Forging Method of Small Gasoline Engine Connecting Rod

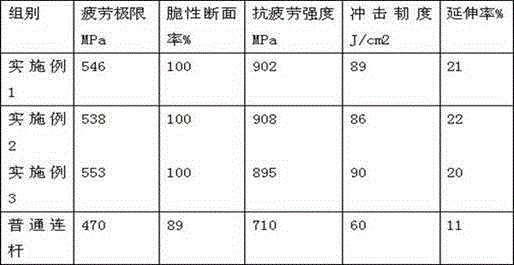

A small gasoline engine and connecting rod technology, applied in the field of mechanical forging, can solve the problems of poor tensile, impact and fatigue resistance, more equipment and processing personnel, and low steel utilization rate, etc., to achieve elongation and fatigue strength Improve and reduce the workload of mechanical processing, the effect of simple and feasible forging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A forging method for a connecting rod of a small gasoline engine, comprising the following steps: 1) Weighing raw materials; 2) Ball milling; 3) Powder compacting; 4) Sintering; 5) Cooling; 6) Spraying graphite powder; 7) Induction heating; 8 ) forging and demoulding; specifically include the following steps:

[0025] 1) Weigh raw materials: 1000 parts by weight of iron, 4 parts of titanium, 3 parts of nickel, 2 parts of manganese, 1 part of chromium, 3 parts of silicon carbide, 2 parts of titanium carbide, 2 parts of aluminum nitride, and 1 part of barium titanate 1 part, 1 part of zinc stearate, 1 part of talcum powder, 1 part of sodium silicate; 7 parts of graphite powder;

[0026] 2) Ball milling: mix iron, titanium, nickel, manganese, chromium, silicon carbide, titanium carbide, aluminum nitride and barium titanate to obtain mixture 1, add 0.1 times the weight of mixture 1 in water, and send it to a ball mill for ball milling to obtain 400 mesh powder, then spray-...

Embodiment 2

[0034] A forging method for a connecting rod of a small gasoline engine, comprising the following steps: 1) weighing raw materials; 2) ball milling; 3) powder compact; 4) sintering; 5) cooling; 6) spraying graphite powder; 7) induction heating; 8) Forging and demoulding; specifically include the following steps:

[0035] 1) Weigh raw materials: 1100 parts by weight of iron, 5 parts of titanium, 4 parts of nickel, 3 parts of manganese, 2 parts of chromium, 4 parts of silicon carbide, 3 parts of titanium carbide, 3 parts of aluminum nitride, and 2 parts of barium titanate 2 parts, 2 parts of zinc stearate, 2 parts of talcum powder, 2 parts of sodium silicate, 8 parts of graphite powder;

[0036] 2) Ball milling: Mix iron, titanium, nickel, manganese, chromium, silicon carbide, titanium carbide, aluminum nitride and barium titanate to obtain mixture 1, add 0.1 times the weight of the mixture 1 water, send it to the ball mill for ball milling, and obtain 400 mesh powder, then spr...

Embodiment 3

[0044] A forging method for a connecting rod of a small gasoline engine, comprising the following steps: 1) weighing raw materials; 2) ball milling; 3) powder compact; 4) sintering; 5) cooling; 6) spraying graphite powder; 7) induction heating; 8) Forging and demoulding; the above forging method specifically includes the following steps:

[0045]1) Weigh raw materials: 1200 parts by weight of iron, 6 parts of titanium, 4 parts of nickel, 3 parts of manganese, 2 parts of chromium, 4 parts of silicon carbide, 3 parts of titanium carbide, 3 parts of aluminum nitride, and 2 parts of barium titanate 2 parts, 2 parts of zinc stearate, 2 parts of talcum powder, 1 part of sodium silicate, 9 parts of graphite powder;

[0046] 2) Ball milling: mix iron, titanium, nickel, manganese, chromium, silicon carbide, titanium carbide, aluminum nitride and barium titanate to obtain mixture 1, add 0.1 times the weight of mixture 1 in water, and send it to a ball mill for ball milling to obtain 400...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com