Molding method of aramid fiber composite material frequency selection surface reflector

A technology of frequency selective surfaces and composite materials, which is applied to chemical instruments and methods, aircrafts, and aerospace vehicles to achieve the effect of ensuring surface quality and profile accuracy and avoiding large changes in profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

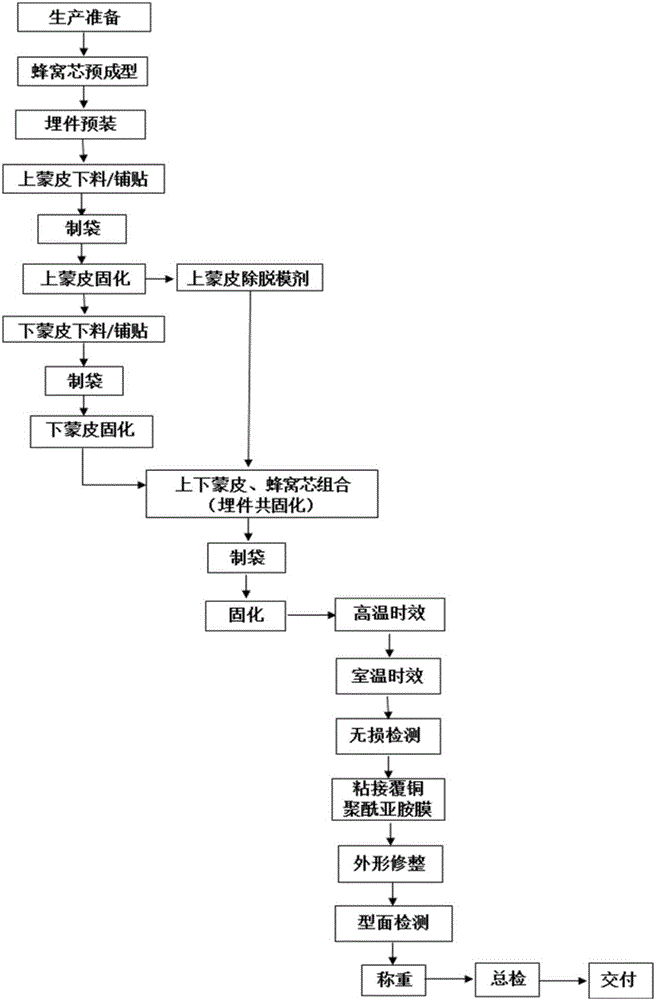

Method used

Image

Examples

Embodiment

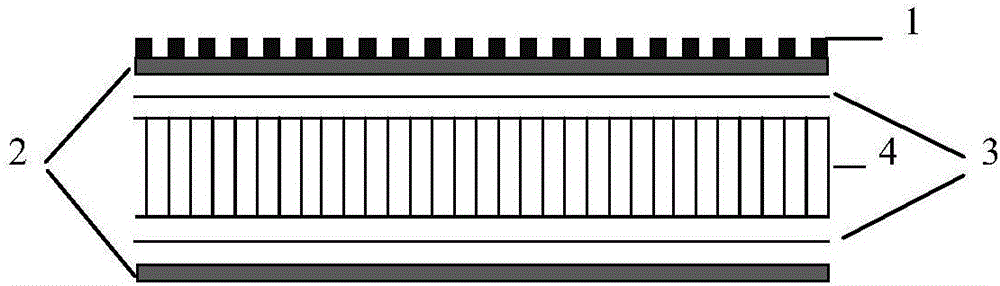

[0055] Implementation example: manufacture of a satellite frequency selective sub-reflector

[0056] Main materials: Aramid fiber prepreg Kevlar 49-120, adhesive film REDUX 312UL, NOMEX honeycomb core ("B" stage pre-cured), copper-clad polyimide film, foam glue FM410-1

[0057] 1) Reflector forming mold

[0058] The material of the reflector forming mold is ductile iron, hollow structure, the thickness requirement is 15mm, the surface roughness is not greater than 0.8, and the surface precision RMS is not greater than 0.03.

[0059] 2) Honeycomb core preforming

[0060] Lay the "B" stage pre-cured NOMEX honeycomb core 4 on the reflector forming mold, and cure and form it in an autoclave after bag making.

[0061] 3) Forming of the upper skin (non-working surface)

[0062] Based on the reflector forming mold, a dummy for upper skin molding is manufactured, and the thickness of the dummy is equal to the sum of the thickness of the reflective surface skin and the honeycomb cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com