Punching composite die for filter element end cover

A composite mold and filter element technology, applied in the field of cold stamping molds, can solve problems such as cumbersome process, repeated positioning, affecting product appearance quality and dimensional accuracy, and achieve the goals of reducing production costs, improving production efficiency, and ensuring appearance quality and dimensional accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment and accompanying drawing thereof, the present invention is described in further detail:

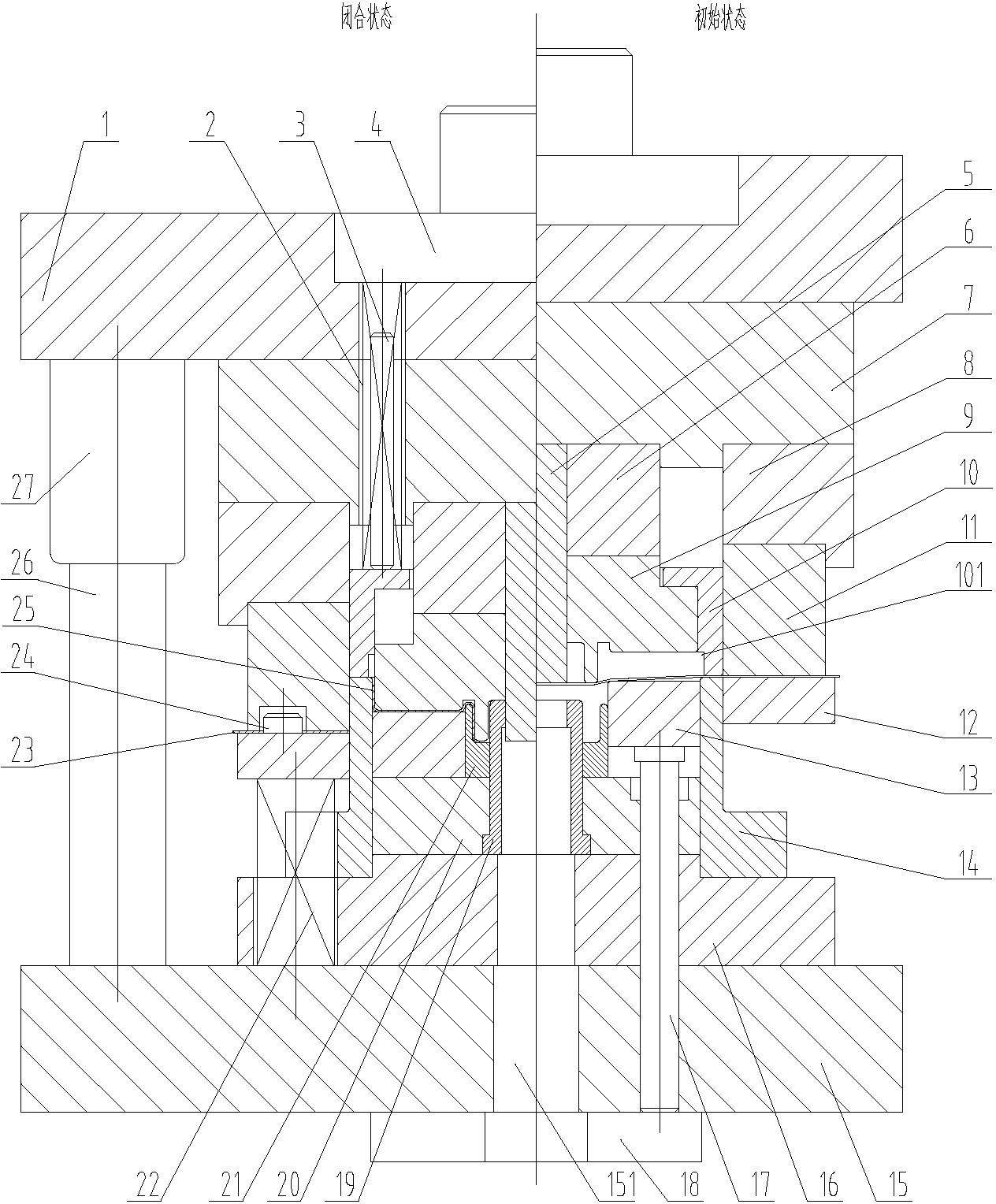

[0014] like figure 1 As shown, a filter element end cover stamping composite mold includes an upper mold bottom plate 1 and a lower mold bottom plate 15 with a guide post 26 and a guide sleeve 27, and a composite device installed between the upper mold bottom plate 1 and the lower mold bottom plate 15 Composition; the composite device includes an upper die fixing plate 7, a punching punch fixing plate 6, a punching punch 5, a flanging punch 9, a pressing ring 10, a blanking die fixing plate 8, a blanking die 11, a flat wire Helical spring 2, guide column 3, die handle 4, lower die fixing plate 15, punching die 19, punching die fixing plate 20, lower die forming core 21, convex and concave die 14, round wire coil spring 22, guide material Pin 24, binder plate 12, ejector pin 17, ejector plate 13.

[0015] The upper mold bottom plate 1 is equipp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com