Vertical annular welding tool

A girth welder, vertical technique

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0048] Example Vertical girth welding tooling

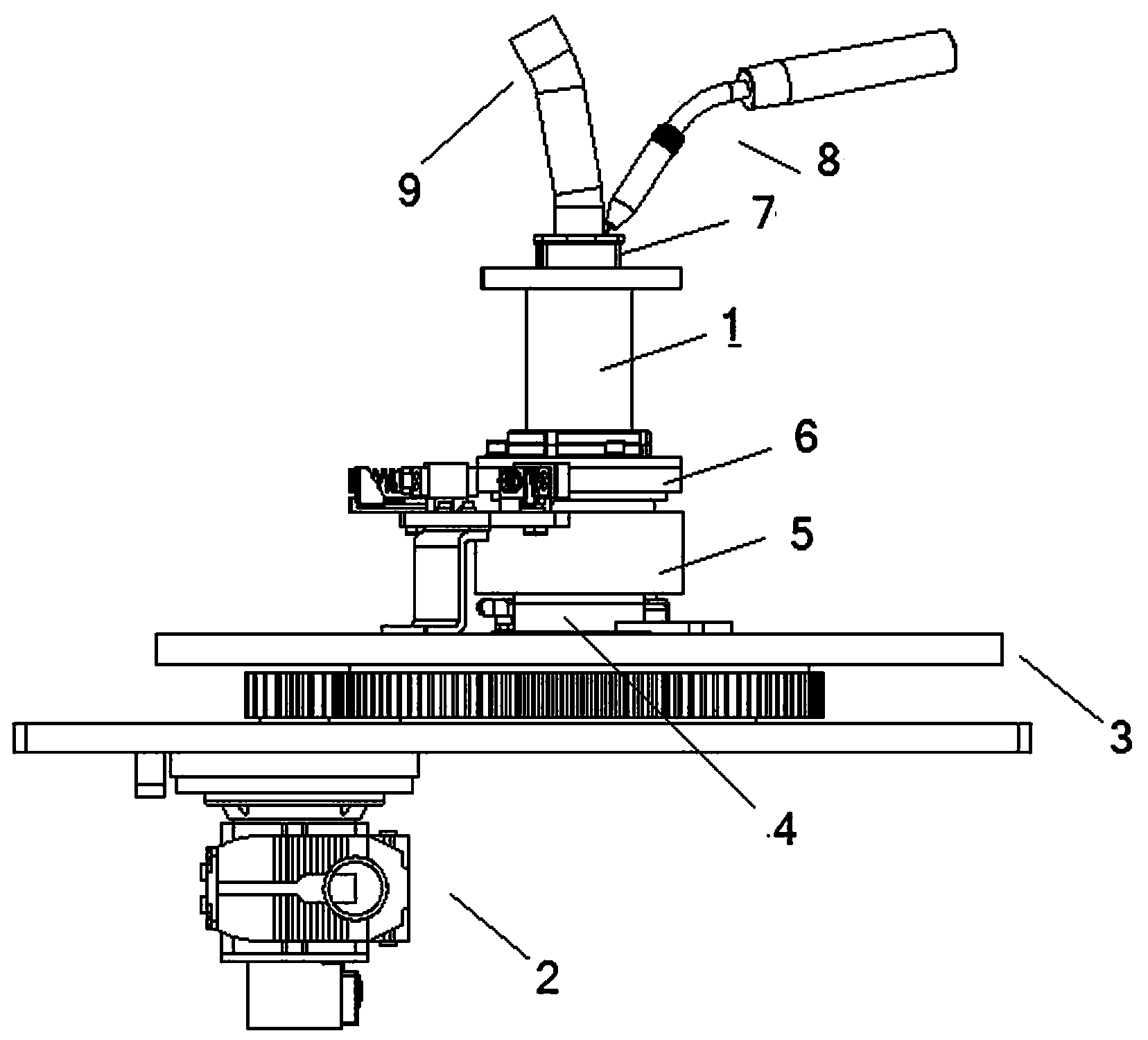

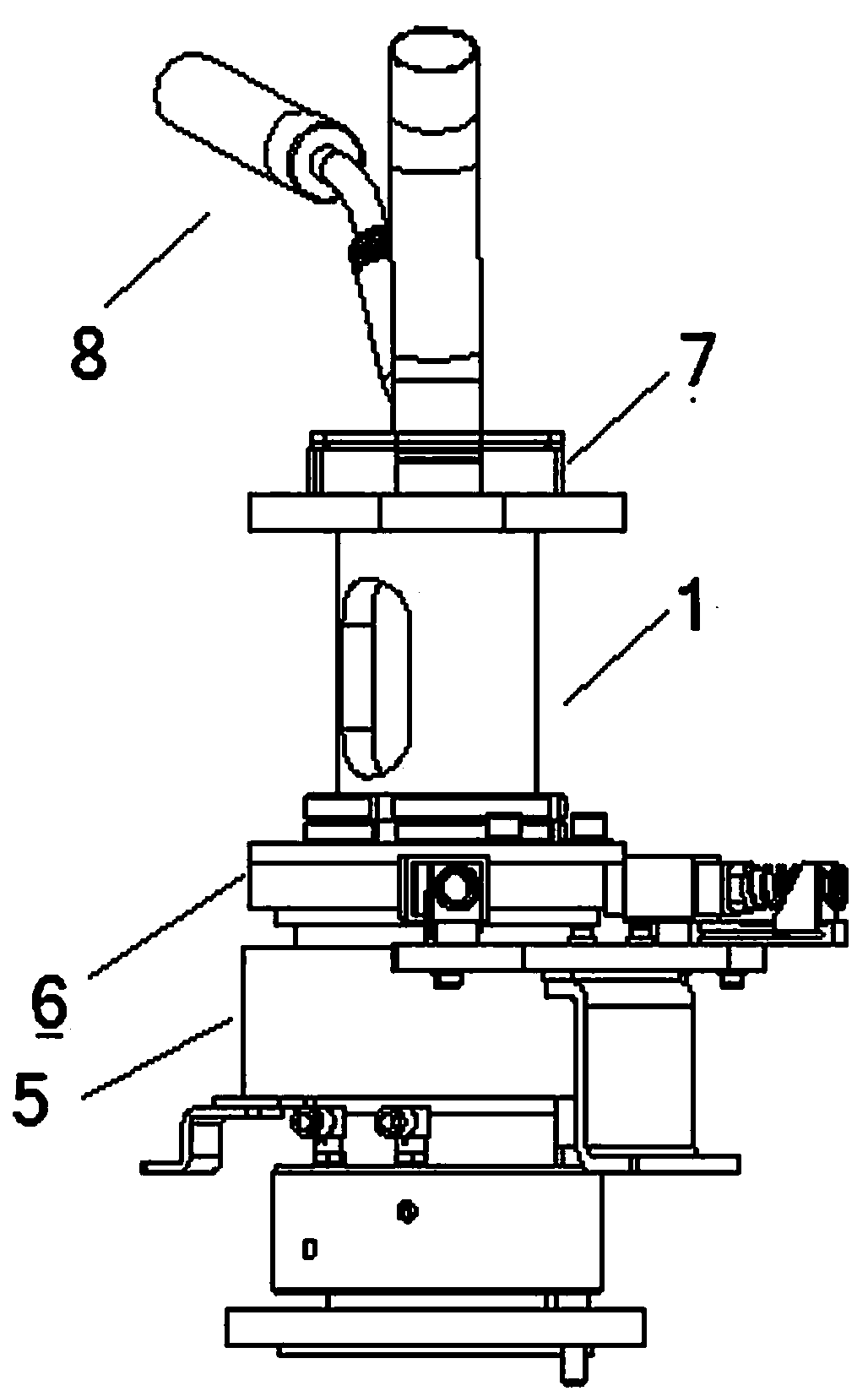

[0049] reference figure 1 , figure 2 , Figure 5 , Image 6 , This embodiment includes a fixed horizontally extending base, and also includes a rotatable platform 3 and a hollow column 1.

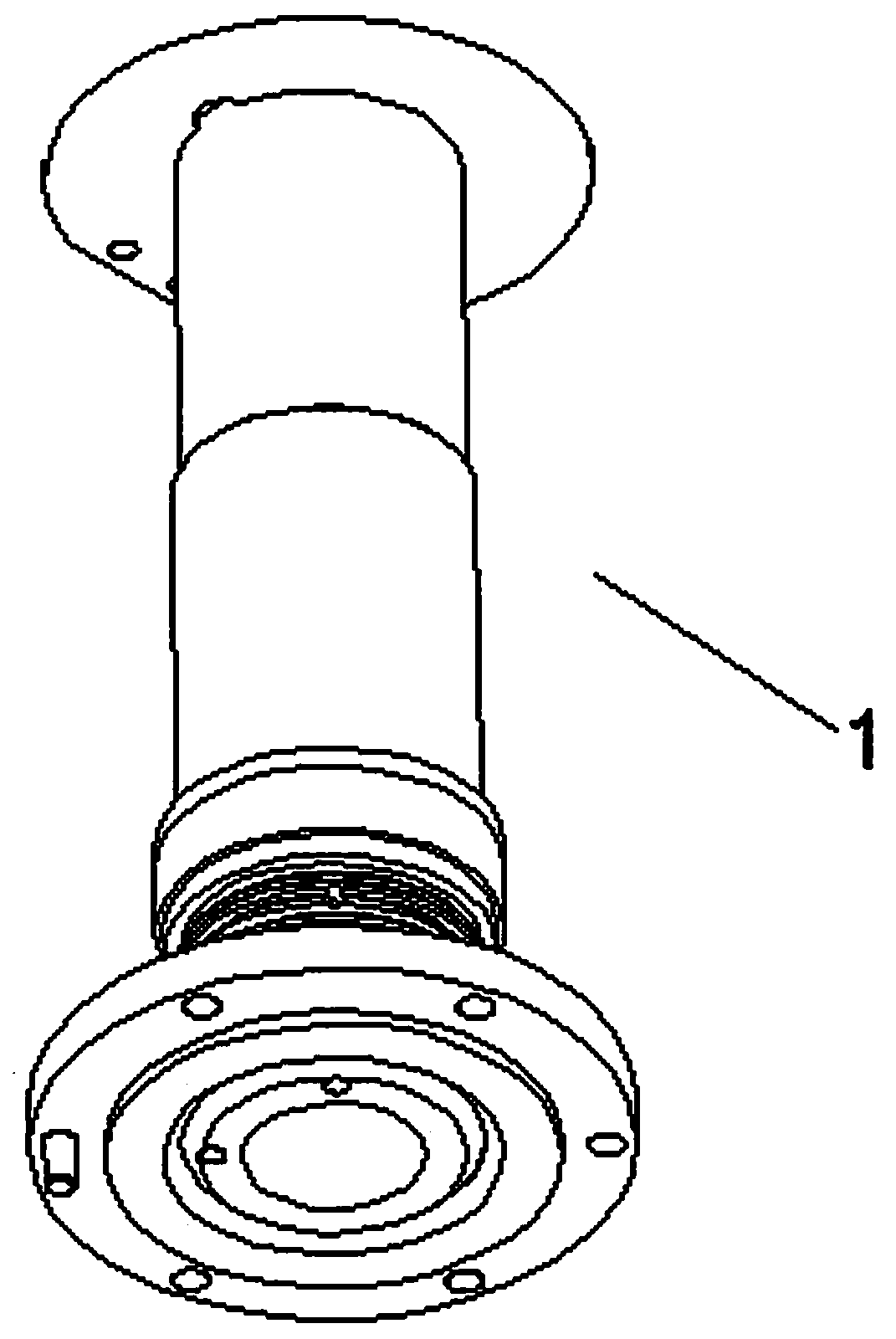

[0050] The overall structure of column 1 is as image 3 versus Figure 4 Shown. The column 1 is fixed on the base and extends upward. The column 1 is covered with an air guide ring 4, a conductive ring 5, and a grounding copper ring 6 from bottom to top. A workpiece positioning mechanism 7 is fixed on the upper part of the column 1 by bolts.

[0051] The hollow cavity of the column 1 is provided with an air circuit connected with the air guide ring 4 and an electric control circuit connected with the conductive ring 5, and a welding ground wire connected with the grounding copper ring 6 is also provided.

[0052] The speed reduction mechanism 2 is fixed on the base, the output end is a vertical rotating shaft, and the vertical rotating shaft is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com