An Optical Method to Simultaneously Measure Liquid Surface Tension Coefficient and Contact Angle

A technology of liquid surface tension and surface tension coefficient, which is applied in the direction of surface tension analysis, measuring devices, surface/boundary effects, etc., can solve the problems of poor operability and large measurement limitations, and achieve strong operability and experimental Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

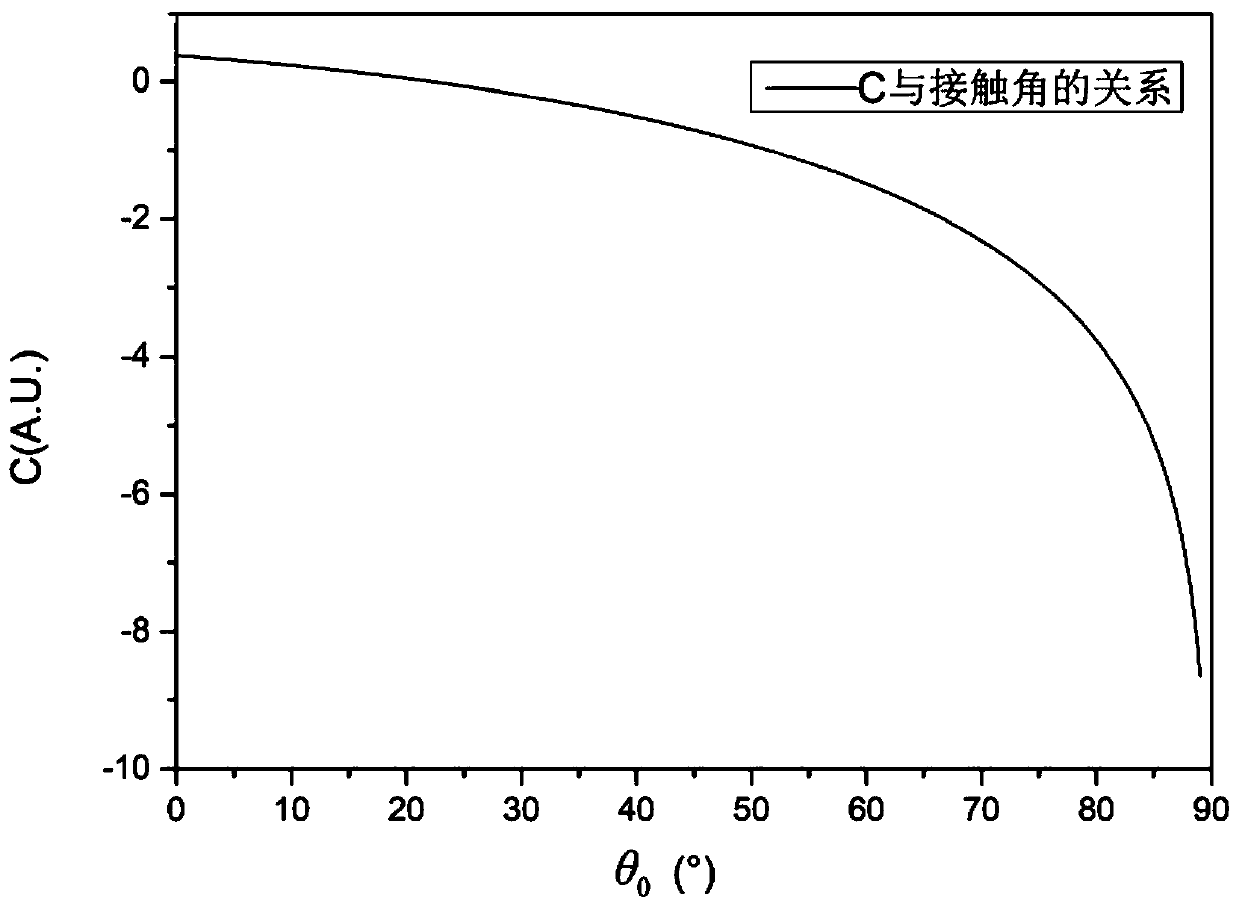

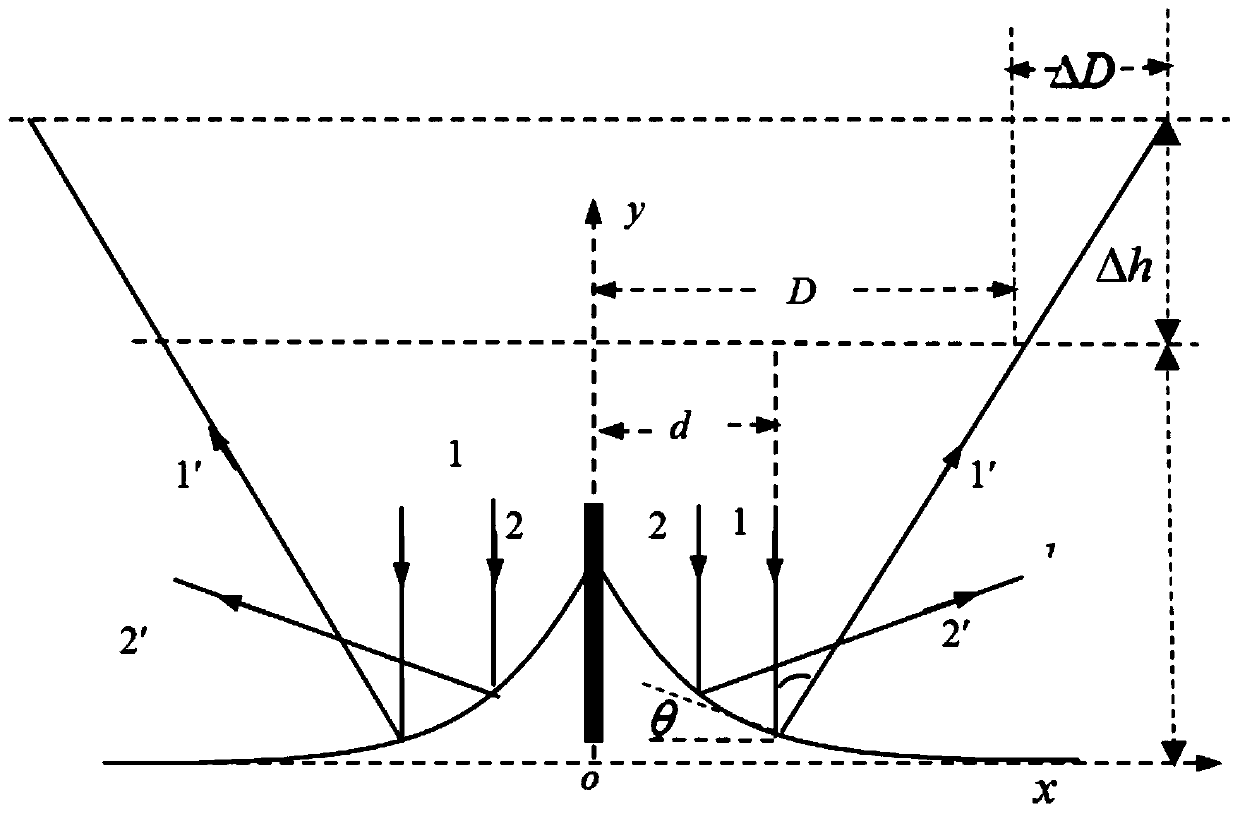

[0042] The present invention provides an optical method for synchronously measuring the surface tension coefficient and contact angle of a liquid. It is solved by the Young-Laplace equation to obtain the curved surface equation of the curved liquid surface, and the expressions of the surface tension coefficient and contact angle are solved respectively. Moreover, the expressions of the surface tension coefficient and the contact angle are independent of each other. The surface tension of the liquid can be measured when the contact angle of the liquid to be measured and the equipment material is unknown, and the contact angle can also be measured simultaneously.

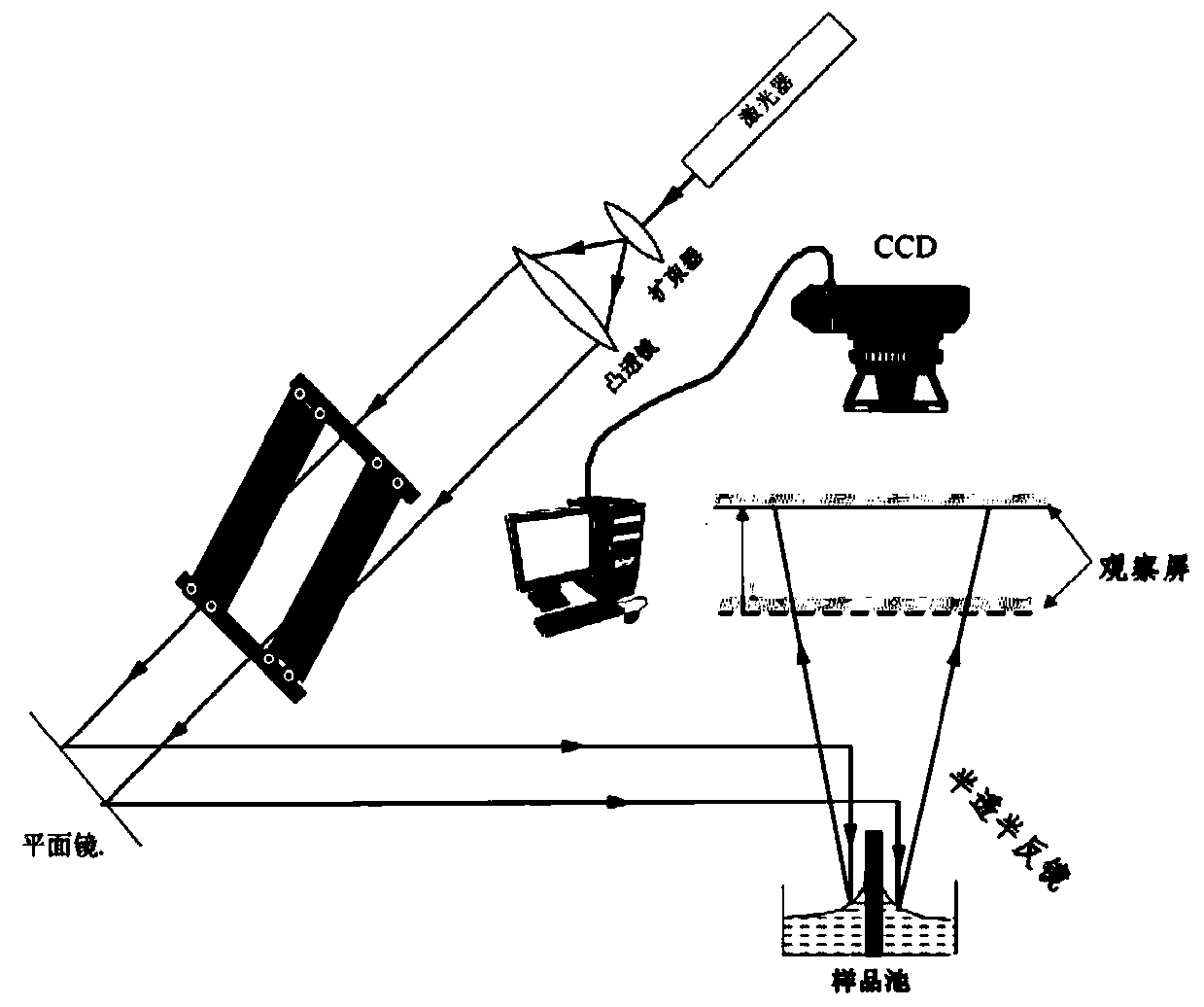

[0043] In terms of technical operation, this method uses parallel laser beams to irradiate the curved liquid surface vertically. By changing the position of the observation screen, the area array micro camera (CCD) and computer image processing are used to obtain the characteristics of the reflected light field of the obse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com