Added material manufacturing device and method

A technology of additive manufacturing and control department, which is applied in the field of additive manufacturing of metal materials to achieve the effects of ensuring quality and dimensional accuracy, improving mechanical properties, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The additive manufacturing device and method involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0029]

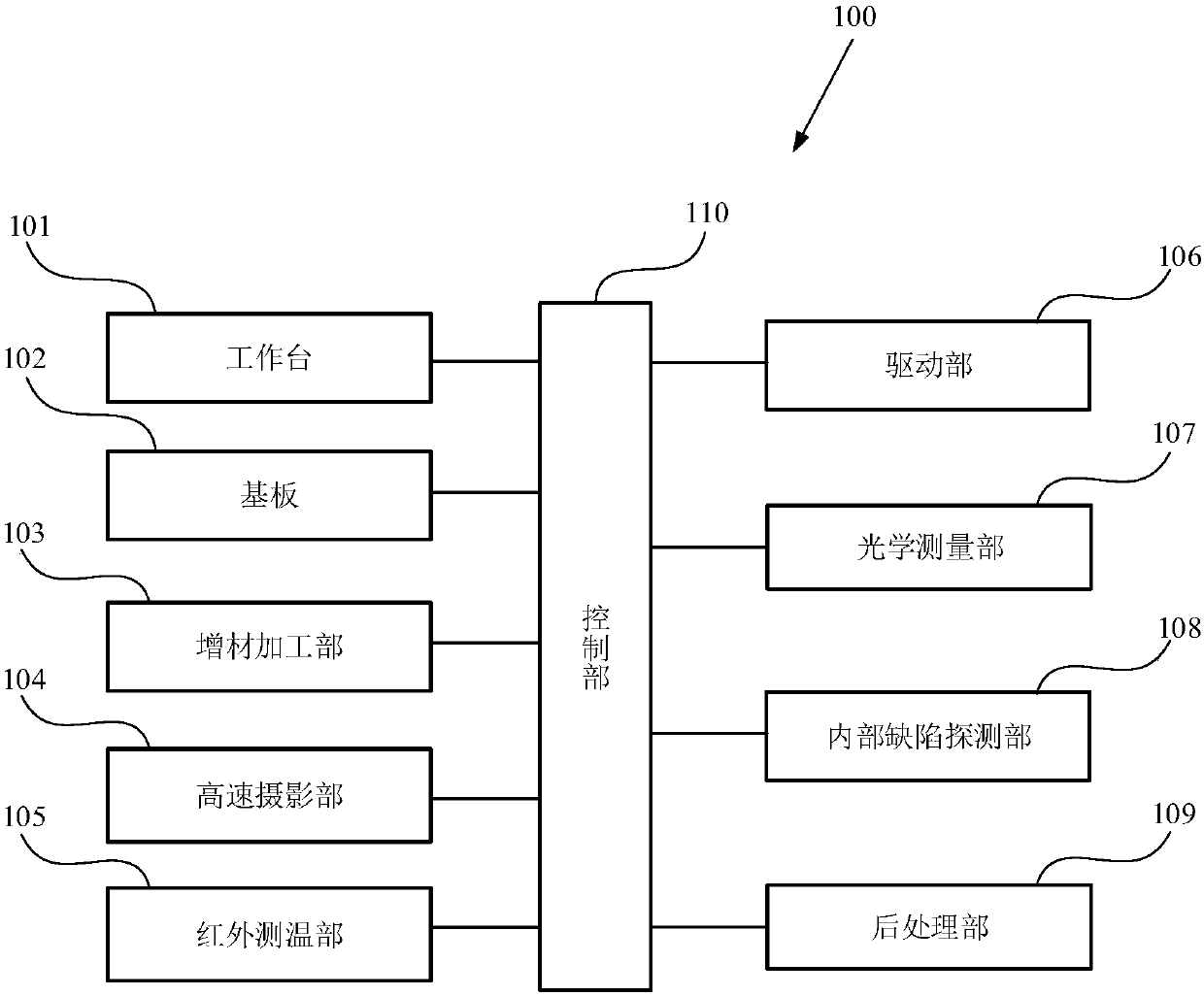

[0030] Such as figure 1 As shown, the additive manufacturing device 100 includes: a workbench 101, a substrate 102, an additive processing unit 103, a high-speed photography unit 104, an infrared temperature measurement unit 105, a drive unit 106, an optical measurement unit 107, an internal defect detection unit 108, and a rear A processing unit 109 and a control unit 110 .

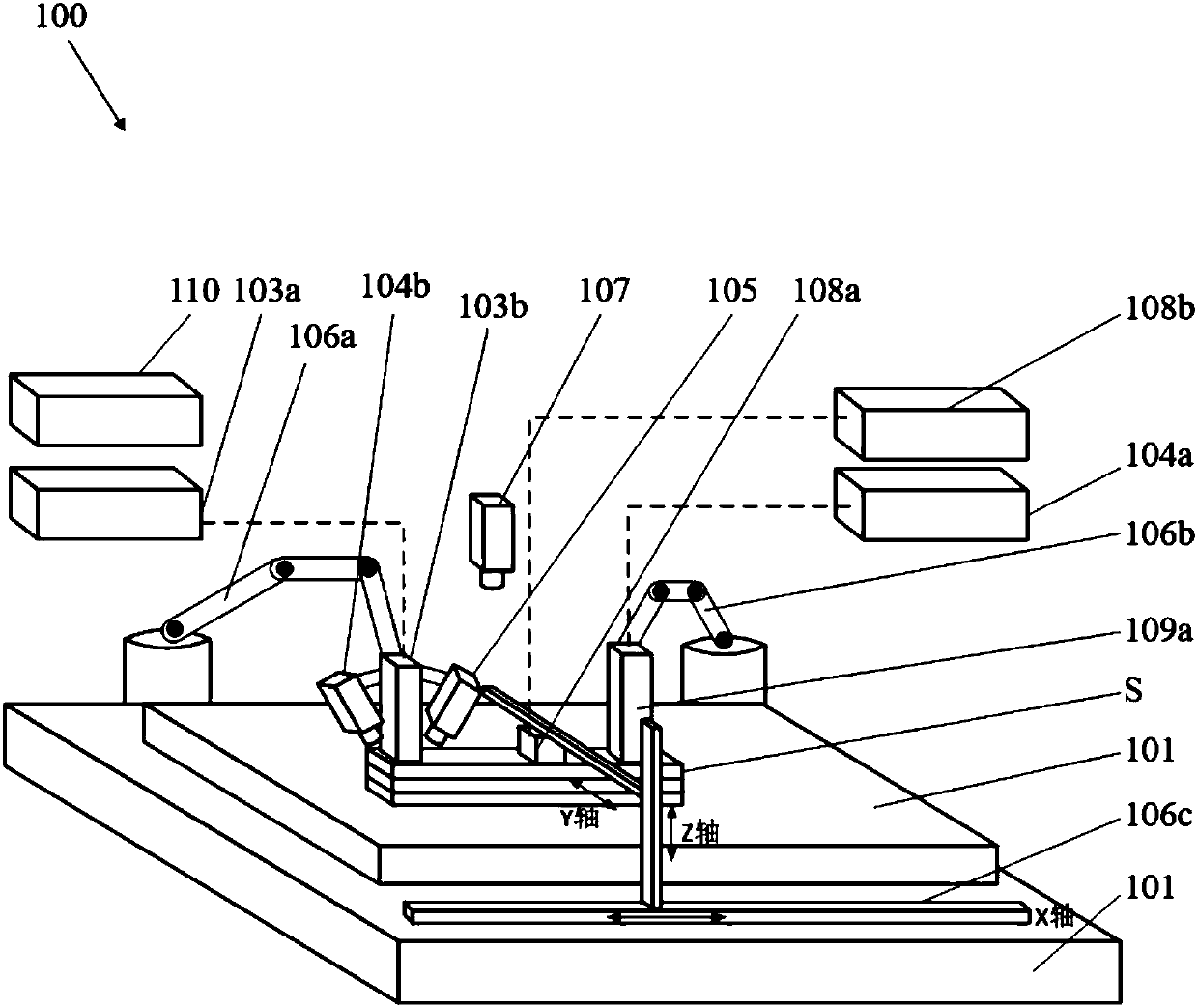

[0031] Such as figure 2 As shown, the substrate 102 is placed on the workbench 101, used to carry the material to be processed, has a heating function, preheats the processing environment, and suppresses stress concentration.

[0032] The additive processing unit 103 includes: a high energy beam generator 103a and an additive processing head 103b. The high-energy beam generator 103a can generate a high-energy beam and transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com