Multi-direction block forging device and process of special-shaped fuel injector body based on guide pin

A technology of closed forging and fuel injectors, which is applied in the direction of forging/pressing/hammer devices, manufacturing tools, metal processing equipment, etc., can solve the problems of long production cycle and low production efficiency, achieve simplified forging process, improve production efficiency and Product performance, the effect of realizing mechanization and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

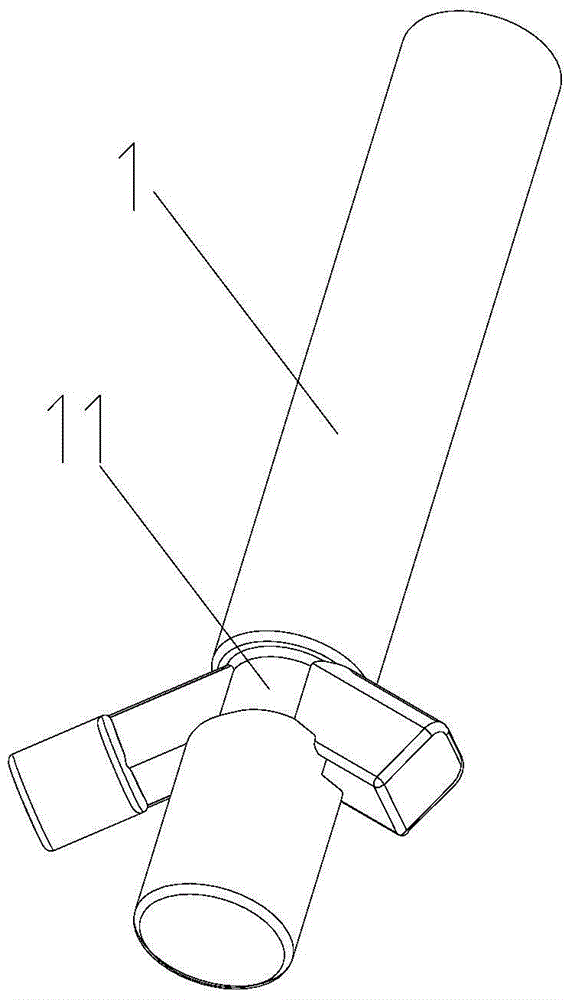

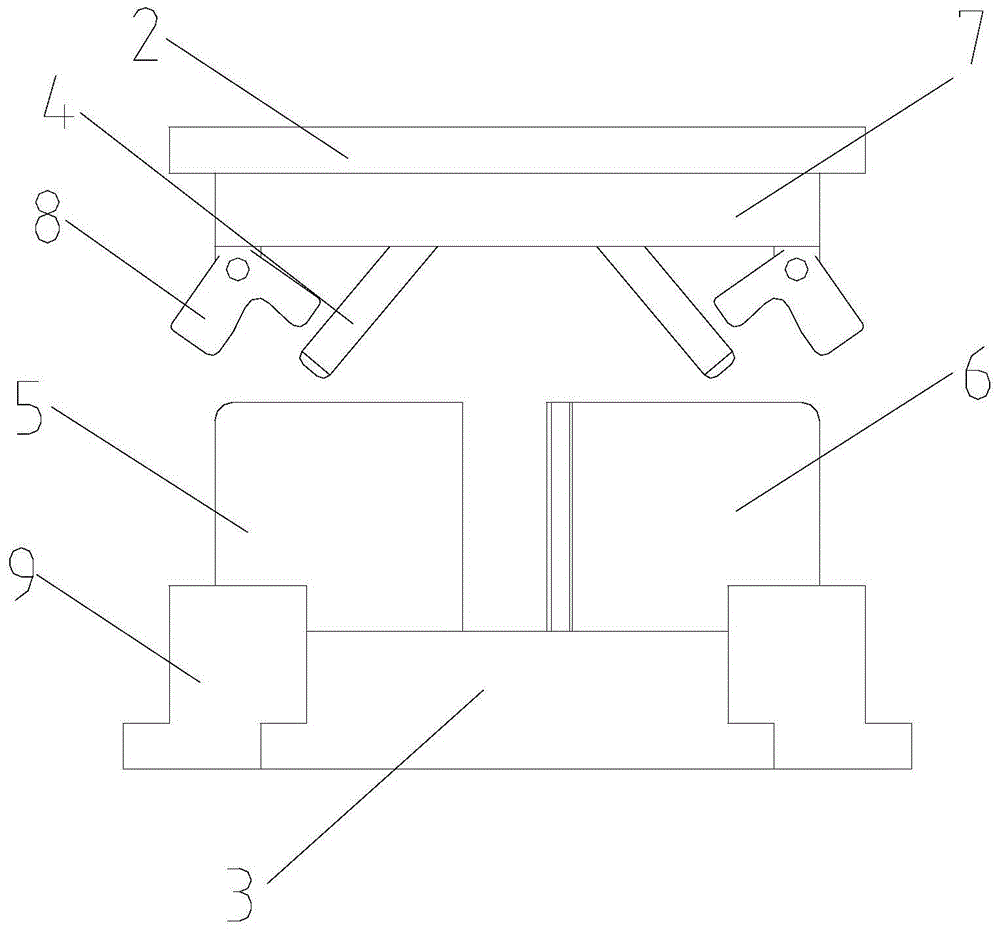

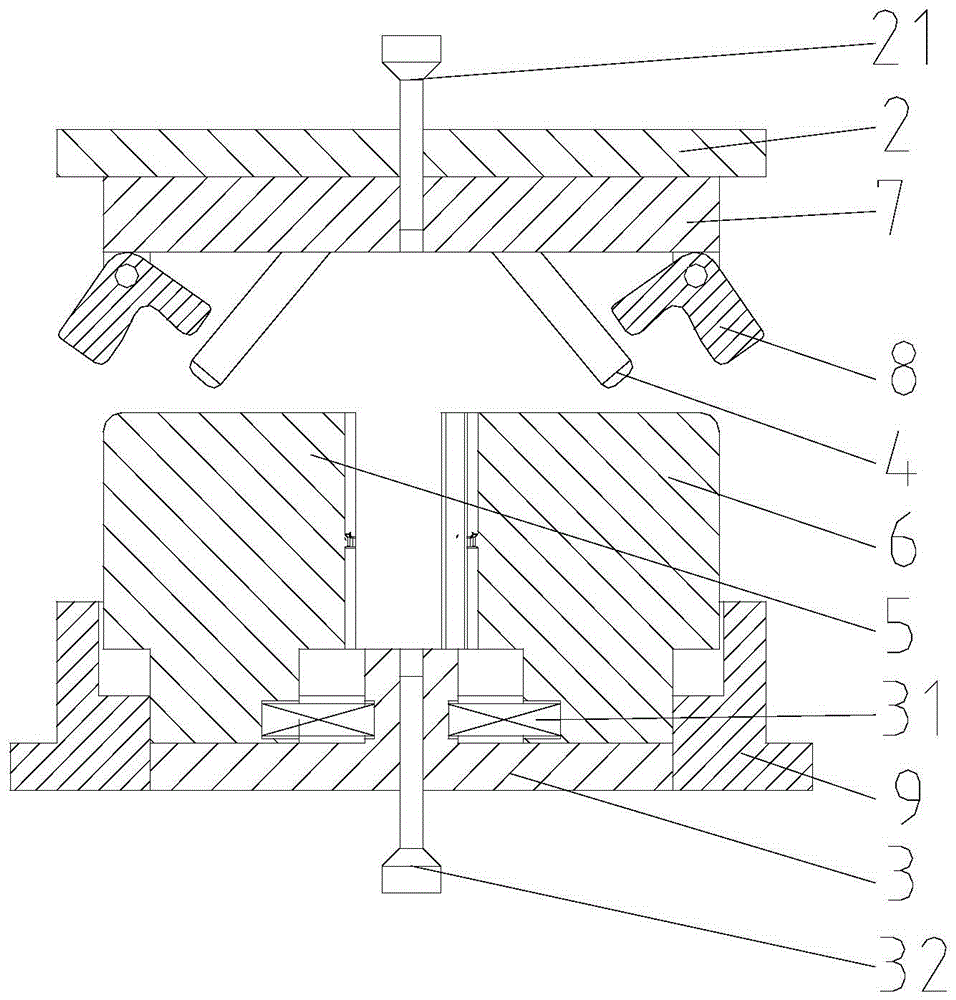

[0030] Such as figure 2 and 3 As shown, a multidirectional block forging device based on guide pins for a special-shaped fuel injector body includes an upper mold 2 and a lower mold 3; the lower surface of the upper mold 2 is fixed with a fixing plate 7 by screws and pins, and the A pair of guide pins 4 arranged obliquely in the vertical direction are installed on the fixed plate 7, and the two guide pins 4 are in the shape of "eight"; the two sides of the lower mold 3 are provided with a left die 5 and a right die 6 ,Such as Figure 5 and 6 As shown, the left die 5 and the right die 6 are provided with an oblique guide hole 51 corresponding to the guide pin 4, the diameter of the oblique guide hole 51 is slightly larger than the diameter of the guide pin 4, and the oblique guide hole The end of the sliding hole 51 is provided with rounded corners; the left die 5 and the right die 6 are respectively provided with a cavity 61 matching the shape of the injector body 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com