Double-station automatic grinding and cutting machine for ceramic green body tubes

A ceramic blank and grinding and cutting machine technology, which is applied in the direction of grinding racks, grinding machines, manufacturing tools, etc., can solve the problems of difficulty in automation and fragility, and achieve the effect of saving land area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

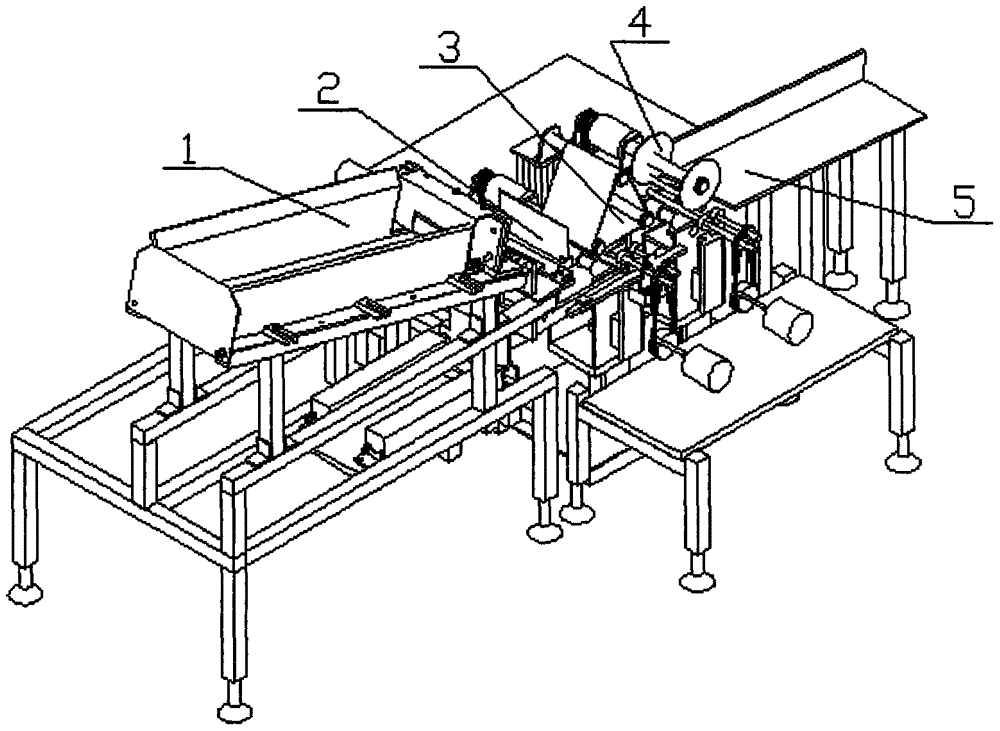

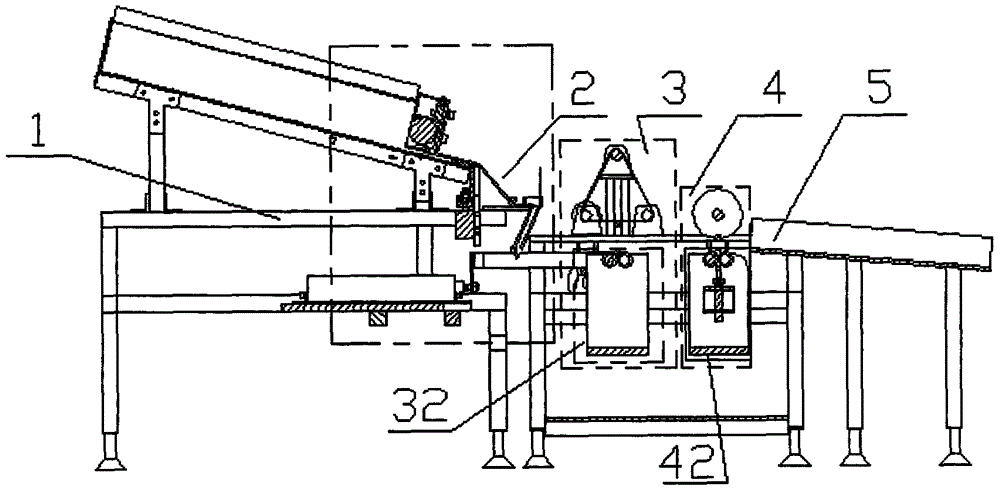

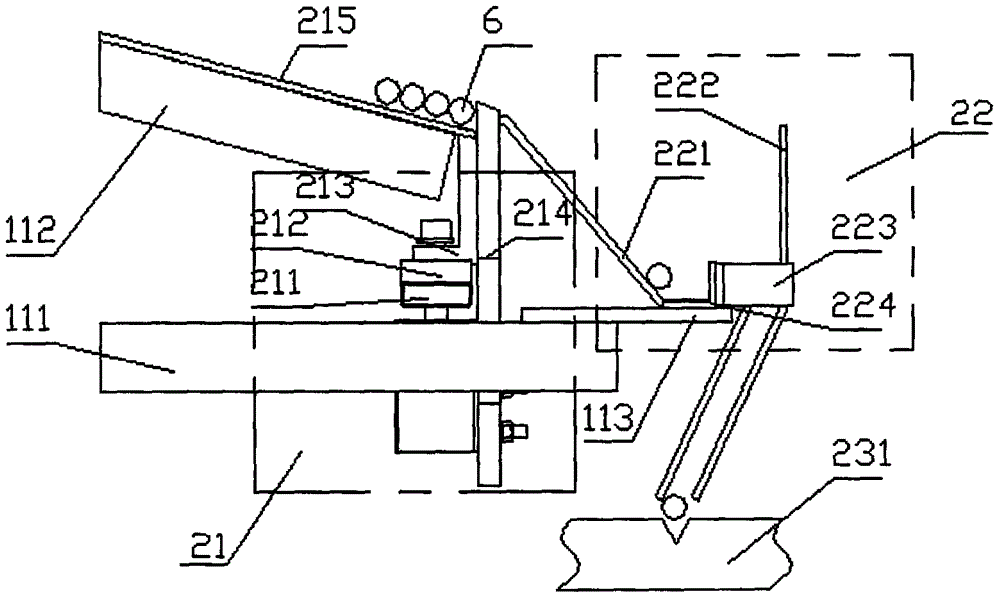

[0037] Such as figure 1 with figure 2 As shown, a double-station automatic grinding and cutting machine for ceramic green tubes includes a frame part 1 and a feeding station 2 arranged on the frame 1 . A grinding station 3 is arranged on the frame, and the grinding station 3 includes an abrasive belt 312 and a centerless support device 32 for the workpiece. The cutting station 4 comprises a blade cutting section 41 , a centerless support device 42 for the workpiece and a magnetic drive device 43 . Simultaneously, the unloading device 5 of workpiece is set on the frame.

[0038] The improvement of the present invention lies in: the grinding and cutting process of the ceramic lamp tube is realized by one machine, and the double-station synchronous transmission device-double V-groove transport bracket is used to transmit the workpiece, and the magnetic drive is used Device and centerless support device to complete the automatic feeding, conveying, grinding, cutting and unload...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com