Incremental bending and forming method of hat-shaped member

A hat-shaped and arc-shaped technology, which is applied in the field of progressive bending forming methods and molds for hat-shaped parts, can solve the problems of long design and manufacturing cycle, low mold reuse rate, and large springback.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

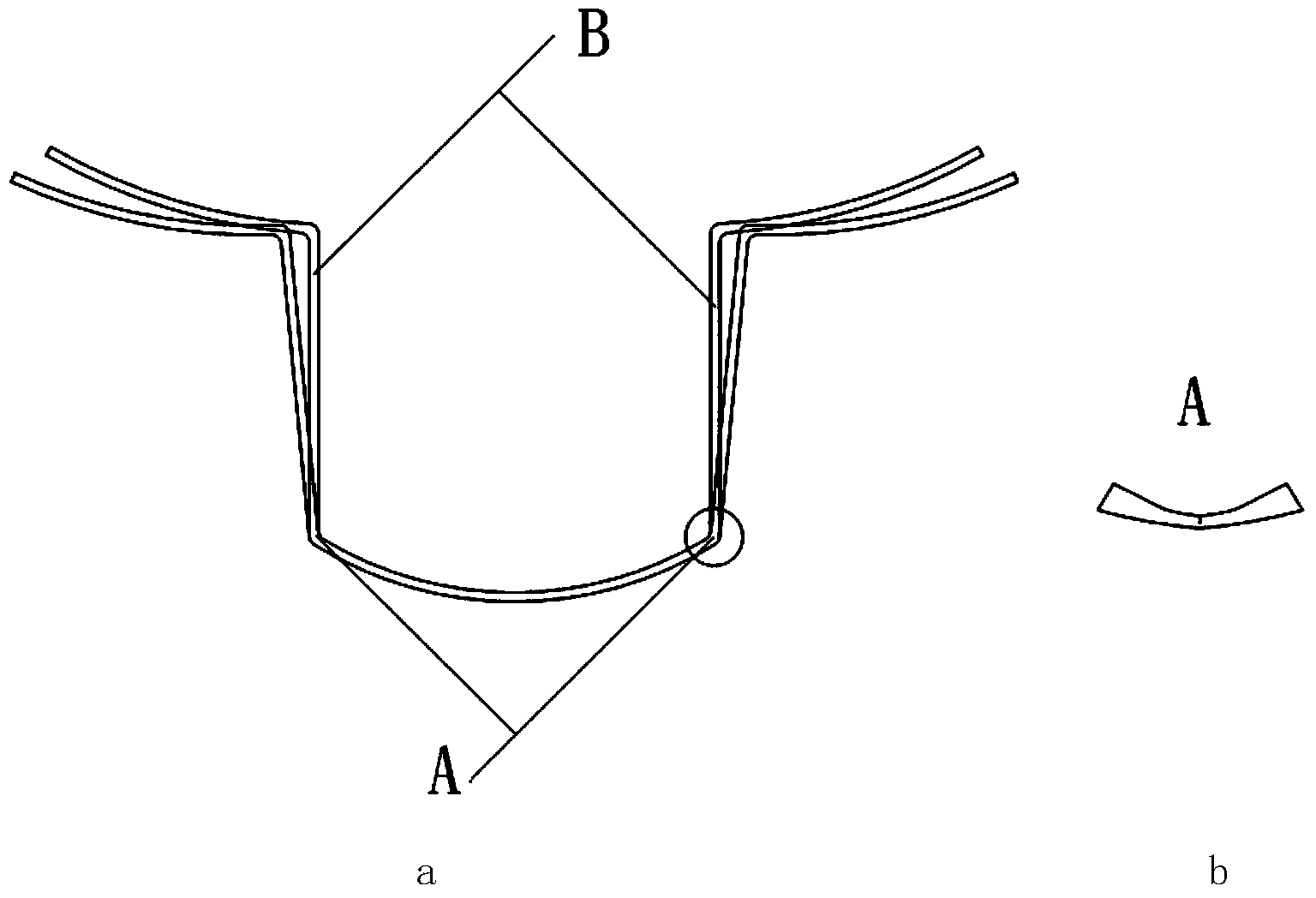

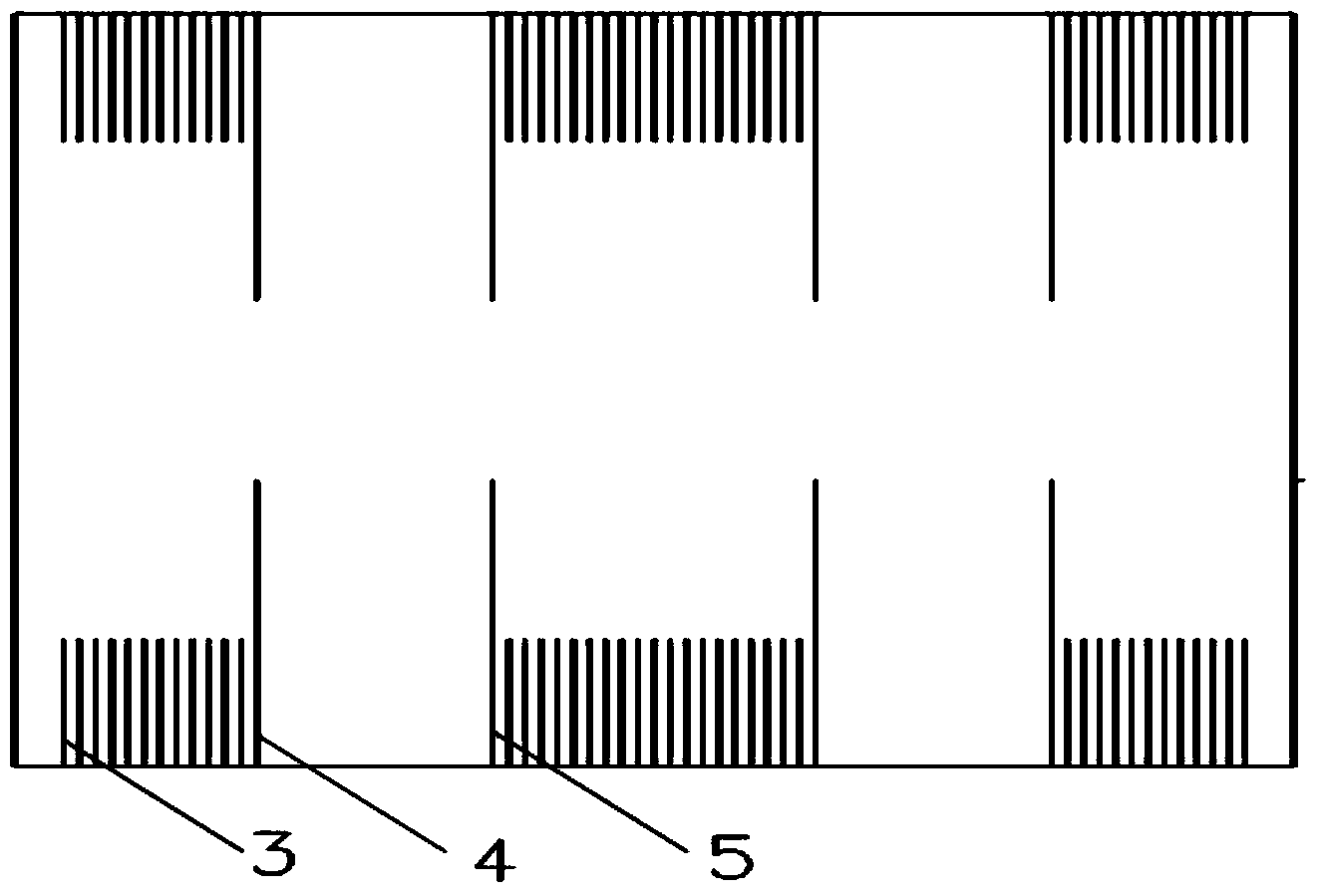

[0050] This embodiment is a method for progressive bending and forming of a titanium alloy plate with a size of 420mm×360mm and a thickness of 1mm. After forming, the part is a hat-shaped piece with a radius of 125mm at both ends, a length of 57mm, and a vertical side length of 80mm on both sides. , the radius of the middle arc is 80mm, and the length is 92mm.

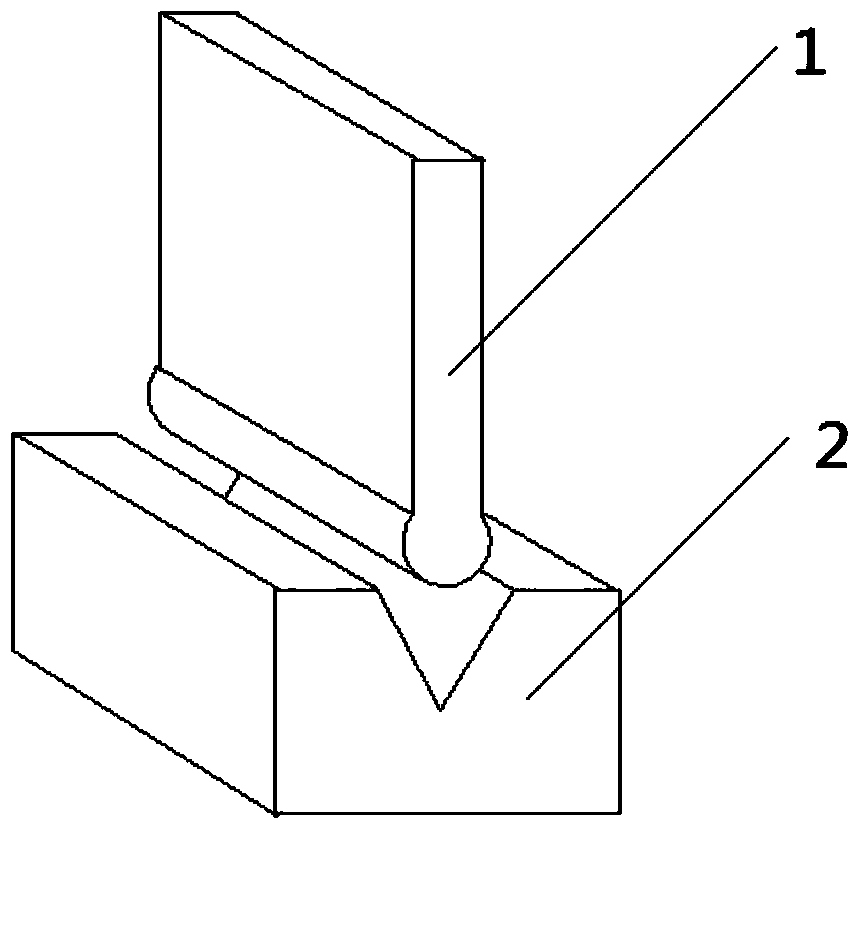

[0051] The forming mold used adopts the punch 1 and the die 2 in the prior art. The cavity of the die 2 is V-shaped, and the angle of the V-shaped cavity is 60°. The depth of the V-shaped cavity is 35mm. The cross-section of the forming surface of the punch 1 is a convex circle, and the diameter of the forming surface of the punch is smaller than the cavity opening of the die 2, so that the forming surface of the punch 1 can be aligned with the cavity of the die 2 Cooperate.

[0052] In this embodiment, the radius of the round head of the punch is 10mm. When in use, the die 2 is located on the workbench of the bend...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com