Integral type hinge beam closed-die forging and pressing forming die and hinge beam manufacturing method

A forming mold and beam closed technology, which is applied in forging/pressing/hammering machinery, forging/pressing/hammer devices, manufacturing tools, etc., can solve the problem of heavy weight of hinged beams, low material utilization rate, and large machining allowance and other problems, to achieve the effect of improving mechanical properties, simplifying the forging process, and reducing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing a hinged beam of an integral hinged beam closed die forging die, comprising the following steps:

[0035] Step 1: Heating the steel ingot blank to 1150-1200°C and keeping it warm for 15-20 hours to make the internal temperature of the steel ingot blank uniform;

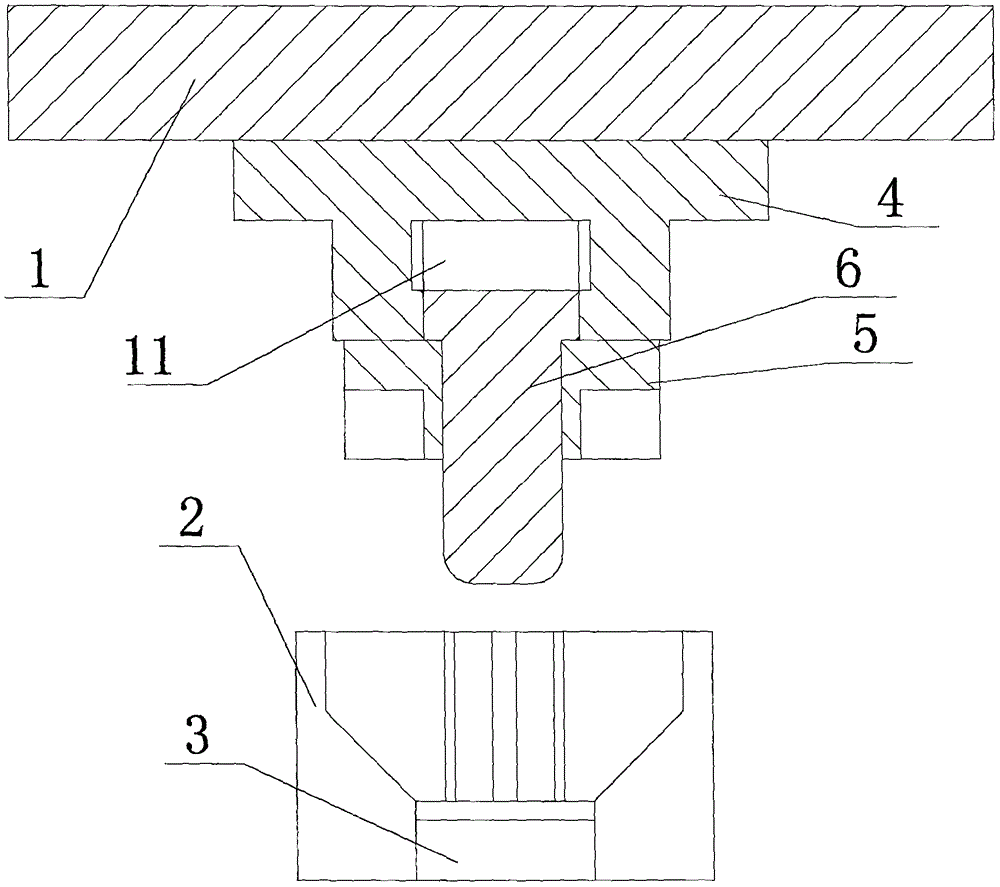

[0036] Step 2: Install the upper die base 4 on the slider 1 of the large-tonnage press, the punch 5 is installed on the bottom of the upper die base 4, the punch pad 11 is installed in the upper die base 4, and the upper die base 4 4 and the punch 5 are equipped with a punch 6, and the die punch is a primary pressing die punch at this time;

[0037] Step 3: Place the steel ingot blank after heat preservation in step 1 in the forming die 2, and use the large-tonnage press and the punch of the primary pressing die described in step 2 to press the steel ingot blank once, so that the forming die 2 The steel ingot blank becomes the hinge beam blank;

[0038] Step 4: Use the hydraulic cylinde...

Embodiment 1

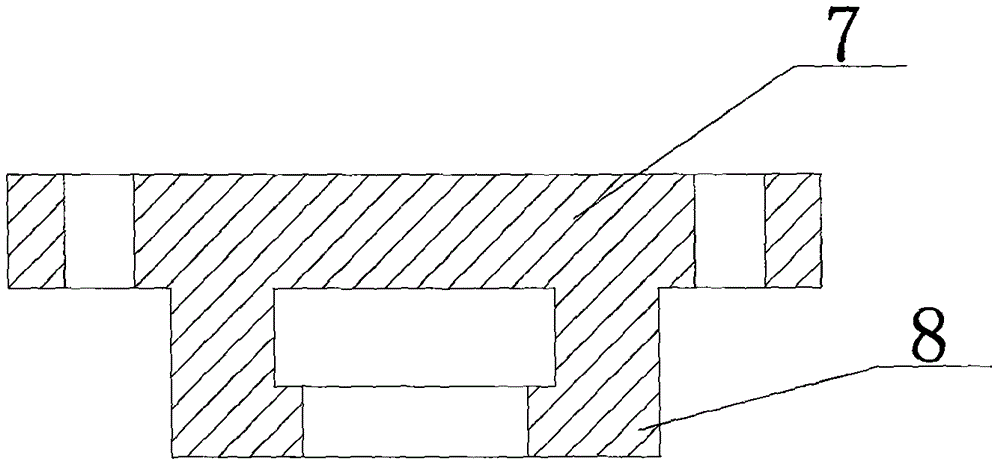

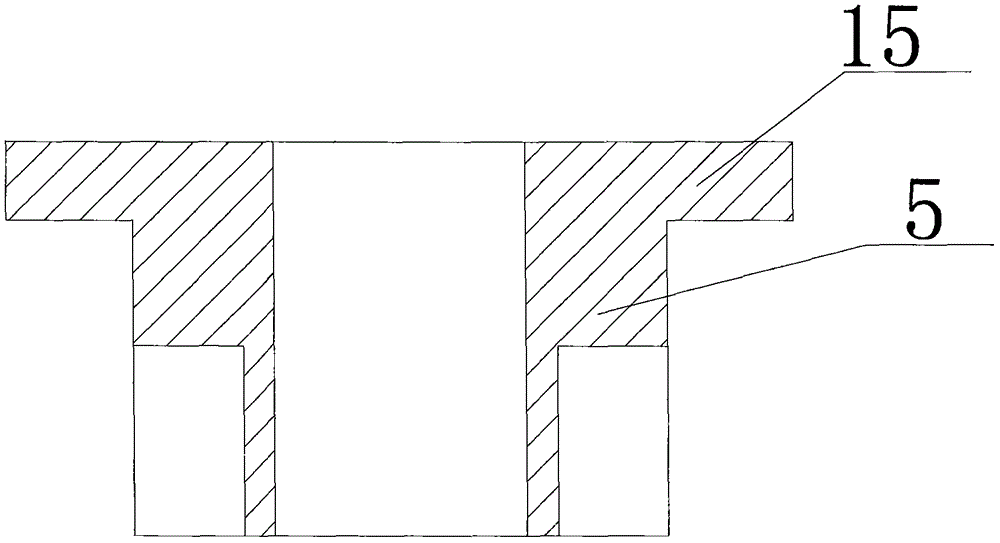

[0047] An integral hinged beam closed die forging forming die, the forming die includes a die punch connected to a press slider 1, a forming die 2 and a top material block 3 arranged at the inner bottom of the forming die 2; The die punch includes an upper die base 4 connected to the press slide block 1, a punch 5 connected to the upper die base 4, and a punching punch 6 passing through the punch 5 is provided in the upper die base 4; 2 is the structure of the upper and lower through holes 13, and the shape of the inner cavity is adapted to the hinge beam; the ejector block 3 is movably arranged at the inner bottom of the through hole 13 of the forming die. The upper mold base 4 includes a slider connecting plate 7 and a connecting seat 8 arranged at the top, and one side of the connecting seat 8 is provided with a pad channel, and the pad channel is connected with the punching pad provided inside the connecting seat 8 The block chamber is connected, and the bottom of the conn...

Embodiment 2

[0058] An integral hinged beam closed die forging forming die, the forming die includes a die punch connected to a press slider 1, a forming die 2 and a top material block 3 arranged at the inner bottom of the forming die 2; The die punch includes an upper die base 4 connected to the press slide block 1, a punch 5 connected to the upper die base 4, and a punching punch 6 passing through the punch 5 is provided in the upper die base 4; 2 is the structure of the upper and lower through holes 13, and the shape of the inner cavity is adapted to the hinge beam; the ejector block 3 is movably arranged at the inner bottom of the through hole 13 of the forming die. The upper mold base 4 includes a slider connecting plate 7 and a connecting seat 8 arranged at the top, and one side of the connecting seat 8 is provided with a pad channel, and the pad channel is connected with the punching pad provided inside the connecting seat 8 The block chamber is connected, and the bottom of the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com