Heat pipe

A technology of heat pipes and tube shells, which is applied in the field of heat conduction structures, can solve the problems of unsatisfactory capillary performance of heat pipe liquid-absorbing cores and unfavorable improvement of heat conduction efficiency of heat pipes, and achieve the effects of improving capillary performance, increasing surface tension coefficient, and improving heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

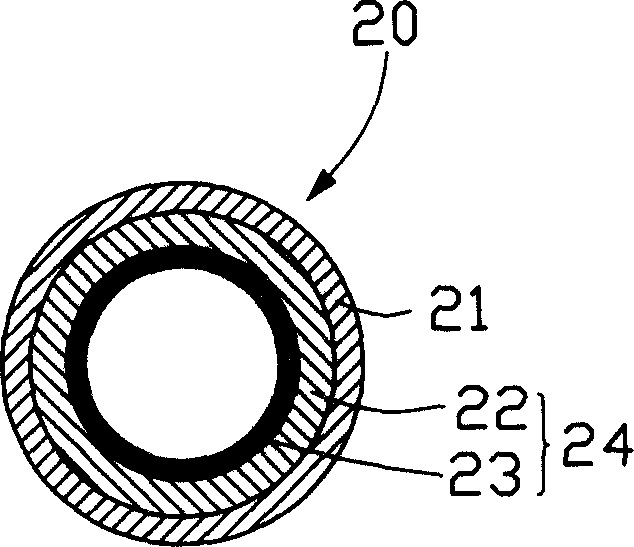

[0026] Such as figure 2 As shown, the heat pipe 20 provided by the present invention includes a shell 21 , a wick 24 with a capillary structure, and a working fluid (not shown), wherein the wick 24 includes a hydrophilic material 23 formed on the surface of the wick 24 .

[0027] The tube shell 21 is generally a copper tube, and different materials can also be used according to different needs, such as aluminum, steel, carbon steel, stainless steel, iron, nickel, titanium, etc. and their alloys. The radial cross section of the shell 21 can be a standard circle, or a special shape, such as ellipse, square, rectangle, triangle, etc. The tube shell 21 can be a straight tube, or any other curved tube. The diameter of the pipe is 2 mm to 200 mm, and the length of the pipe can range from a few millimeters to tens of meters.

[0028] In this embodiment, a copper tube with a circular radial cross-section is used, with a diameter of 4 mm and a length of 50 mm.

[0029] The wick 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com