Forging and forming method of integral hinge beam

A hinge beam, integral technology, applied in the field of forging and forming of large forgings, to achieve the effects of improving performance, simplifying the forging process, and compacting defects in the core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) The material used for forging is 35CrMo alloy structural steel. According to the heating specification, the steel ingot is heated to the initial forging temperature of 1200°C and held for 18 hours to make the internal temperature uniform. The weight of the steel ingot used is 15 tons; the final forging temperature is 950°C during forging.

[0038] (2) Carry out the conventional processes of pressing the ingot tongs, chamfering and removing the tail of the ingot. The main part of the completed ingot is as follows: figure 1 As shown (the figure omits the clamp), the height-to-diameter ratio of the steel ingot is 2.0:1; heat the billet to 1200°C and keep it warm for 18 hours;

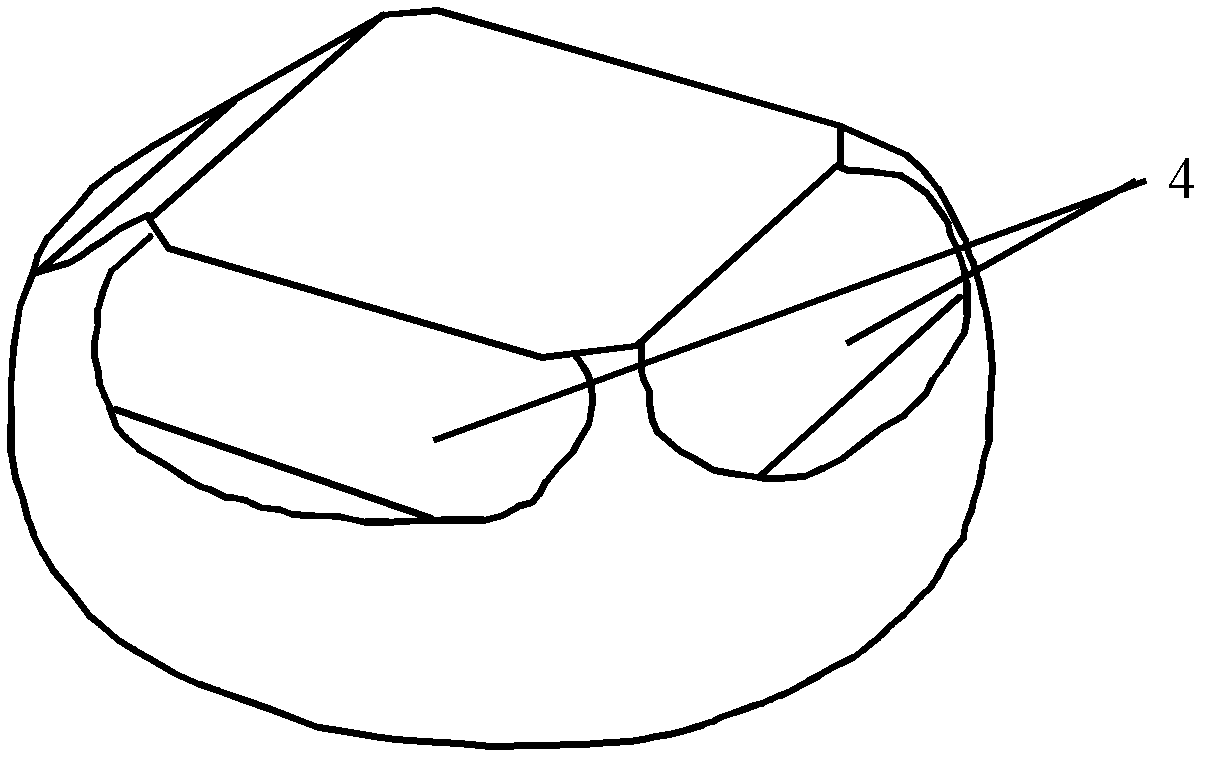

[0039] (3) Upsetting the billet to such as figure 2 After the cylinder with the height-to-diameter ratio shown is 1, use an anvil to upset the billet as image 3 The circular cake shape with four symmetrical slopes 4 is shown; the billet is heated to 1200°C and kept for 18 hours;

[0040] (4)...

Embodiment 2

[0045] (1) The material used for forging is 40CrMnMo alloy structural steel. According to the heating specification, the steel ingot is heated to the initial forging temperature of 1150°C and held for 20 hours to make the internal temperature uniform. The weight of the steel ingot used is 10 tons; the final forging temperature during forging is 930°C.

[0046] (2) Carry out the conventional processes of pressing the ingot tongs, chamfering and removing the tail of the ingot. The main part of the completed ingot is as follows: figure 1 As shown (the figure omits the clamp), the height-to-diameter ratio of the steel ingot is 1.2:1; the billet is heated to 1150°C and kept for 20 hours;

[0047] (3) Upsetting the billet to such as figure 2 After the cylinder with the height-to-diameter ratio shown is 1, use an anvil to upset the billet as image 3 The circular cake shape with four symmetrical slopes 4 is shown; the billet is heated to 1150°C and kept for 20 hours;

[0048] (4) ...

Embodiment 3

[0053] (1) The material used for forging is 20CrNi alloy structural steel. According to the heating specification, the steel ingot is heated to the initial forging temperature of 1250°C and held for 15 hours to make the internal temperature uniform. The weight of the steel ingot used is 20 tons; the final forging temperature during forging is 980°C.

[0054] (2) Carry out the conventional processes of pressing the ingot tongs, chamfering and removing the tail of the ingot. The main part of the completed ingot is as follows: figure 1 As shown (the figure omits the clamp), the height-to-diameter ratio of the steel ingot is 3:1; the billet is heated to 1250°C and kept for 15 hours;

[0055] (3) Upsetting the billet to such as figure 2 After the cylinder with the height-to-diameter ratio shown is 1, use an anvil to upset the billet as image 3 The circular cake shape with four symmetrical slopes 4 is shown; the billet is heated to 1250°C and kept for 15 hours;

[0056] (4) Pull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com