Precision lifting and positioning device for inner-support mold tire at conical bottom of storage box

A technology of lifting positioning and positioning device, which is applied in the field of welding to achieve the effect of ensuring welding accuracy and welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

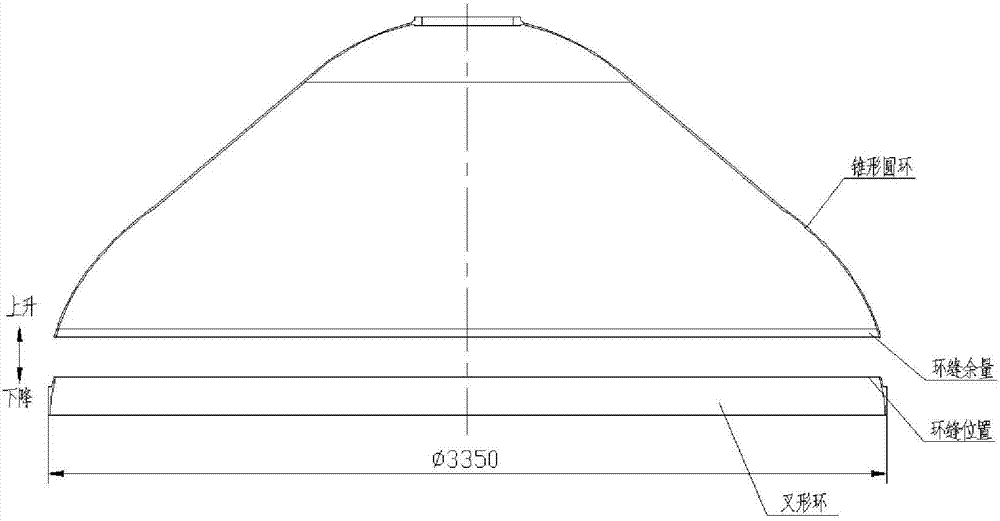

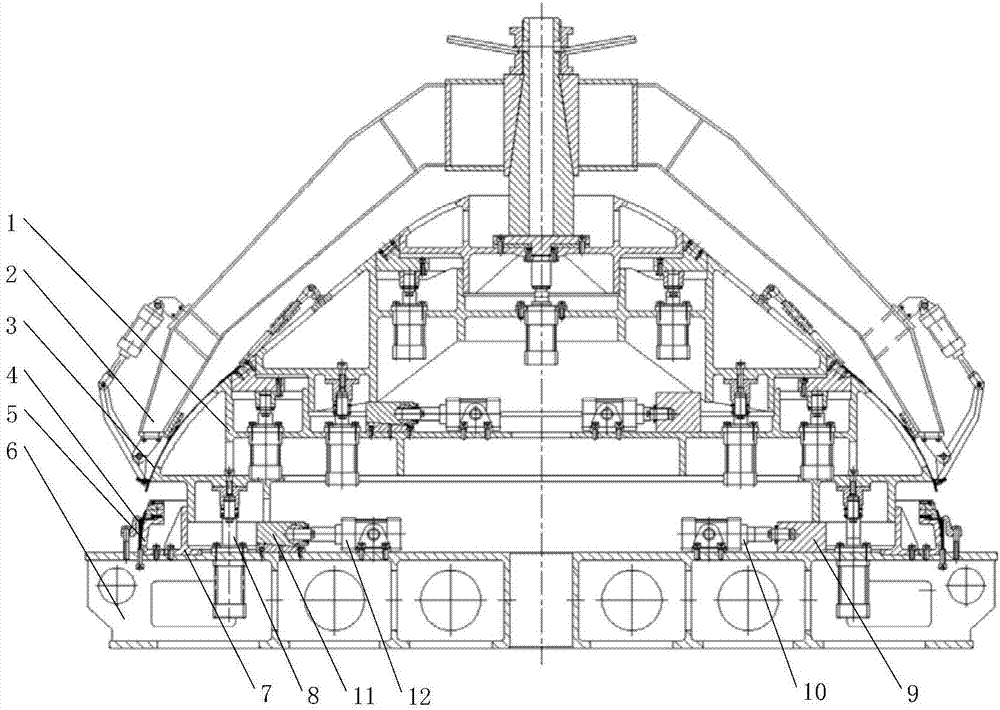

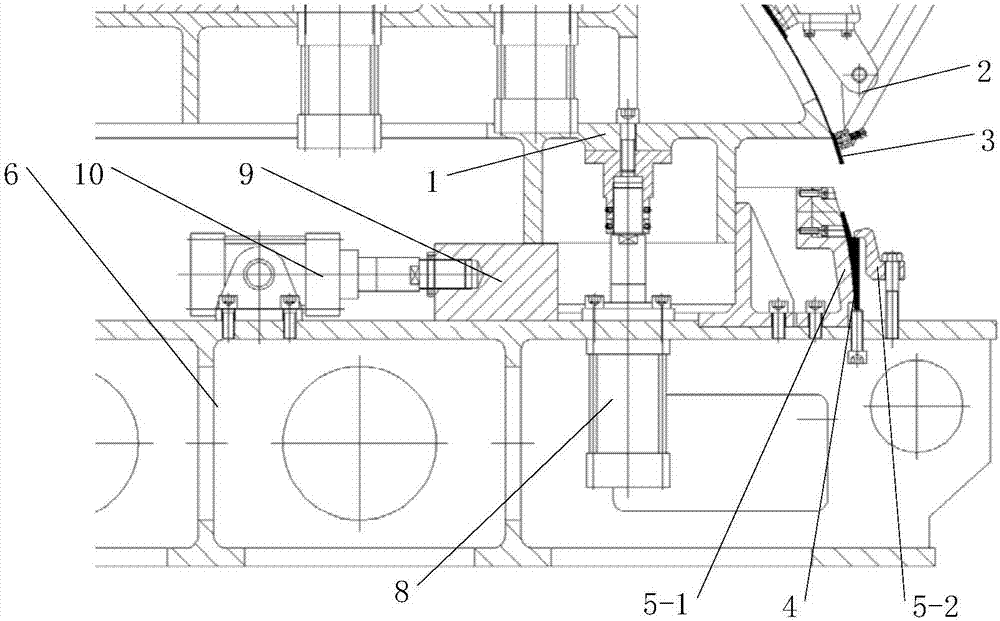

[0041] The aluminum alloy conical tank bottom fork ring and conical ring ring seam assembly before welding figure 1 Shown. According to the practical experience of friction stir welding engineering accumulated for many years, when welding 8mm thick aluminum alloy siding, the union of the two sidings must not exceed 0.3mm in order to meet the acceptance requirements of friction stir welding welds, and the welding of the sidings The smaller the and gap, the higher the welding quality. Since the inner surface of the conical bottom is a quadric surface controlled by the equation, the margin milling of the lower part of the conical ring should be controlled very accurately, namely figure 1 The milling height of the circumferential seam allowance must be controlled very accurately. In order to ensure the quality of the subsequent welding, it is strictly required that the tapered circumferential seam allowance is milled and the theoretical height error is controlled within 0.2mm. The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com