Lateral shaping process for hybrid excitation claw poles

A hybrid excitation, claw pole technology, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of workpiece deformation, reduction of claw tooth height, etc., to improve product performance, flow length, and reduce adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

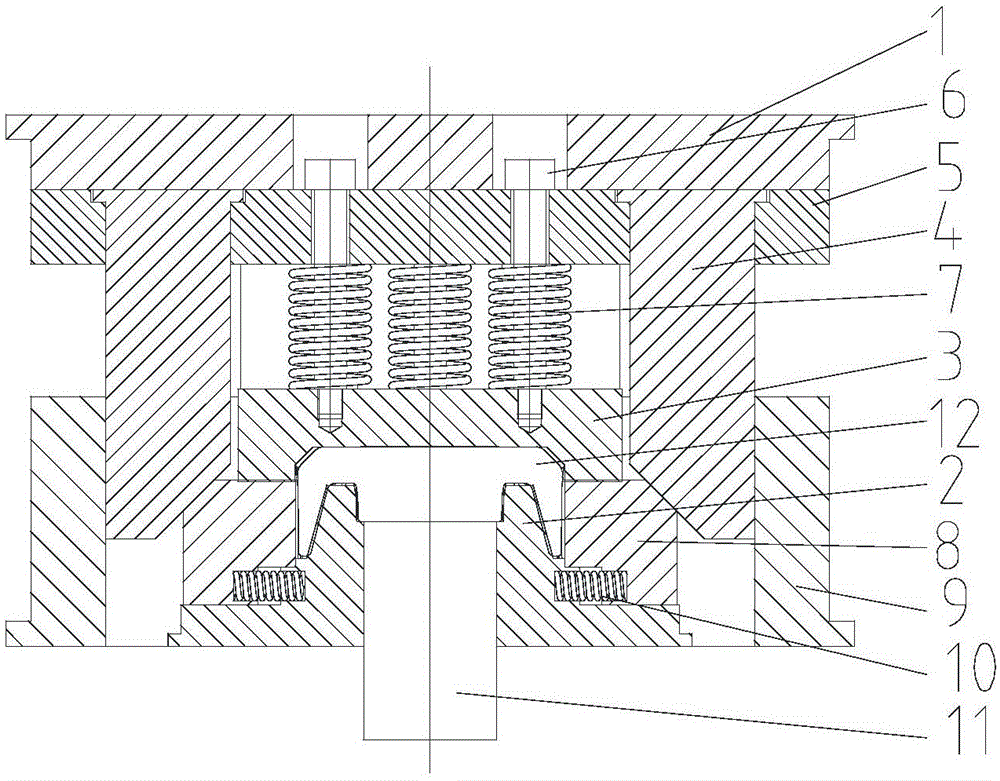

[0028] A lateral shaping process of hybrid excitation claw poles is to fix claw pole forgings on a mold, and then apply pressure to claw teeth and wings of claw poles along the radial direction of the claw poles for shaping.

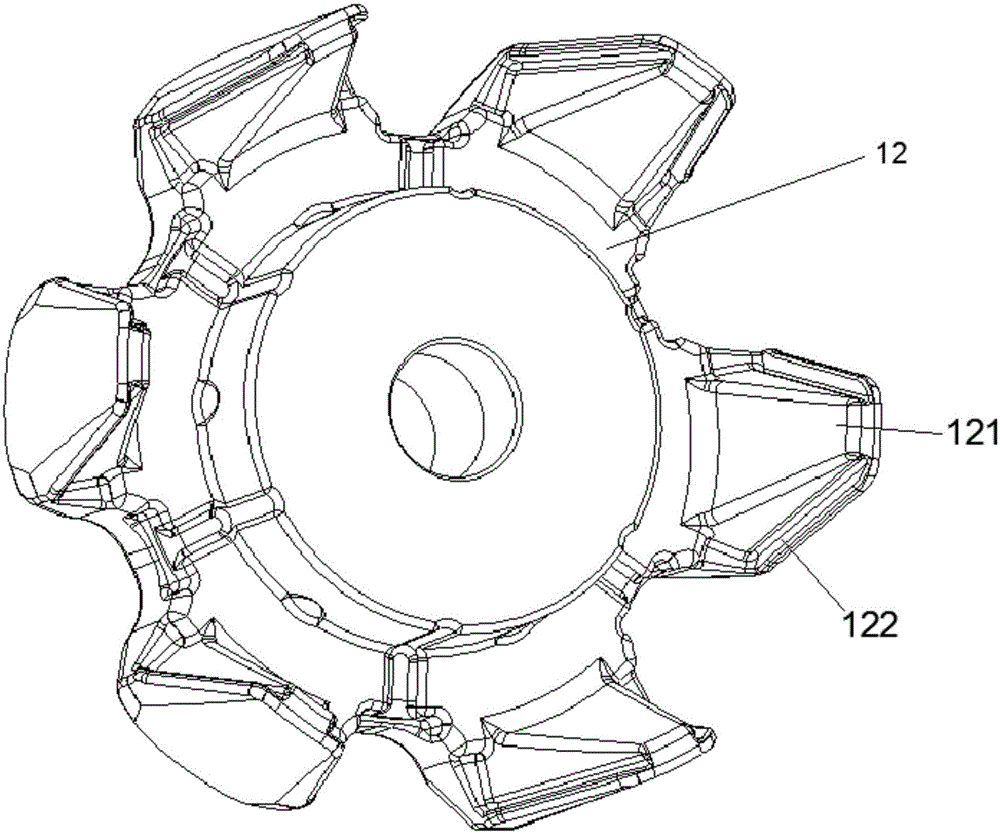

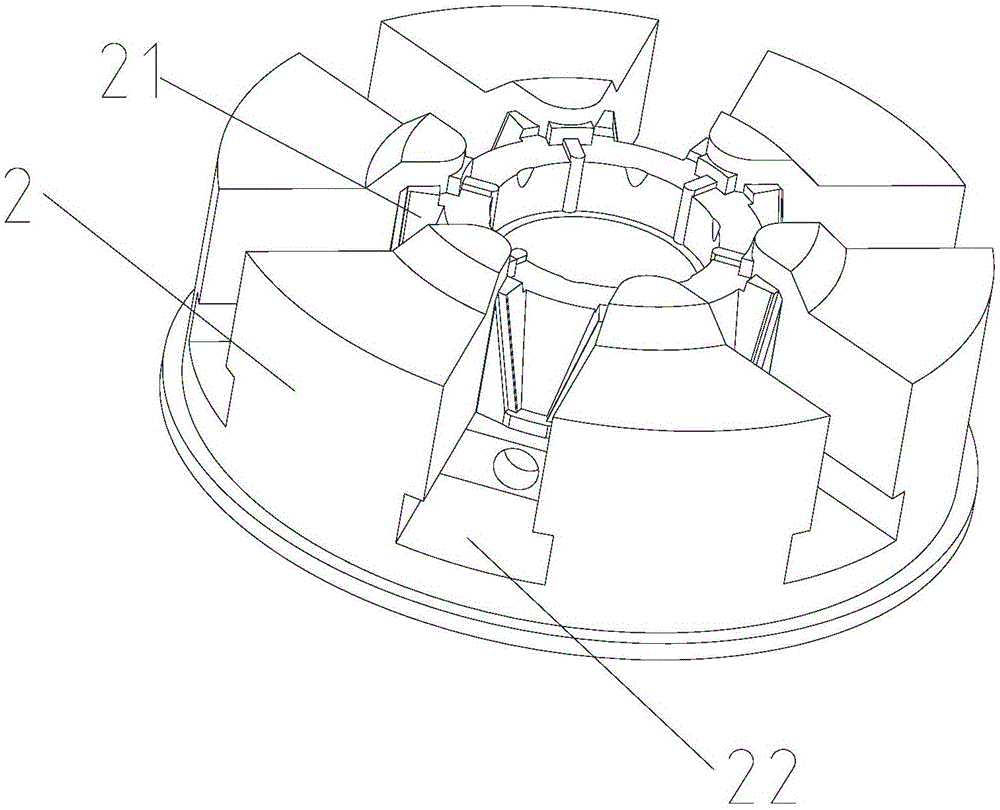

[0029] Such as figure 2 As shown, the mold for laterally shaping the hybrid excitation claw pole 12 using the above-mentioned process includes an upper mold base 1 and a lower mold base 2; an upper binder plate 3 and several wedges 4 are arranged below the upper mold base 1; The lower surface of the upper binder plate 3 is provided with an upper die, the upper die matches the shape of the upper surface of the claw pole 12, and the plurality of inclined wedges 4 are distributed on the outer side of the upper binder plate 3. The inclined wedges 4 The number is equal to the number of claw teeth 121 and wings 122 of the claw pole 12;

[0030] Such as figure 2 As shown, specifically, in order to facilitate the installation of the upper binder plate 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com