A kind of preparation method of compact ti2alc material

A dense and mixed material technology is applied in the field of preparation of dense Ti2AlC materials, which can solve the problems of easy occurrence of impurity phase in products, difficult industrialization promotion, complicated process, etc., and achieve the effects of reducing oxygen content, simple process and high preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

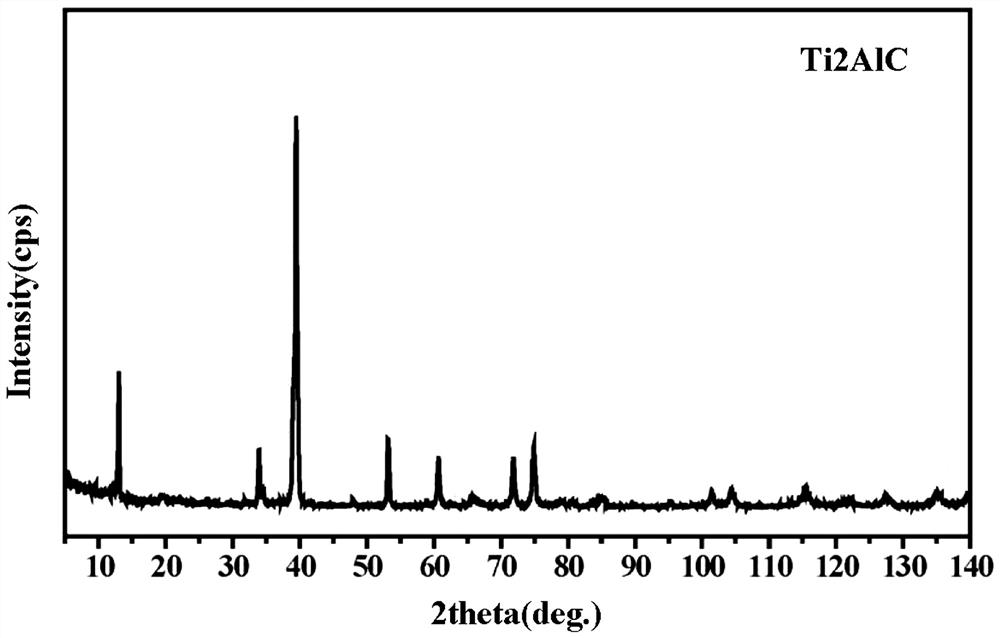

Image

Examples

Embodiment 1

[0018] Example 1: A preparation method of a dense Ti2AlC material, using Ti powder, Al powder and carbon nanotubes as raw materials, and adopting a near-isothermal sheath forging method to prepare a dense Ti2AlC material at one time.

[0019] The atomic ratio of the Ti powder, Al powder and carbon nanotubes is 2:1:1; the Ti powder has a particle size of 100 μm, the Al powder has a particle size of 20 μm, and the carbon nanotube has a particle size of 100 μm.

[0020] The specific preparation method is:

[0021] (1) Mixing: mix Ti powder, Al powder and carbon nanotubes in a V-shaped mixer in proportion, each time the mass is 500g, the mixing time is 2h, and the speed is 100r / min;

[0022] (2) Preparation of the prefabricated block body: put the uniformly mixed powder into the mold, and then press it on the press, the pressure is controlled at 100MPa, the pressure is kept for 10 minutes, and then the pressure is automatically reduced to prepare the prefabricated block body;

[...

Embodiment 2

[0026] Example 2: A preparation method of a dense Ti2AlC material, using Ti powder, Al powder and carbon nanotubes as raw materials, and adopting a near-isothermal sheath forging method to prepare a dense Ti2AlC material at one time.

[0027] The atomic ratio of the Ti powder, Al powder and carbon nanotubes is: 3:1.5:1. The particle size of the Ti powder is 150 μm, the particle size of the Al powder is 35 μm, and the particle size of the carbon nanotube is 150 μm.

[0028] The specific preparation method is:

[0029] (1) Mixing: mix Ti powder, Al powder and carbon nanotubes in a V-type mixer in proportion, each time the mass is 500g, the mixing time is 4h, and the speed is 300r / min;

[0030] (2) Preparation of the prefabricated block body: put the uniformly mixed powder into the mold, and then press it on the press, the pressure is controlled at 150MPa, the pressure is maintained for 15 minutes, and then the pressure is automatically reduced to prepare the prefabricated block...

Embodiment 3

[0034] Example 3: A preparation method of a dense Ti2AlC material, using Ti powder, Al powder and carbon nanotubes as raw materials, and adopting a near-isothermal sheath forging method to prepare a dense Ti2AlC material at one time.

[0035] The atomic ratio of the Ti powder, Al powder and carbon nanotubes is: 4:2:1. The particle size of the Ti powder is 200 μm, the particle size of the Al powder is 50 μm, and the particle size of the carbon nanotube is 200 μm.

[0036] The specific preparation method is:

[0037] (1) Mixing: mix Ti powder, Al powder and carbon nanotubes in a V-type mixer in proportion, each time the mass is 500g, the mixing time is 6h, and the speed is 400r / min;

[0038] (2) Preparation of the prefabricated block body: put the uniformly mixed powder into the mold, and then press it on the press, the pressure is controlled at 200MPa, the pressure is kept for 20 minutes, and then the pressure is automatically reduced to prepare the prefabricated block body; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com