Patents

Literature

59 results about "Surface tension coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

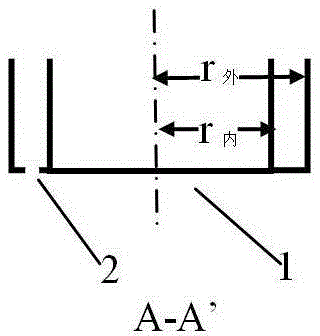

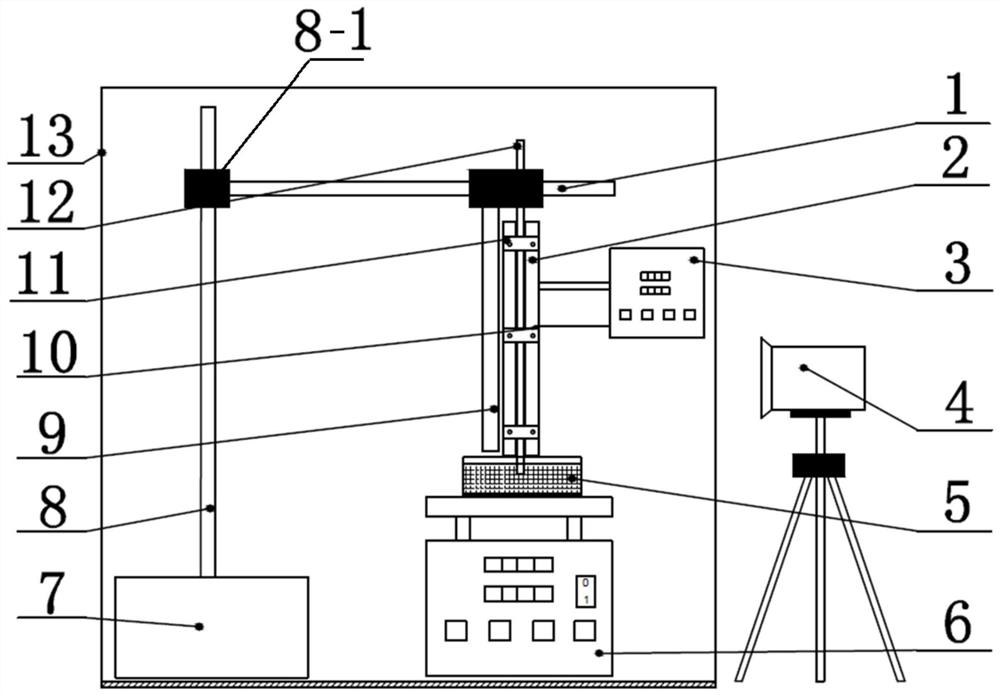

Experimental apparatus for determining surface tension coefficient of temperature-variable liquid

InactiveCN1844888ASimple structureEasy to operateHeating or cooling apparatusSurface tension analysisTemperature controlEngineering

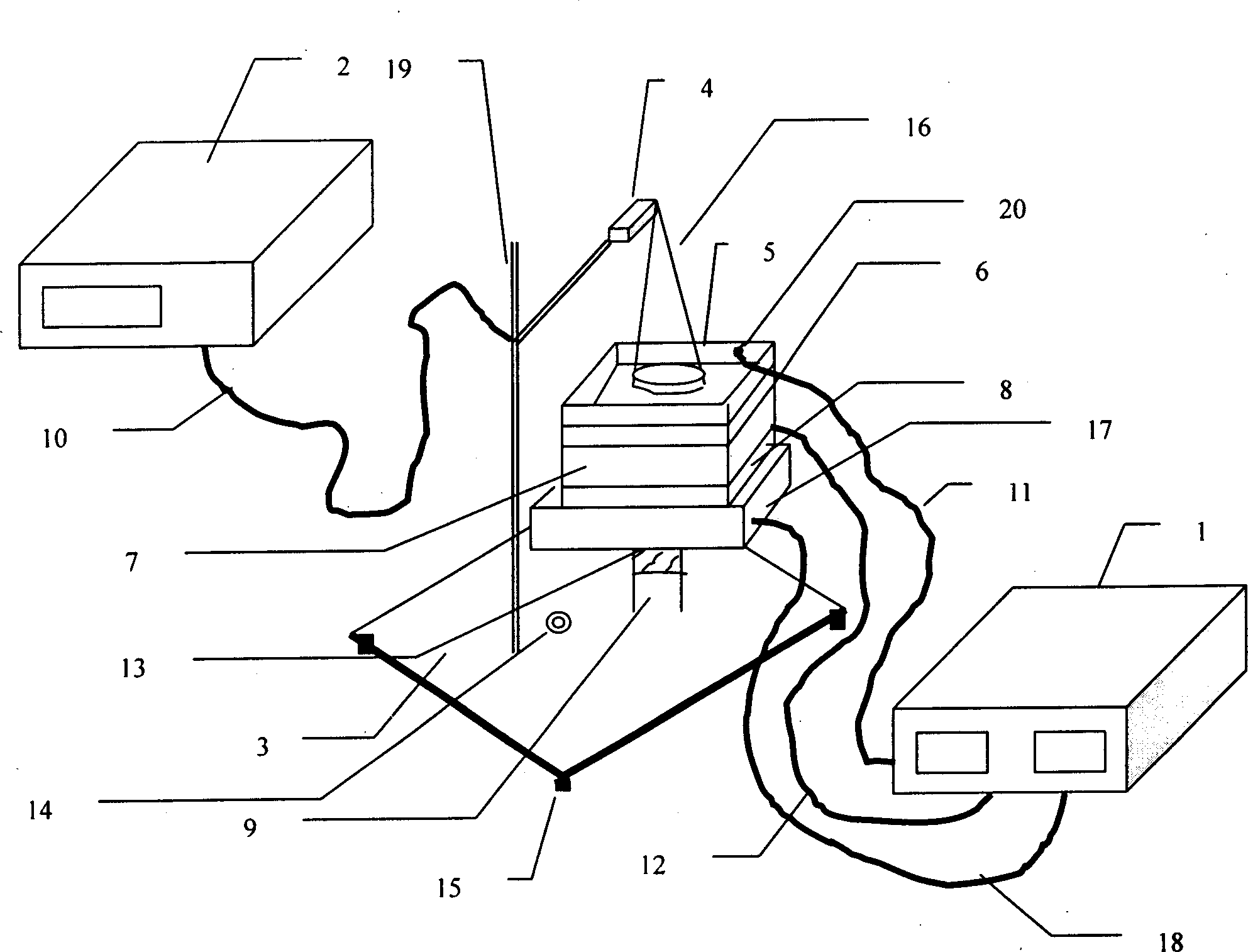

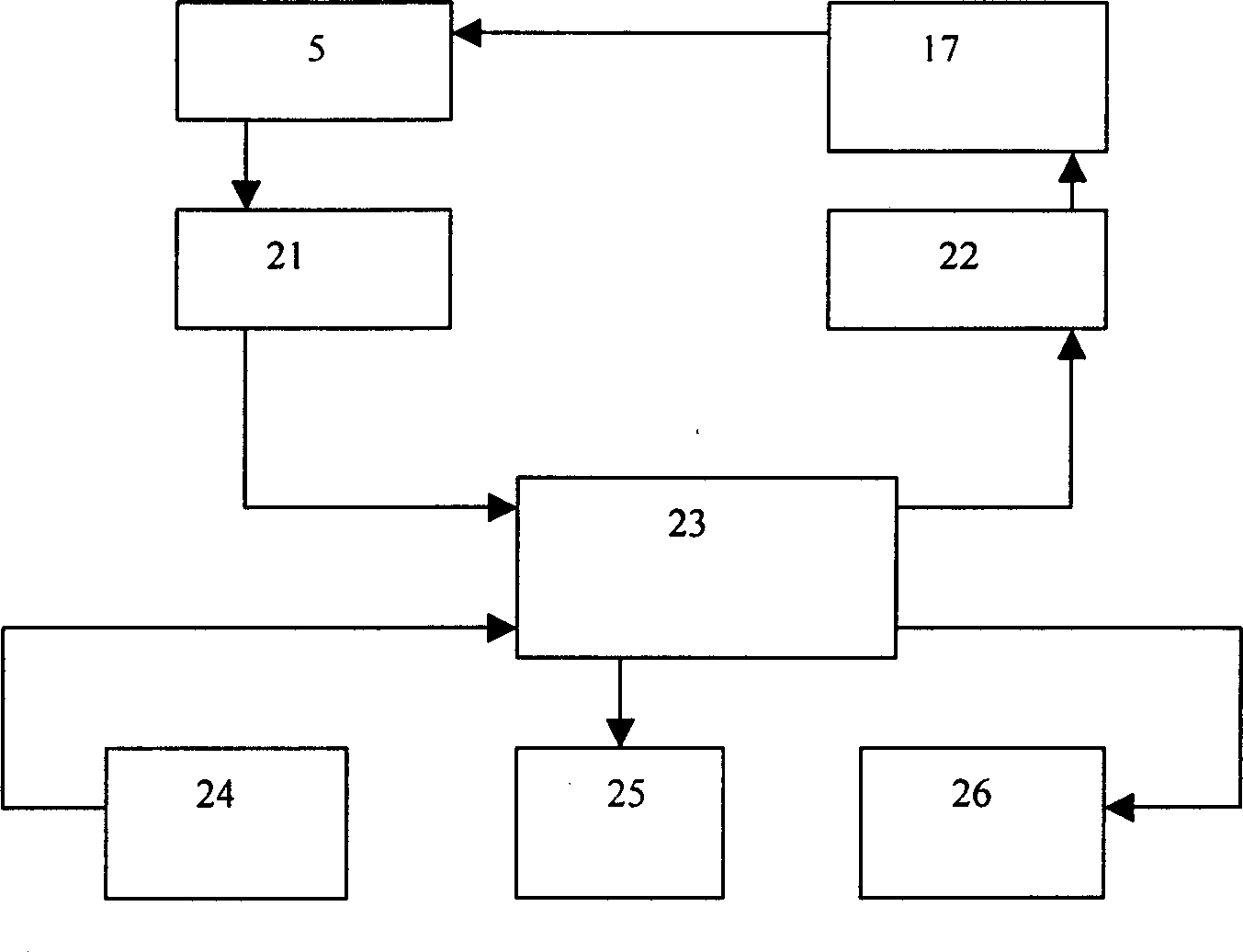

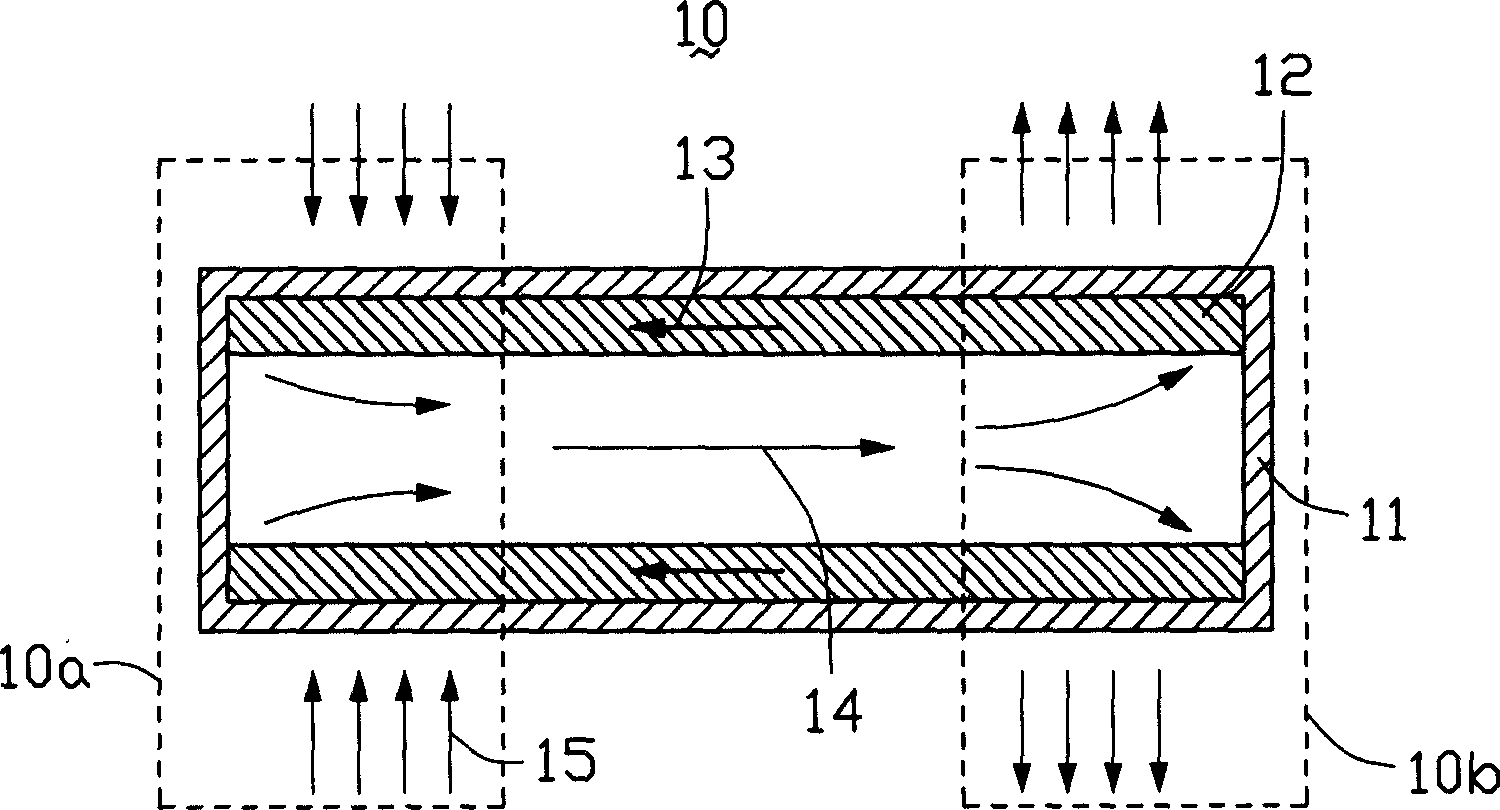

The invention relates to a device for testing the surface tension parameter of warm liquid, which comprises a pressure resistance sensor, a digital millivoltmeter, a temperature controller, a semi-conductor refrigerator, a metallic container, a swing ring, a heat emit fan, a support and a base. Wherein, the semi-conductor refrigerator is under the metallic container that containing liquid, which is connected to the temperature controller; the temperature sensor is inserted into said liquid; the support base has adjust bolt and horizontal instruction foam; the support is mounted with a pressure resistance sensor connected to the digital millivoltmeter; the pressure resistance sensor is connected to the swing ring whose bottom surface contacts the liquid surface of metallic container. The invention can set and control the temperature of tested liquid, to detect the surface tension parameter at different temperature, with simple structure and easy operation.

Owner:SOUTHWEST UNIVERSITY

Heat pipe

InactiveCN1624411AImprove thermal efficiencyHydrophilicIndirect heat exchangersWorking fluidEngineering

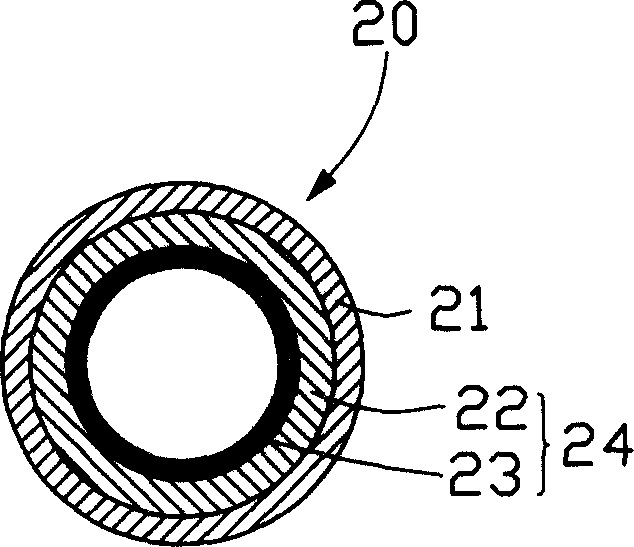

The invention relates to a heat pipe which includes a hollow pipe shell, solution absorption core stick to the inner wall of the shell: with filled liquid. There is a larger of hydrophilic material on the surface of solution absorption core , which can increase the coefficient of surface tension of solution absorption core, resulting in increased the efficiency of heat pipe. The heat pipe supplied by the invention with high efficiency of heat pipe , is suitable for heat sink device in electric instrument.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

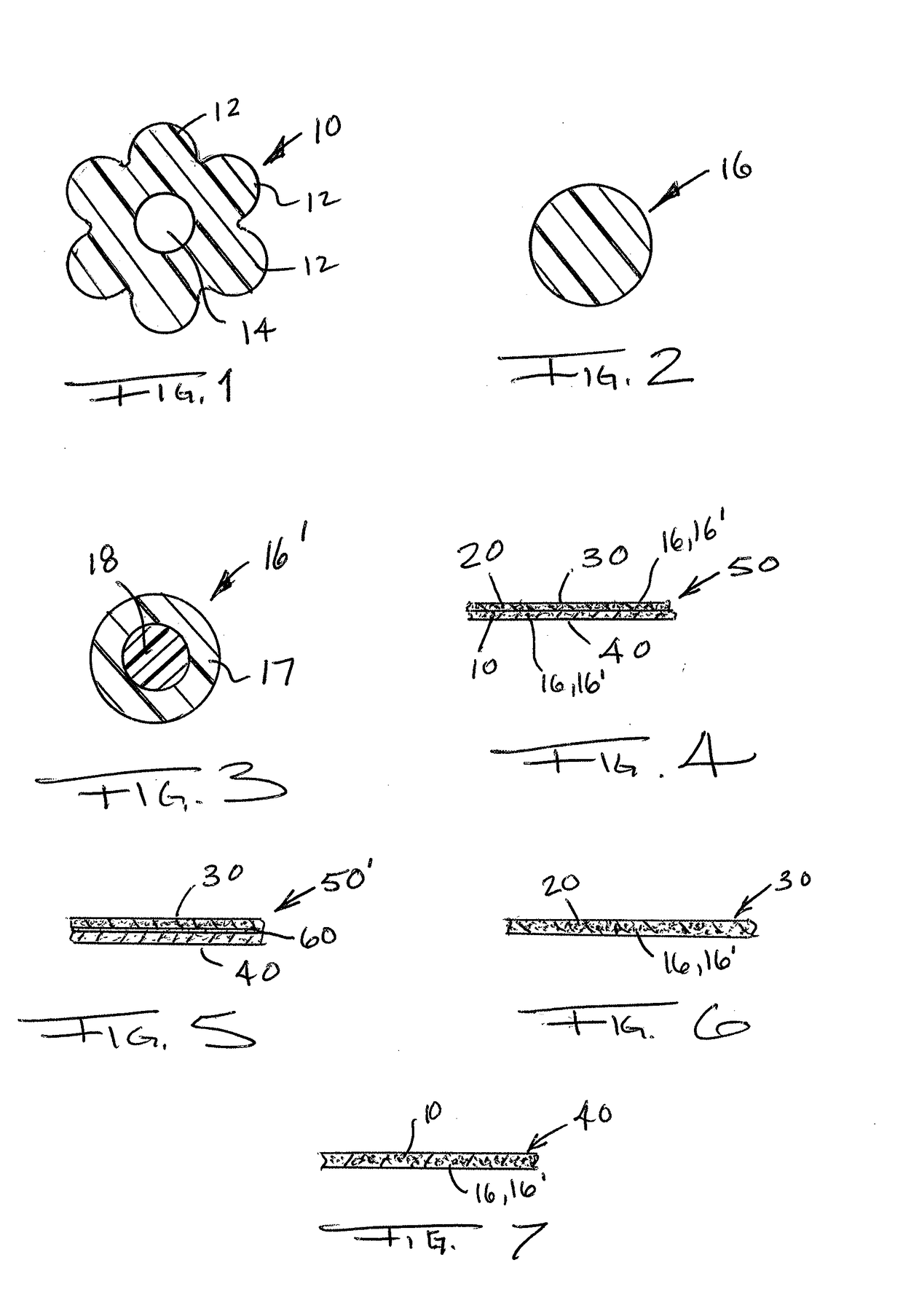

Enhanced ice peel resistance/non-woven moldable composite systems with added sound acoustical properties

A nonwoven laminate is provided having multi-purposes. One embodiment is an A-layer having a high surface tension factor to prevent water absorption and can be used for fender liners or underbody surfaces of motor vehicles to prevent water from absorbing into the material as well as ice accumulation. The water resistant properties are the result of utilizing a newly engineered hydrophobic PET (H-PET) fiber. Another embodiment, useable alone or in combination with the A-layer is a B-layer that has hollow multi-lobe cross-sectional fibers to provide enhanced sound absorption properties. One or both layers have thermo-moldable characteristics that allow them to be shaped into a specific geometry. In this case, the low melt fibers provided in one or both layers are “fused” and interlock or bridge together to yield a rigid nonwoven water / ice resistant and / or sound absorbing composite.

Owner:FOSS PERFORMANCE MATERIALS LLC

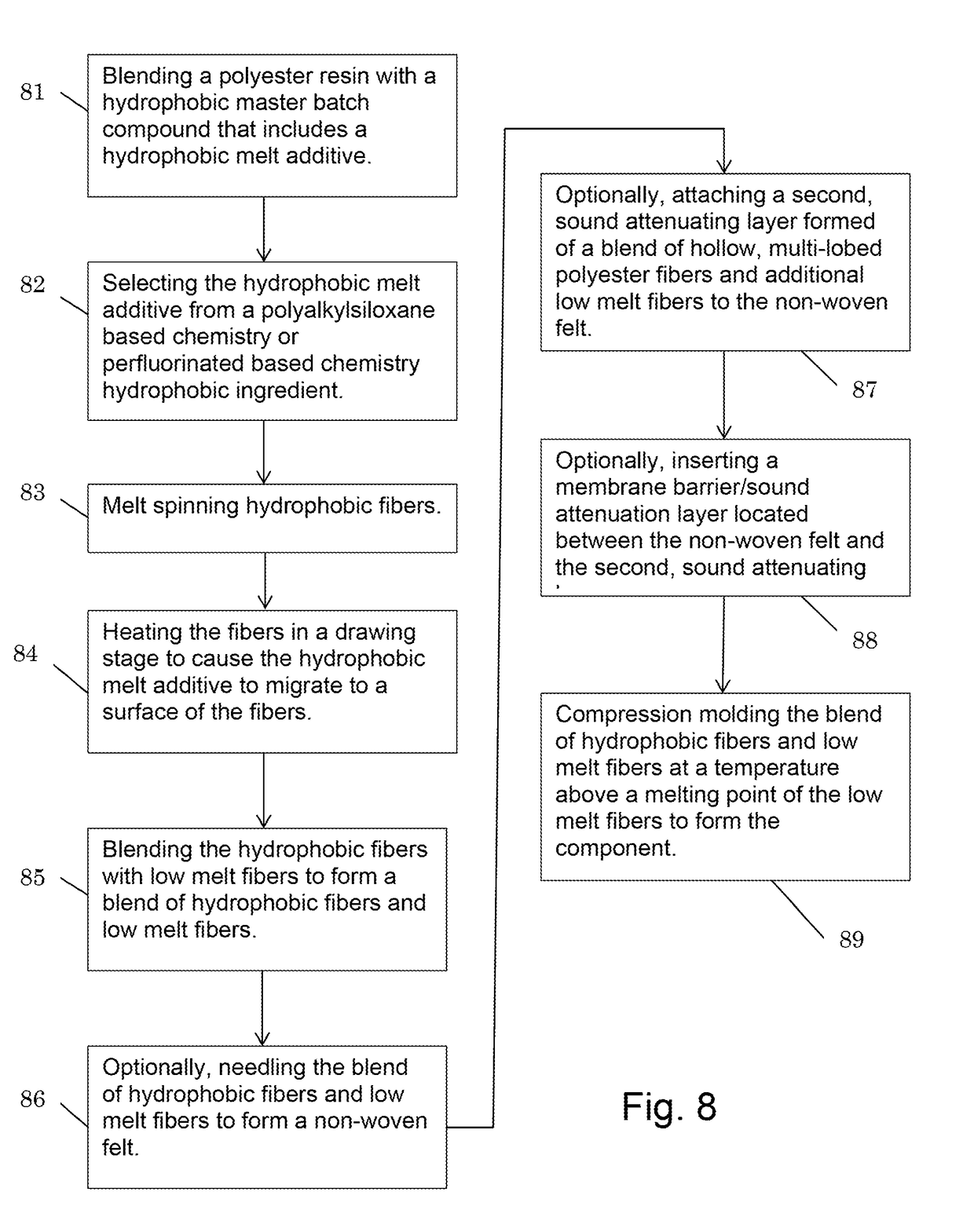

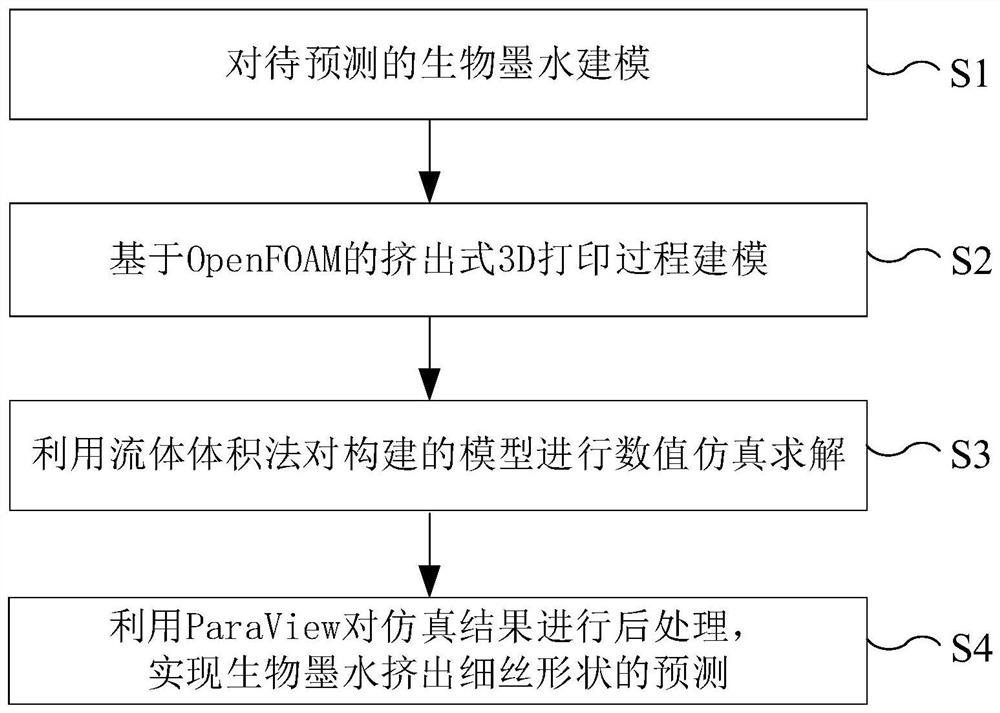

Shape prediction method of extrusion type 3D printing bio-ink extrusion filament

PendingCN113554743AHigh precisionImprove consistencyGeometric CADAdditive manufacturing apparatusThermodynamicsComputer printing

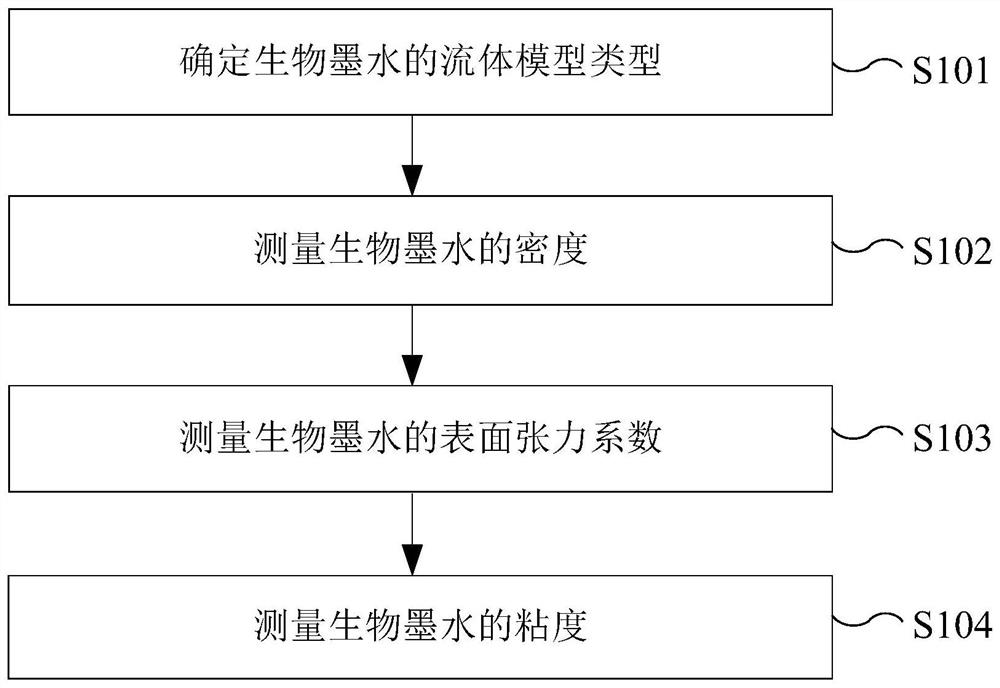

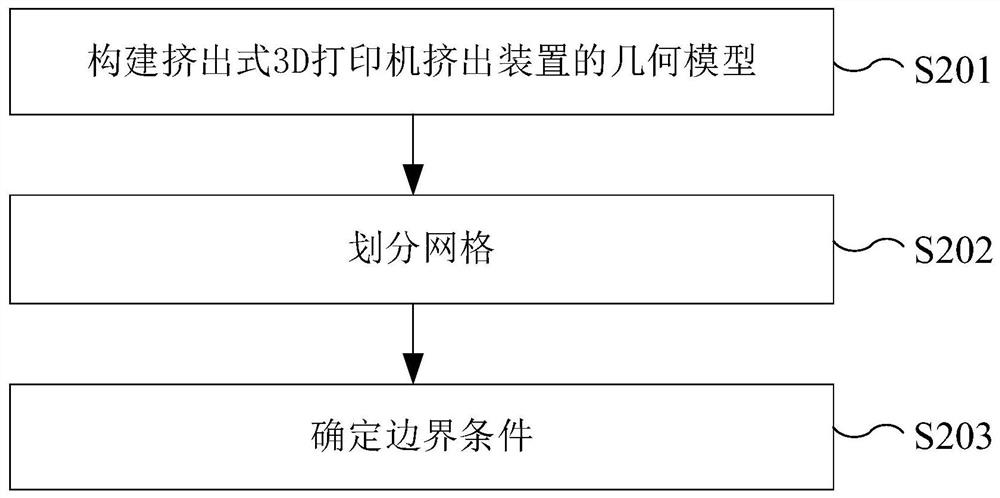

The invention discloses a shape prediction method for extrusion type 3D printing bio-ink extrusion filaments, and the method comprises the following steps: S1, modeling bio-ink to be predicted, and determining and obtaining three material characteristic parameters for constructing a bio-ink model, namely the density rho b of the bio-ink, the surface tension coefficient sigma of the bio-ink and the viscosity mu b of the bio-ink; s2, performing modeling on the basis of an OpenFOAM extrusion type 3D printing process, the modeling being realized through three steps of constructing a geometric model of an extrusion type 3D printer extrusion device, dividing grids and determining boundary conditions in sequence; s3, performing numerical simulation solution on the model constructed in the step S2 by using a fluid volume method; and S4, performing post-processing on the simulation result by using ParaView, and drawing a boundary between the bio-ink and air at different moments to obtain a prediction result of the shape of the extruded filament of the bio-ink. The method is high in prediction result precision, has higher consistency compared with an actual result, and is reasonable and effective.

Owner:BEIHANG UNIV

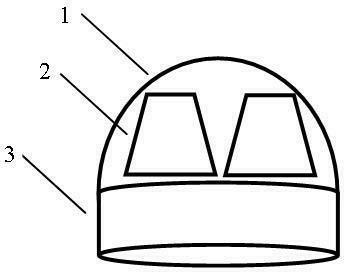

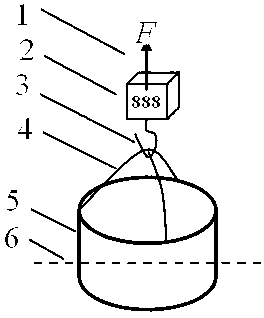

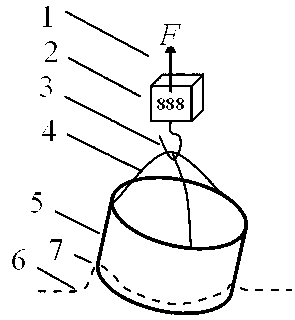

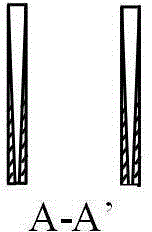

Automatic horizontal hanging ring for measuring surface tension of liquid by using abruption method

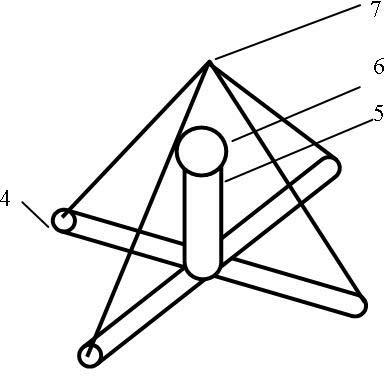

InactiveCN102636416AReduce experimental conditioning stepsSimple experimentSurface tension analysisRolling resistanceHorizon

The invention discloses an automatic horizontal hanging ring for measuring the surface tension of liquid by using an abruption method, which relates to the field of physical experimental devices, and especially relates to the automatic horizon of a hanging ring for an experiment of measuring the surface tension coefficients of liquid by using an abruption method. In the current experiments, through manually bending one metal wire in a hanging ring, the hanging ring is in a horizontal state, and the horizontal adjustment of the hanging ring is difficult. The invention adopts the following technical scheme: the surface tension exerted on each part of a non-horizontal hanging ring is not balanced, so that an effect of point contact is achieved between the hanging ring and a wire drawing device; and under the action of the surface tension and through the advantage of small rolling friction, the automatic horizon of the non-horizontal hanging ring is realized before an abruption operation is performed. The hanging device disclosed by the invention has the advantages of carrying out automatic horizon adjustment, reducing an experiment adjusting step, simplifying the experiment process, improving the experiment efficiency, and improving the experiment accuracy.

Owner:SICHUAN UNIV

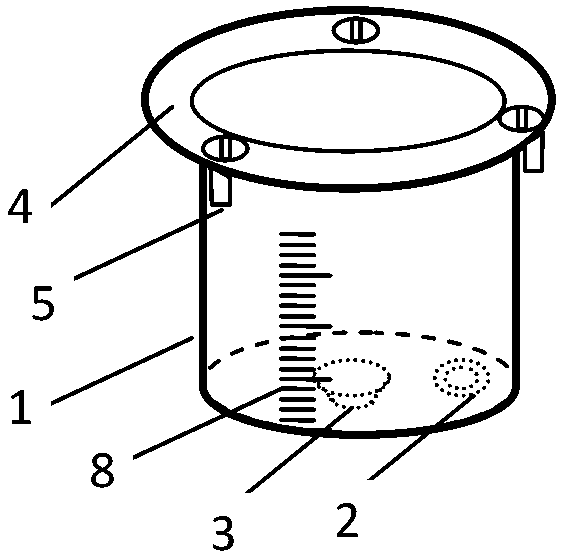

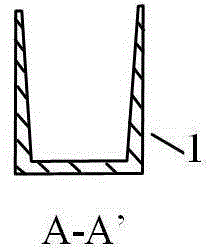

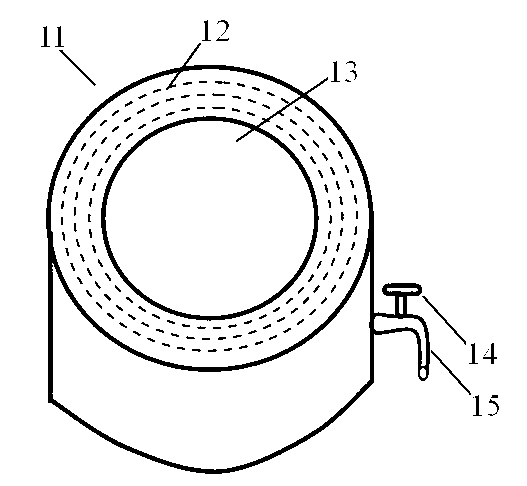

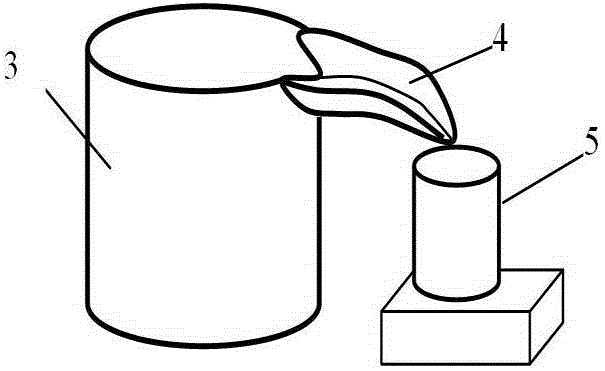

Liquid surface tension coefficient measuring method

A liquid surface tension coefficient measuring method relates to measurement of liquid physical parameters and adopts the technical scheme that a spirit bubble is arranged on the bottom surface of theinner side of a cylindrical container, a water outlet pipe is fixed on the bottom surface of the cylindrical container, and the outer diameter of an outlet of the water outlet pipe is d; the inner bottom surface of the cylindrical container is horizontal; a recovery container is arranged below the outlet of the water outlet pipe of the cylindrical container; liquid is injected into the cylindrical container until liquid drops flow to the recovery container from the outlet of the water outlet pipe, the distance h between the liquid level at the upper end and the horizontal plane of the outletis measured when no liquid drops drop from the outlet of the water outlet pipe, and the diameter of the inner side of the cylindrical container is more than 100 times of the outer diameter of the outlet of the water outlet pipe; the surface tension coefficient sigma of the liquid is equal to rho * g * h * d / 4, rho is the density of the liquid, and g is the gravitational acceleration. The measurement method is simple and accurate.

Owner:SICHUAN UNIV

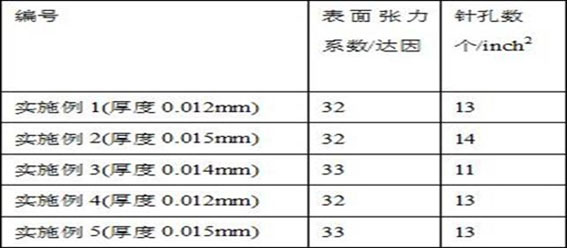

Aluminum foil for power battery and preparation process of aluminum foil

The invention relates to an aluminum foil for a power battery and a preparation process of the aluminum foil. The aluminum foil is prepared from the following raw materials in percentage by weight: 0.05-0.2% of Si, 0.2-0.7% of Fe, 0.2% of Cu, 0.05% of Mn, 0.05% of Mg, 0.05% of Zn, 0.01-0.06% of Ti and the balance of Al. The preparation process of the aluminum foil comprises six steps of casting, primary cold rolling, annealing, secondary cold rolling, foil rolling and slitting. The prepared aluminum foil is large in surface tension coefficient, the surface tension of the aluminum foil can reach 31 dynes or above without subsequent oil removal treatment, usage requirement of a user is met, technological process is simplified, production cost is reduced, the surface is attractive and fine, the preparation technology is simple, the route is mature, and wide industrial application prospects are achieved.

Owner:郑州金辉新能源电子材料有限公司

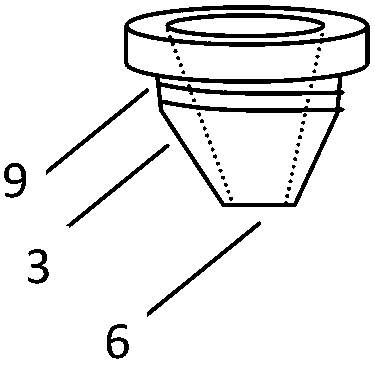

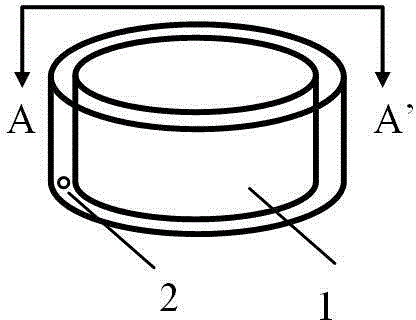

Method for measuring surface tension coefficient of liquid by injecting liquid into round tank

InactiveCN104458507ASimple structureReduce cost of measurementSurface tension analysisGreek letter sigmaEngineering

The invention provides a method for measuring a surface tension coefficient of liquid by injecting the liquid into a round tank and relates to measurement of physical parameters. The round tank comprises two cylinders with the same center axis and a sealing bottom plate shared by the two cylinders, and a small hole is formed in the sealing bottom plate of the round tank. The round tank is put on a platform, the small hole of the round tank is suspended outside the platform, a measuring glass is put under the small hole, the liquid with the volume of Q1 is poured into the round tank, the round tank stands still until no liquid drops from the lower side of the small hole, the volume Q2 of the liquid in the measuring glass is read, the radius ro of the inside of the outer cylinder and the radius ri of the outside of the inner cylinder are measured, and the surface tension coefficient of the liquid is sigma=[rho*(Q1-Q2)*g] / [2pi*(ro+ri)]. The method has the beneficial effects that if the measurement precision of mass or volume is high enough, the largest error of a device is gravity generated by mass of a liquid drop, so the error is small; the structure is simple and the cost is low.

Owner:SICHUAN UNIV

Liquid surface tension coefficient measuring device based on optical fiber FP cavity

InactiveCN103926175AHigh measurement accuracySimple structureSurface tension analysisBroadbandLength wave

The invention discloses a liquid surface tension coefficient measuring device based on an optical fiber FP cavity. According to the device, a broadband spectrum with the central wavelength being 1550nm is used as a measuring light source, a single-mode hollow core optical fiber is used as the FP cavity, detected liquid enters the hollow core optical fiber under the capillary action, the length of the hollow core optical fiber, namely the FP cavity, is changed, the change of interferometric fringes of output light is caused, and the surface tension coefficient of detected liquid can be obtained by monitoring the change. The device has the advantages that the liquid surface tension coefficient can be measured accurately by using the change of the interferometric fringes of the light, the measuring accuracy is high, the structure is simple, the use is convenient, the defects that the accuracy is low, the controllability is poor and the like caused by individual operation in conventional measuring methods are avoided. A method is suitable for being used in occasions in which the liquid surface tension coefficients are required to be measured fast and accurately in scientific researches, medical science and the like.

Owner:CHINA JILIANG UNIV

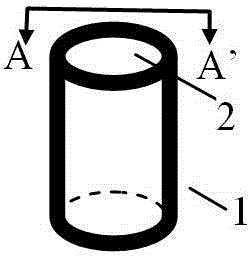

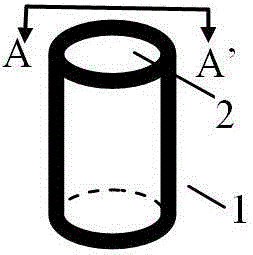

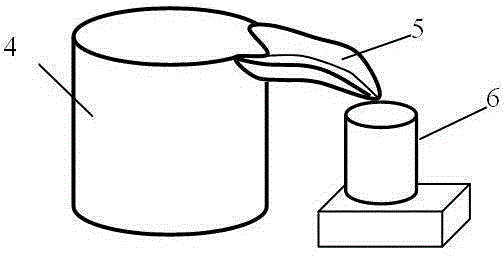

Method for measuring surface tension coefficient of liquid by virtue of liquid discharge of hollow cylinder

InactiveCN104390888AImprove stabilityReduce shakingSurface tension analysisLiquid densityEngineering

The invention discloses a method for measuring the surface tension coefficient of liquid by virtue of liquid discharge of a hollow cylinder and relates to measurement of physical parameters. The technical scheme is as follows: the bottom part of the hollow cylinder is sealed, the upper end of the hollow cylinder is opened, the outer radius of the hollow cylinder is R, and the average density of the hollow cylinder is 0.5-0.8 times the density of the liquid; liquid is injected into a water overflowing groove, when no liquid drips at the tail end of a flow guiding channel, the mass m1 of a water cup is measured, and then the water cup is put just below the tail end of the flow guiding channel; the mass m of the hollow cylinder is measured, the hollow cylinder is slowly put into the water overflowing groove, when no liquid drips from the tail end of the flow guiding channel, the mass m2 of the water cup containing the liquid is measured, and the surface tension coefficient sigma of the liquid is equal to (m-(m2-m1))*g / (2pi R). The method disclosed by the invention has the beneficial effects of simple structure, low cost and easiness in operation.

Owner:SICHUAN UNIV

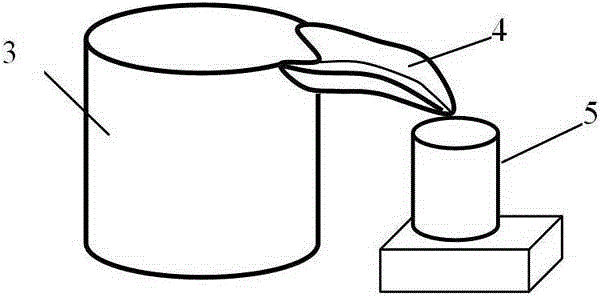

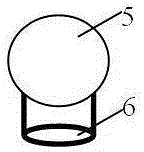

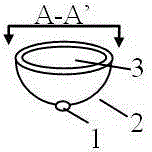

Device for measuring liquid surface tension by pull-out method

InactiveCN103245594AReduce the difficulty of adjustmentHigh precisionSurface tension analysisEngineeringMechanical engineering

The invention relates to a device for measuring liquid surface tension by a pull-out method, which relates to the field of measurement of physical parameters and particular to measurement of surface tension coefficients, and aims to avoid errors caused by a non-horizontal hoisting ring during surface tension measurement. According to the technical scheme, a hoisting ring is formed by a cylinder and a spherical surface which are connected with each other; liquid is stored in a circular water tank, and a hole is formed in the middle of the circular water tank; and a small ball is arranged at the top of a connecting rod of a pressure sensor, the connecting rod extends into the hole from the lower part of the hole, the small ball is in contact with the neighboring part of the top of the spherical surface of the hoisting ring, and a water pipe and a water pipe switch are arranged in the circular water tank. The device has the benefits that the spherical surface is in point contact with the small ball, the bottom of the hoisting ring is not horizontal to lead to asymmetry of surface tension at the bottom of the hoisting ring, and the surface tension acts in the form of a tension arm and drives the spherical surface to make micro displacement, so that the bottom of the cylinder of the hoisting ring is in one horizontal plane.

Owner:SICHUAN UNIV

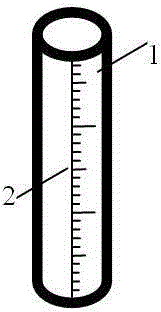

Method for measuring liquid surface tension by using transparent glass tube with scale marks

InactiveCN104390889AUnderstand clearlySimple methodSurface tension analysisEngineeringAirbag deployment

The invention discloses a method for measuring liquid surface tension by using a transparent glass tube with scale marks, and relates to measurement of physical parameters. According to the technical scheme, the method comprises the following steps: arranging a millimeter graduated scale on the outer side of the transparent glass tube, wherein the scale mark 0 of the millimeter graduated scale is positioned at a tube opening in one end of the transparent glass tube; mounting a rubber suction bulb which consists of an airbag and an airbag opening, tightly arranging the airbag opening at one end, at which the scale mark 0 of the millimeter graduated scale of the transparent glass tube is positioned, in a sleeving manner; compressing the airbag of the rubber suction bulb, sucking part of liquid into the transparent glass tube to form a liquid column, and vertically fixing the transparent glass tube on a bracket; removing the rubber suction bulb at the lower end of the transparent glass tube, so that a liquid column in the transparent glass tube moves downwards; stretching the open end of a liquid delivery tube into the liquid column in the transparent glass tube, slowly injecting the liquid into the transparent glass tube till the height of the liquid column does not rise any more, and recording the height h, wherein the surface tension coefficient sigma of the liquid is equal to d*h*rho*g / 4. The method has the beneficial effect that the change of the surface tension inside the glass tube and at the tube opening can be clearly observed.

Owner:SICHUAN UNIV

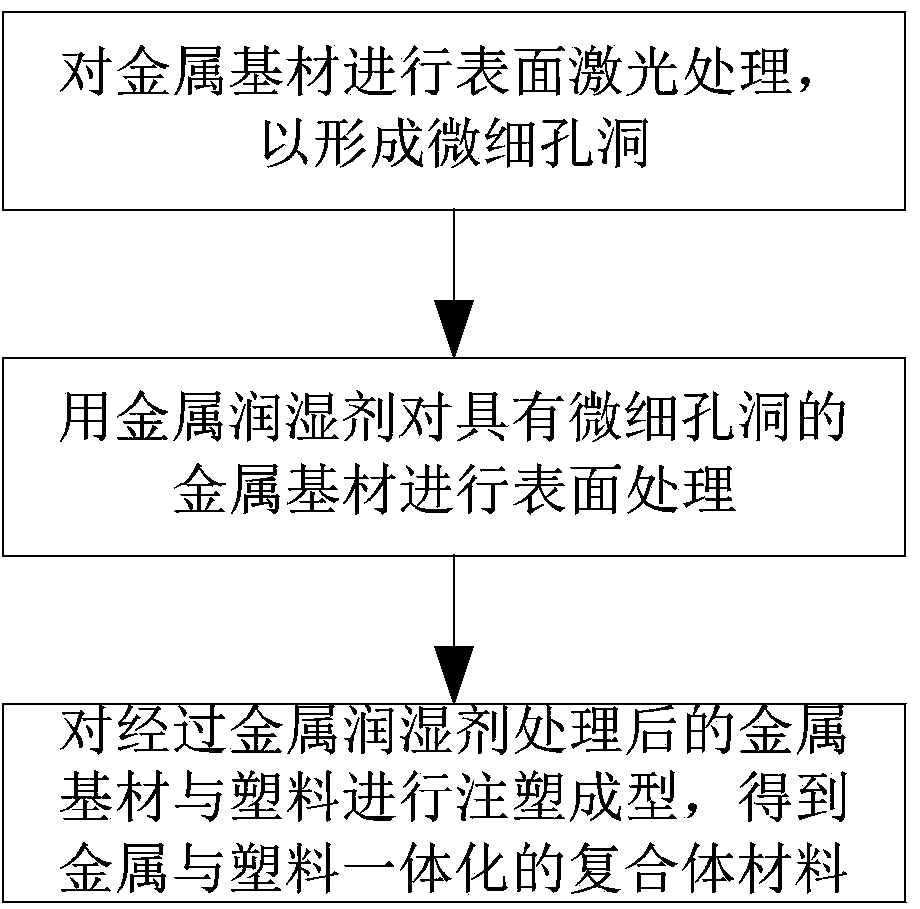

Liquid metal wetting agent and preparation method for composite material

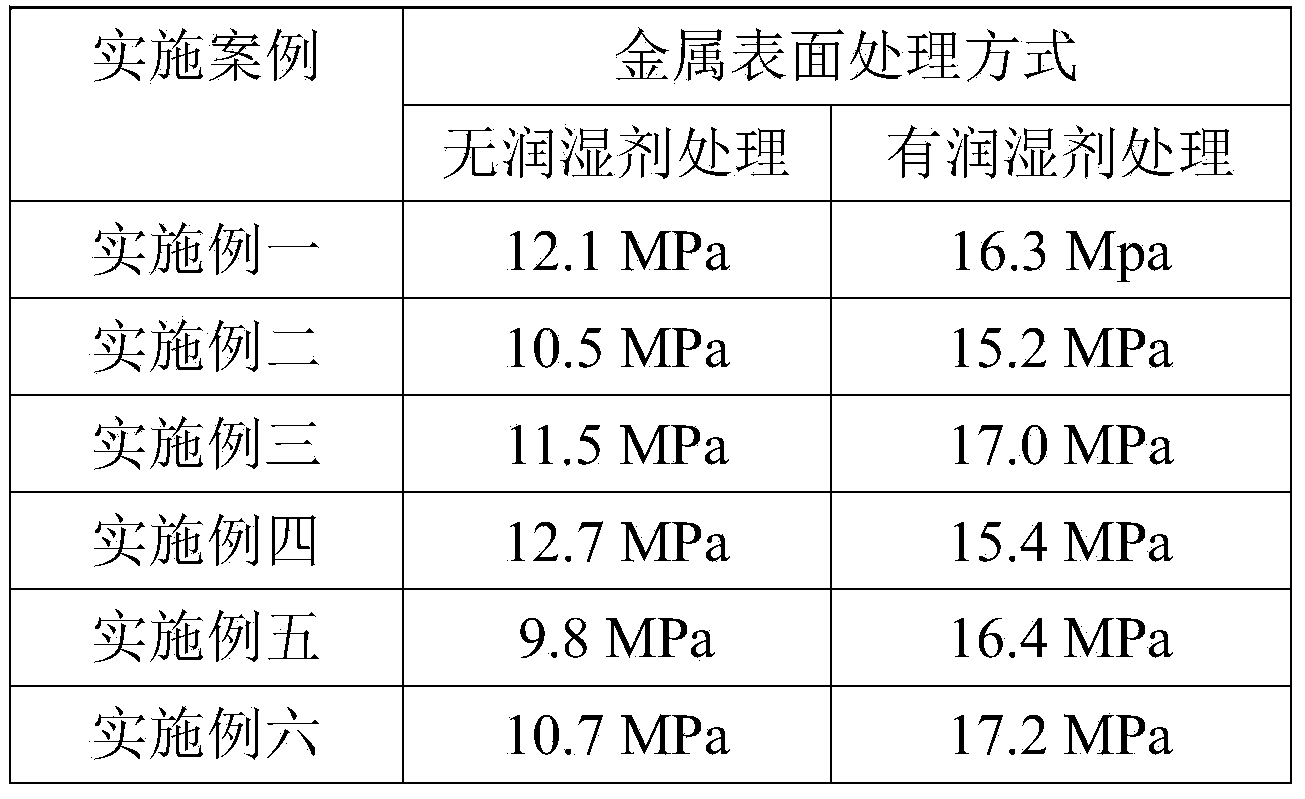

ActiveCN104149262AHigh glossImprove surface tension coefficient differenceCoatingsLiquid stateLiquid metal

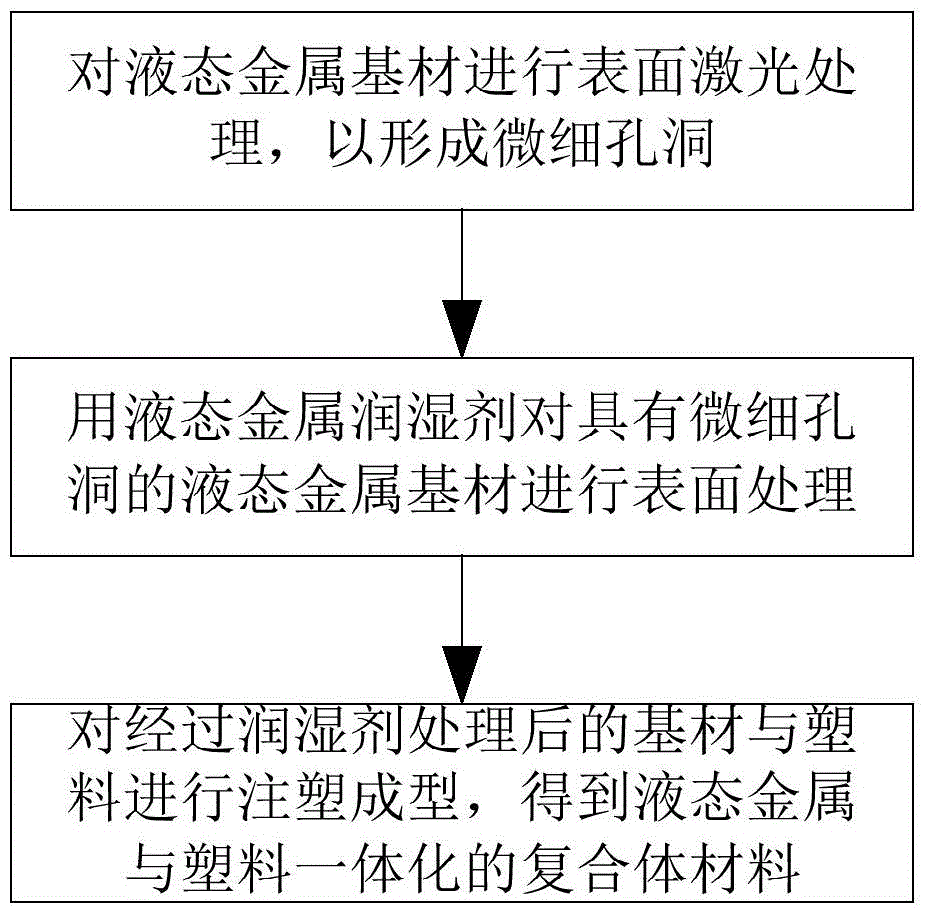

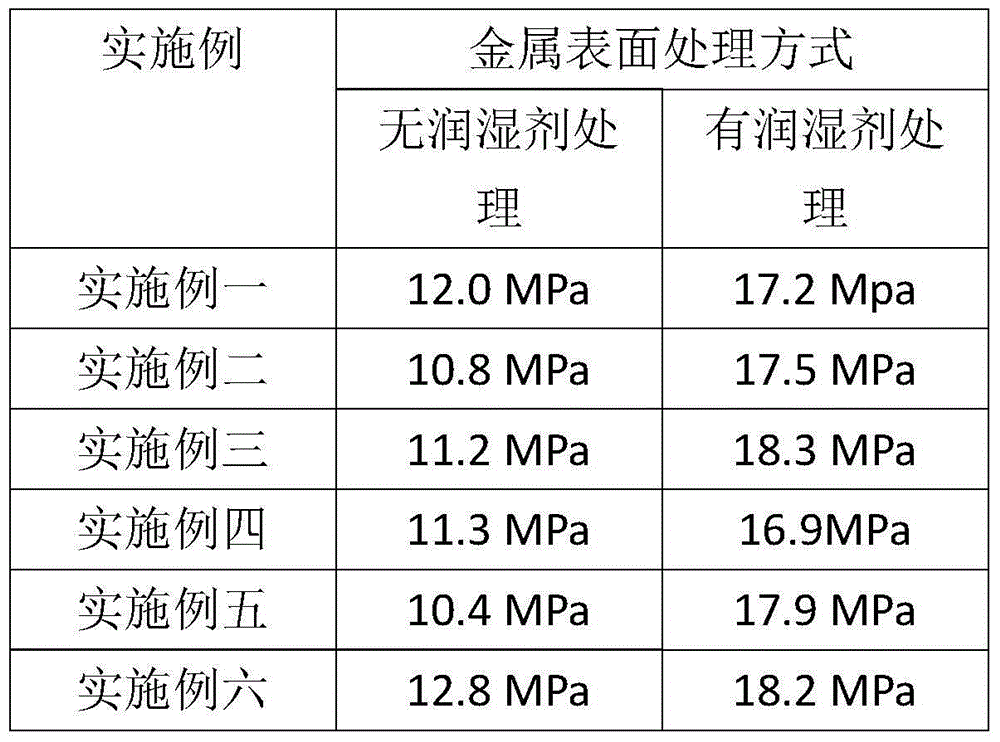

The invention discloses a preparation method for a composite material, and a liquid metal wetting agent. The method comprises the following steps: (1) carrying out laser treatment on the surface of a liquid metal base material to form fine holes; (2) carrying out surface treatment on the liquid metal base material with the fine holes by using the liquid metal wetting agent; and (3) carrying out injection molding on plastic and the liquid metal base material treated by the liquid metal wetting agent to obtain the composite material integrating liquid metal and the plastic. The liquid metal wetting agent contains an organic modifier for improving a surface tension coefficient difference between the liquid metal base material and the plastic. According to the preparation method for the composite material, and the liquid metal wetting agent, the bonding strength of the liquid metal and the plastic can be improved.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

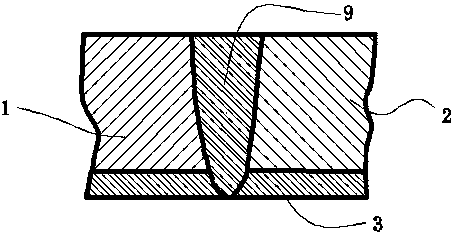

Laser welding method of plates of moderate thickness

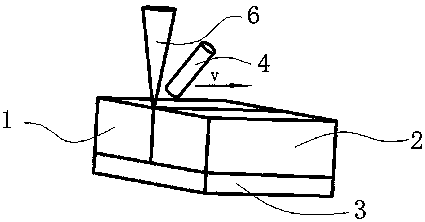

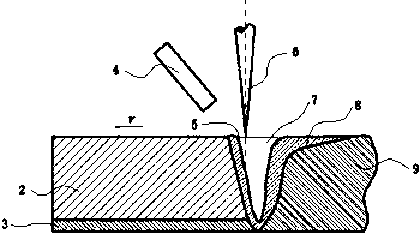

InactiveCN109332897AIncrease surface tensionInhibition of collapseWelding/soldering/cutting articlesLaser beam welding apparatusHigh power lasersSlag

The invention provides a laser welding method of plates of moderate thickness. The laser welding method is characterized by comprising the steps of (1) providing a first base metal and a second base metal; (2) providing a slag plate for welding; (3) accurately butting the first base metal and the second base metal; (4) putting the slag plate just below the first base metal and the second base metal, and tightly abutting with the first base metal and the second base metal; (5) irradiating high-power laser beams formed by focusing of a laser welding head on the upper surfaces of the first base metal and the second base metal, so that the penetration welding of the first base metal and the second base metal and the slag plate is realized; (6) removing the slag plate by adopting a machining method; and (7) removing bottom welding seams of the first base metal and the second base metal by adopting the machining method. According to the laser welding method, the slag plate is arranged at thebottom of the first base metal and the second base metal, and oxide with a large high-melting point surface tension coefficient in the slag plate is adsorbed on the surface of a bottom molten pool during laser welding, so that the surface tension of the bottom molten pool is greatly increased, the stress balance of the laser welding molten pool is effectively promoted, and the defects of collapse, root exposure and the like during laser welding of the plates of moderate thickness are avoided.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

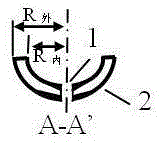

Method for measuring surface tension coefficient of liquid through discharging liquid by hollow cylinder

InactiveCN104406890AImprove stabilityReduce shakingSurface tension analysisLiquid densityEngineering

The invention provides a method for measuring the surface tension coefficient of liquid through discharging liquid by a hollow cylinder, relates to physical parameter measurement and adopts the technical scheme that one hollow cylinder is adopted, the outer radius of the hollow cylinder is radius Out, the inner radius of the hollow cylinder is radius In, and the average density of the hollow cylinder is 0.5-0.8 times of liquid density; liquid is injected into an overflow trough until the liquid overflows from a guide ditch on the edge of the upper end of the overflow trough into a water cup at the lower end of the guide ditch, the mass m1 of the water cup is measured when liquid stops dripping from the bottom end of the guide ditch, and then, the water cup is put right below the bottom end of the guide ditch; the mass m of the hollow cylinder is measured, the hollow cylinder is slowly put in the overflow trough, liquid flows into the water cup from the bottom end of the guide ditch, and the mass m2 of the water cup holding the liquid is measured when no liquid drips from the bottom end of the guide ditch, and the surface tension coefficient of the liquid sigma=[m-(m2-m1)]*g / [2*pi*(R In+R Out)], wherein g refers to gravity acceleration. The method has the benefits of simple structure, low cost and easy operation.

Owner:SICHUAN UNIV

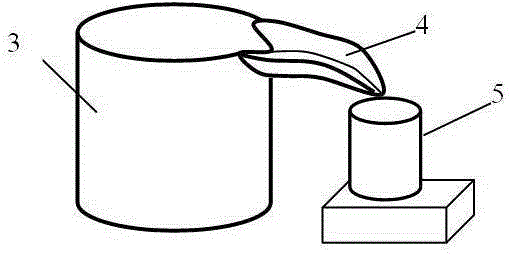

Method and device for measuring alkali metal surface tension coefficients at different temperatures

PendingCN112986061ASolve easy oxidationSolve the difficult problem of experimental testing at high temperatureSurface tension analysisPhysical chemistryMaterials science

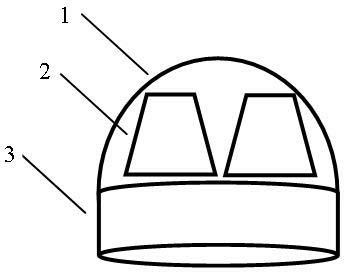

The invention discloses a method and a device for measuring alkali metal surface tension coefficients at different temperatures. The device comprises an electric heating table for melting alkali metal; a container used for containing alkali metal melt; a wick used for measuring the surface tension coefficient of the alkali metal melt; a heater for heating the wick; and a lifting mechanism for clamping and adjusting the height of the wick. The method and the device for measuring the surface tension coefficients of the alkali metal at different temperatures have the advantages that the technical means is simple and easy to implement, the manufacturing cost is low, the surface tension coefficients of the alkali metal at different temperatures can be quickly and accurately measured, and the method and the device have important scientific value and engineering application value.

Owner:SOUTH CHINA UNIV OF TECH

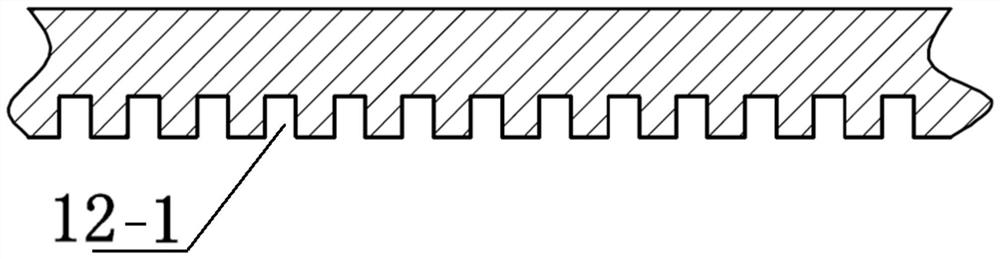

Metal wetting agent and preparation method of composite material

ActiveCN103950147AImprove surface tension coefficient differenceImprove bindingCoatingsInjection mouldingUltimate tensile strength

The invention discloses a preparation method of a composite material and a metal wetting agent. The method comprises the following steps: (1) carrying out surface laser treatment on a metal substrate so as to form fine holes; (2) carrying out surface treatment on the metal substrate with the fine holes by virtue of the metal wetting agent; (3) carrying out injection molding on plastic and the metal substrate processed by virtue of the metal wetting agent so as to form the composite material integrating metal and the plastic. The metal wetting agent contains an organic acid agent for improving the difference of surface tension coefficients of the metal substrate and the plastic. By virtue of the metal wetting agent, the bonding strength of the metal and the plastic can be effectively improved.

Owner:宜宾市创世纪机械有限公司

Novel process for increasing surface tension of metal product

InactiveCN107400912ASolve the problem that it is difficult or even impossible to cover the surfaceCompact structureShaping toolsAdhesion forceElectronic component

The invention discloses a novel process for increasing a surface tension of a metal product, and belongs to the technical field of electronic materials. A surface tension coefficient of a material is commonly known as a Dyne value, and replaced by the Dyne value hereinafter. The novel process disclosed by the invention comprises the steps of carrying out an improved electroplating process on a raw material of the metal product at first, and the improved electroplating process comprises the steps of 1) electrolytic degreasing, 2) water cleaning, 3) acid cleaning, 4) water cleaning, 5) gold plating, 6) water cleaning, 7) gold peeling, 8) water cleaning, 9) ultrasonic hot water cleaning and 10) drying; then carrying out stamping with grease protection; and cleaning after the stamping, and the cleaning comprises the steps of 1) hydrocarbon cleaning, 2) hydrocarbon cleaning and 3) steam drying; and in this way, the Dyne value of the final product is increased, and an adhesion force of a product with a high Dyne value during surface film coating is high, so that coated films with various functions such as a waterproof function, an anti-static function, an insulation function and a heat-isolation function can be long-term effective, and finally, quality and life of the product are ensured. The novel process disclosed by the invention is high in practicability, and capable of being greatly used for electronic components, thereby improving special performance of the various electronic components in various aspects.

Owner:AQ HOLMBERGS SUZHOU LTD CHINA

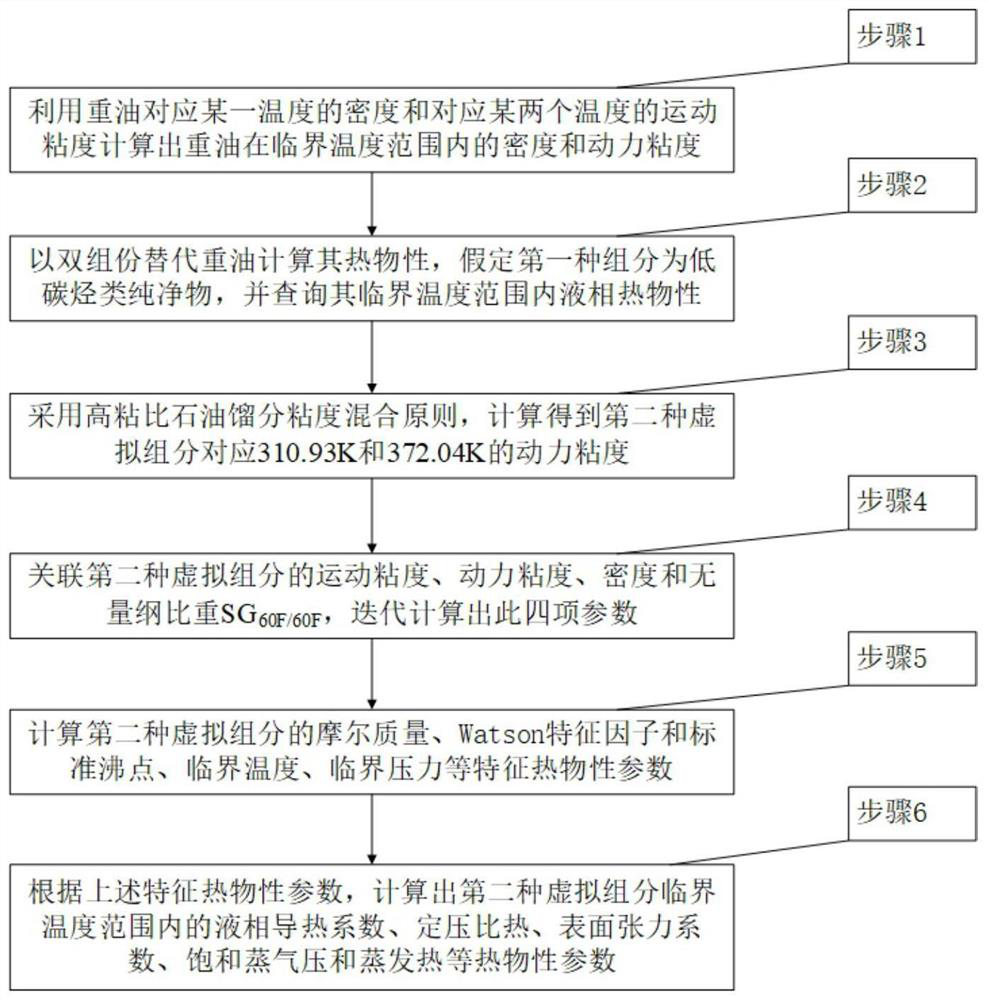

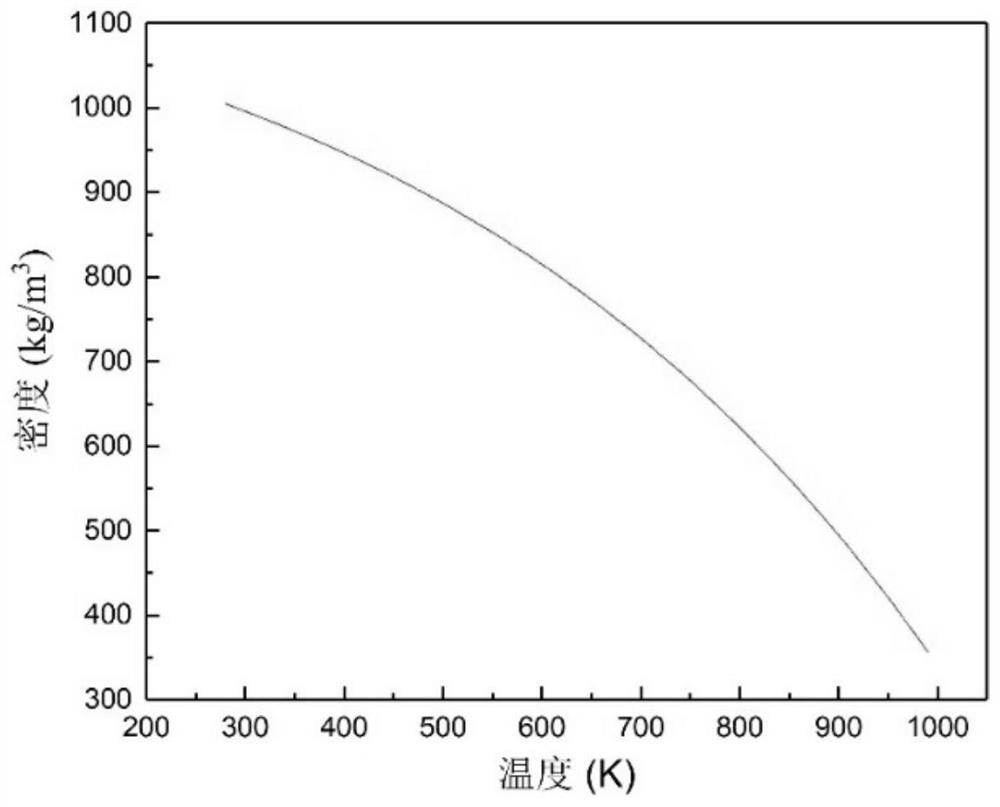

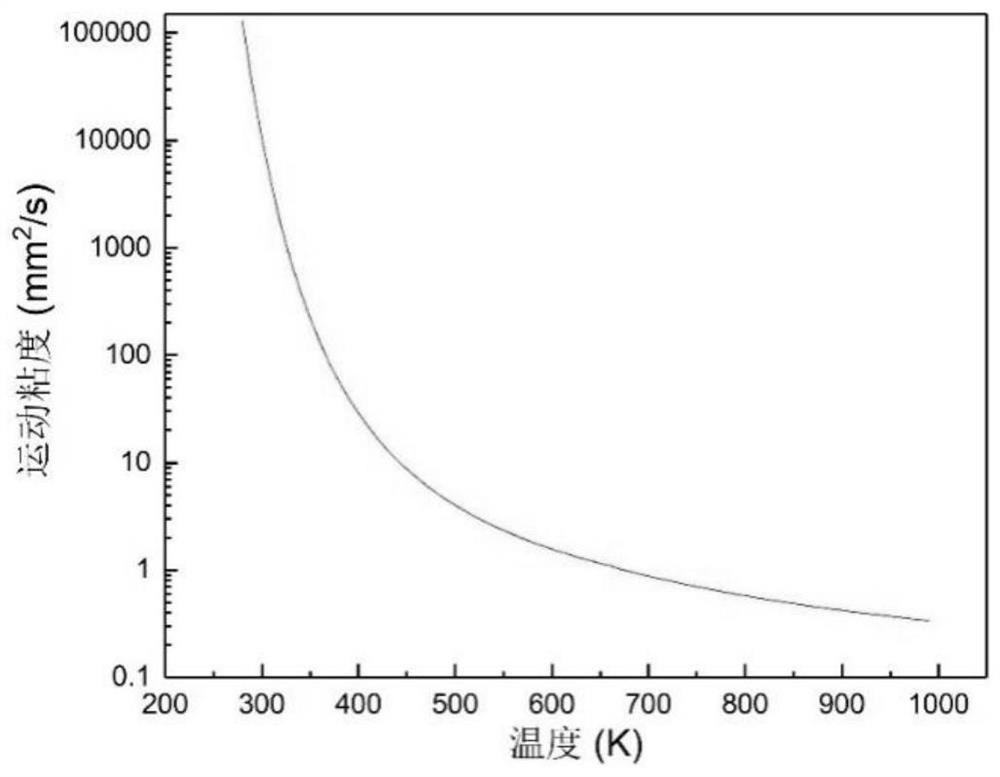

Marine heavy oil liquid phase thermophysical property calculation method

PendingCN114792552AChemical property predictionComputational theoretical chemistryFluid phaseFuel oil

The invention discloses a marine heavy oil liquid-phase thermophysical property calculation method, and the specific scheme is as follows: the marine heavy oil liquid-phase thermophysical property calculation method comprises the step of calculating the thermophysical property by replacing heavy oil with two components, the two components comprise a first virtual component and a second virtual component, the first virtual component is a low-carbon-number hydrocarbon pure substance, the second virtual component is a low-carbon-number hydrocarbon pure substance, and the third virtual component is a low-carbon-number hydrocarbon pure substance. Calculating the average density and the average kinematic viscosity of the heavy oil in the critical temperature range, and calculating the average kinematic viscosity of the heavy oil; calculating the dynamic viscosity of the second virtual component at the first temperature and the second temperature; the kinematic viscosity, the dynamic viscosity, the density and the dimensionless specific gravity parameters of the second virtual component at the first temperature and the second temperature are correlated and iteratively calculated, and then the basic characteristic parameters of the second virtual component are calculated; and calculating the liquid-phase heat conductivity coefficient, the specific heat at constant pressure, the surface tension coefficient, the saturated vapor pressure and the evaporation heat thermophysical property parameters of the second virtual component in the critical temperature range.

Owner:中船发动机有限公司

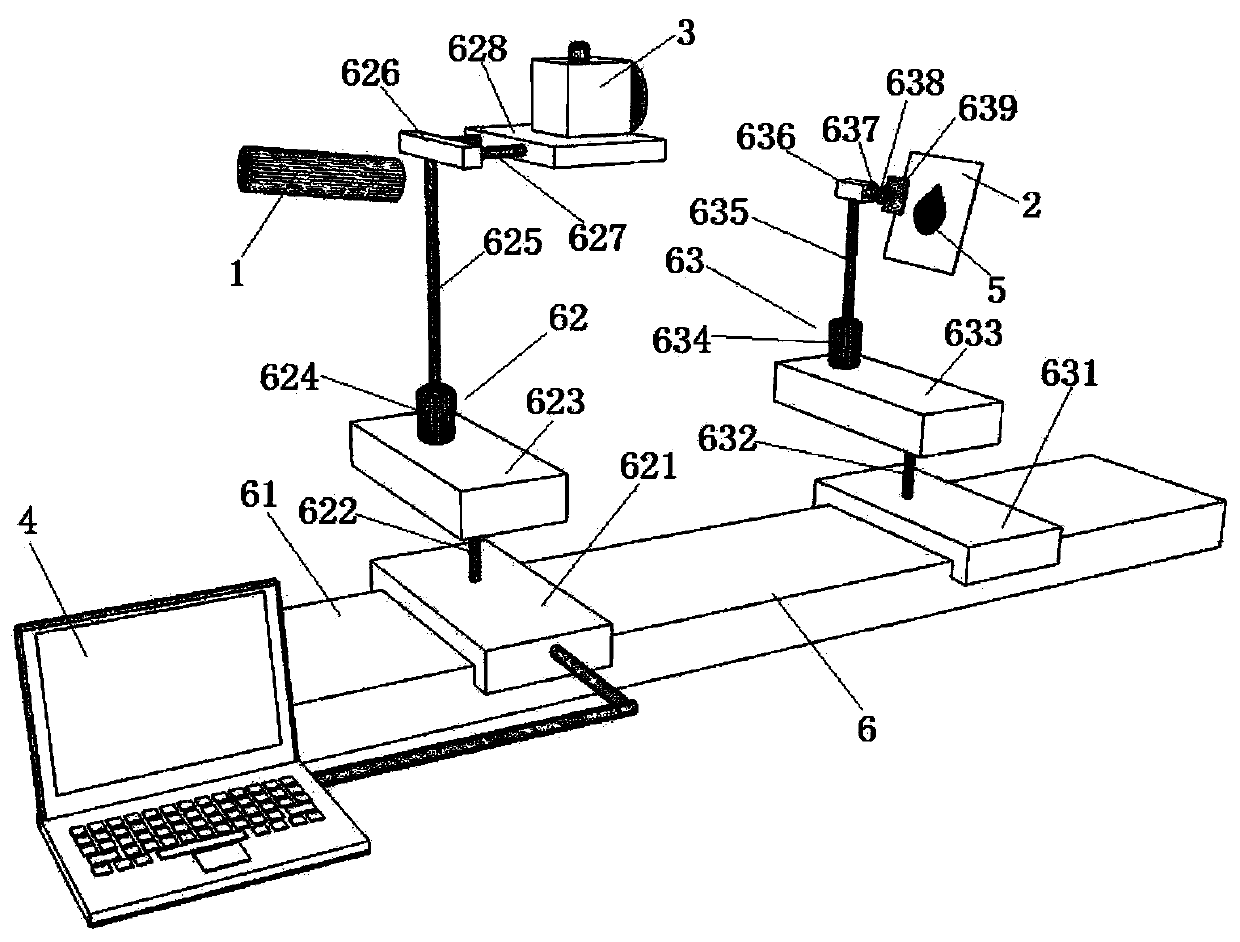

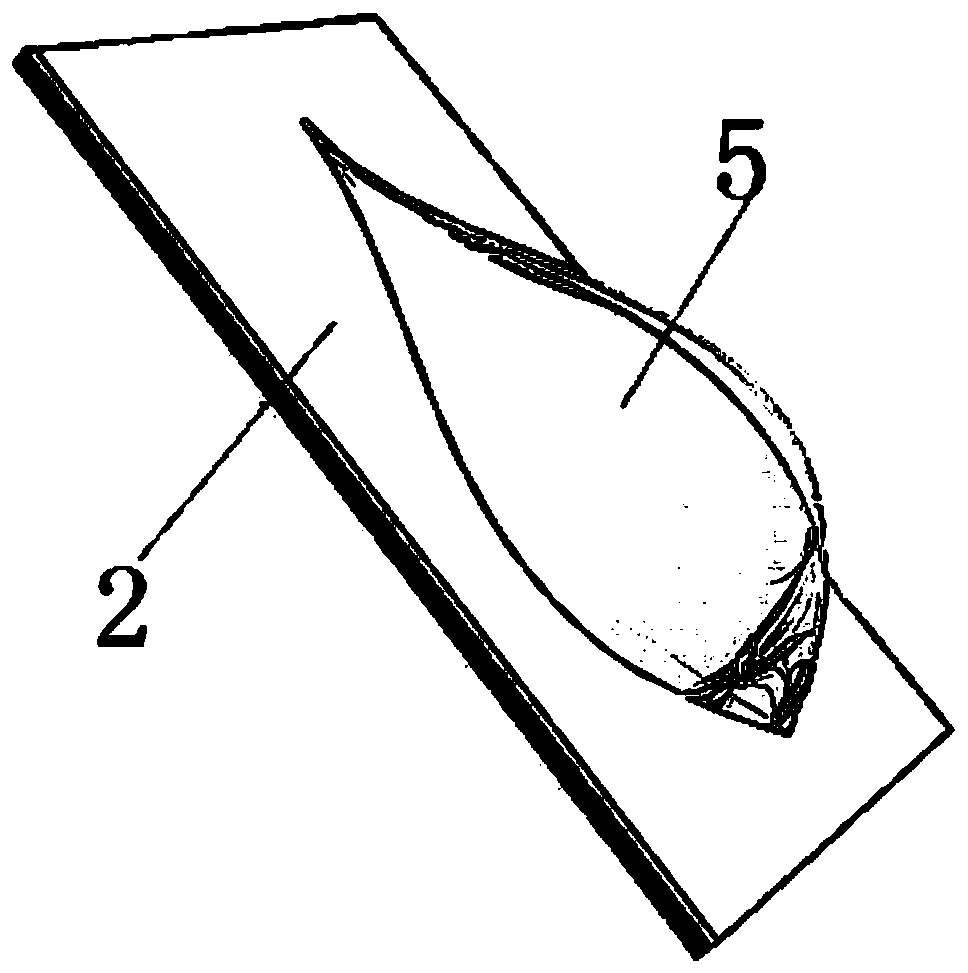

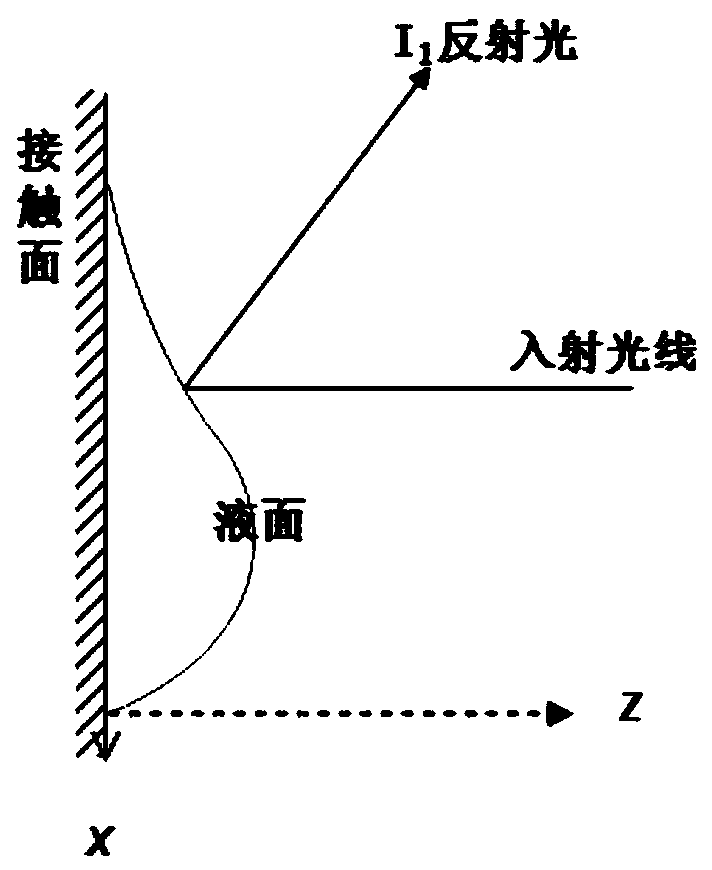

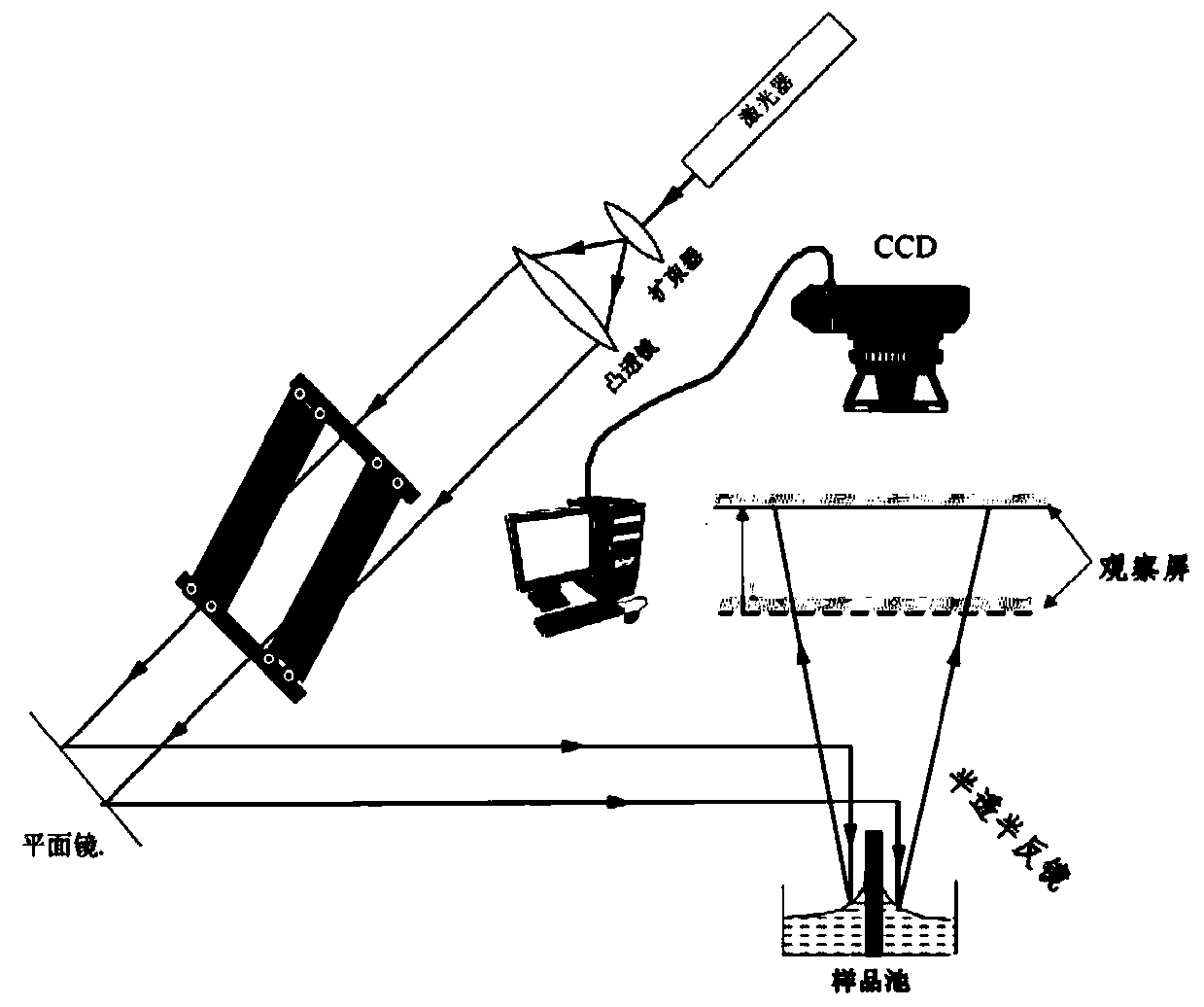

Liquid surface tension measuring device and method based on light reflection

ActiveCN111537399AReduce demandEasy to operateNuclear energy generationSurface tension analysisGlass sheetLiquid surfaces

The invention discloses a liquid surface tension measuring device and method based on light reflection. The device comprises a light source which is used for generating a parallel light beam, and a flat plate is obliquely disposed on a light path of the parallel light beam; droplets are arranged on the surface of the flat plate and close to one side of the light source; a linear array CCD and thelight source are arranged on the same side and are spaced up and down; parallel light beams irradiate the liquid drops; after the parallel light beams are reflected by the surfaces of the liquid drops, the reflected light beams are completely emitted into the linear array CCD, and the linear array CCD is used for collecting light intensity distribution of the reflected light beams and transmittingthe light intensity distribution to a computer. According to the invention, the a to-be-detected liquid drop is arranged on a glass sheet in an inclined direction, a gas-liquid interface of the to-be-detected liquid drop is irradiated by a light beam, the light beam on the gas-liquid interface is reflected, and the image of the diffraction signal after the phase modulation of the incident beam ofthe linear CCD is used; the surface tension coefficient of the to-be-measured liquid is solved by using various known parameters of the liquid and the density of the to-be-measured liquid; non-contact measurement is adopted in the measurement process; equipment is simple; and operability is high.

Owner:SHAANXI UNIV OF SCI & TECH

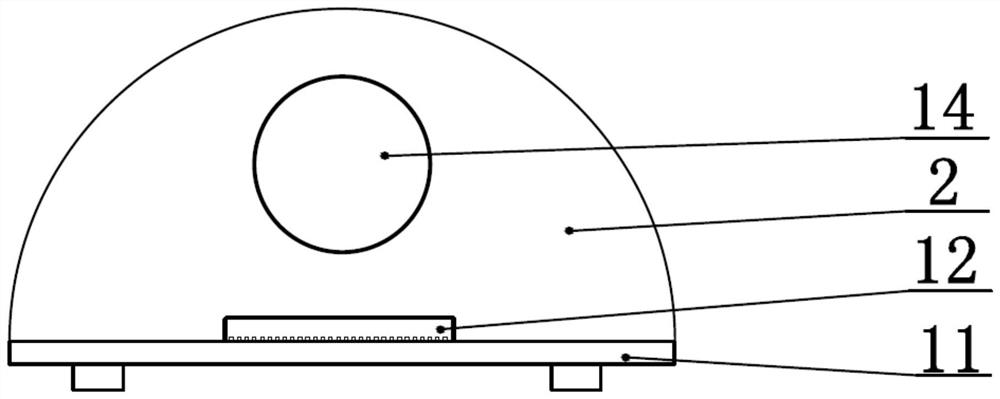

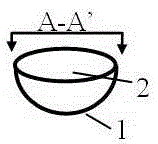

Method for measuring surface tension coefficient of liquid through liquid drainage of semi-spherical shell

InactiveCN104406891AImprove stabilityReduce shakingSurface tension analysisLiquid densitySurface tension force

The invention relates to the measurement of physical parameters, in particular to a method for measuring the surface tension coefficient of a liquid through liquid drainage of a semi-spherical shell. The method adopts the technical scheme that the spherical shell outside radius of the semi-spherical shell is R, and the average density of the semi-spherical shell is 0.5 to 0.8 time of the liquid density; the liquid is injected into an overflow trough until the liquid overflows to a cup at the lower end of a guide trench through the guide trench at the upper edge of the overflow trough; when the liquid stops dripping at the tail end of the guide trench, the mass m1 of the cup is measured, and the cup is then placed right below the tail end of the guide trench; the mass m of the semi-spherical shell is measured; the semi-spherical shell is slowly placed into the overflow trough in a manner that the opening of the semi-spherical shell is upward, the liquid flows into the cup at the tail end of the guide trench, the mass m2 of the cup accommodating the liquid is measured when no liquid drips at the tail end of the guide trench, and the liquid surface tension is [m-(m2-m1)] * g; the surface tension coefficient of the liquid sigma=[m-(m2-m1)]*g / (2*pi*R2), and R2 is the radius of the contact circle of the liquid level and the spherical shell. The method has the benefits of being simple in structure, low in cost and easy in operation.

Owner:SICHUAN UNIV

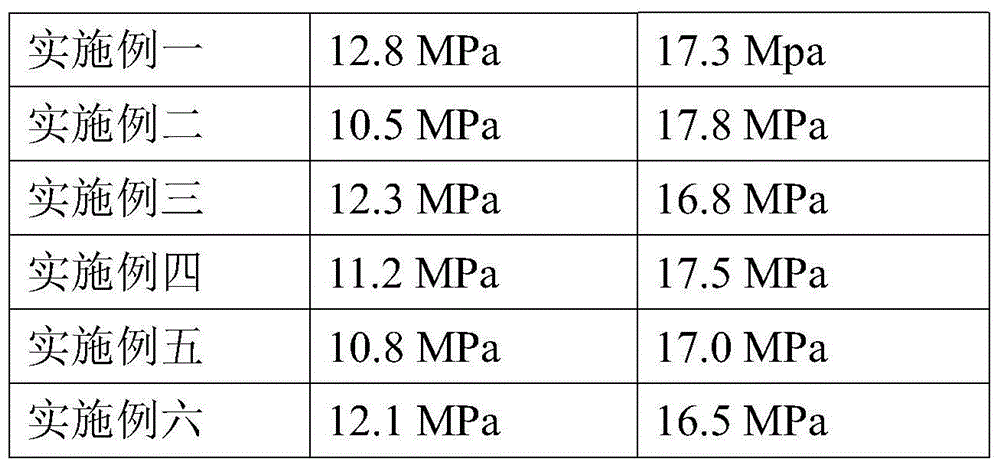

Porous metal modifier and preparation method of composite material

ActiveCN104151788AImprove surface tension coefficient differenceImprove bindingCoatingsOrganic acidOrganic Ester

The invention discloses a preparation method of a composite material, as well as a porous metal modifier. The method comprises the following steps: 1) forming a porous metal base material through a powder metallurgy sintering technology, wherein the surface of the porous metal base material has micrometer-scale holes; 2) performing surface treatment to the porous metal base material through the porous metal modifier; and 3) injection-molding the metal base material treated by the porous metal modifier, and plastic, to obtain a metal-plastic integrated composite material. The porous metal modifier contains an organic ester and organic acid blend for improving the surface tension coefficient difference of the metal base material and the plastic. According to the porous metal modifier, the bonding strength of the metal and plastic can be effectively enhanced.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

Polyolefin microporous membrane and preparation method thereof

ActiveCN109054073AComplete structureIncrease surface tensionSecondary cellsCell component detailsPolyolefinPolymer science

The invention discloses a preparation method of polyolefin microporous membrane. The method comprises the following steps that polyolefin resin and a diluent are subjected to fusion and blending in atwin-screw extruder, extrudate is extruded from a die head, through a casting roll, a casting piece is cooled, and then after two-way stretching, extraction and drying are conducted, microporous membrane A is prepared; in the presence of a photosensitizer, a low pressure mercury lamp is used for conducting irradiation on the surface of the microporous membrane A to obtain microporous membrane B; the microporous membrane B is subjected to transverse thermoforming treatment to obtain microporous membrane C; the microporous membrane C is subjected to corona treatment by means of a corona treaterto obtain the polyolefin microporous membrane. After the polyolefin resin is subjected to wet processing, before a rolling procedure, through ultraviolet light irradiation and corona, the polyolefin microporous membrane is subjected to two-time surface treatment, under a condition of not destructing a polyolefin microporous membrane microporous structure, a surface tension coefficient of the microporous membrane is increased, and the polyolefin microporous membrane with a high surface tension coefficient is prepared, so that the safety and the energy density of a lithium battery are improved.

Owner:HEFEI XINGYUAN NEW ENERGY MATERIAL CO LTD

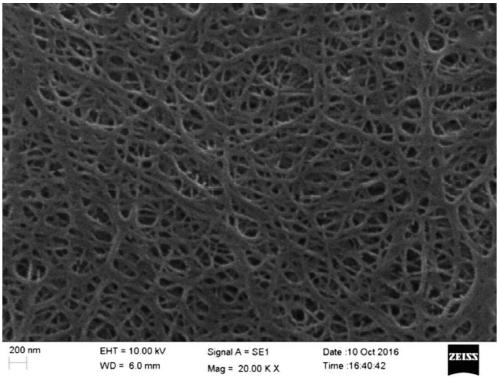

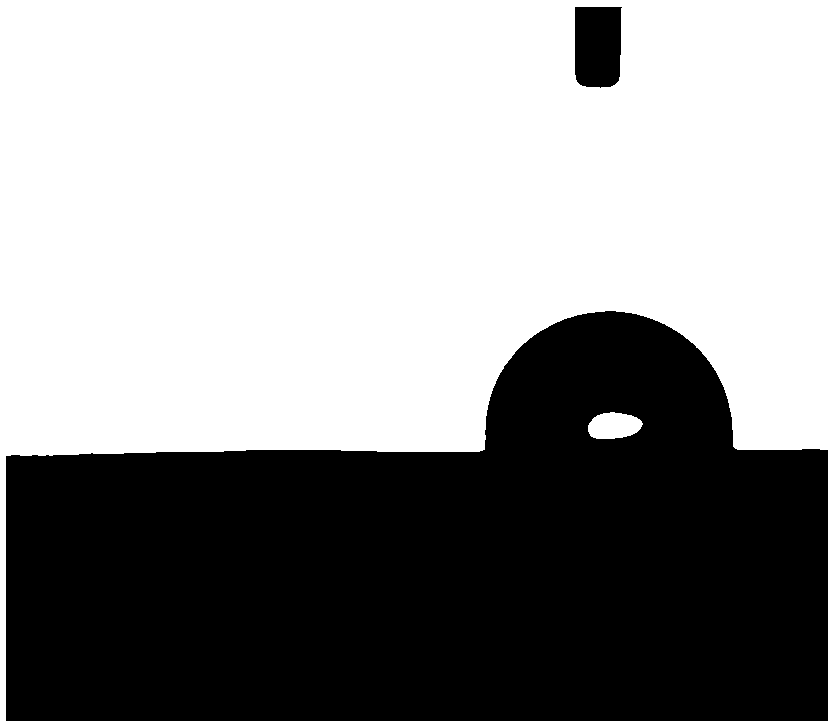

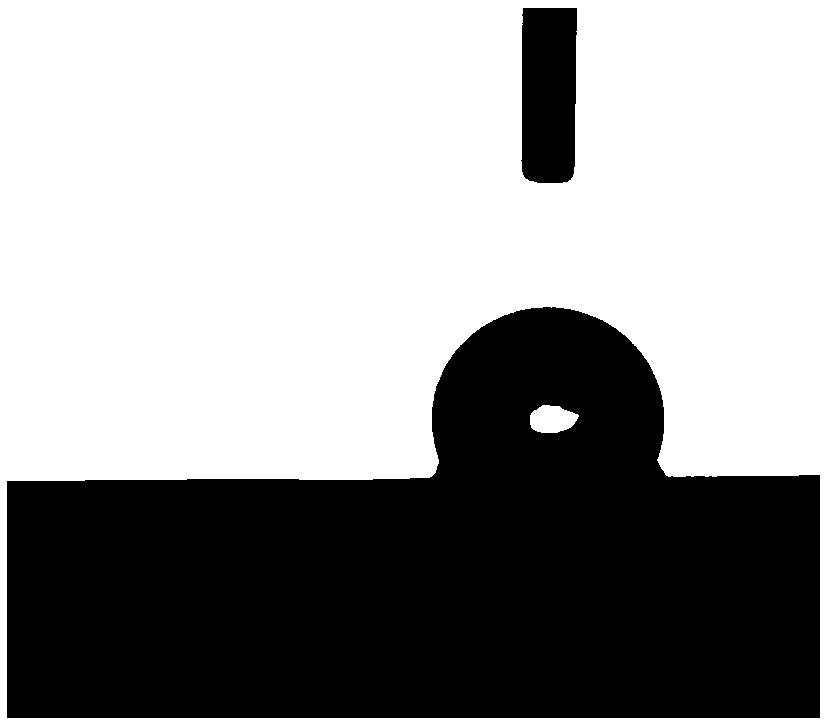

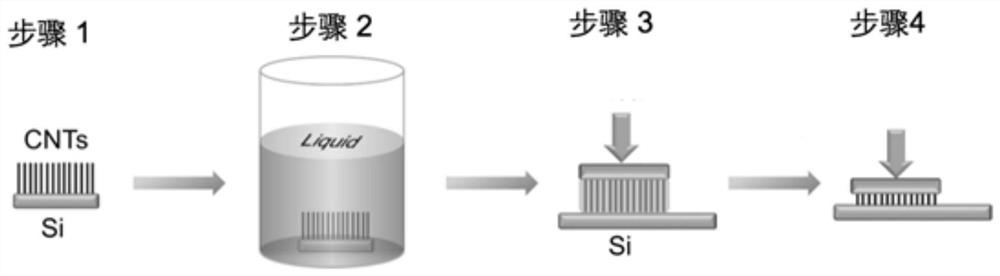

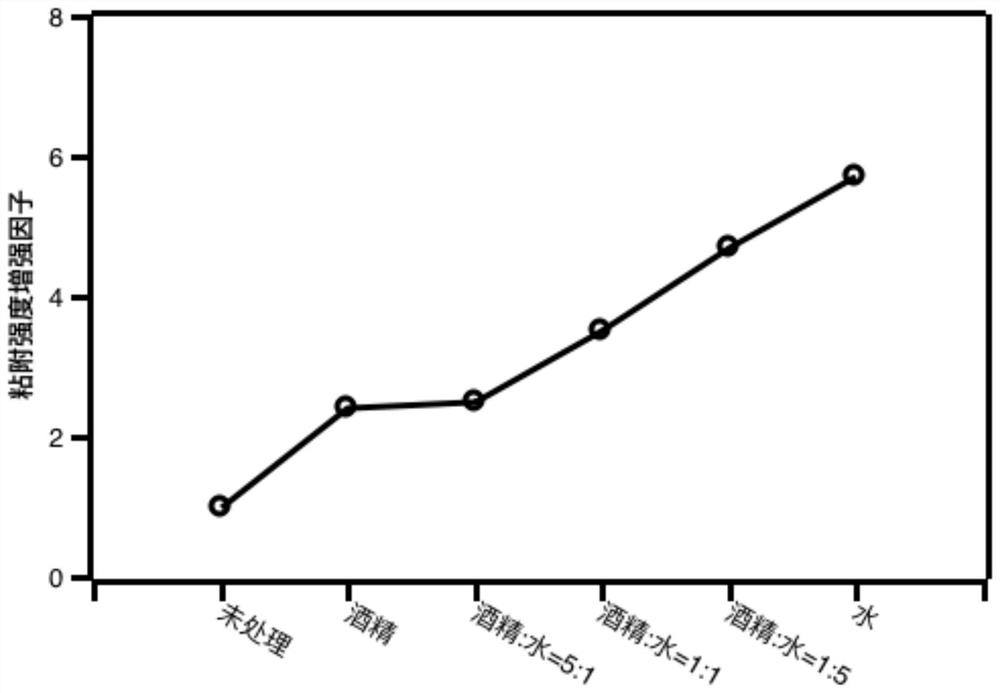

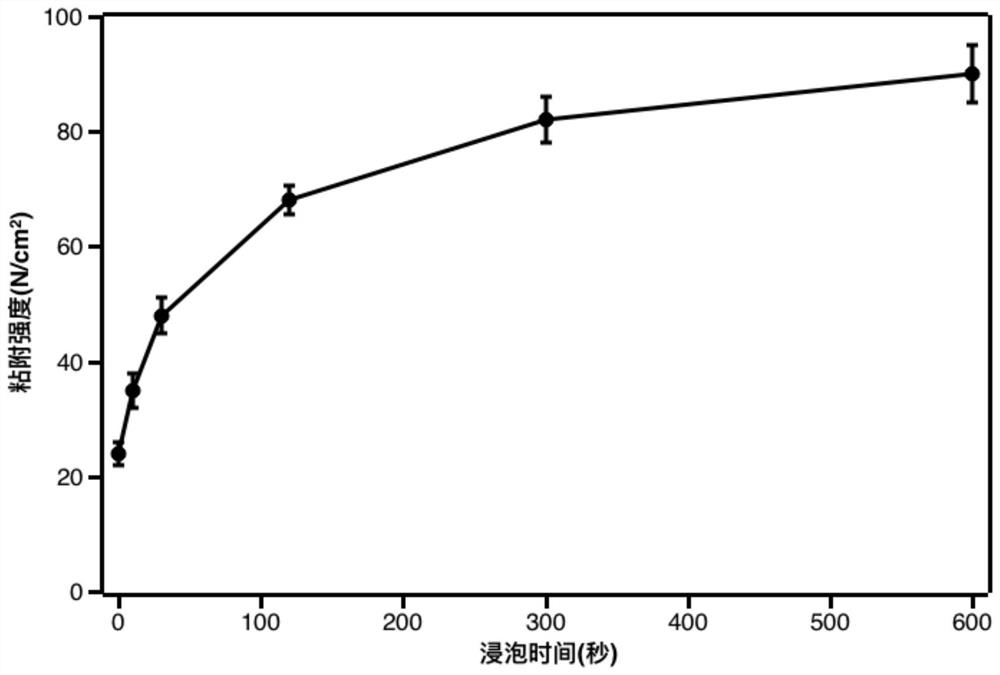

Adhesion method for improving adhesion performance of carbon nanotube dry glue

ActiveCN111607334AIncrease contact areaImprove adhesion strengthAdhesive processesCarbon compoundsCarbon nanotubeDry glue

The invention belongs to the related technical field of preparation of carbon nanotube dry glue materials, and discloses an adhesion method for improving the adhesion performance of carbon nanotube dry glue. The method comprises the following steps: (1) placing a carbon nanotube array in a liquid with a predetermined surface tension coefficient, and transferring the carbon nanotube array to a target adhesion substrate after the carbon nanotube array is completely infiltrated in the liquid; and (2) continuously applying pressure to the carbon nanotube array until the liquid in the carbon nanotube array is completely evaporated, thereby completing the adhesion for improving the adhesion performance of the carbon nanotubes. The carbon nanotube array is subjected to liquid treatment, and the contact area of the carbon nanotubes and the target adhesion substrate is increased along with the increase of pressure after the liquid treatment, so that the Van der Waals' force is correspondingly increased, the adhesion strength is increased in the final reaction, the cost is low, and the efficiency is high.

Owner:HUAZHONG UNIV OF SCI & TECH

Profile of elastic silica aerogel for lithium ion power batteries of new energy vehicles

InactiveCN109103369AImprove reliabilityImprove securitySecondary cellsCell component detailsInsulation layerNew energy

The invention discloses a profile of elastic silica aerogel for lithium ion power batteries of new energy vehicles. The profile is arranged between single battery cells. A manufacture method comprises: firstly, the mould is designed according to the shape of the single cell core; secondly, the silica sol is put in the designed mould to form wet gel after aging, and the solvent with low surface tension coefficient is used for at least two times to replace the water in the wet gel, and then the elastic silica aerogel profiles are obtained by drying and demoulding after displacing the water in the wet gel. As the method is adopted, the invention added the profile between the single cells of lithium ion batteries, and slows down the propagation speed of heat runaway; the profile can also be applied to the heat insulation and shock protection between the modules, the external cold protection layer and the high temperature insulation layer of the battery box, so as to improve the reliabilityand safety of the power supply of the lithium-ion power battery of the new energy vehicle, and to assist the development of the new energy vehicle industry in China.

Owner:PAN ASIAN MICROVENT TECH JIANGSU CORP

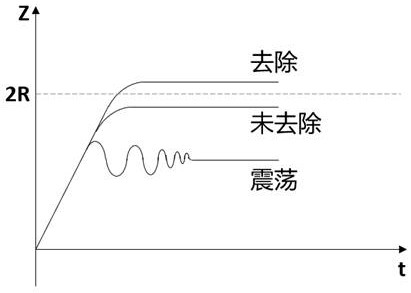

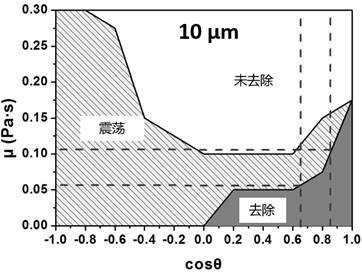

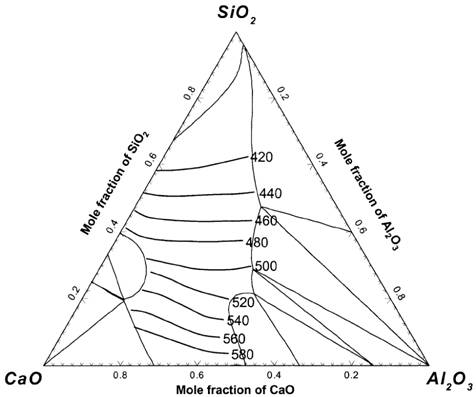

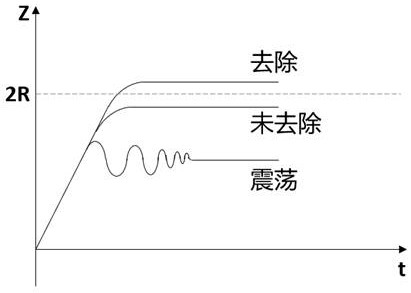

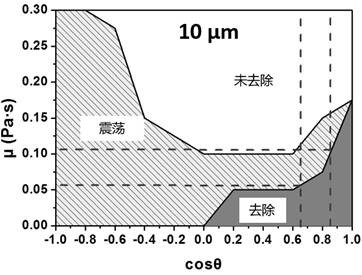

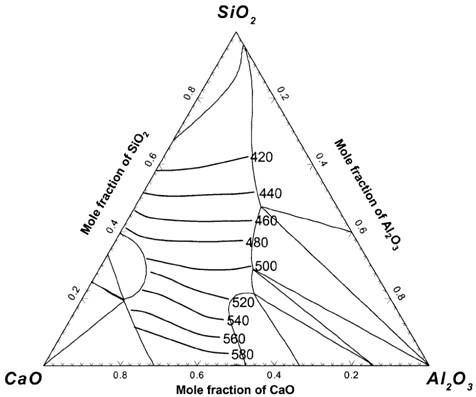

Design method of refining slag system for removing magnesium aluminate spinel inclusions

The invention provides a design method of a refining slag system for removing magnesium aluminate spinel inclusions. The design method comprises the steps of establishing a motion model of the magnesium aluminate spinel inclusions, obtaining the relation between displacement and time of the magnesium aluminate spinel inclusions is obtained, and thus judging the state of the magnesium aluminate spinel inclusions; calculating required viscosity and interface characteristic conditions of the refining slag system when the inclusions with different sizes are removed; drawing a removal advantage region graph; obtaining the maximum size of the non-removed inclusions in steel according to steel type requirements, and selecting target slag viscosity and surface tension coefficients according to theremoval advantage region graph; and respectively calculating to obtain a first refining slag system component composition and a second refining slag system component composition according to the target slag viscosity and the surface tension coefficients, and taking an intersection of both compositions to determine a target refining slag system component composition. According to the design method, the slag system for efficiently removing the inclusions can be obtained.

Owner:UNIV OF SCI & TECH BEIJING

Design method of refining slag system for removal of magnesium aluminum spinel inclusions

ActiveCN112501390BImprove the environmentOptimizationDesign optimisation/simulationProcess efficiency improvementSlagViscosity

The invention provides a method for designing a refining slag system for removing magnesium-aluminum spinel inclusions. The design method includes: establishing a motion model of magnesium-aluminum spinel inclusions, obtaining the relationship between the displacement and time of magnesium-aluminum spinel inclusions, and judging the state of magnesium-aluminum spinel inclusions; calculating the removal of inclusions of different sizes should meet The viscosity and interface characteristic conditions of the refining slag system; draw the removal advantage zone map; obtain the maximum size of the inclusions in the steel that have not been removed according to the requirements of the steel type, and select the target slag viscosity and surface tension coefficient according to the removal advantage zone map; according to the target slag viscosity The composition of the first refining slag system and the composition of the second refining slag system are obtained by calculating the surface tension coefficient respectively, and their intersection is taken to determine the composition of the target refining slag system. The design method provided by this application can obtain a slag system that efficiently removes inclusions.

Owner:UNIV OF SCI & TECH BEIJING

Method for measuring surface tension coefficient of liquid through liquid drainage of semi-spherical shell with bottom hole

InactiveCN104406889AReduce volumeImprove stabilitySurface tension analysisLiquid densityStructure of the Earth

The invention relates to the measurement of physical parameters, in particular to a method for measuring the surface tension coefficient of a liquid through liquid drainage of a semi-spherical shell with a bottom hole. The method adopts the technical scheme that the inside semi-spherical radius of the hollow semi-spherical shell is R inside, the outside semi-spherical radius of the hollow semi-spherical shell is R outside, and a through hole is formed in the bottom of the hollow semi-spherical shell; the average density of the semi-spherical shell is 0.5 to 0.8 time of the liquid density; the liquid is injected into an overflow trough until the liquid overflows to a cup at the lower end of a guide trench through the guide trench at the upper edge of the overflow trough; when the liquid stops dripping at the tail end of the guide trench, the mass m1 of the cup is measured, and the cup is then placed under the tail end of the guide trench; the mass m of the semi-spherical shell is measured; the semi-spherical shell is slowly placed into the overflow trough, and the mass m2 of the cup accommodating the liquid is measured when no liquid drips at the tail end of the guide trench; the liquid surface tension coefficient sigma=[m-(m2-m1)]*g / [2*pi*(R2 outside+R2 inside)], R2 inside is the radius of the inside contact circle of the liquid level and the spherical shell, and R2 outside is the radius of the outside contact circle of the liquid level and the spherical shell. The method has the benefits of simple structure, low cost and easiness in operation.

Owner:SICHUAN UNIV

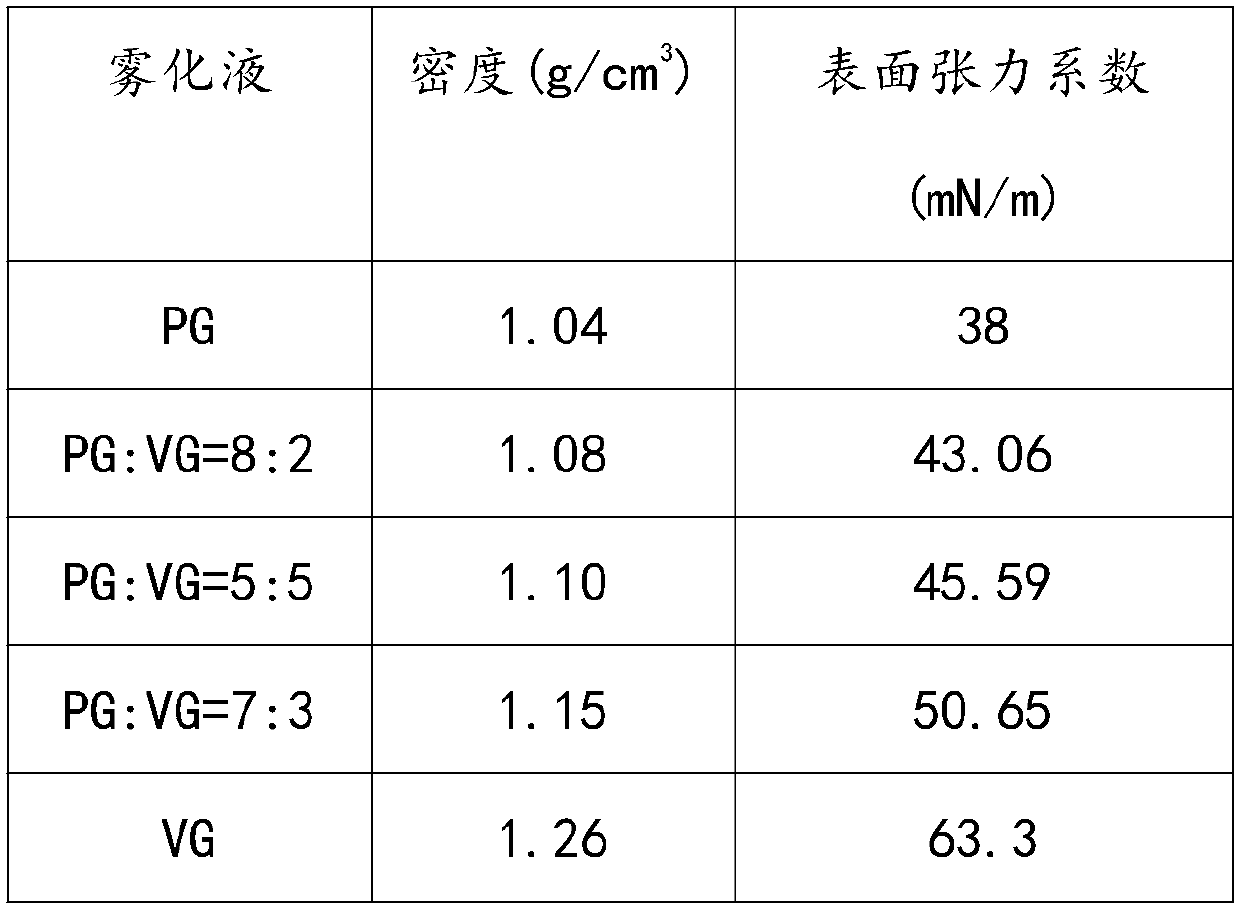

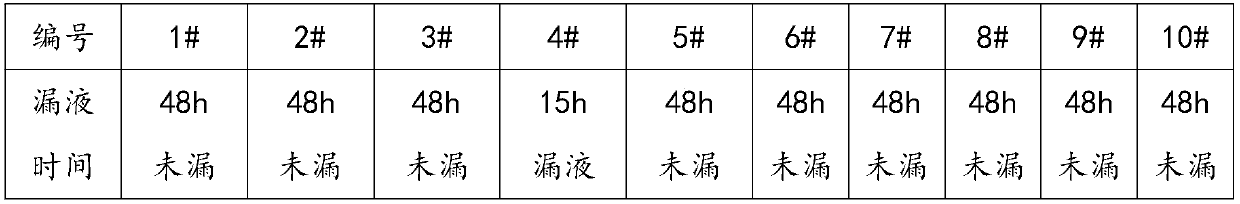

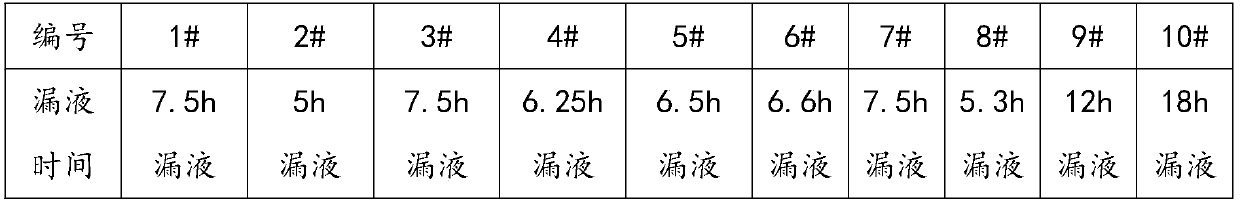

Method for evaluating probability of liquid leakage of electronic atomizer

The invention discloses a method for evaluating the probability of liquid leakage of an electronic atomizer, and belongs to the technical field of atomizers. The method includes the steps that atomized liquid is selected, and the density and surface tension coefficient of the atomized liquid are determined; an atomizer is selected, and the volume of an E-liquid storage bin of the atomizer, the perimeter of the contact surface of E-liquid guide cotton / rope and the atomized liquid, the perimeter of the contact surface of E-liquid stop cotton and the atomized liquid and the perimeter of the contact surface of the atomized liquid and the E-liquid storage bin are determined; the gravity G of the atomized liquid, the surface tension f1 of the atomized liquid and the E-liquid storage bin, the surface tension f2 of the atomized liquid and the E-liquid guide cotton / rope and the surface tension f3 of the atomized liquid and the E-liquid stop cotton / rope are calculated; the resultant force in thegravity direction is calculated according to the formula f=G+f1+f2+f3, and when the resultant force direction is consistent with the gravity direction, it is judged that liquid leakage occurs; when the resultant force direction is opposite to the gravity direction, the larger the resultant force is, the smaller the probability of liquid leakage will be.

Owner:SMISS TECH

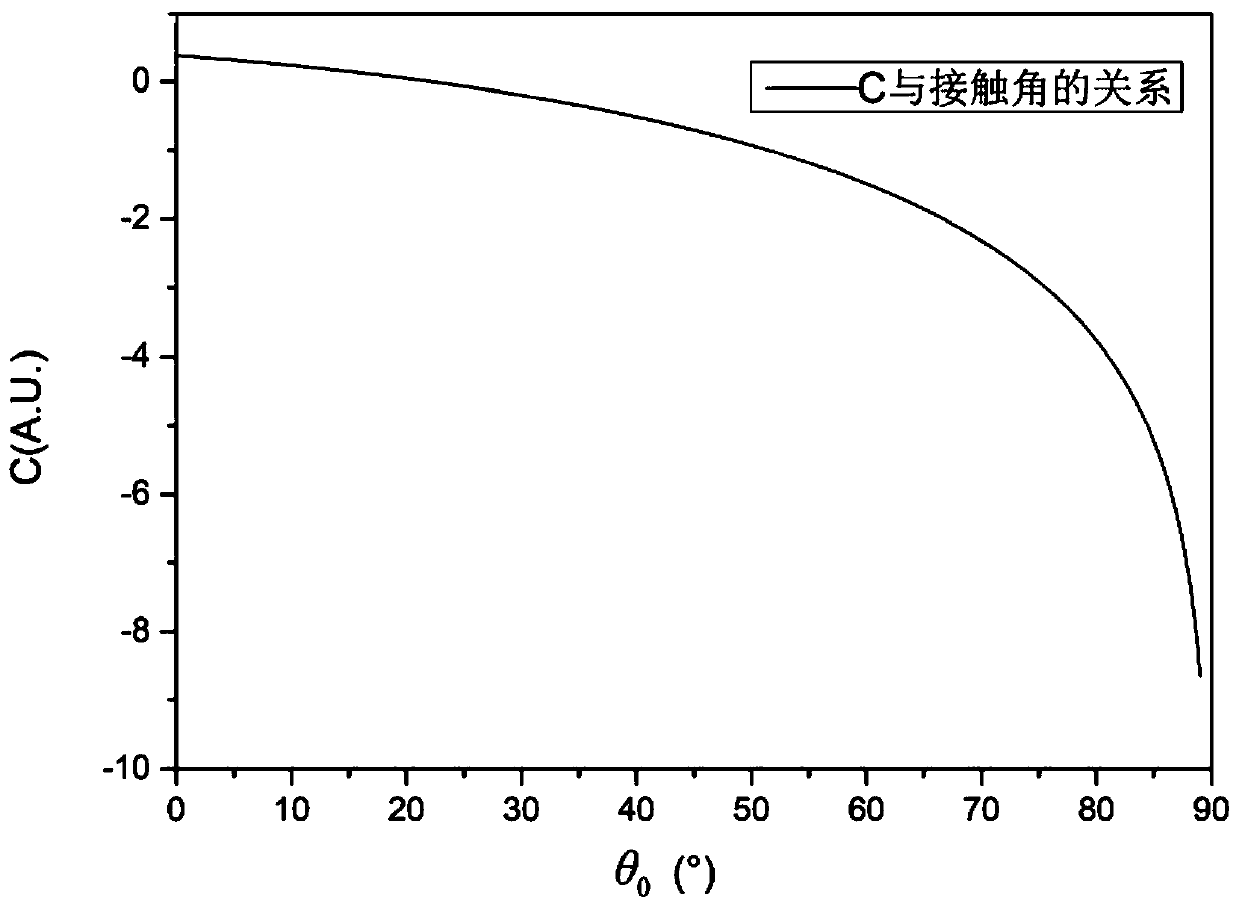

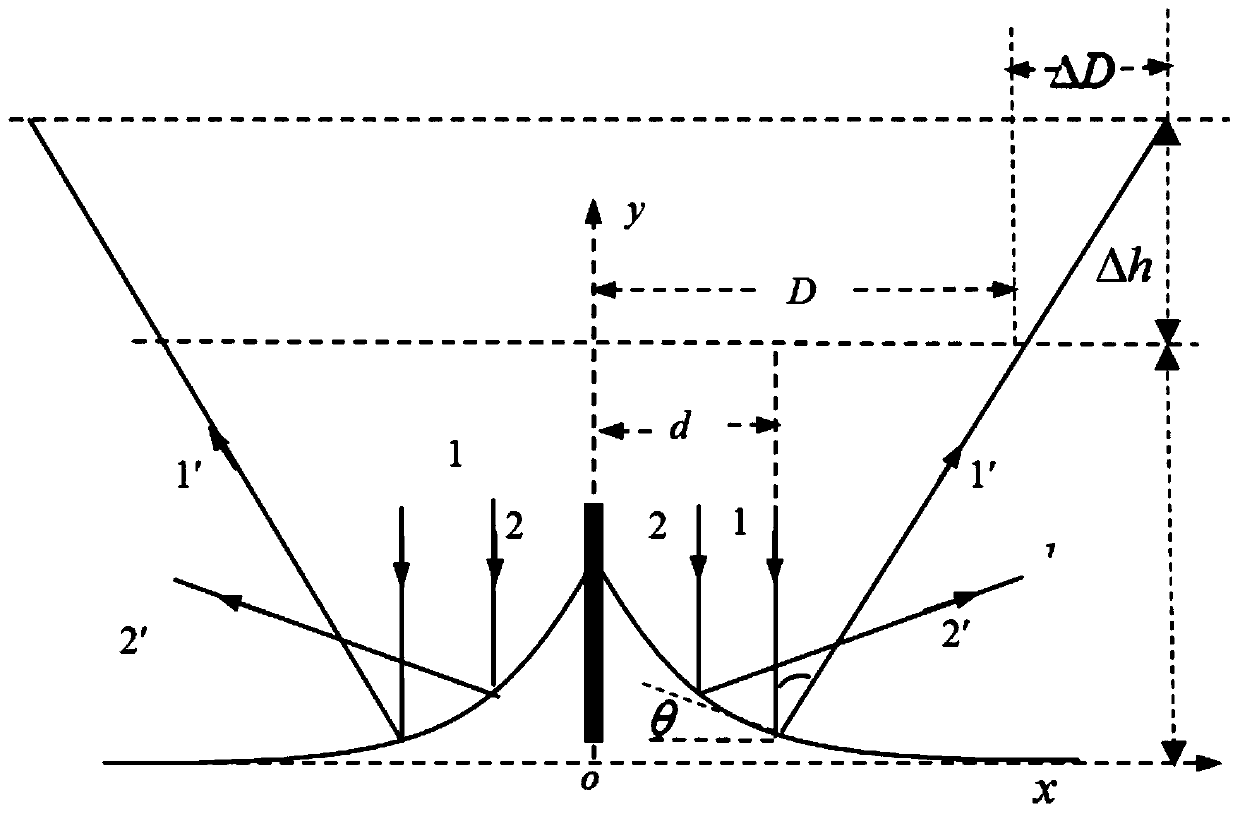

An Optical Method to Simultaneously Measure Liquid Surface Tension Coefficient and Contact Angle

ActiveCN108956384BEasy to operateEasy accessSurface tension analysisDevice materialImage manipulation

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com