invention relates to precise metal forming technology, and is especially precise automobile claw forging process. The technological process includes four steps of upset, lateral hot extrusion in separable female die to form prefabricated blank, final forging and cutting overlap after heating. The simplified forging process had less steps, high product quality, saving in material, low in power consumption, and prolonged die service life.

Owner:YANSHAN UNIV

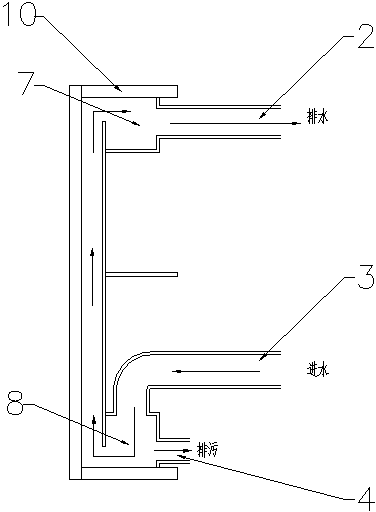

Electroslag smelting and casting sector-plate special-shaped crystallizer

The invention discloses an electroslag smelting and casting sector-plate special-shaped crystallizer, and belongs to the technical field of crystallizers. The electroslag smelting and casting sector-plate special-shaped crystallizer is composed of a front portion and a rear portion which are symmetrical. Taking the front portion as an example , the front portion is composed of an inner cavity shaping plate, an outer cavity shaping plate, a water discharging pipeline and a water feeding pipeline. When the electroslag smelting and casting sector-plate special-shaped crystallizer is used, the front portion and the rear portion are connected together through nuts in the mode that bolts penetrating through bolt holes A, and a plurality of electroslag smelting and casting sector-plate special-shaped crystallizers can be stacked for use in the vertical direction. After the front portion and the rear portion are combined, a cavity is formed by the inner cavity shaping plate, wherein the left side and the right side of the cavity are parallel, and the upper side and the lower side of the cavity are respectively in an arc shape; the outer cavity shaping plate has the same shape as the inner cavity shaping plate, a water trough is located between the inner cavity shaping plate and the outer cavity shaping plate, and the thickness of the water trough ranges from 15 mm to 25 mm. The lower portion of the outer cavity shaping plate is provided with a water feeding pipe, the upper portion of the outer cavity shaping plate is provided with a water discharging pipe, the water feeding pipe is connected with the water feeding pipeline, the water discharging pipe is connected with the water discharging pipeline, and the water feeding pipeline is further provided with a sewage discharging hole. The electroslag smelting and casting sector-plate special-shaped crystallizer has the advantages that the number of forging procedures is reduced, production procedures are simplified, and production cost is reduced.

Owner:HEILONGJIANG XINYUAN SPECIAL STEEL

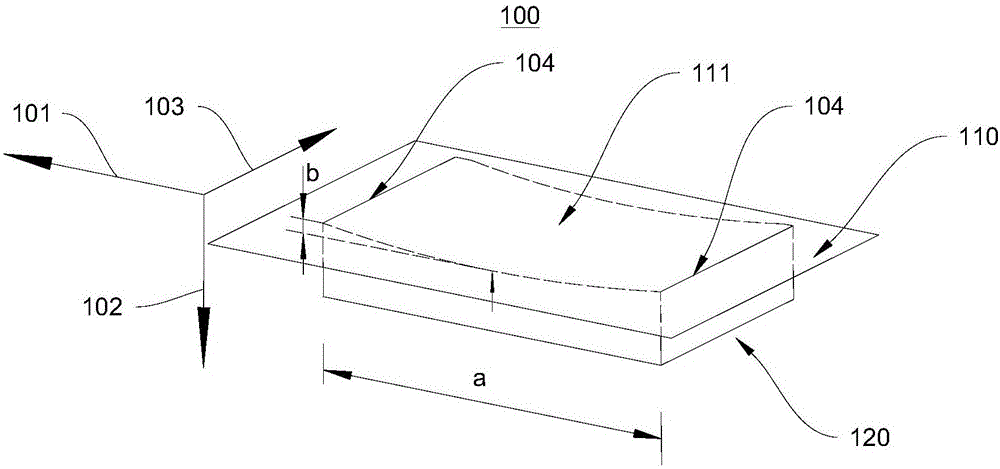

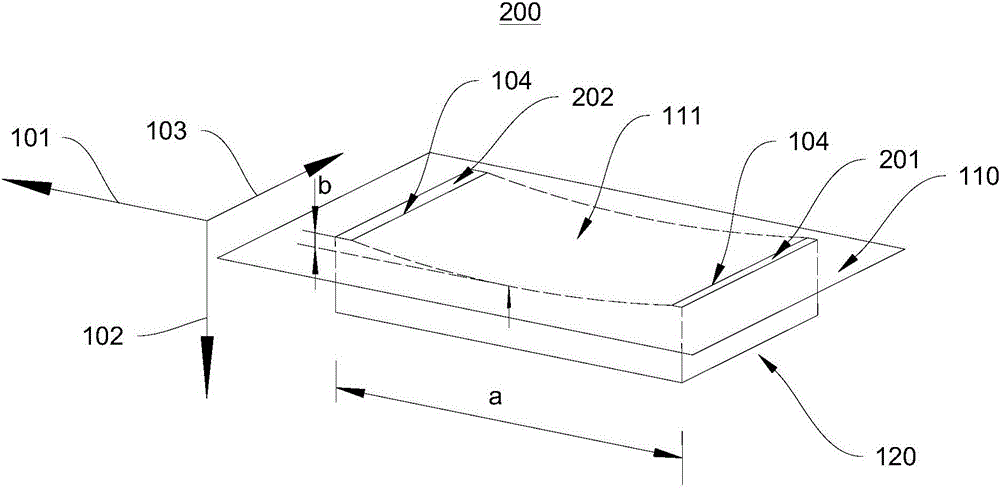

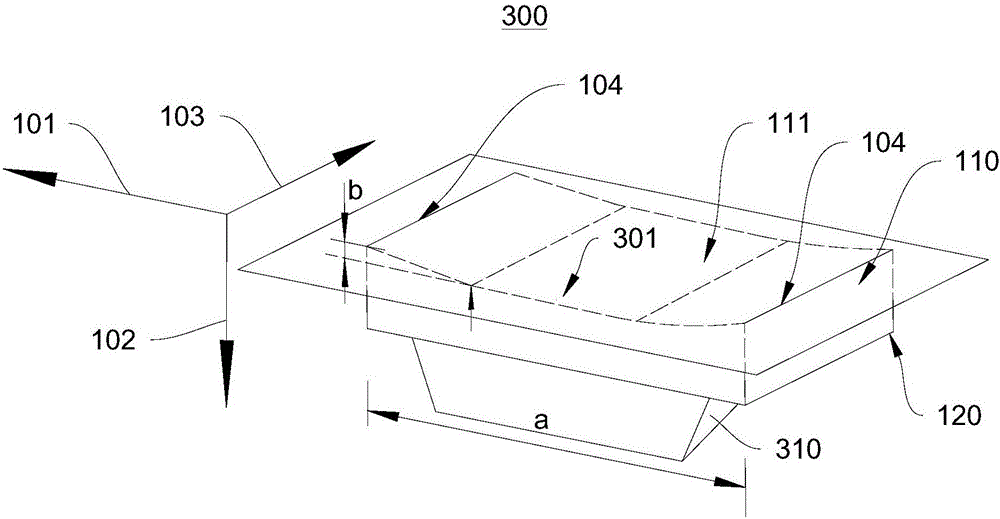

Near-net-shape casting production method for automotive aluminum alloy parts

ActiveCN102319876ASimplify the forging processHigh utilization rate of raw materialsNear net shapeAluminium alloy

The invention provides a near-net-shape casting production method for automotive aluminum alloy parts. A semicontinuous casting crystallizer which has the same shape and dimension as a forged product is adopted, a near-net-shape cast ingot is produced by the semicontinuous casting method, the ratio of the cross-sectional area of the cast ingot to the cross-sectional area of the forged product is 1.35:1 to 1.05:1, the cast ingot is cut into sheets, which are then directly formed by one or two times of die forging, and thereby aluminum alloy forged products are obtained. The shape of the ingot produced by the method is near to the shape of the finished forged product, the ingot-preforging step is reduced, the comprehensive utilization rate of alloy materials is increased, meanwhile, coarse recrystallization cannot occur in the process of forging, and the overall properties of the product are enhanced.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

Lateral shaping process for hybrid excitation claw poles

ActiveCN105099093AReduce the adverse effects of formingSimplify the forging processManufacturing dynamo-electric machinesEngineeringExtrusion

The invention belongs to the technical field of claw preparation, aims to overcome the defect that the claw pole shaping process in the prior art reduces the height of claw teeth and deforms work pieces, and provides a lateral shaping process for hybrid excitation claw poles. The outer side of a lower die holder of a shaping mold is equipped with lateral sliders matched with lower concave dies on the lower die holder, a claw pole is fixed to the mold, force is applied to the lateral sliders along the radial direction of the lower die holder to make the lateral sliders move to the lower die holder and match the lower concave dies, and force along the radial direction of the lower die holder continues to be applied to the lateral sliders to shape claw teeth and wings of the claw pole. The beneficial effects are as follows: the wings of a hybrid excitation claw pole are shaped through lateral force, and the wings can be shaped under the action of a small force; materials flow laterally, the flow length is small, and the adverse impact of friction to shaping during claw pole shaping under forward extrusion can be reduced; moreover, there is no need to open a material accommodating slot during hot forging, the forging process is simplified, and the product performance is improved.

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

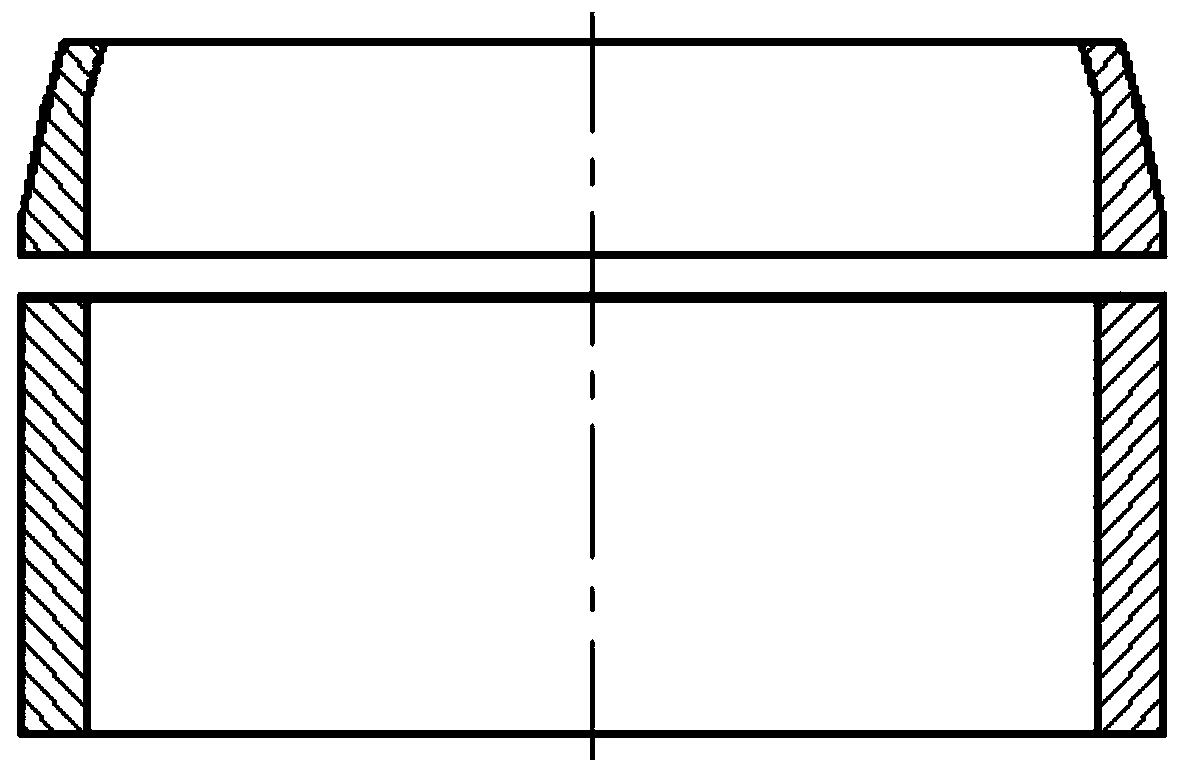

Concave anvil used for forging and forging device

ActiveCN106424512AReduce unevennessEliminate elasticityForging/hammering/pressing machinesEngineeringFiber structure

The invention provides a concave anvil used for forging and a forging device and belongs to the field of machinery. The concave anvil used for forging is provided with a concave surface, and a reference plane opposite to the concave surface is defined on the concave anvil. The distance between the concave surface and the reference plane is gradually and synchronously decreased from the center to the two ends of the concave surface. The difference value between the maximum distance and the minimum distance between the concave surface and the reference plane is 3.5 mm-6.5 mm. The forging device comprises the concave anvil used for forging. According to the concave anvil used for forging, the defect problem of a forging is solved, so that the fiber structure of the forging and the shape of the forging are kept consistent, the metallurgical quality of the forging is improved, and meanwhile, the forging cost is also reduced.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

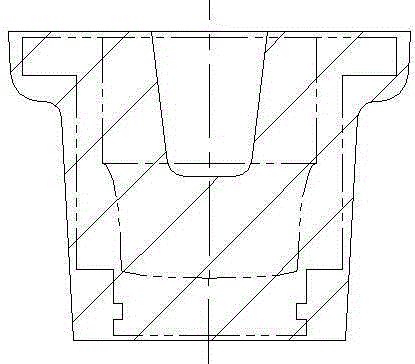

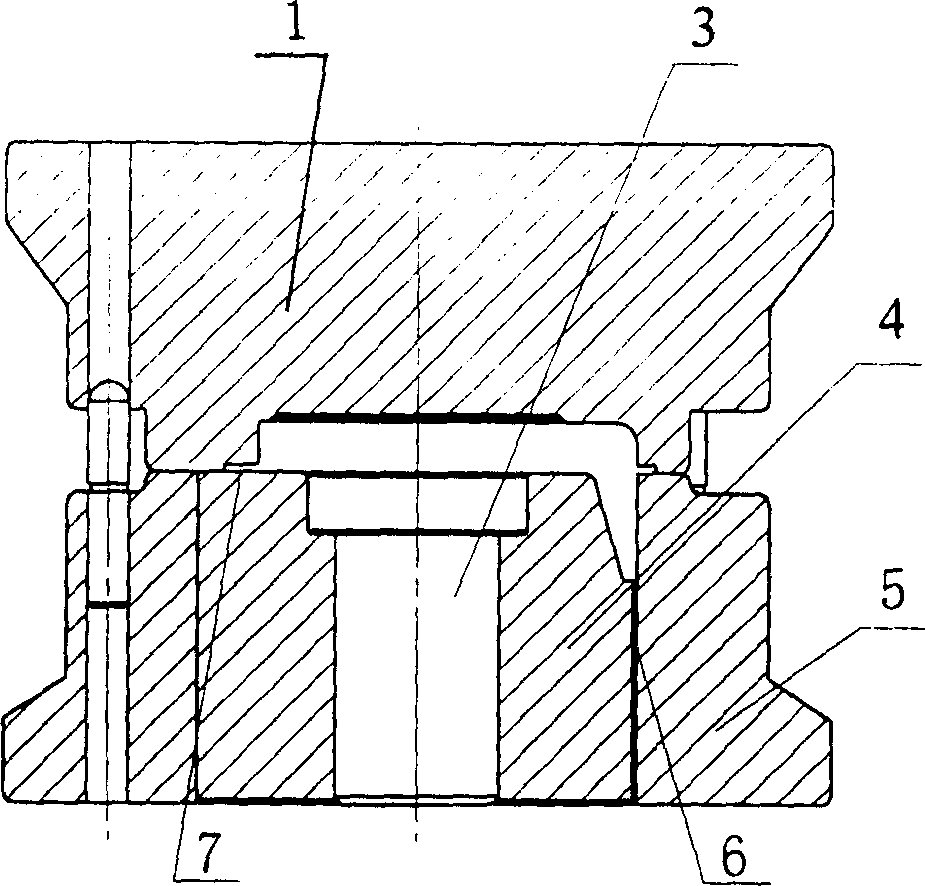

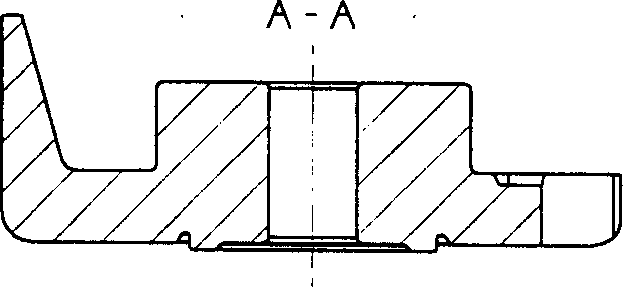

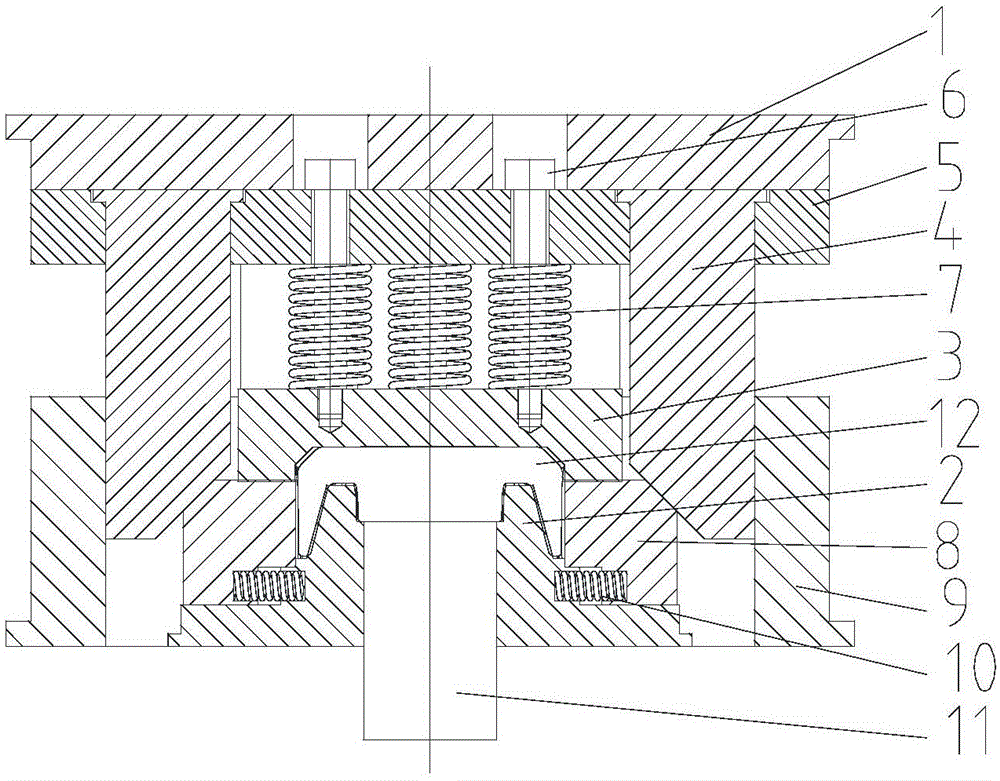

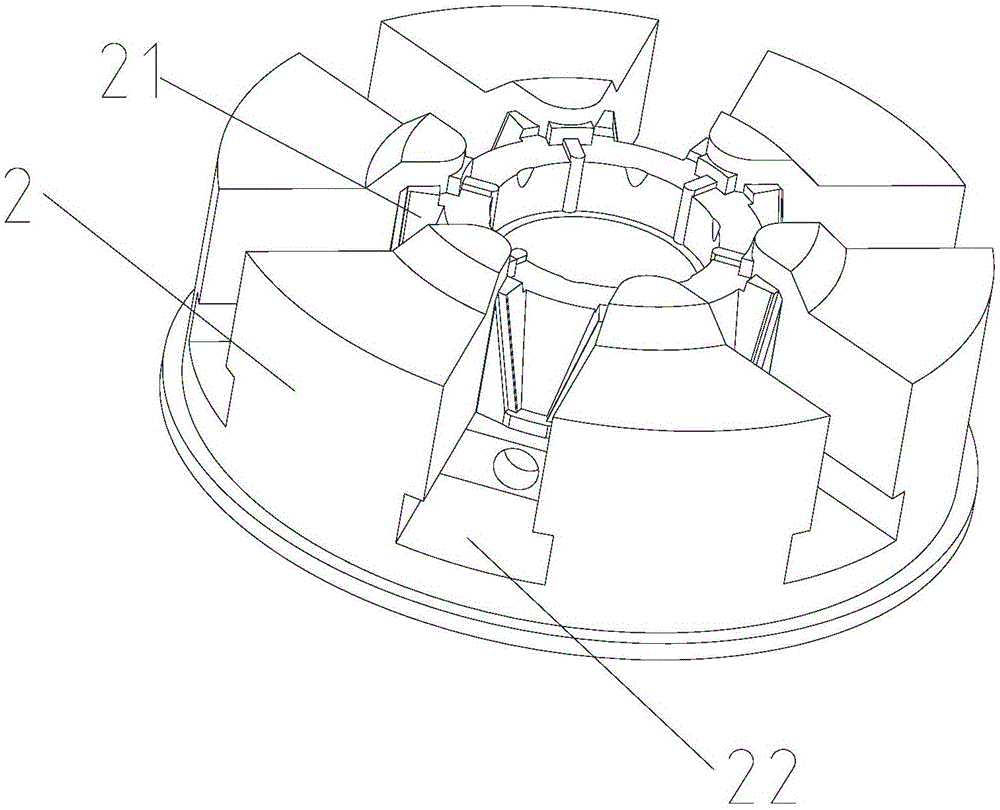

Metal acetabular outer cup closed-type forging die and method

InactiveCN110899594AIncrease profitGuaranteed offsetForging/hammering/pressing machinesEngineeringMaterials science

The invention provides a metal acetabular outer cup closed-type forging die. The problems that procedures are complicated, the manufacturing cycle is long, the material utilization rate is low, filling defects are prone to being generated, adjustment of forging equipment is difficult and the production cost is high due to the fact that existing metal acetabular outer cups are manufactured by an open-type die forging process can be solved. The metal acetabular outer cup closed-type forging die includes a punch and a female die. The female die is provided with an impression penetrating in an up-down mode. The impression includes a guide cylinder, a cavity and an extrusion port which coaxially communicate with one another sequentially from top to bottom, and the shape of the cavity is matchedwith the outer shape of the acetabular outer cups. A guide part and a forming part which are coaxially arranged from top to bottom are arranged on the bottom surface of the punch, the guide part is in clearance fit with the guide cylinder, and the shape of the forming part is matched with the inner shape of the acetabular outer cups. Meanwhile, the invention further provides a metal acetabular outer cup closed-type forging method.

Owner:无锡航亚科技股份有限公司

Near-net-shape casting production method for automotive aluminum alloy parts

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

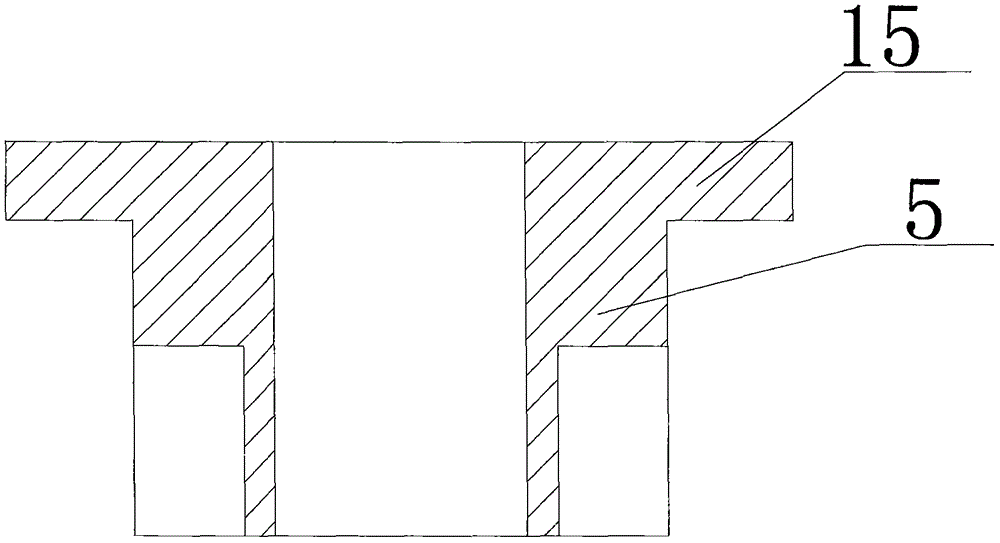

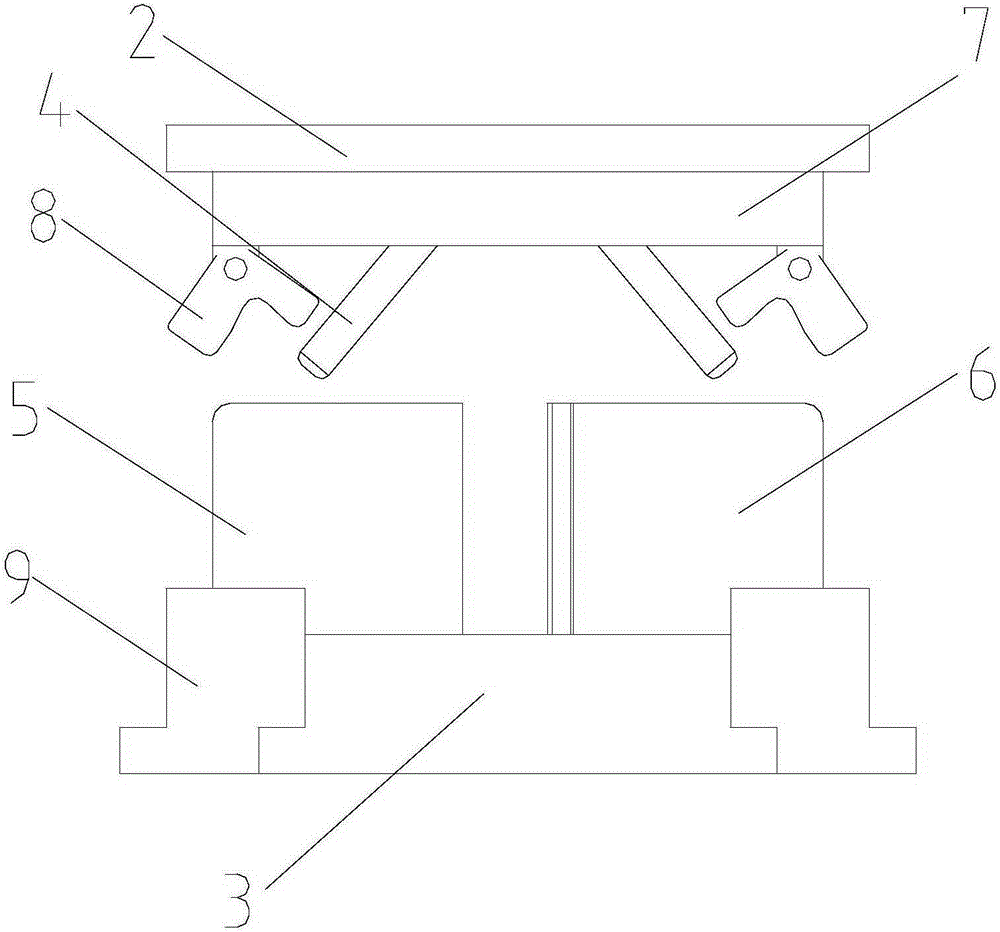

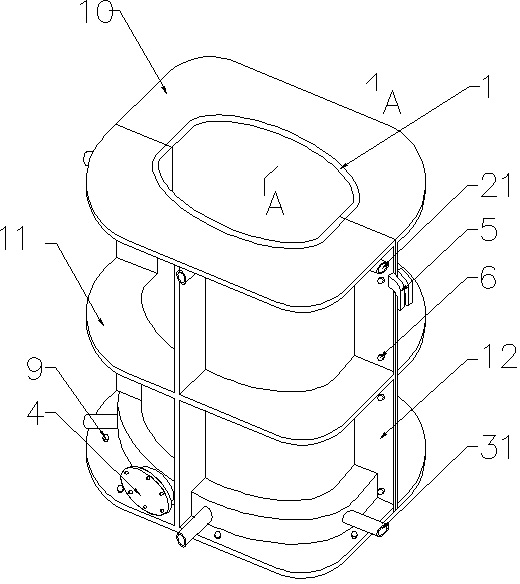

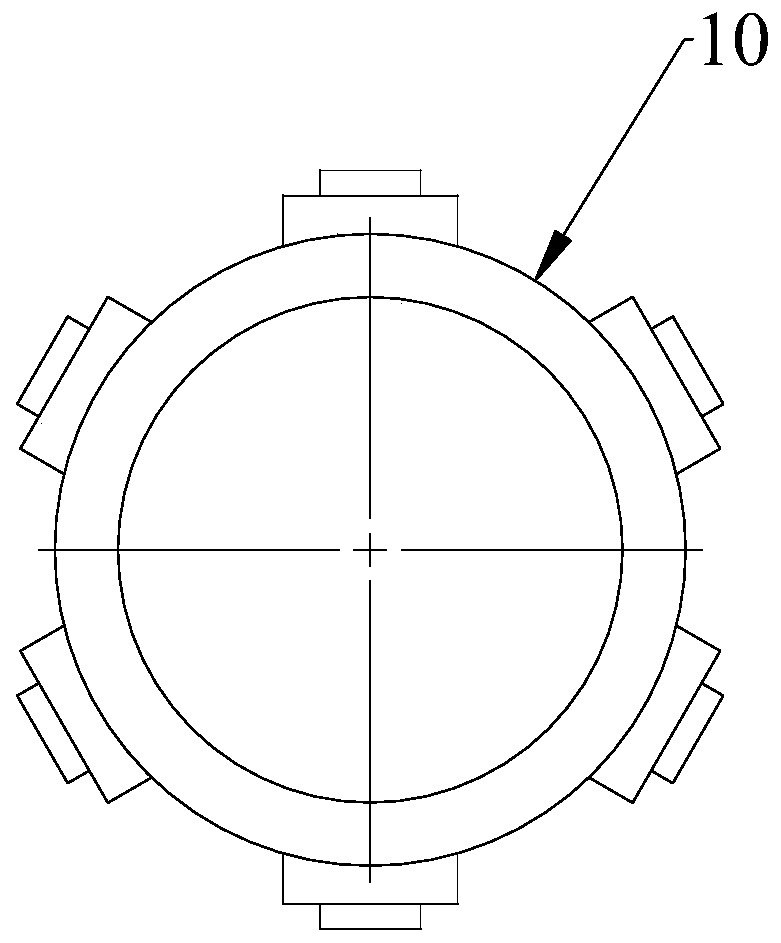

Equipment for manufacturing ring type components

PendingCN108655323ASimplify the forging processReduce manufacturing costForging/hammering/pressing machinesWheelsManufacturing cost reductionPunching

The invention provides equipment for manufacturing ring type components. The equipment comprises a female die and a movable die which is matched with the female die to form a closed cavity. An upsetting die moving relative to the movable die is arranged in the movable die cavity, and a punch moving relative to the upsetting die is arranged in the upsetting die cavity. According to the provided equipment, through cooperation of several components including the female die, the movable die, the upsetting die and the punch, upsetting, punching and other technology processes can be finished at a time, the formed ring type components are machined, the forging process is simplified, meanwhile, waste cannot be generated, and the manufacturing cost is greatly reduced. Batched and continuous producing and machining of the ring type components can be achieved, and the ring type component machining efficiency is greatly improved.

Owner:CHENGDU HAONENG TECH CO LTD

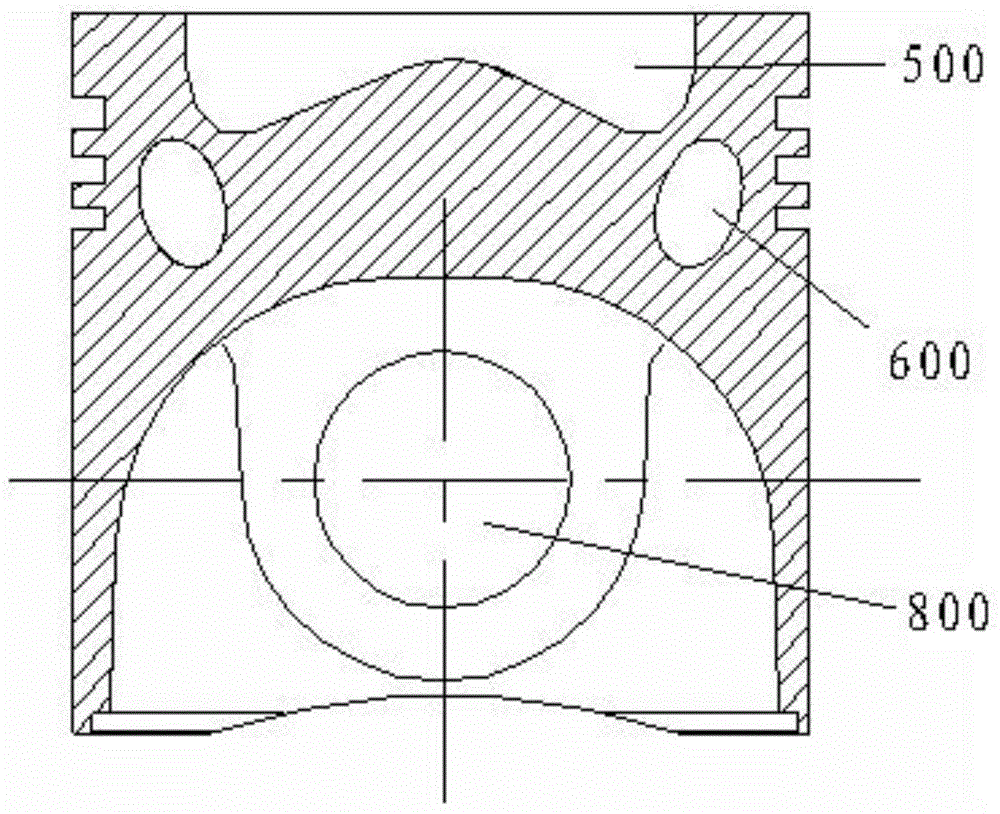

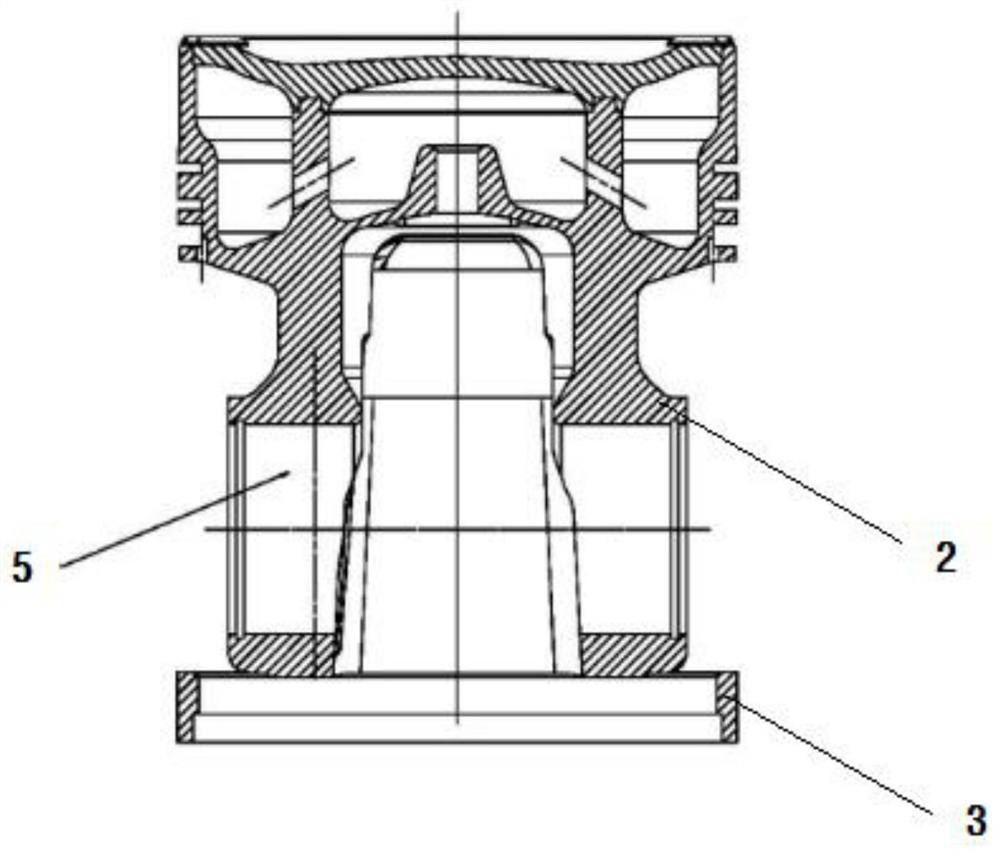

Large-cylinder-diameter integrally-forged steel piston

PendingCN112302828ASimplify the forging processReduce equipment tonnage requirementsMachines/enginesPistonsPhysicsGudgeon pin

The invention relates to a large-cylinder-diameter integrally-forged steel piston. A piston skirt part and a piston head part are both forged parts, the top of the piston skirt part and the piston head part are fixed to form a piston body, a closed cooling oil cavity or two communicated double cooling oil cavities is / are formed in the piston body, and a skirt part annular part is fixed to the lower end of the piston skirt part; and the cross section of a corresponding oil annular groove lower annular bank on the outer wall of the top of the piston skirt part is in an oval shape with the long axis parallel to the direction of a piston pin hole, and the annular bank and the skirt part annular part jointly participate in guiding of a piston body. Blanks of the piston head part and the pistonskirt part are separately forged and machined, so that the forging process is simplified, and the requirements and investment on equipment, cutters and the like are reduced. The piston skirt part annular part is independently machined, the forging depth of the piston body skirt part is reduced, the piston production difficulty is reduced, and the piston production efficiency is improved. The piston skirt part annular part and the oil annular groove lower annular bank jointly participate in piston guiding, stable operation of an engine is facilitated, the eccentric wear phenomenon of the pistonis reduced, and use safety and reliability of the piston are improved.

Owner:BINZHOU DONGHAILONG PISTON

Forging and forming method of integral hinge beam

InactiveCN102513482BImprove performanceExtended service lifeMetal-working apparatusUltra high pressureDiameter ratio

The invention belongs to the field of the forging and forming of the large forging and particularly relates to a forging and forming method of an integral hinge beam in a cubic press used for ultra-high pressure synthesis. A steel ingot is heated to the initial forging temperature according to the heating specification, wherein, reheating according to the heating specification during each work procedure is needed, and the initial forging temperature is not lower than 900 DEG C; after the steel ingot is upset to have the height-diameter ratio of 1, the billet is upset by using a swage into a round disc with an inclined surface at the bottom; after the round-disc shaped billet is drawn out into the cross-shaped billet, tong handles are cut off, a central hole is punched, and the billet is mechanically processed. Due to the adoption of the forging and forming method of the integral hinge beam, the problem on the central compaction of the hinge beam in the forging process is solved, the performance of the product is improved, the service life of the product is prolonged, the process of forging for producing is simplified, the utilization rate of the steel ingot is improved, the production efficiency is enhanced, and the production cost is reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

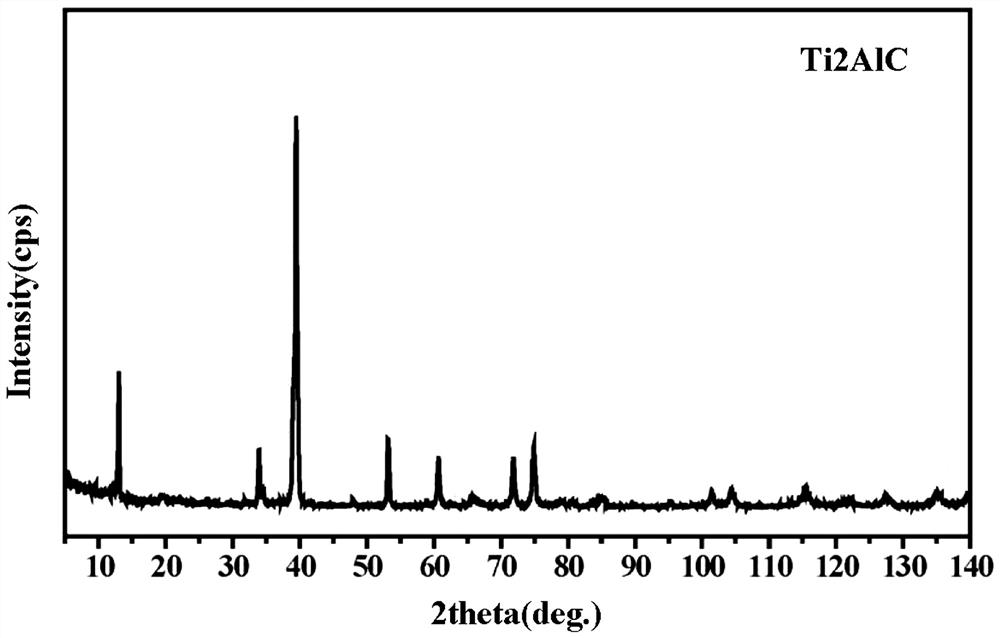

A kind of preparation method of compact ti2alc material

The invention belongs to the technical field of high polymer materials, aiming to solve the problems that conventional equipment for preparing Ti2AlC material is expensive and has the disadvantages ofhigh cost, complex process and difficulty in industrial promotion, and products obtained by the equipment always contain impurity phases which cause poor performance to limit application of the material. According to the preparation method, Ti powder, Al power and carbon nano tubes are taken as the raw materials to prepare the compact TiAlC material at one step by a near-isothermal canned forgingmethod; the powder mixing process is simplified. Since the operation is carried on a common hydraulic press directly, industrial production is facilitated, processing is simplified and cost is lowered. Further, by the way of high-temperature large-deformation, the Ti2AlC material prepared by the method has the advantages of high compactness and high fineness of grains.

Owner:TAIYUAN UNIV OF TECH

Wheel edge planet wheel shaft structure of loader drive axle

PendingCN112081905ASimplify the forging processReduce processing costsAxle unitsGearing detailsTransaxleAutomotive engineering

The invention discloses a wheel edge planet wheel shaft structure of a loader drive axle. The wheel edge planet wheel shaft structure comprises a wheel edge end cover and a planet wheel shaft, a planet wheel is installed on the planet wheel shaft through a roller bearing assembly, and the roller bearing assembly is limited through a check ring so that it can be guaranteed that the roller bearing assembly cannot get loose; the wheel edge end cover and the planet wheel shaft are in a split type, and the planet wheel shaft is in an independent flange type; a plurality of screw holes which are uniformly distributed are formed in the wheel edge end cover, and are fixed on the wheel edge end cover through screws; and an independent flange type planet wheel shaft is formed by forging a 20CrMnTi material and then carrying out carburizing and quenching treatment, so that the rigidity is improved. The problems that in the prior art, the manufacturing cost is high due to the fact that four standcolumns of the wheel edge end cover need to be forged and formed many times, and the failure rate is high due to stress concentration easily caused by roots of the four stand columns of the wheel edgeend cover are solved.

Owner:龙工(福建)桥箱有限公司

Engine crankshaft and manufacturing method

InactiveCN108019417ALess deformationConvenient heat treatmentCrankshaftsFurnace typesCrankshaftHeat treated

The invention discloses an engine crankshaft and a manufacturing method. The crankshaft comprises the raw materials of, by weight, 0.35%-0.5% of C, 0.3%-1.5% of Mn, 1.5%-3% of Cr, 0.15%-1.2% of Si, 0.5%-1.2% of Ni, 0.1%-0.8% of Cu, trace amount-0.2% of Ti, trace amount-0.05% of B, trace amount-0.15% of S, trace amount-0.08% of Al, trace amount-0.2% of Mg, and the balance Fe. The method has the characteristics of simplifying the heat treatment steps, being simple in process and being low in cost.

Owner:贵州福润达汽车配件有限公司

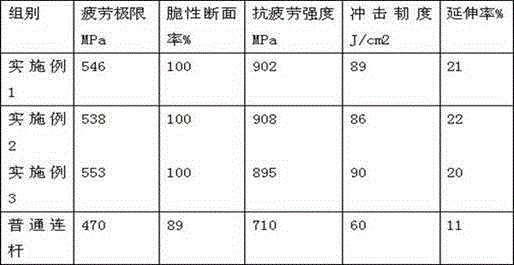

Forging Method of Small Gasoline Engine Connecting Rod

ActiveCN103921086BSimplify the forging processNo chipsTransportation and packagingMetal-working apparatusBiochemical engineeringRaw material

The invention belongs to the field of mechanical forging, and discloses a forging method of a small gasoline engine connecting rod, comprising the following steps: 1) weighing raw materials; 2) ball milling; 3) powder compact; 4) sintering; 5) cooling; 6) spraying Graphite powder; 7) induction heating; 8) forging and demoulding. Compared with the prior art, the forging method greatly improves the performance of the connecting rod, improves the product quality, reduces the scrap rate, reduces the processing procedures, reduces industrial energy consumption, and simultaneously improves the production efficiency of the enterprise.

Owner:临沂市金立机械有限公司

Combined mould for precasting ring-type forge piece cast steel billet

InactiveCN100368116CSimplify the forging processReduce manufacturing costMetal-working apparatusIngotForge

The invention discloses an annular forge-piece cast ingot prefabricating combined mould for separating the cast ingot from the bottom molding body and preventing the cast ingot body from producing cracks or rips. Its technical key points: setting combined inner ring body in the die space of the bottom molding body, where the inner ring body is composed of two, three or four small ring or wedge blocks, and there is a concave-arc or concave-isoceles triangular annular surface on the inner ring body.

Owner:齐虎成

Multi-direction block forging device and process of special-shaped fuel injector body based on guide pin

ActiveCN105195659BSimplify the forging processIncrease productivityForging/hammering/pressing machinesInduction furnaceIndustrial engineering

Owner:JIANGSU LONGCHENG PREC FORGING CO LTD

Forging device and forging method for multi-directional die forging of large complex forgings

ActiveCN110153349BSimplify the forging processSimple processForging/hammering/pressing machinesEngineeringForging

The invention discloses a forging device and a forging method for multidirectional die forging for a large complex forged piece. The forging device comprises a first upper die, a second upper die, a first lower die and a second lower die, wherein a through hole is formed in the sidewall of the first lower die, and a forming pin is arranged in the through hole; the second lower die detachably sleeves the periphery of the first lower die, and an impression corresponding to the through hole is formed in the inner side surface of the second lower die; and the first upper die extrudes a blank intothe space between the first lower die and the second lower die, the second upper die is matched with the forming pin, and horizontal die forging is carried out on the blank to jack the blank into theimpression to form a boss structure. According to the forging device and the forging method for multidirectional die forging for the large complex forged piece, by forming the through hole in the first lower die and arranging the forming pin in the through hole, after the blank is placed, the boss structure can be formed at a position corresponding to the through hole, on the blank through the matching of the first upper die, the second upper die and the forming pin, so that the die forging for the blank in the vertical direction and the horizontal direction is realized, and a forging processfor the forged piece with the boss structure is simplified.

Owner:TSINGHUA UNIV

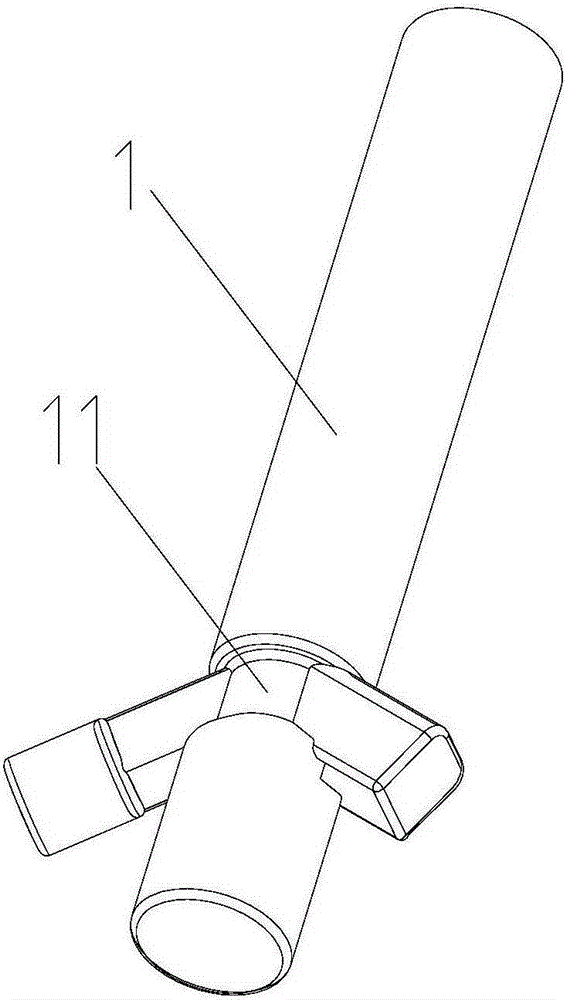

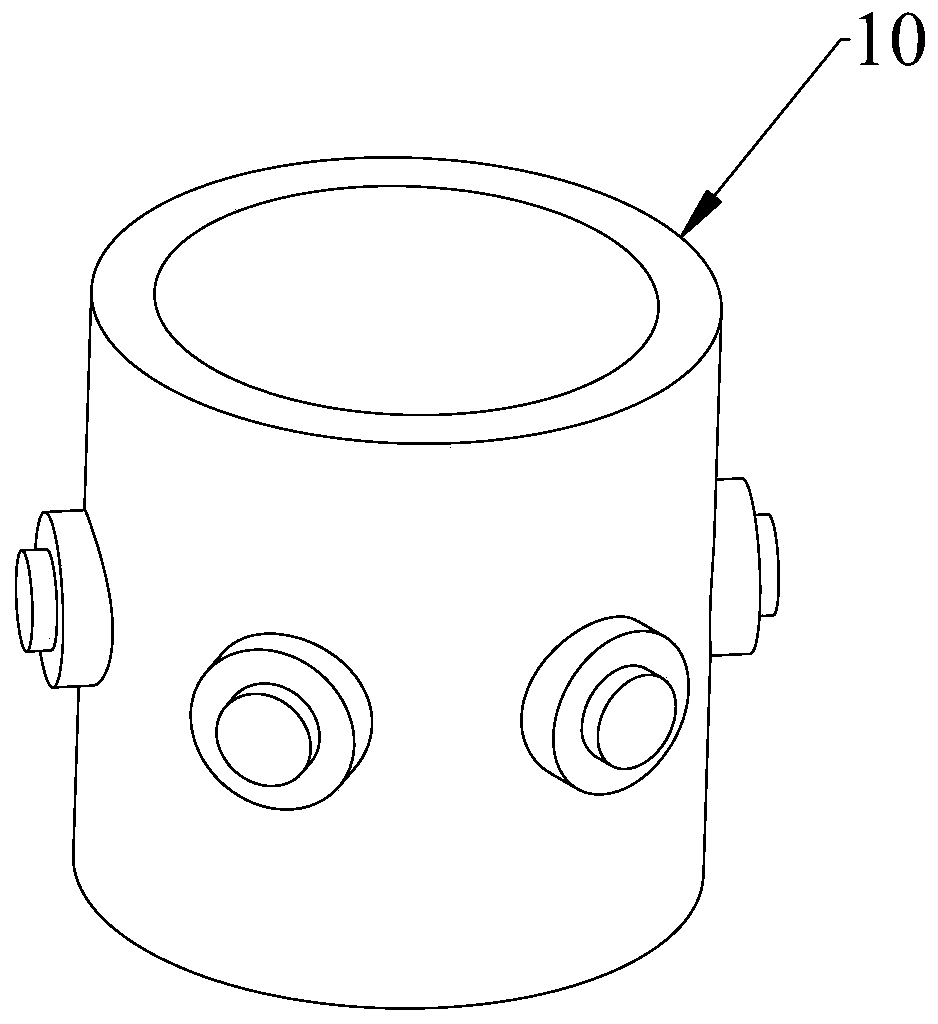

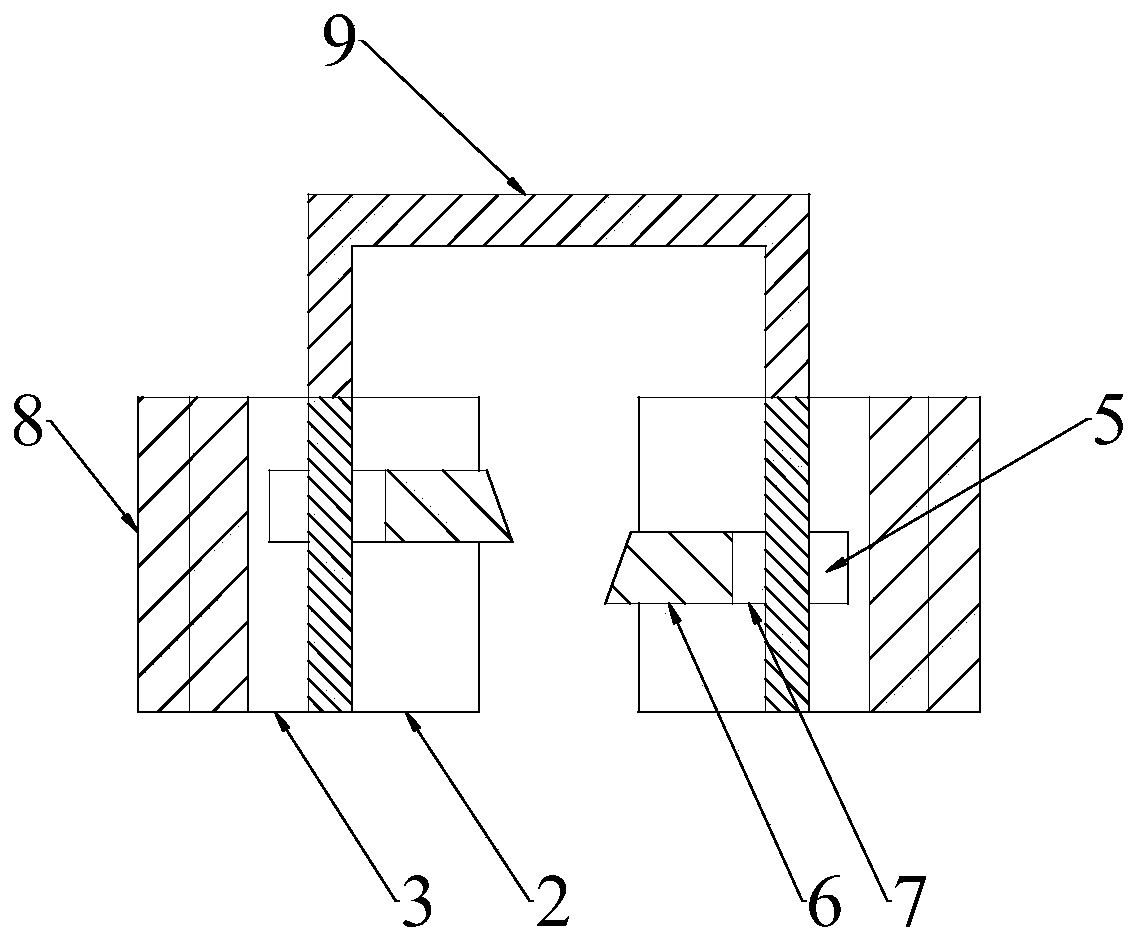

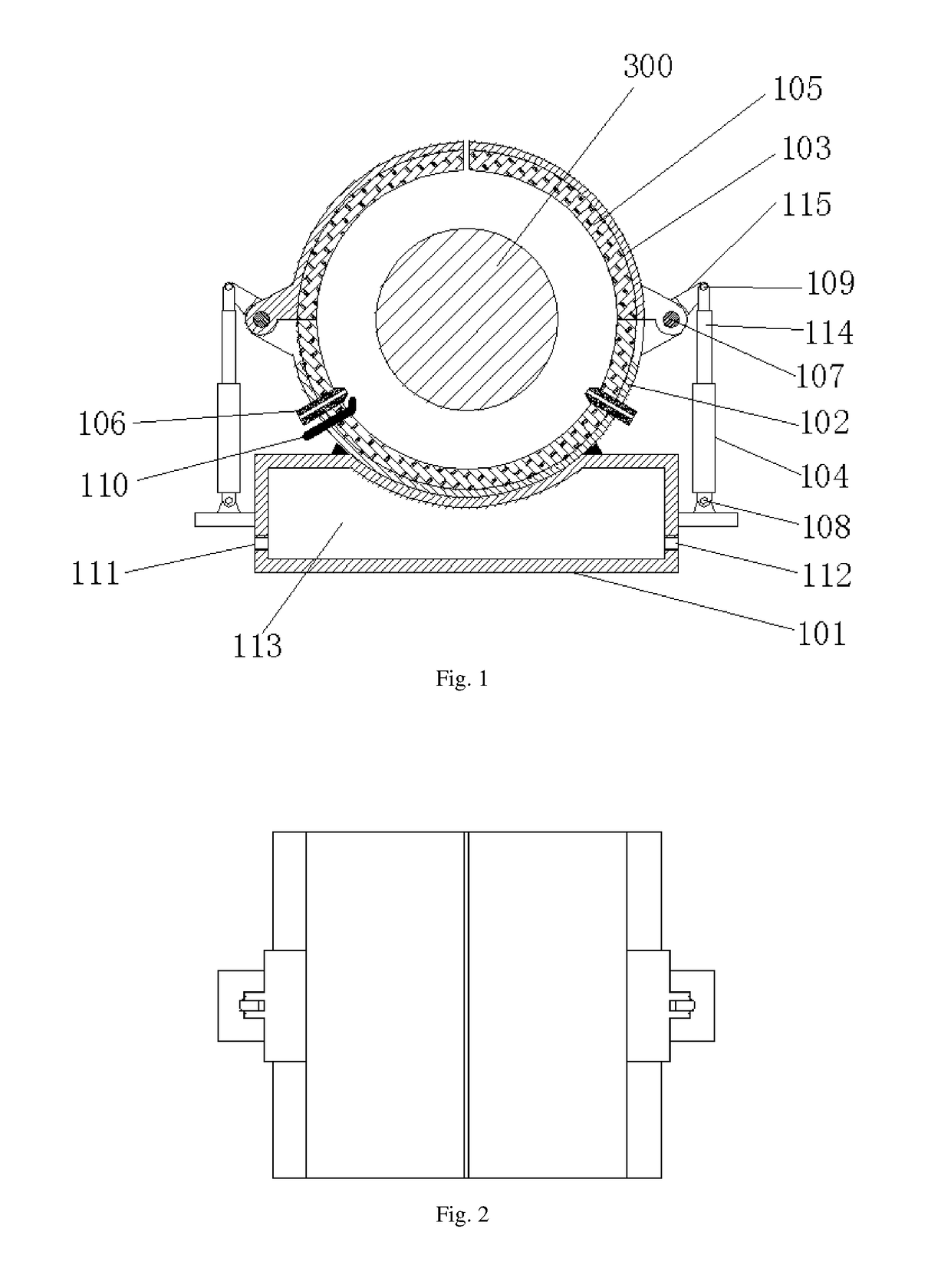

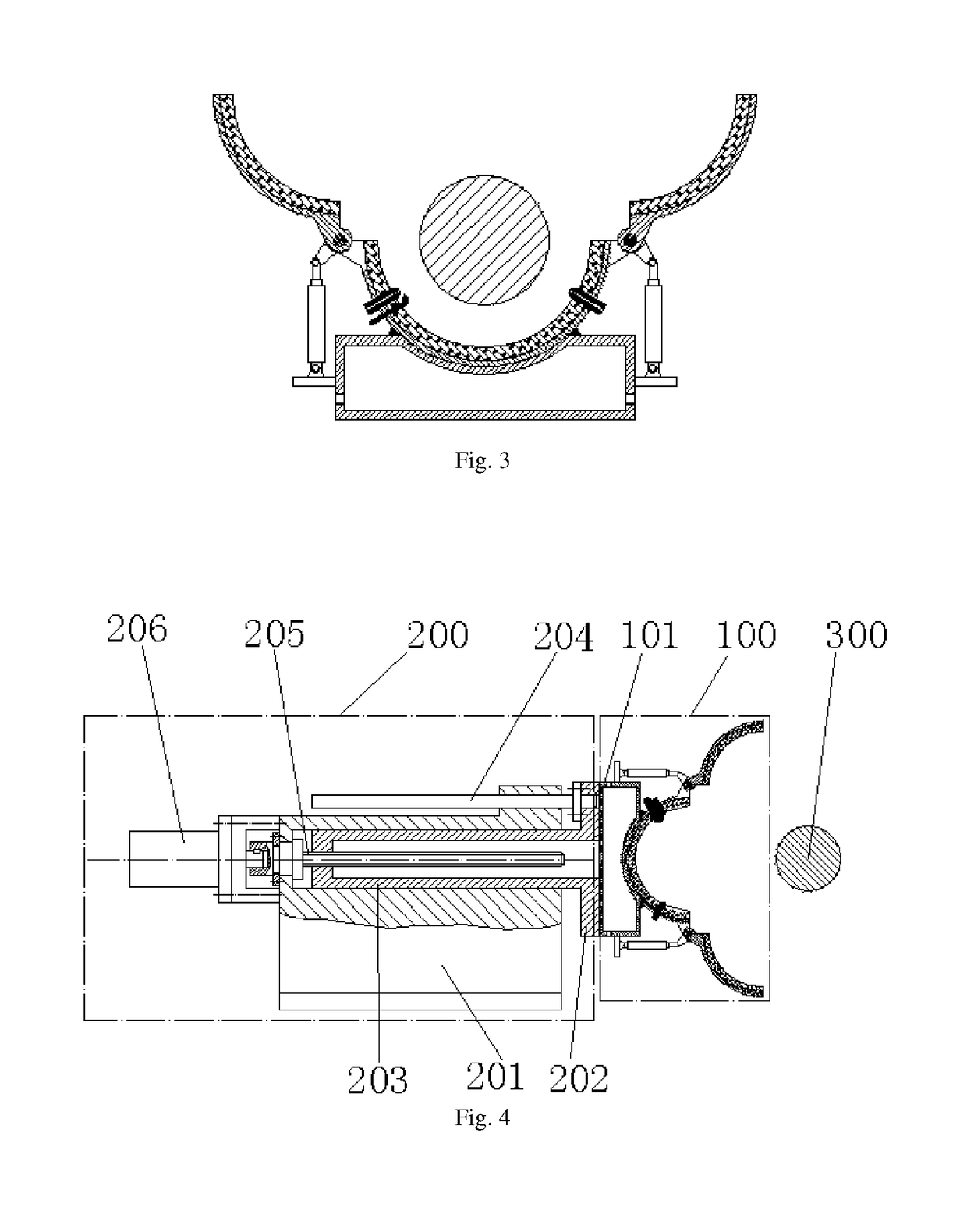

Opening-and-Closing Type Heater and Wind Generator Shaft Forging Process Using the Same

ActiveUS20180345355A1Improve mechanical propertiesGuaranteed StrengthEngine componentsHeating/cooling devicesEngineeringWind force

A heating / heat-retaining device, particularly to a heating / heat-retaining device used in the forging process, and more particularly to an opening-and-closing type heater and a wind generator shaft forging process using the same. The opening-and-closing type heater comprises a base, a tube body mounted on the base and a tube body opening-and-closing mechanism; the tube body comprises a fixed tube body and a movable tube body, the fixed tube body and the movable tube body are arc-shaped shells, and form a hollow shape when the openings thereof match with each other; the tube body opening-and-closing mechanism is connected to the movable tube body for realizing the opening-and-closing of the movable tube body and the fixed tube body. The invention solves heat retaining and heating problems during the forging process of the main shaft forgings and avoids internal defects due to rapid temperature drop of the main shaft forgings.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

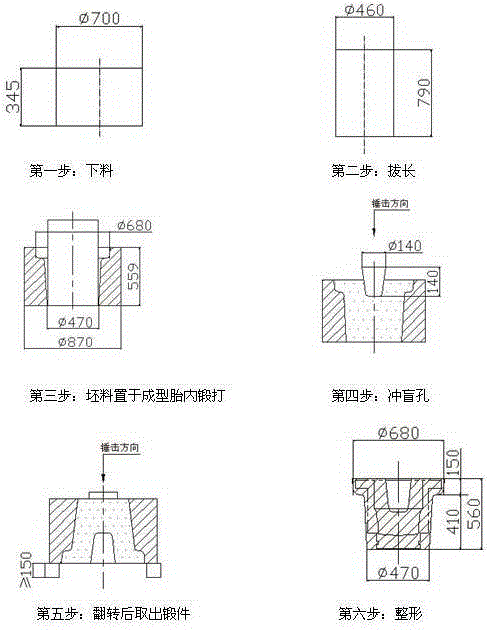

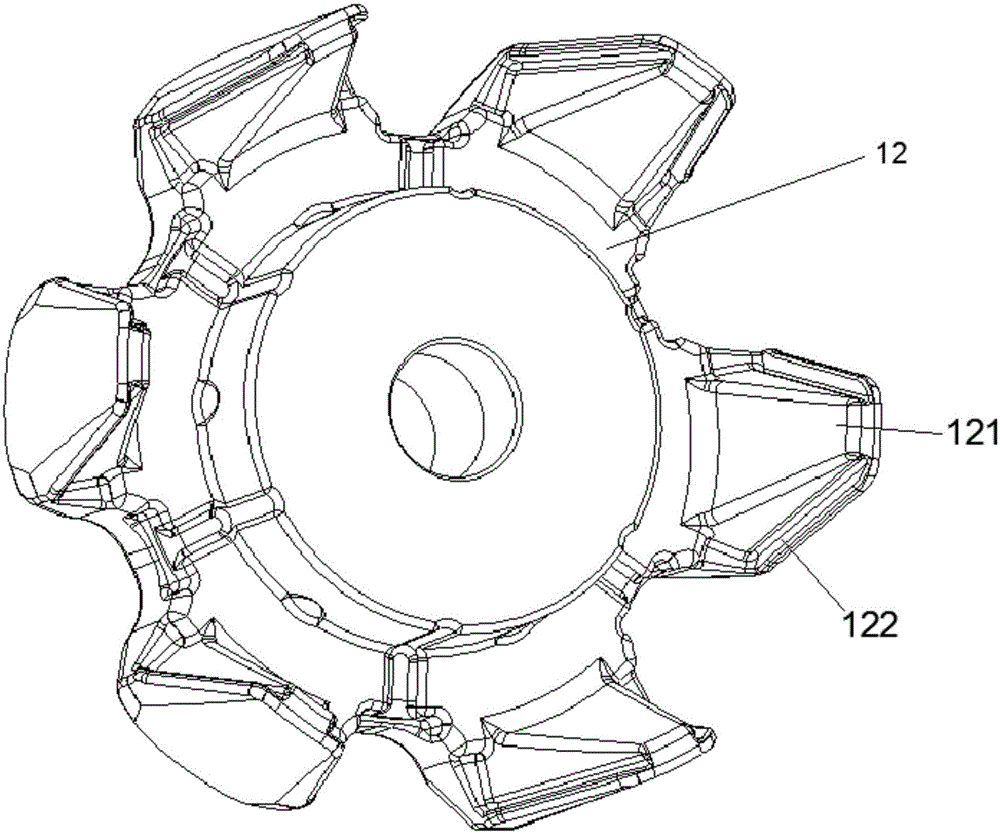

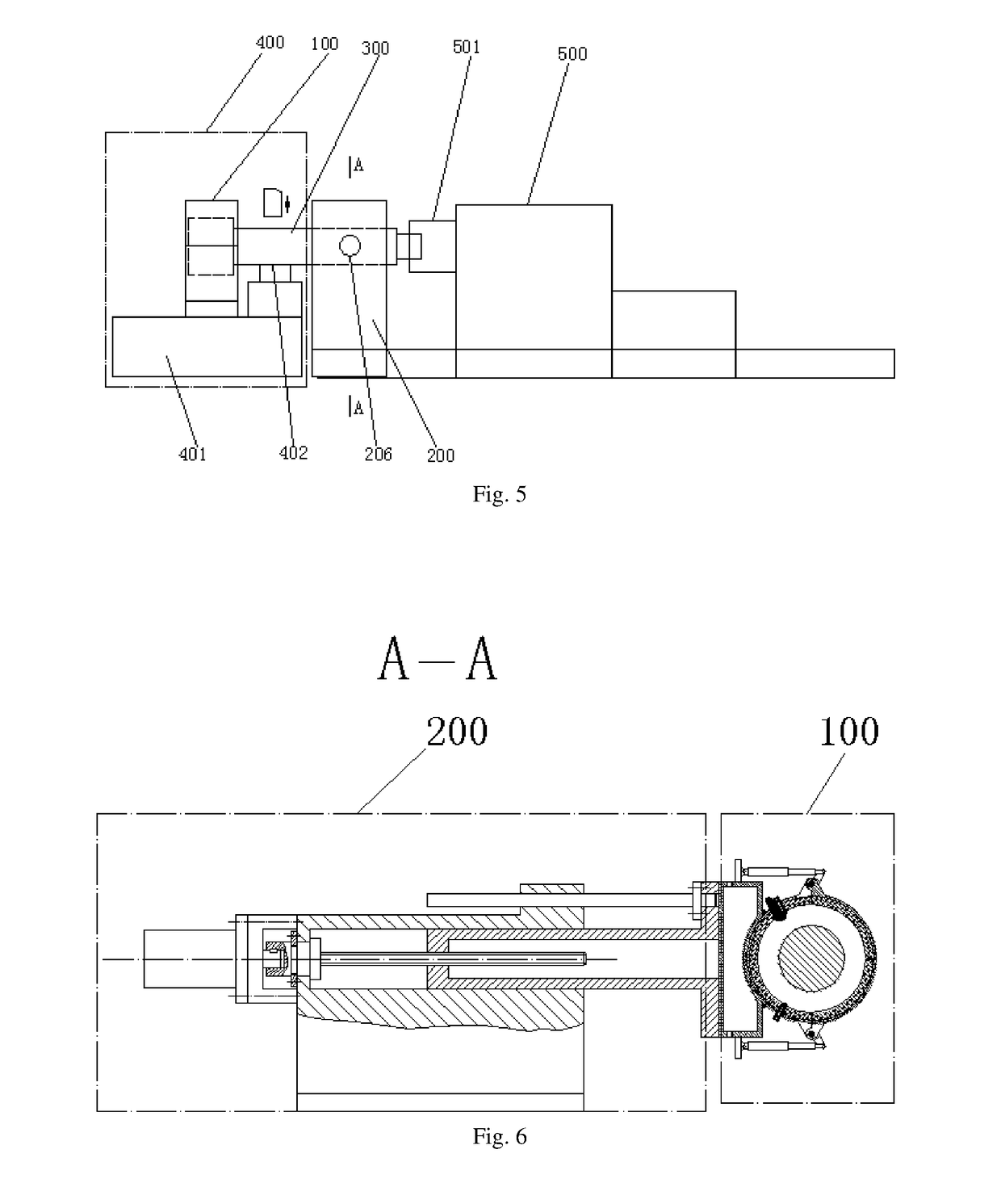

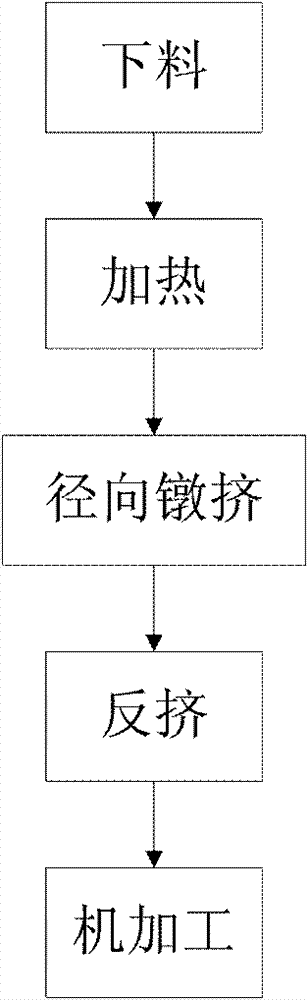

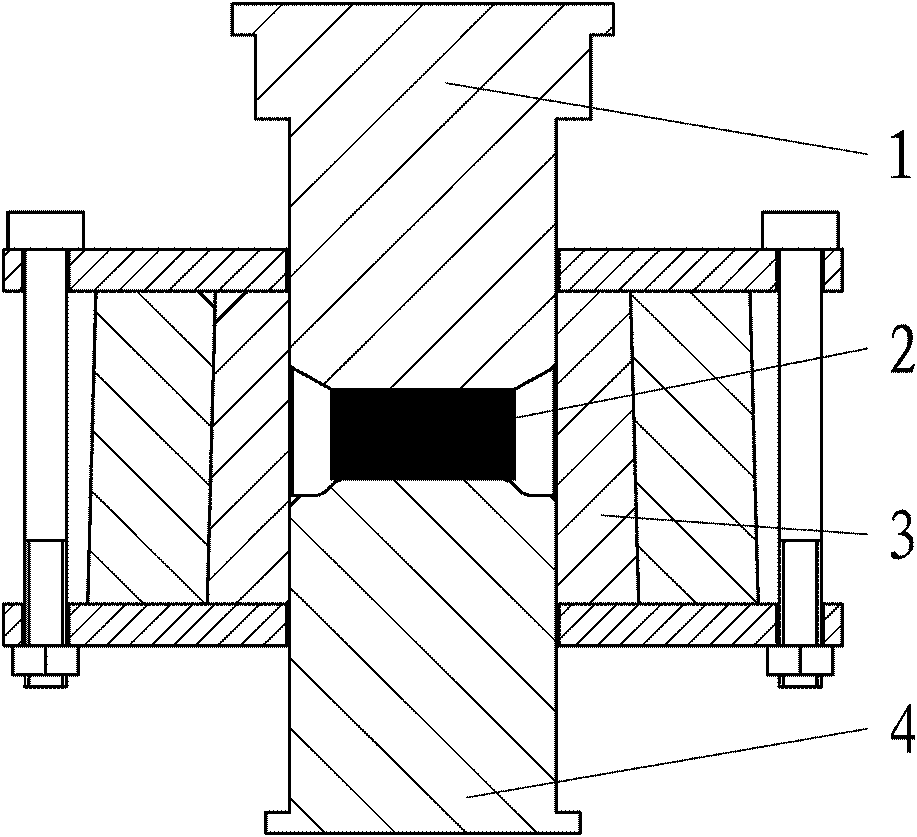

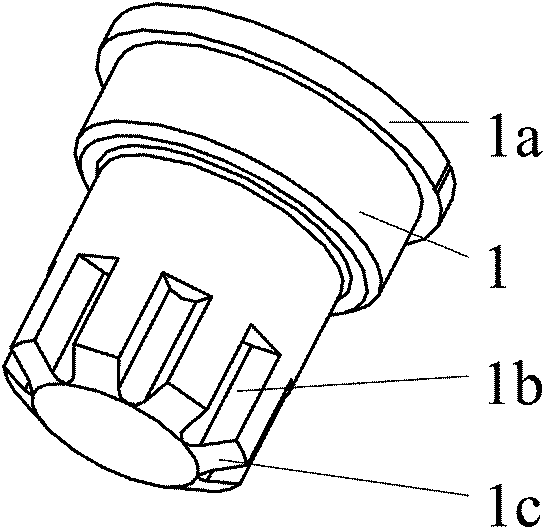

Process for forming generator claw pole of vehicle

InactiveCN102179464BIncrease profitSimplify the forging processForging/hammering/pressing machinesEngineeringExtrusion

The invention relates to a process for forming a generator claw pole of a vehicle, and the process provided by the invention comprises the following steps: firstly baiting; then heating; performing radial upsetting extrusion so as to form a middleware; reversely extruding a claw part into a final forging; and finally machining and preparing the forging into an end product workpiece, wherein the radial upsetting extrusion and the reverse extruding forming are realized by using a radial upsetting extrusion mould and a reverse extruding mould. According to the invention, the forging processing process is simplified, so the process provided by the invention has the advantages that the process is simple, the production period is short, the use ratio of materials is high, and the product precision is high.

Owner:XI AN JIAOTONG UNIV

Forging molding technological method for multi-lug part

InactiveCN105057557ASimplify the forging processReduce weight ratioEngine componentsRound barForging

The invention discloses a forging molding technological method for a multi-lug part. The forging and molding technological method for the multi-lug part is completed according to the following steps that firstly, blanking and heating are conducted, wherein heating is conducted after a round bar blank is blanked; secondly, flattening is conducted, wherein one end of the round bar blank is arranged on a pressing die, and after the pressing die is closed once, one end of the round bar blank is flattened; thirdly, upsetting pressing is conducted, wherein the flattened end of the round bar blank is vertically inserted into a blank forming die cavity of the pressing die, upsetting pressing is conducted on the other end of the round bar blank, and therefore a blank with the outline matched with a cavity of a pre-forging die is obtained; fourthly, forging molding is conducted, the blank obtained after blank forming is conducted is put into the pre-forging die to be pre-forged, and then the pre-forged blank is input into a final-forging die to be forged into a finished blank. According to the forging molding technological method for the multi-lug part, the process of the forging technology of the multi-lug part becomes easy, the production efficiency is improved, an air hammer and a roller forging machine are not used any more, blank waste is reduced, and comprehensive benefits are improved.

Owner:CHONGQING HAIAO PRECISION FORGING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com