Hot forging method of wetland track plate and hot forging die thereof

A technology of hot forging molds and track shoes, which is applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., and can solve problems such as insufficient strength of casting track shoes, increased machine power consumption, and plastic deformation , to achieve balanced and stable mass production, reduce power consumption, and compact forging structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

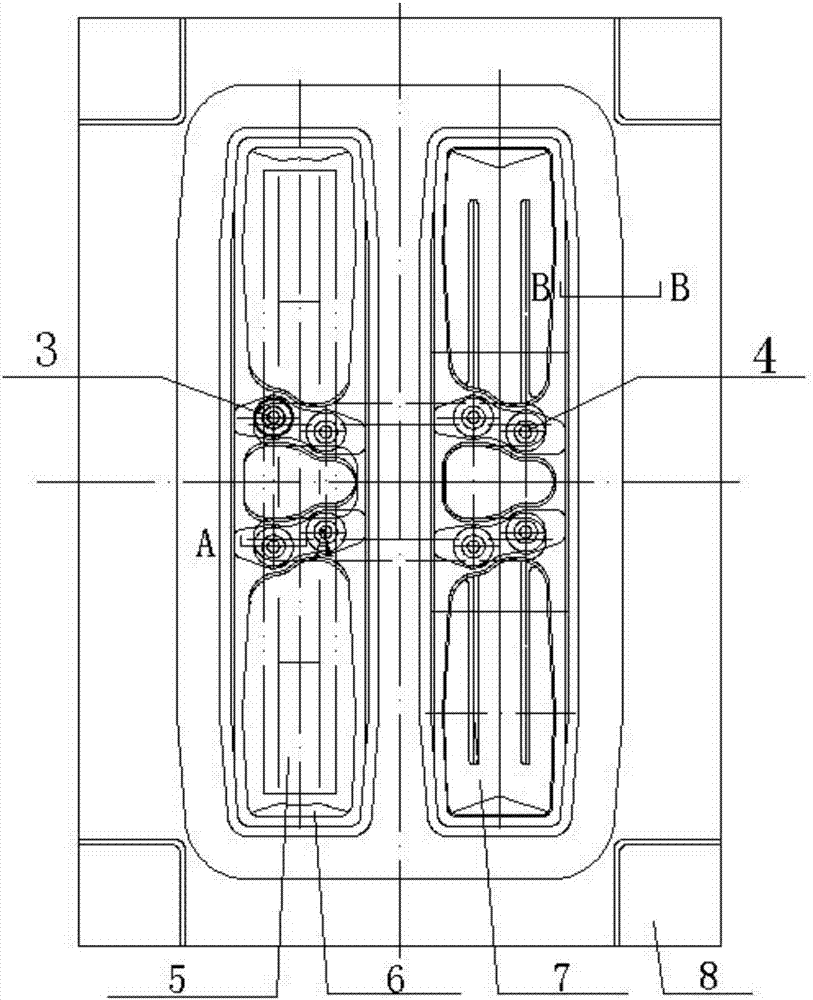

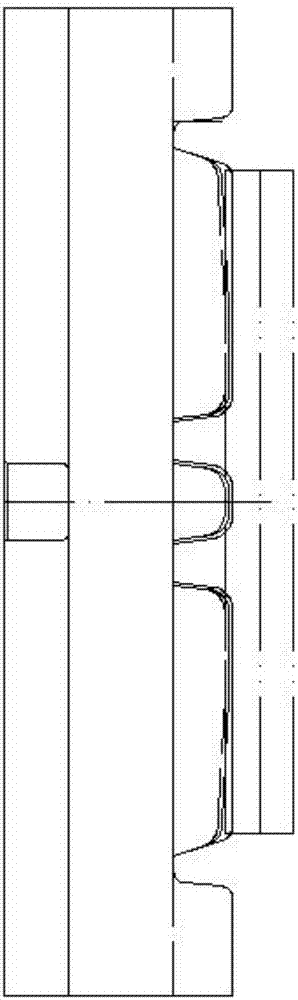

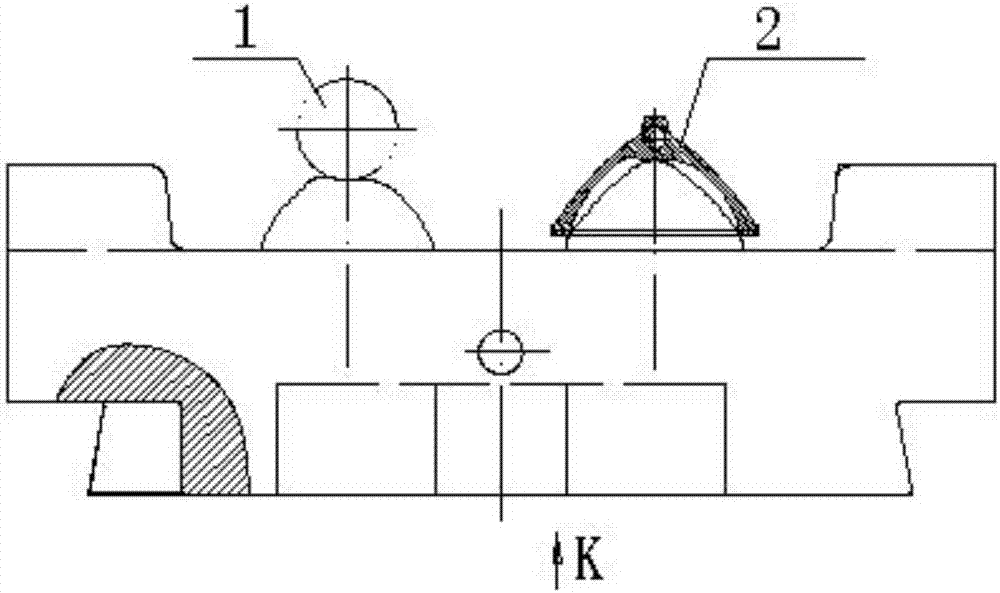

[0038] Such as Figure 1-Figure 16 As shown, the hot forging method of wetland track shoes includes the following steps: a. placing the blank 1 in an intermediate frequency induction furnace for diathermy, and the temperature is controlled at 1150±30°C; b. removing the oxide scale from the diathermy blank 1; c. Fully preheat the hot forging die, and maintain the temperature of the hot forging die at 200-300°C; d. Position the blank 1 after descaling through the groove 5 of the lower die into the pre-forging cavity 6 of the lower die, and the upper die The blank 1 is hit downwards to form the pre-forging; e. The upper die moves upward, and the pre-forging ejector rod of the pre-forging cavity 6 of the lower die ejects the pre-forging 2; f. Moves the pre-forging 2 into the final forging cavity 7 of the lower die , the upper die goes down to hit the pre-forging 2, and the final forging is formed; g. the upper die moves up, and the final forging ejector rod of the lower die's fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com