Skid-steer loader and control method thereof

A skid steer loader and central control unit technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of high noise and large emission of skid steer loader, reduce working noise, facilitate automation and The effect of intelligence and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

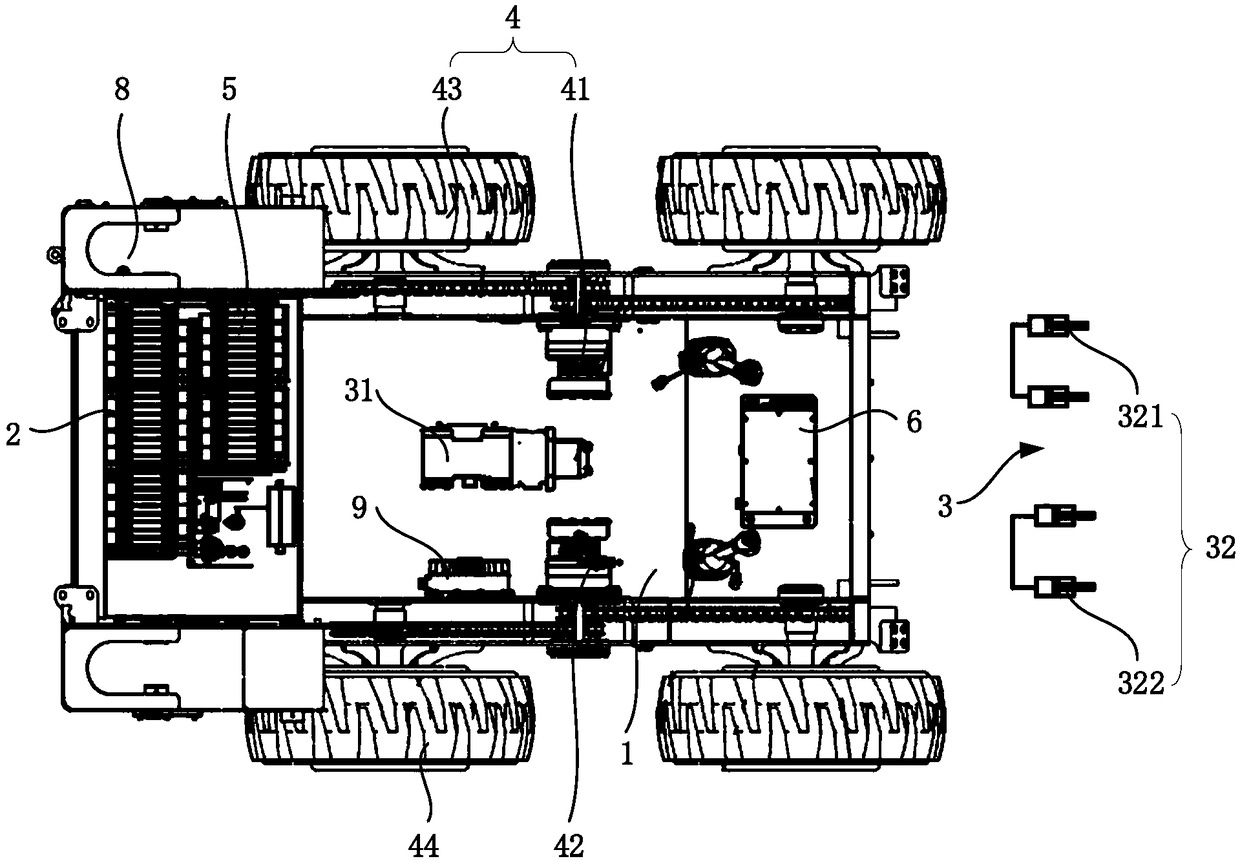

[0042] Combine below Figure 1 ~ Figure 3 The technical solution provided by the present invention is described in more detail.

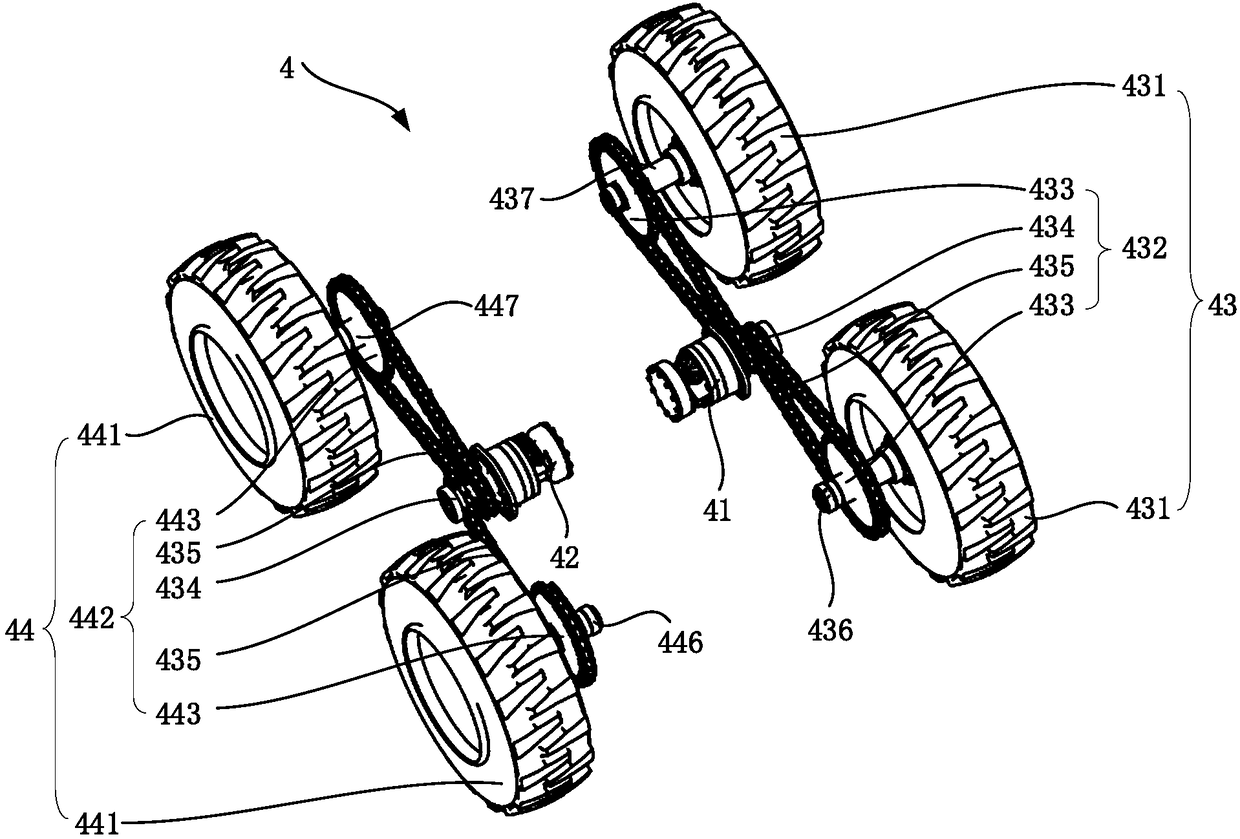

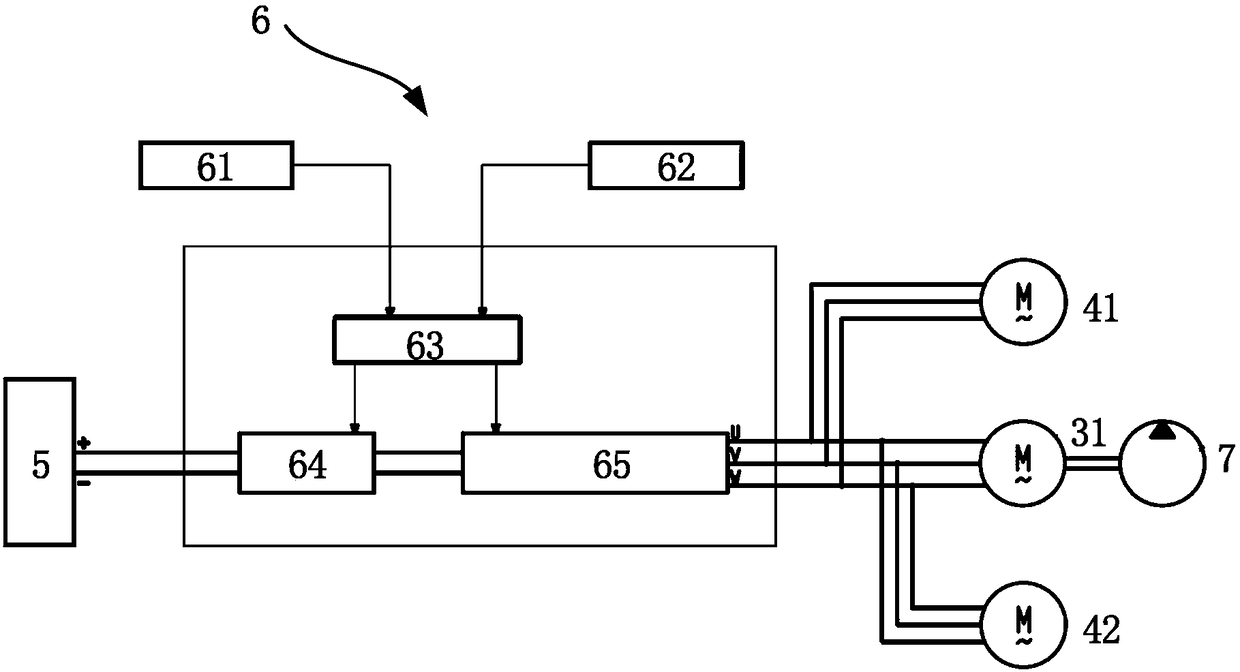

[0043] An embodiment of the present invention provides a skid steer loader, including a vehicle frame 1 , a rechargeable battery 2 , a working system 3 and a traveling system 4 . The working system 3 includes a working motor 31 and an actuator 32 . The traveling system 4 includes a first traveling motor 41 , a second traveling motor 42 , a first traveling wheel assembly 43 and a second traveling wheel assembly 44 . The vehicle frame 1 provides support for the installation of other components. The rechargeable battery 2 is located on the vehicle frame 1 . The rechargeable battery 2 is used to provide power for the working motor 31 and each traveling motor on the skid steer loader.

[0044] In some embodiments, the rechargeable battery 2 comprises a secondary battery or a lithium battery.

[0045] see figure 1 , the working motor 31 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com