External spiral cone beam CT (computed tomography) scanning imaging method of large-size industrial long pipeline pipe wall

A technology of CT scanning and imaging methods, which is applied in the field of CT scanning and imaging, and can solve problems such as distorted and reconstructed images

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

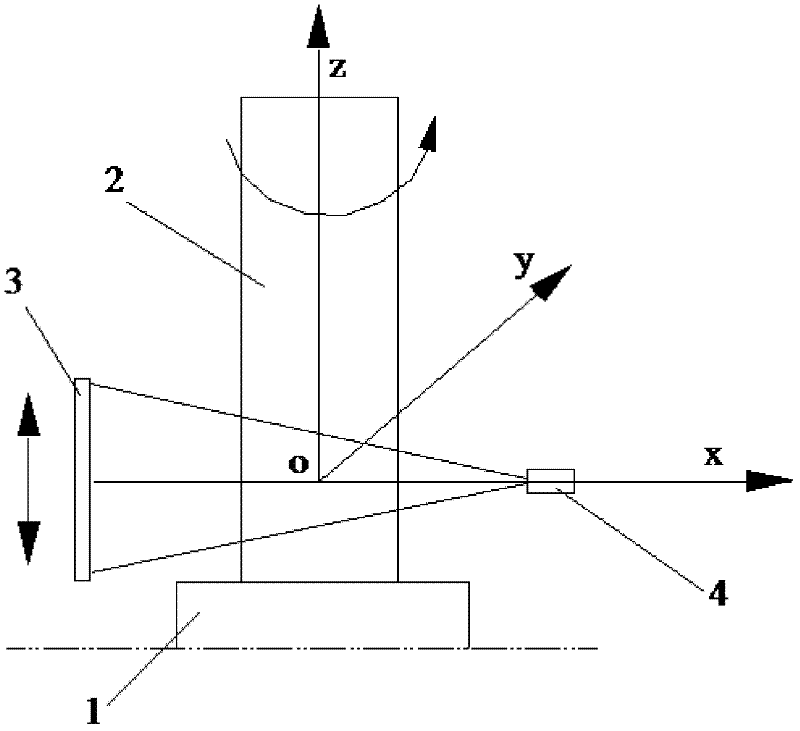

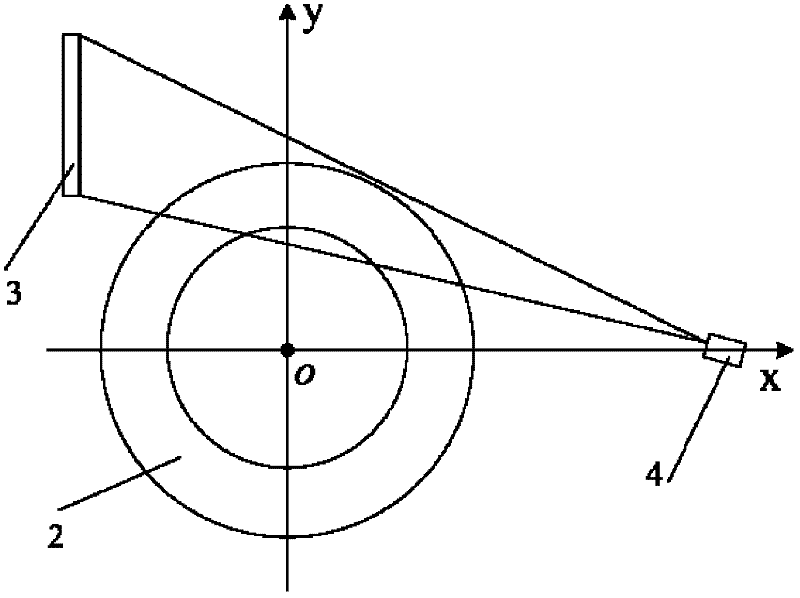

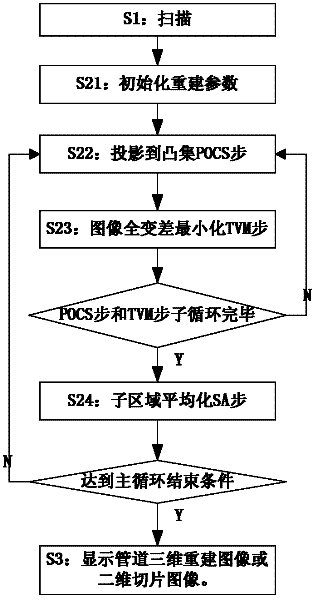

[0070] figure 1 It is a schematic diagram of the pipeline detection structure of the present invention; figure 2 It is a schematic cross-sectional view of the pipeline to be detected when scanning in the present invention; image 3 It is a block diagram of the scanning imaging method of the present invention, as shown in the figure: in the external spiral cone beam CT scanning imaging method of a large-scale industrial long pipe wall provided by the present invention, the pipeline 2 to be detected is arranged on the rotary table 1, and the rotary table The center of 1 is the origin to establish a rectangular coordinate system, the x-axis is the connection between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com