Clamping device

A technology of clamping device and clamping block, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large space occupied by welding fixtures, inconvenient control operation, high manufacturing cost, etc., to achieve The structure is simple, the space occupied is small, and the effect of reducing the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

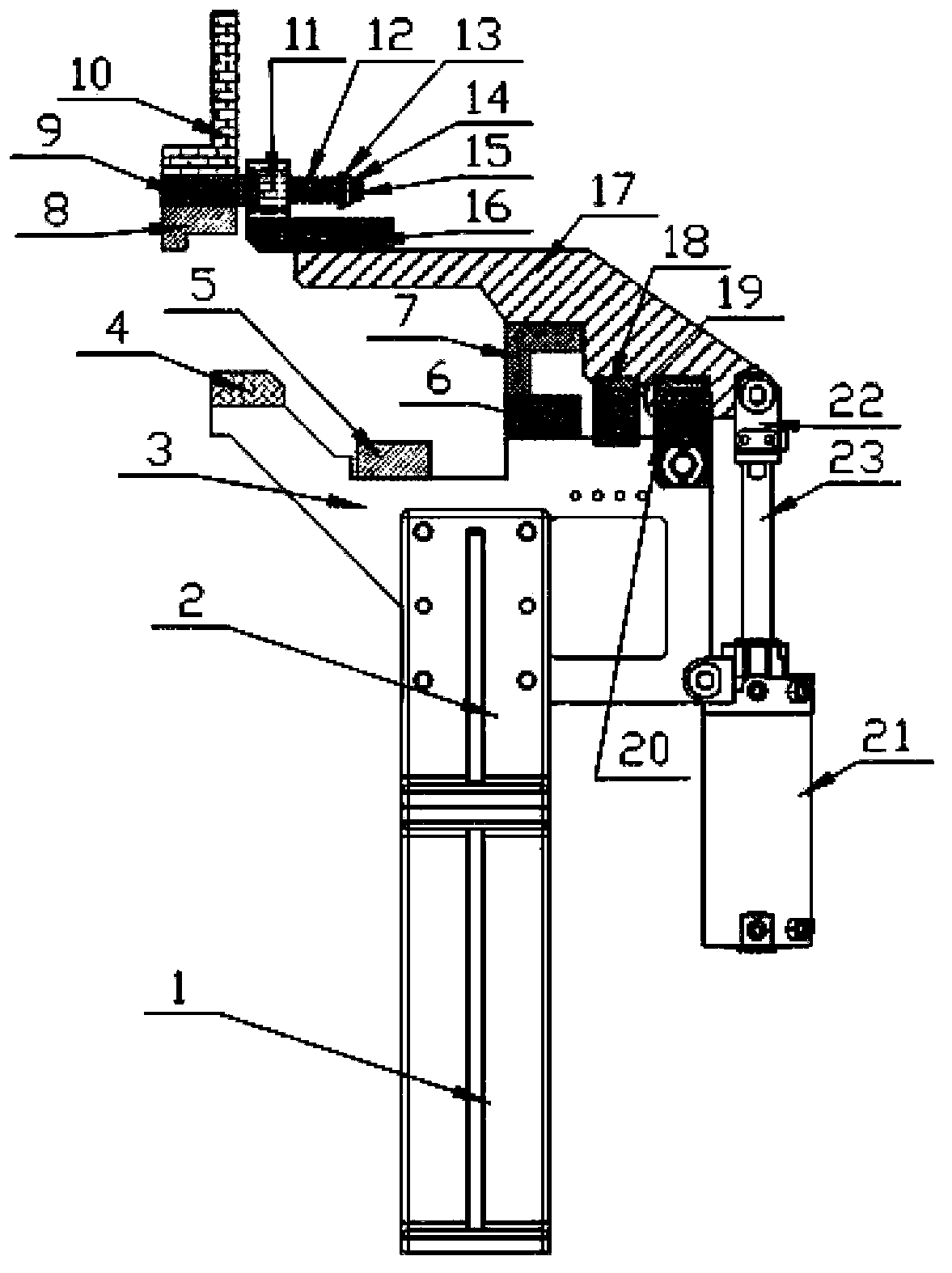

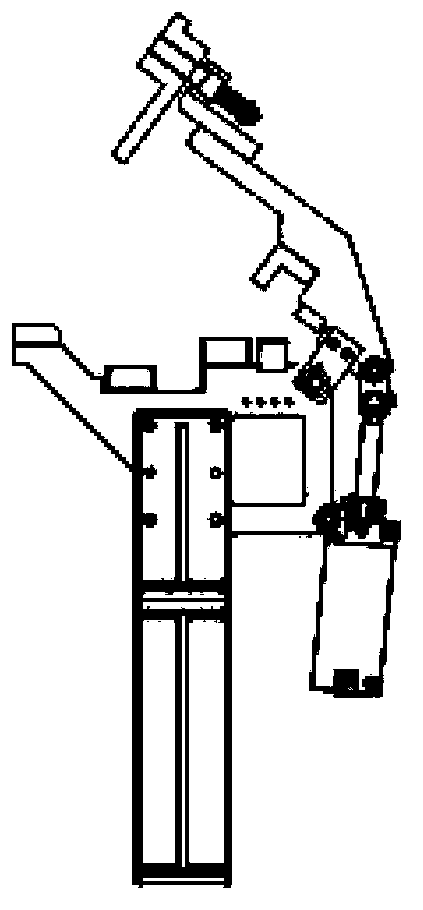

[0027] Such as figure 1 As shown, the clamping device of this embodiment includes a support seat, a lower support plate 3, an upper support plate 17 and a telescopic drive mechanism; the support seat includes a base 1 and an L-shaped plate 2, and the L-shaped plate 2 is fixed on the base by fastening bolts 1. The upper and lower support plates 3 are fixed on the L-shaped plate 2 by fastening bolts. One end of the lower support plate 7 is rotatably connected to the upper support plate 17, and the other end is provided with the first lower clamping block 4; telescopic drive device Select the air cylinder, the cylinder barrel 21 of the cylinder is connected with the lower support seat 3, the piston rod 23 of the cylinder is connected with the upper support seat 17, and the joints between the cylinder and the lower support seat 3 and the upper support seat 17 are located at the lower support seat 3 and the upper support seat. Near the junction of seat 17.

[0028] The upper suppo...

Embodiment 2

[0037] Such as figure 1 As shown, the difference between the clamping device of this embodiment and that of Embodiment 1 is that the upper clamping block fixing base 9 is a 3-prism, each side of which is provided with an upper clamping block, and the corresponding concave of the rotating support The groove is triangular; the rotary chuck in this case has three upper clamping blocks of different sizes, but its manufacturing cost and difficulty are greater than that of Example 1, so different types of rotary chucks should be selected according to the needs of the actual situation. Similarly, the rotary chuck can also be provided with other numbers.

[0038] The specific connection method between the telescopic drive mechanism of this embodiment and the lower support plate 3 and the upper support plate 17 can also be changed, and the materials and connection methods of each component should also be selected according to the actual situation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com