Wheel edge planet wheel shaft structure of loader drive axle

A technology for planetary wheel shafts and loaders, which is applied to axles, wheels, mechanical equipment, etc. It can solve the problems of high production cost, high failure rate, and stress concentration of the four pillars of the wheel end cover, and achieve low processing cost and low failure rate. Low, reduce the effect of after-sales maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

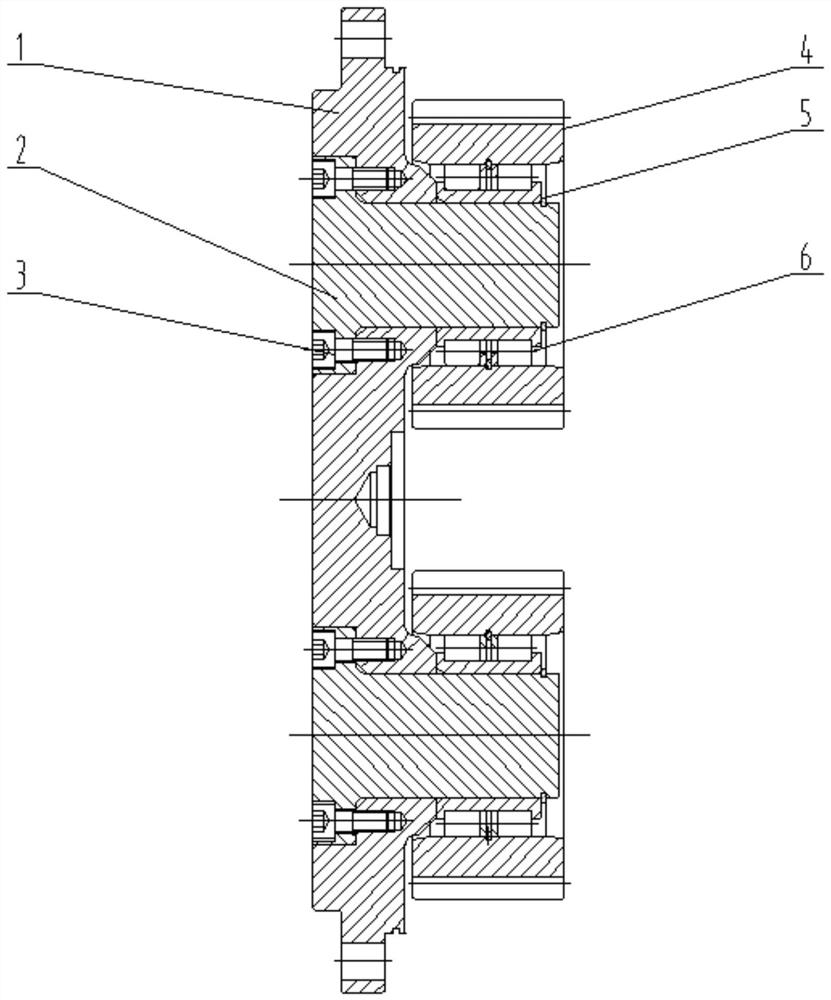

[0011] The structure of the wheel-side planetary wheel axle of the loader drive axle of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] figure 1 As shown, the loader drive axle wheel side planetary wheel shaft structure of the present invention includes wheel side end cover 1 and planetary wheel shaft 2; limit, to ensure that the roller bearing assembly 6 is not loose; the wheel end cover 1 and the planetary shaft 2 adopt a split type, and the planetary shaft 2 is a separate flange type, which is forged from 20CrMnTi material and then carburized and quenched. It is provided with a plurality of evenly distributed screw holes, and is fixed on the wheel side end cover 1 by screws 3 .

[0013] When working, the planetary gear 4 is used to transmit torque. Due to the split design of the wheel side end cover 1 and the planetary wheel shaft 2 in the wheel side planetary shaft structure o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com