Electroslag smelting and casting sector-plate special-shaped crystallizer

A technology of electroslag casting and special-shaped plates, which is applied in the field of electroslag casting fan-shaped plate special-shaped crystallizers, can solve the problems of complex production procedures, low production efficiency, and high production costs, and achieve simplified production procedures, improved production efficiency, and low prices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

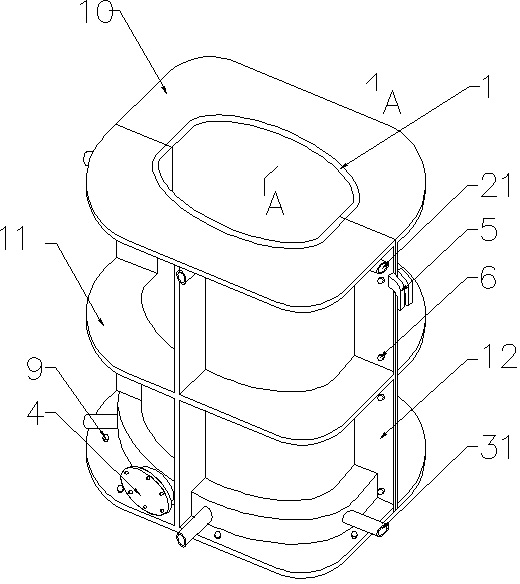

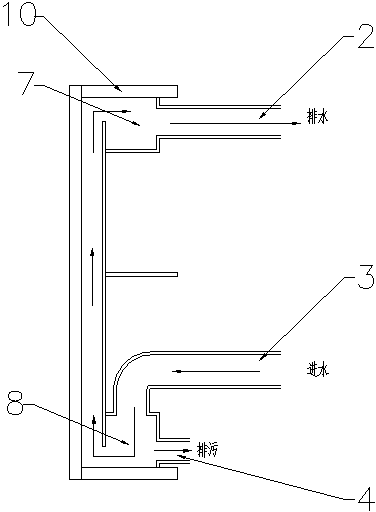

[0015] Such as figure 1 , figure 2 As shown, the electroslag casting fan-shaped plate special-shaped crystallizer is composed of front and rear symmetrical parts. The front part is an example. Composition, when in use, the front and rear parts are connected together by bolts through the screw hole A 6 and nuts, and the upper and lower parts can also be superimposed and used by multiple electroslag casting fan-shaped plate special-shaped crystallizers. After the front and rear parts are combined, the inner cavity mold plate 1 forms a cavity that is parallel to the left and right and the upper and lower sides are circular arcs. The inner cavity mold plate 1 is made of copper alloy material; the outer cavity mold plate 10 has the same shape as the inner cavity mold plate 1. Made of steel material, there is a water tank between the inner cavity type plate 1 and the outer cavity type plate 10, the thickness is 15-25mm, the outer cavity type plate 10 can be manufactured by cold b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com