Fine forging technology for automobile claw pole forging

A precision forging and forging technology, which is applied in the field of precision forging of automobile claw poles, and can solve the problems of multiple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

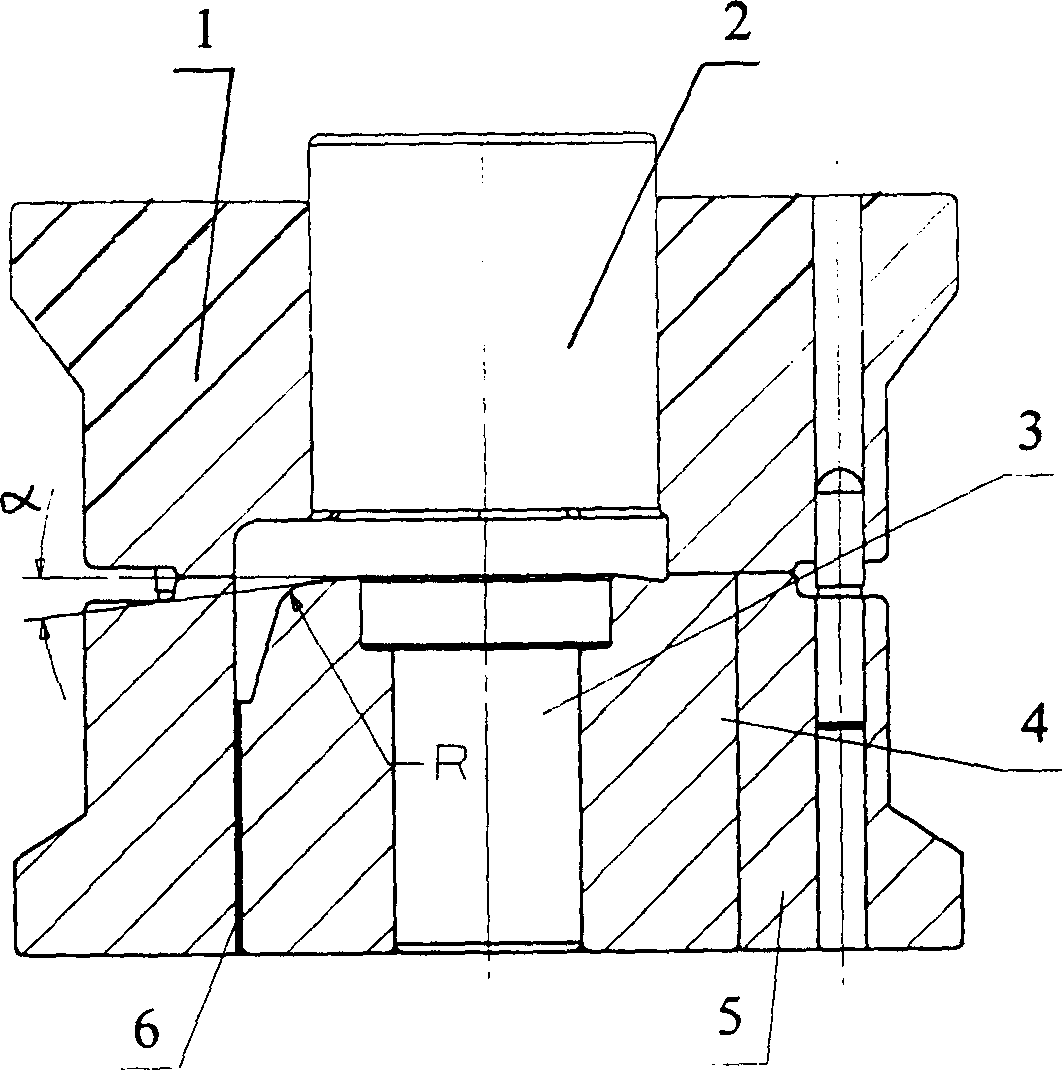

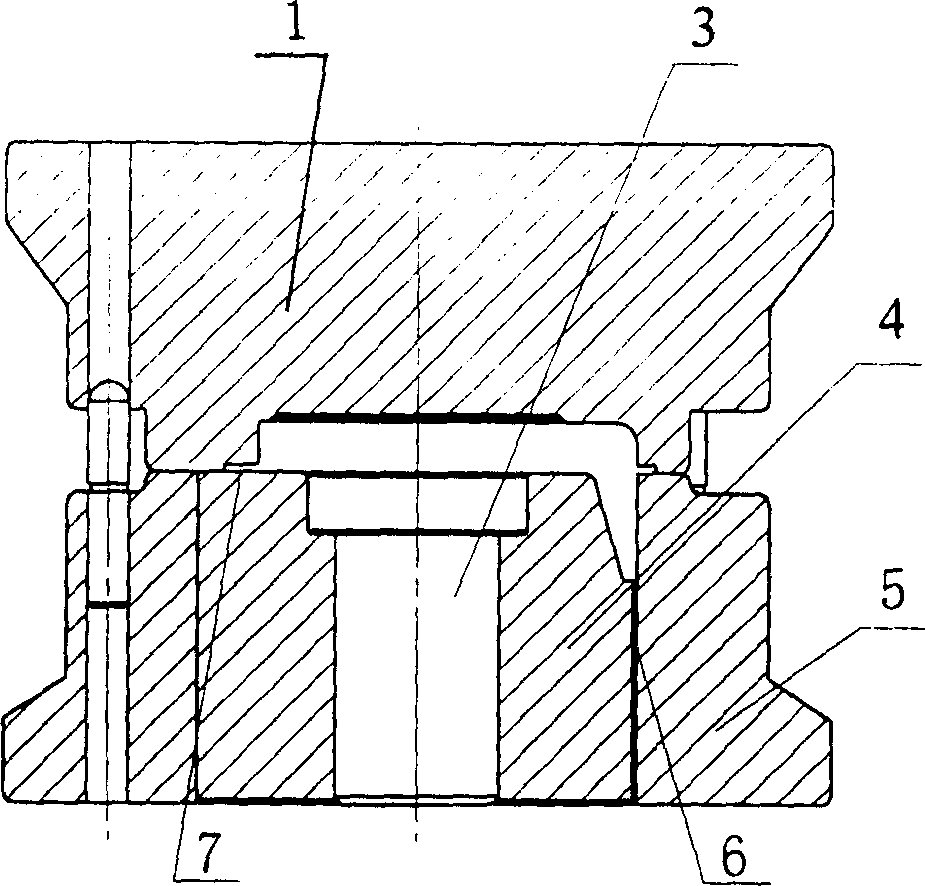

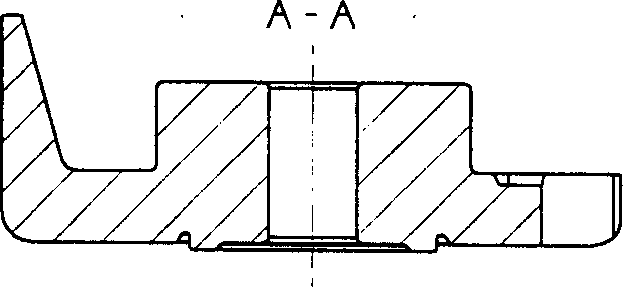

[0017] attached figure 1 , attached figure 2 It is a specific embodiment of the present invention (see figure 1 , figure 2 ,), at first should design cold and hot forgings diagram according to product parts diagram, calculate required billet size (diameter and length); According to the principle and method of the present invention, design can divide die lateral warm extrusion precision prefabricated billet diagram (its The shape and size should be conducive to the filling of the cavity during final forging); calculate the force and energy parameters (extrusion force and die tension, etc.) during deformation; select the die force loading method and equipment type; figure 1 , figure 2 Design the preform mold diagram, final forging forming mold diagram and trimming mold diagram; finally select the appropriate mold material and mold heat treatment, and select the appropriate lubricant material and mold preheating and cooling methods.

[0018] Due to the forging scheme of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com