Forging and forming method of integral hinge beam

A hinged beam and integral technology, applied in the field of forging and forming of large forgings, to achieve the effects of improving performance, compacting core defects, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) The material used for forging is 35CrMo alloy structural steel. According to the heating specification, the steel ingot is heated to the initial forging temperature of 1200°C and kept for 18 hours to make the internal temperature uniform. The weight of the steel ingot used is 15 tons; the final forging temperature during forging is 950°C.

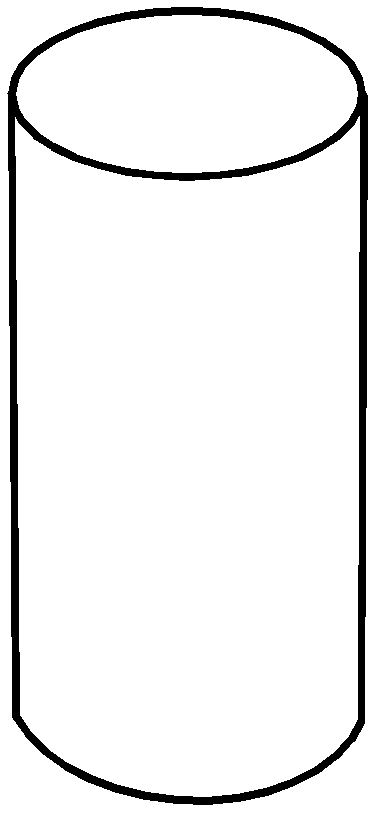

[0038] (2) Carry out the process of conventional steel ingot press pliers, chamfering and removing the tail of the ingot, the main part of the finished steel ingot is as follows figure 1 As shown (the figure omits the clamp handle), the height-to-diameter ratio range of the steel ingot is 2.0:1; the billet is heated to 1200 ° C and kept for 18 hours;

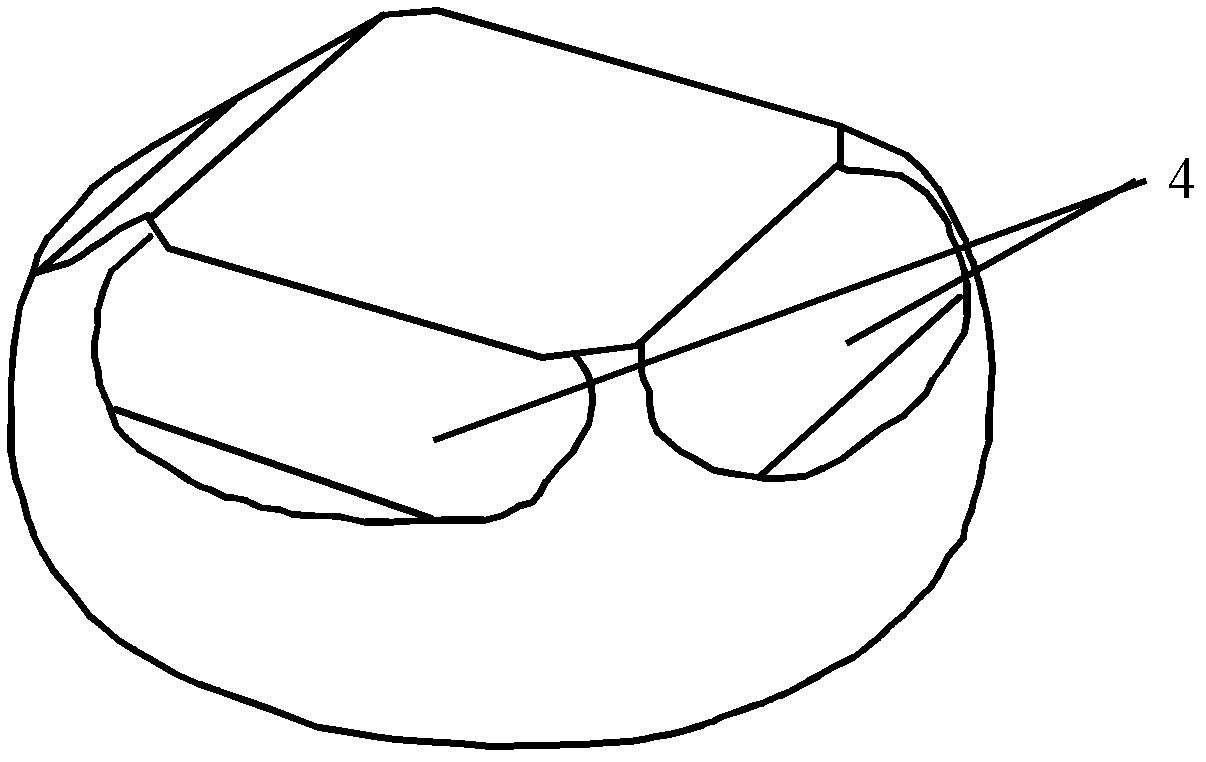

[0039] (3) Upsetting the billet to such as figure 2 After the cylinder with the height-to-diameter ratio shown is 1, use an anvil to upset the billet as image 3 The circular cake shape with four symmetrical slopes 4 is shown; the billet is heated to 1200°C and kept for 18 hours;...

Embodiment 2

[0045] (1) The material used for forging is 40CrMnMo alloy structural steel. According to the heating specification, the steel ingot is heated to the initial forging temperature of 1150°C and kept for 20 hours to make the internal temperature uniform. The weight of the steel ingot used is 10 tons; the final forging temperature during forging is 930°C.

[0046] (2) Carry out the process of conventional steel ingot press pliers, chamfering and removing the tail of the ingot, the main part of the finished steel ingot is as follows figure 1 As shown (the pincers are omitted in this figure), the height-to-diameter ratio range of the steel ingot is 1.2:1; the billet is heated to 1150 ° C and kept for 20 hours;

[0047] (3) Upsetting the billet to such as figure 2 After the cylinder with the height-to-diameter ratio shown is 1, use an anvil to upset the billet as image 3 The circular cake shape with four symmetrical slopes 4 is shown; the billet is heated to 1150°C and kept for 20...

Embodiment 3

[0053] (1) The material used for forging is 20CrNi alloy structural steel. According to the heating specification, the steel ingot is heated to the initial forging temperature of 1250°C and kept for 15 hours to make the internal temperature uniform. The weight of the steel ingot used is 20 tons; the final forging temperature is 980°C during forging.

[0054] (2) Carry out the process of conventional steel ingot press pliers, chamfering and removing the tail of the ingot, the main part of the finished steel ingot is as follows figure 1 As shown (the pincers are omitted in this figure), the height-to-diameter ratio range of the steel ingot is 3:1; the billet is heated to 1250°C and kept for 15 hours;

[0055] (3) Upsetting the billet to such as figure 2 After the cylinder with the height-to-diameter ratio shown is 1, use an anvil to upset the billet as image 3 The circular cake shape with four symmetrical slopes 4 is shown; the billet is heated to 1250°C and kept for 15 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com