Film loading device

A loading device and film technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of high precision and large displacement loading, avoid high cost and improve measurement accuracy , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

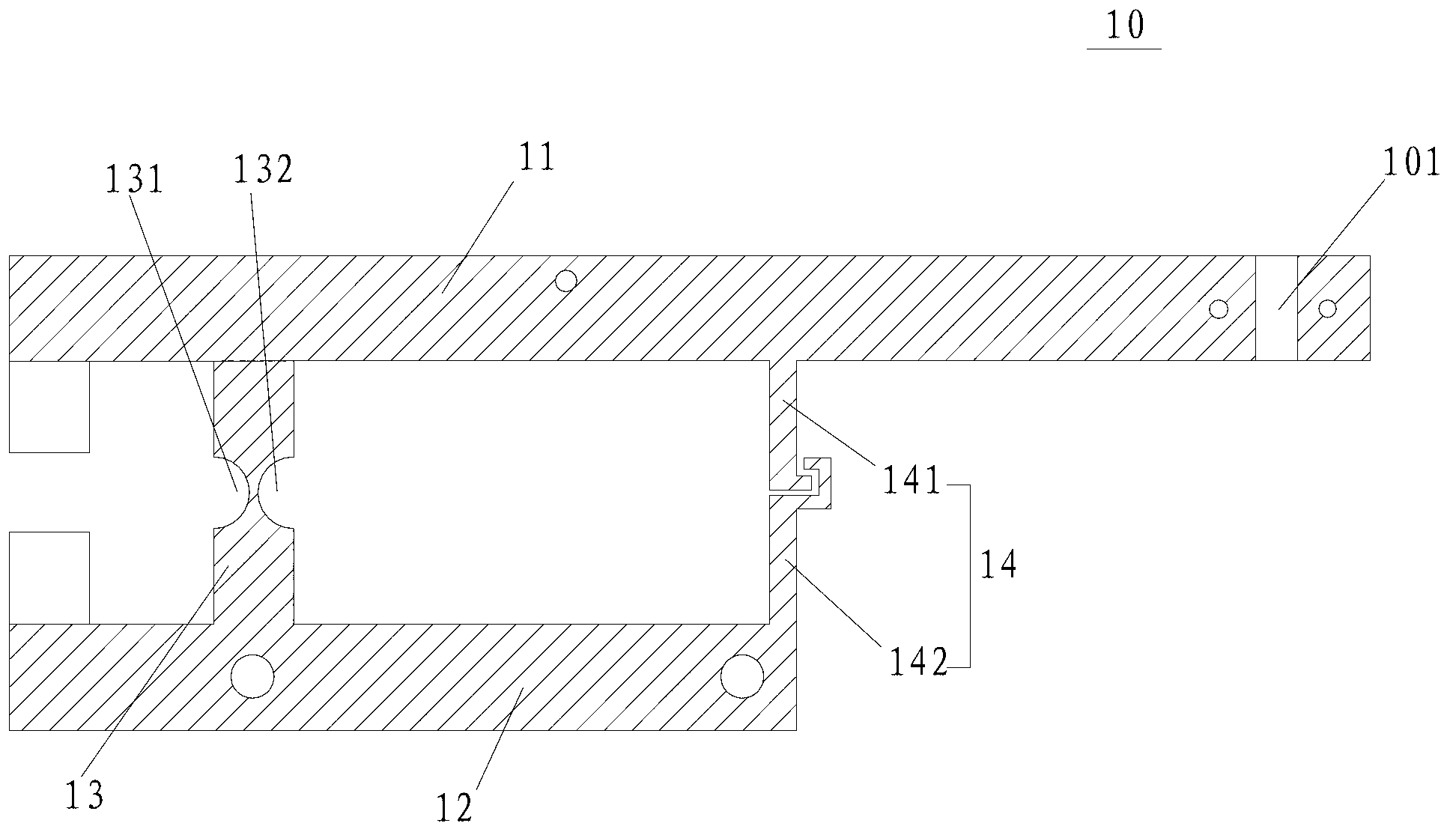

[0066] The parameters of each component are: the maximum linear displacement of the piezoelectric ceramic 20 is 22 μm; the maximum displacement load of the lever assembly 10 is 110 μm; the maximum measuring range of the sensor 40 is 1N, and the precision is 0.0005N.

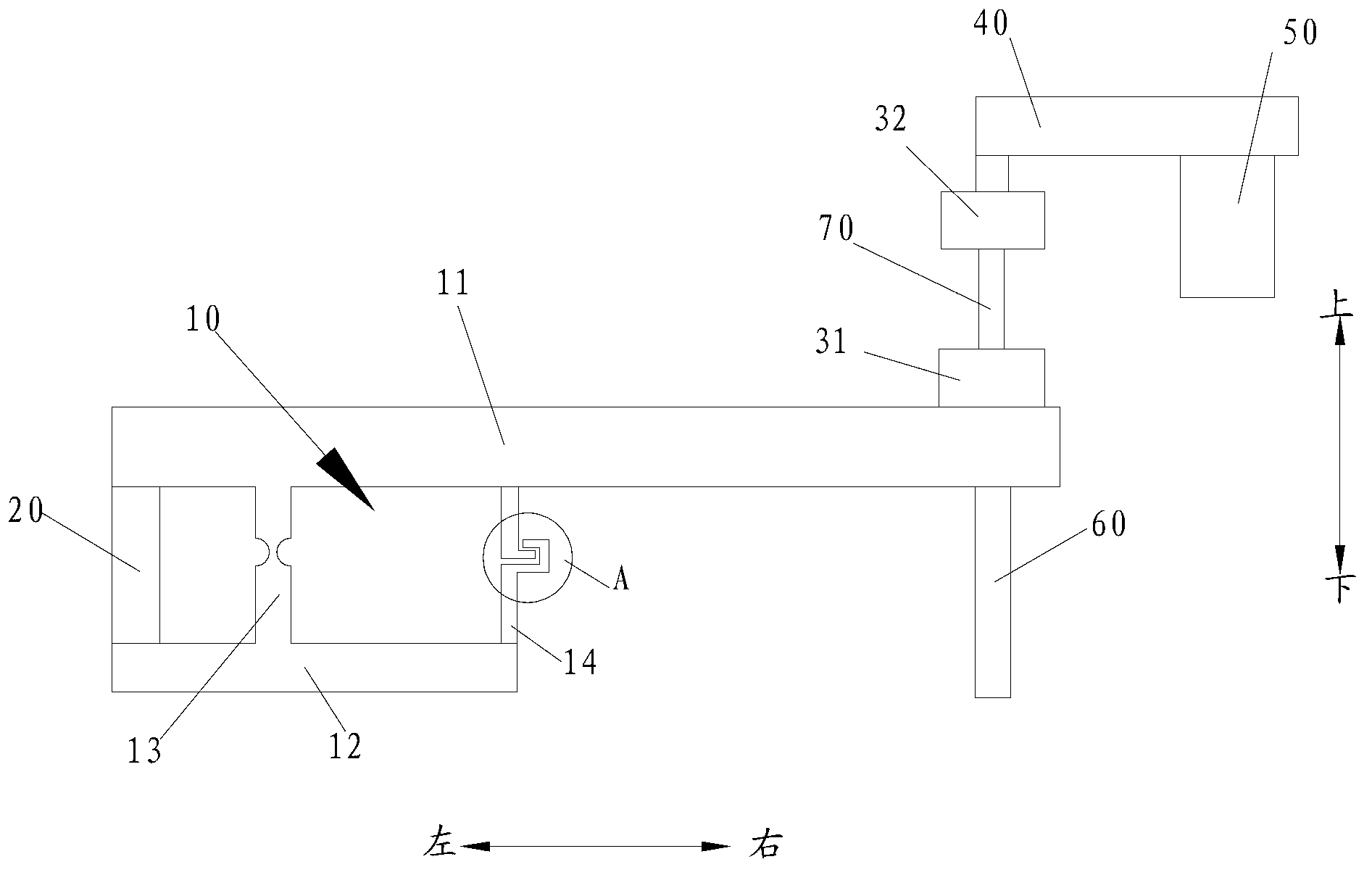

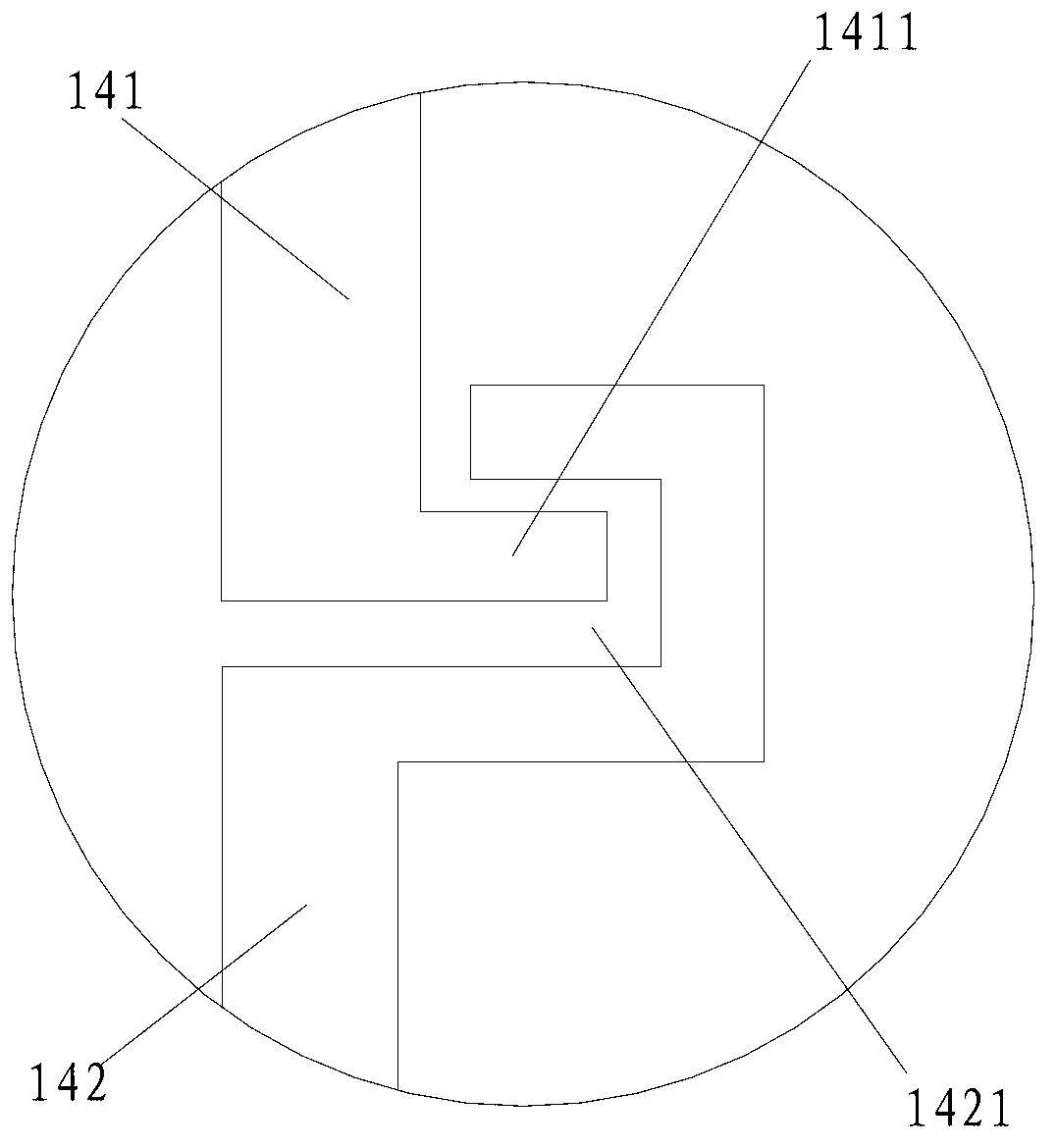

[0067] Such as figure 1 with figure 2 As shown, the device is composed of a lever assembly 10, a piezoelectric ceramic 20, an initial trimmer 50, a film 70, a sensor 40, a guide rail 60 and an external control port (not shown). Typical samples, such as optical fiber samples, plastic films, etc., are pasted on the first clamping piece 31 and the second clamping piece 32 with epoxy glue. During the experiment of the present invention, the force load of the thin film 70 increases uniformly with the increase of the driving voltage of the piezoelectric ceramic 20, and the device has good linearity and high reliability.

Embodiment 2

[0069] Fabricate an aluminum frame with a thin film specimen (eg image 3 ) is fixed on the film loading device with four screw holes, and then the aluminum frame is cut off with a high-speed grinding wheel, so that the film specimen can bear the force load alone. Cutting the edge of the frame causes less vibration than cutting the middle, which is beneficial to protect the film specimen. The loading device was then placed inside a scanning electron microscope for tensile testing. In the tensile test, the load data is obtained by the micro force sensor, and the displacement and strain of the thin film specimen are calculated by the moiré method of the scanning electron microscope. The elastic modulus of the specimen measured by the scanning electron microscope moiré method is 72.1 GPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com