Aluminium alloy crystallizer for electroslag fusion casting of small guide blade

An electroslag casting and aluminum alloy technology, applied in the field of casting molds, can solve the problems of difficulty in production, operation and maintenance of guide vanes, short service life, and high size requirements, and achieve the effects of easy processing, reduced production costs, and good weldability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

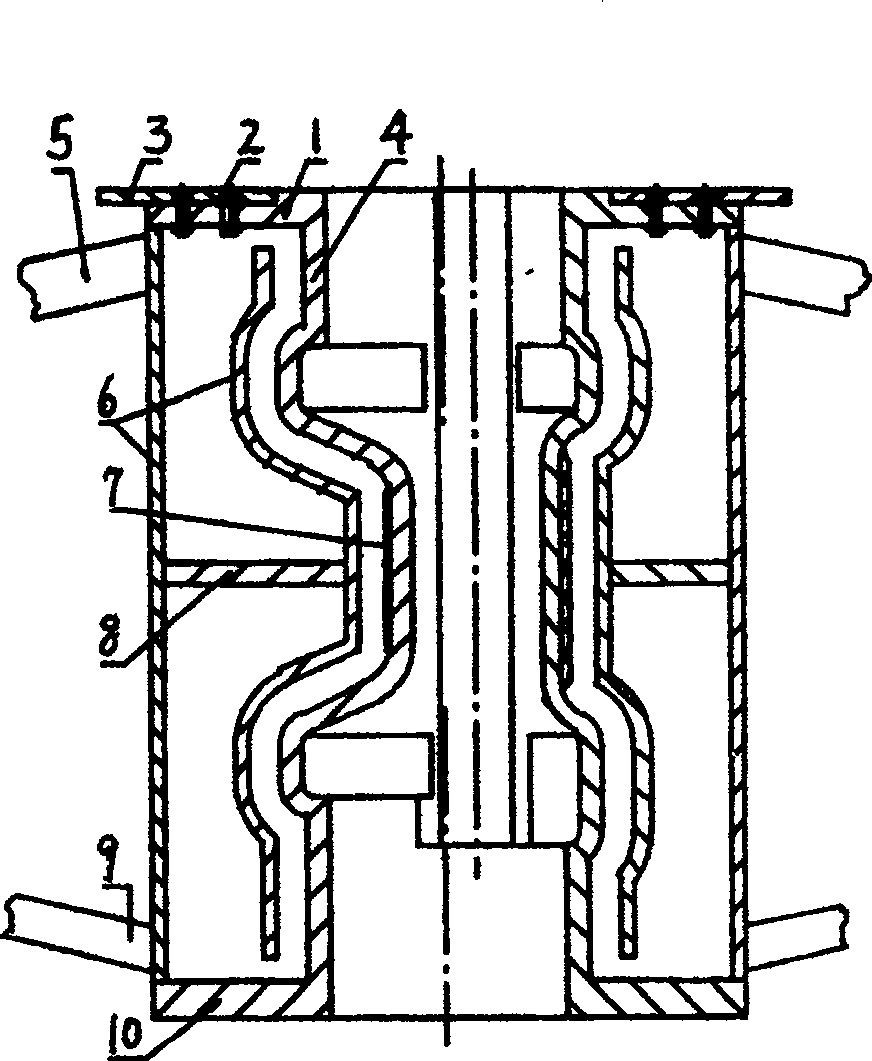

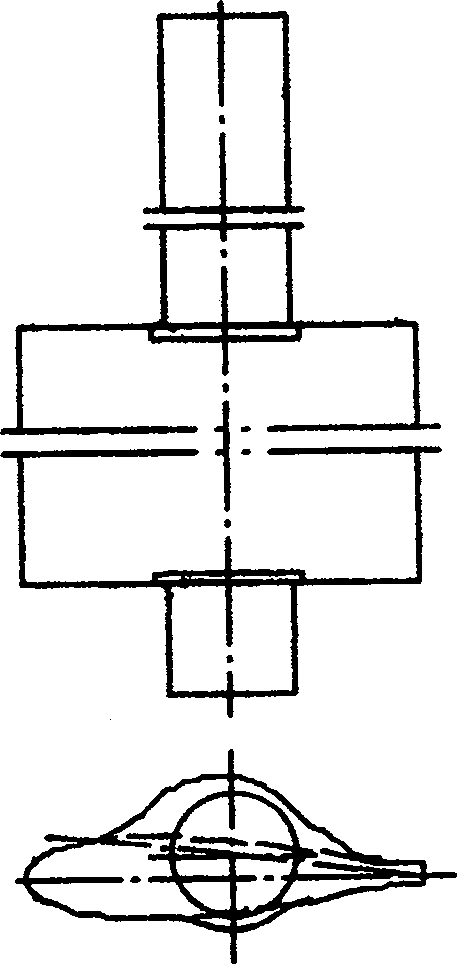

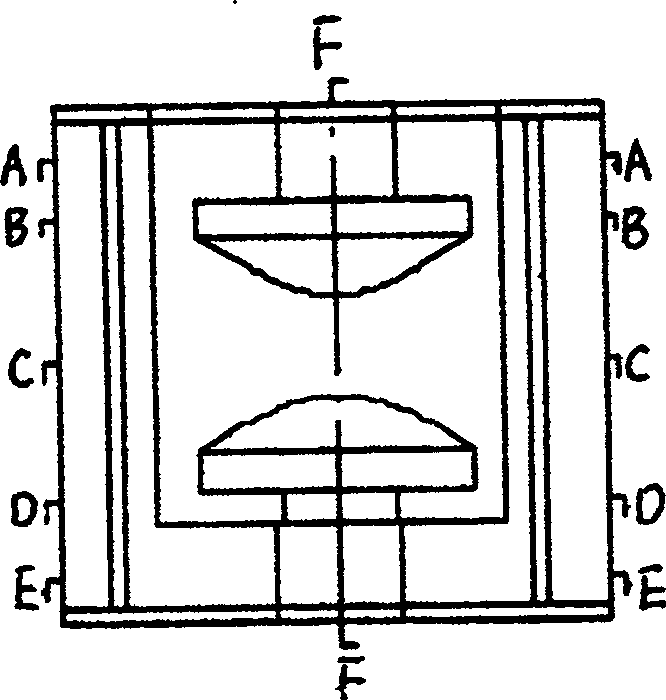

[0023] Aluminum alloy crystallizer for electroslag melting casting small guide vanes, including inner cavity plate 4, outer cavity plate 6, reinforcement rib 7, tie rib 8, upper flange 1 and lower flange 10, water inlet pipe 9 and water outlet pipe 5 , Additional steel plate 3.

[0024] The inner cavity type plate, reinforcing rib, upper flange, and lower flange are cast into an integral structure by casting method; the outer cavity type plate, tie bars, and water inlet and outlet pipes are formed into an integral structure by cold bending welding or casting method. The mold body is formed after the inner cavity mold plate (including reinforcing ribs, upper flange and lower flange) is integrally welded with the outer cavity mold plate (including tie bars and water pipes). The additional steel plate 3 is fixedly connected with the upper flange 1 through bolts 2 . Among them: the thickness of the inner cavity plate is 10-15mm, the thickness of the reinforcing rib is 10-15mm, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com