Process for preparing guide vane by selective laser melting

A technology of laser selective melting and guide blades, which is applied in the direction of process efficiency improvement, mechanical equipment, additive manufacturing, etc., can solve the problems of long production cycle, low yield rate, cumbersome process, etc., and achieve surface quality assurance and forming accuracy assurance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

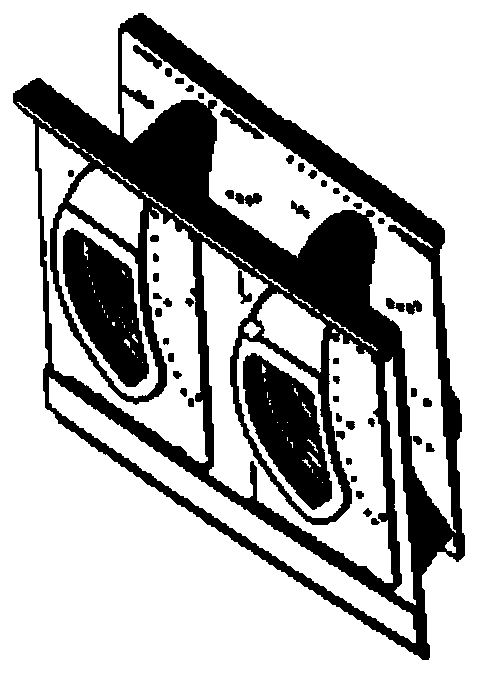

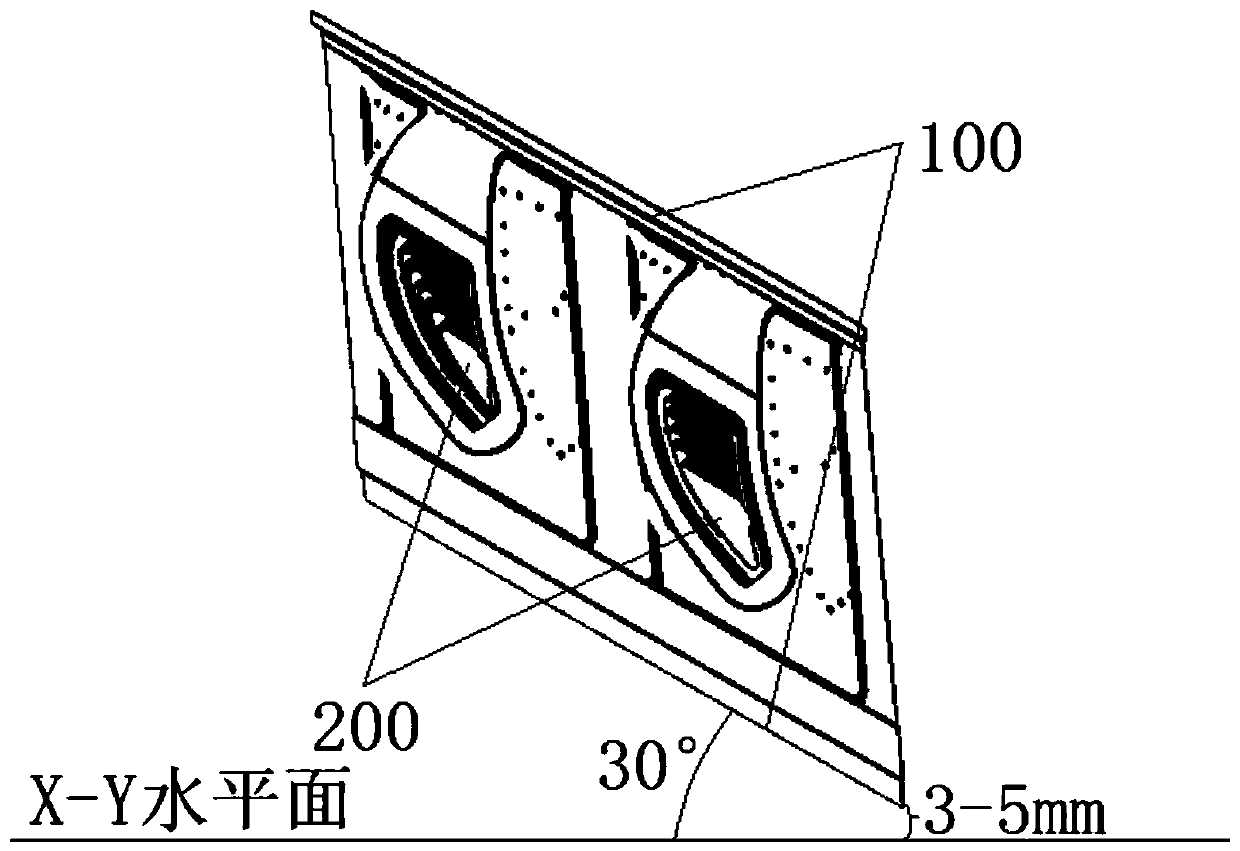

[0022] see Figure 1 to Figure 2 , a process for preparing guide vanes by laser selective melting, comprising the following steps:

[0023] S1. Choose a suitable forming angle: When placing the guide vane, it should choose the direction of spreading powder along the scraper, which is helpful for printing and forming, and avoids the phenomenon of knife jamming. The upper and lower end faces 100 form an included angle greater than 30° with the X-Y horizontal plane, so as to avoid the emergence of large horizontal cross-sections during the forming process and the excessive stress that causes the surface to warp when powder is laid layer by layer and sintered. At the same time, the included angle of 30° can avoid adding supports in the insertion hole 200 of the draft tube, and the added support in the insertion hole cannot be removed. Keep a distance of 3-5mm between the guide vane and the substrate, and use support to suspend the part. After printing, wire cutting separates the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com