Restaurant oil-containing waste water purification processing unit

A technology for wastewater purification and treatment device, which is applied in the fields of oxidized water/sewage treatment, mechanical oscillation water/sewage treatment, magnetic field/electric field water/sewage treatment, etc. problems, to achieve the effect of reducing construction costs, reducing land area, and increasing processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

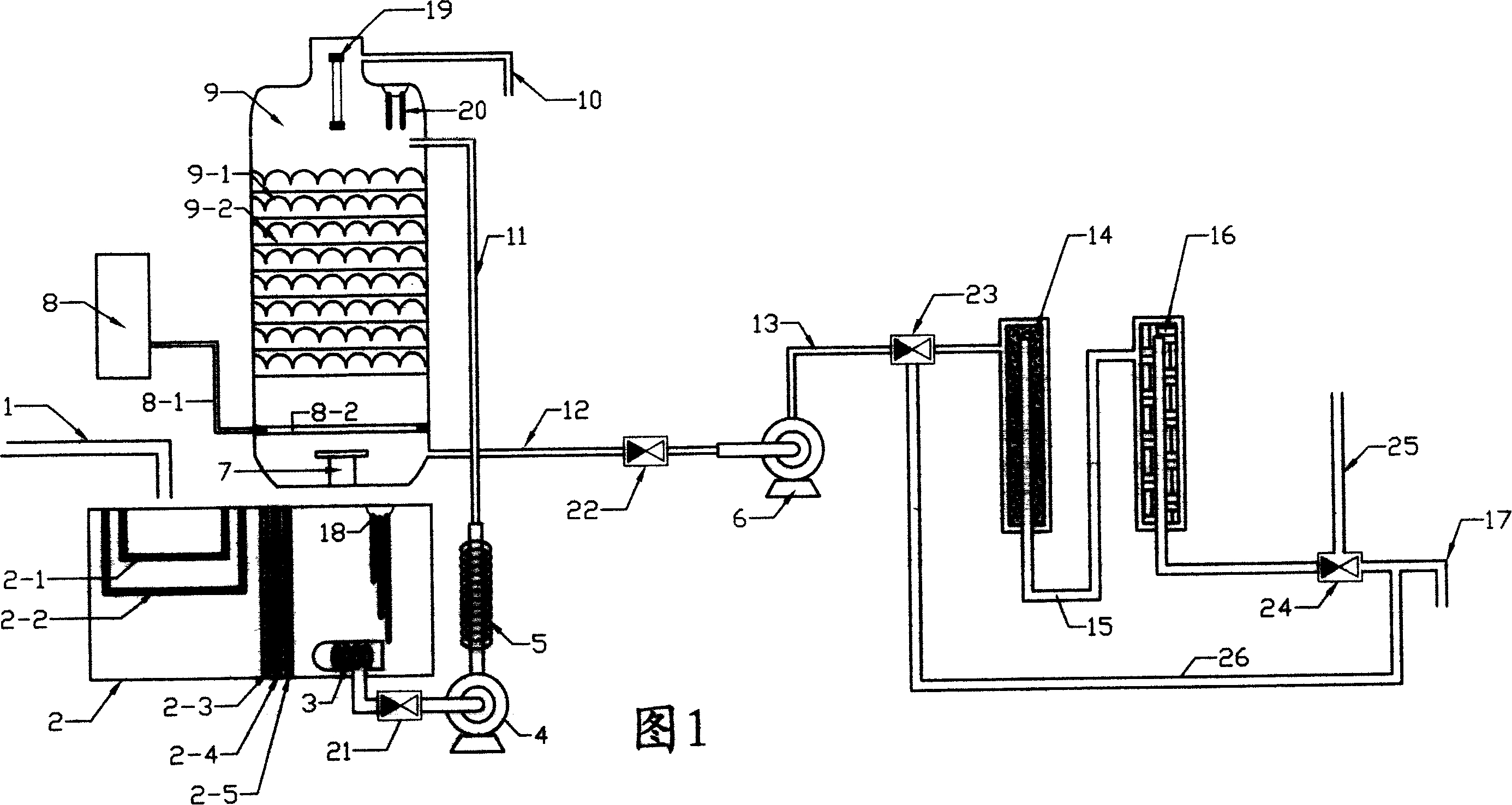

[0009] Below in conjunction with accompanying drawing 1 the present invention will be further described:

[0010] See accompanying drawing 1, there are coarse grille (2-1), fine grille (2-2), coarse filter layer (2-3), fine filter layer (2-4) in the waste water primary filter box (2), Fine filter layer (2-5) and electric heating tube (3). The wastewater primary filter box (2) is connected with the corrugated-flat oil-water separation tank (9) through the sewage lifting pump (4), via the frequency conversion magnetic field section and the sewage conveying pipe. The separated deoiled water is connected with the carbon filter tank (14) through the deoiled water lifting pump (6), the deoiled water delivery pipe (12) and the pressurized deoiled water delivery pipe (13), and then passes through the primary filtered water delivery pipe (15 ) is connected with the ultrafiltration tank (16), and the clear water is discharged through the clear water discharge port (17) after processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com